1056

UFOs exist!

Raised quite recently the problem of transportation of heavy cargo Komrad Jus in his topic, made me remember one article in the magazine PM. For Russia, with its extraordinary expanses north and separated from each other over vast distances settlements, delivery of equipment is oversized sverhaktualnoy. And given the climate and virtually undeveloped transport hubs in many areas, I believe the solution to this problem is becoming a strategically important element in our state. And developments in this matter there.

Source: Journal of the PM and the Internet

1. Several years ago, the specialists of "Metaprocess" was given the task of logistics. It was necessary to bring in the Ryazan region 600-ton hydrocracking reactor built at the Izhora plant near St. Petersburg. It was purchased 500-tonne truck and special barge port on the river Izhorka deepened. Send to a distance of 1,000 km cost of $ 5 million and took 45 days. Then the engineers asked themselves the question: is it possible to deliver such goods by air?

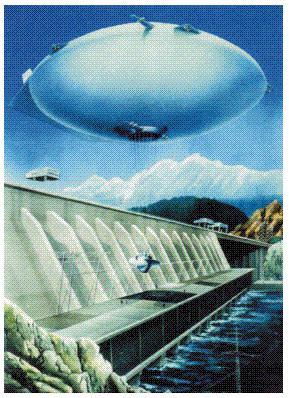

It turned out that it is theoretically possible. However, the most difficult to date, cargo aircraft An-225 "Mriya" has a capacity of "only" 250 tons, so we immediately turned to the airships. First, the limits for the carrying capacity of the airship is not theoretically, secondly, the energy giant aircraft engines almost spent on the maintenance of the lift, and finally, to a cargo airship can be hung, that is no problem with the size. But the classic airship has a number of disadvantages: it can not be unloaded from the air, it is prone to icing in the northern regions, its construction is very expensive. It was then and still remembered the Soviet project "Termoplan" - disc-shaped airship, in which the role of ballast carries the heated air. And breathed new life into the project.

2. In 1996, the German company has already tried to build Cargolifter sverhgruzopodemny airship capable of transporting up to 160 tons of cargo. The project CL 160 has been shown to investors, have gathered a huge amount iinzhenery started the construction of the hangar. Hangar was built and was 360 m in length and 220 in width and 106 (!) In height. At the investors' money ran out and the company went bankrupt Cargolifter safely and hangar that can accommodate the Eiffel Tower, still empty in the suburbs of Wiesbaden.

3. There is one "but." The point is that the delivery of heavy loads - drilling rigs, reactors, machine tools - needed more often in remote areas such as Siberia and Kamchatka, where the relevant plants and wells. A blimp can not fly without ballast. If the airship unloaded 20 tons, it must take on board 20t anything else in return. If no ground (especially if it is chilled) or sand or water? Moreover, demands for unloading the airship landing. And go and plant a large object length of 250 m, for example, in the taiga forest. In the same hovering blimp can not load because it is afraid of the side wind just blows it aside privately. It was then, and remembered the old Soviet project called "Termoplan."

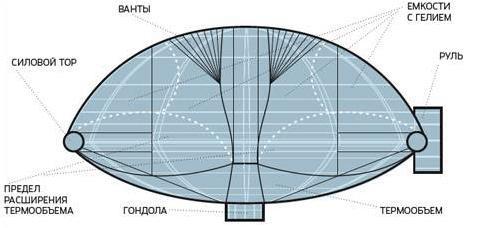

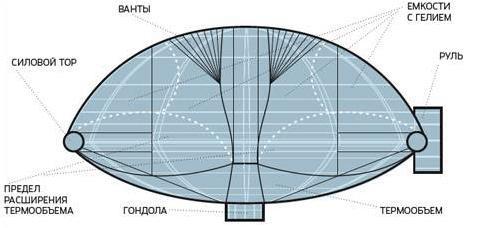

4. What came up with Soviet engineers (Design Bureau "Termoplan", which was headed by Yury A. Ryzhov)? Termoplan was a "flying saucer", consisting of two halves. At the top of the container placed with helium as a conventional airship, and the bottom to perform the functions of so-called termoobema. He was filled with normal air, which is heated by the exhaust gas of engines. Why he needed a hybrid? It was then that he could dispense with the usual ballast: this function is performed in the air termoobeme.

Termoplana device was simple: the circumference of the torus was the power of fiberglass reinforced uglelentami, stretched over a torus shell and the inner cavity of the separation membrane and the volume on termoobem sgeliem. The prototype of the estimated carrying capacity of 3 tons began to build in Ulyanovsk Aviation Industry Complex named Ustinova (now the factory "Aviastar") in 1989. Front engine installed on the Yak-18, and vkachestve cab to the car hung redesigned fuselage of the helicopter MI-2, stuffed with equipment. Termoplan called ALA-40 completed by 1992.

5. The problem was the same: Union collapsed and the funding ceased. We managed to order another power Torr and a set of shells, but the assembly of the second unit of extra money was not - it was necessary to test first. In August 1992, Soviet UFO was taken out of the hangar and took him to the test.

Money for the restoration was not, but CB "Termoplan" existed until 2001. It was developed several original and highly successful catamarans WIG 2EU on the basis of AN-2. In 2008 the factory "Aviastar" needed new production facilities, and the remains of termoplana were finally sent to recycling. But by this time it has already begun a new chapter.

6. Thus, in 2005 Cyril Lyats, CEO of the group of companies "Metaprocess" through their own channels found the very Yuri Ryzhov, who in the 1980s led the project "Termoplan." It turned out that the staff of the former Bureau scattered in different places: Ulyanovsk part of the team who worked on "Aviastar" who Tupolev and Moscow formed CB "aerostatics", develops cigar-shaped airships. Lyats Ryzhov with both teams gathered together in a boarding house Golitsyn, brainstorm and decided: sverhgruzopodemnomu airship - be. The new company was named "LocomoSky" and the unit itself - Locomoskyner. General Designer Alexander became Harchikov, former Deputy General Designer "Termoplana."

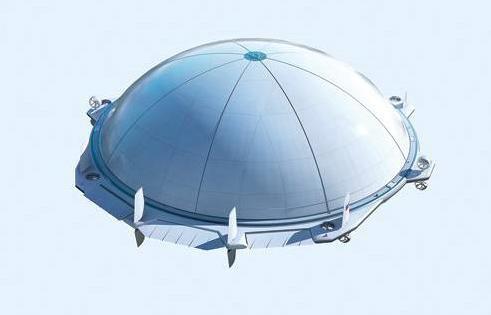

7. Over 15 years have changed almost everything - materials, equipment, the level of computerization. Locomoskyner termoplan similar to the appearance, but they have in common - a principle. For example, in termoplane cavity with helium it was only one, but big. The project also includes a set of Locomoskyner helium bags (16 containers), then there is damage to one or two will not affect the progress and capacity giant.

Striking changes were the principles of heating termoobema. In the original design the exhaust gases from the engine directly flows into the shell, resulting in soot and formed termoplan was necessary to regularly clean the inside. Furthermore, the gas temperature was about 700 ° C, creating a significant risk - you could burn through the shell. Modern Locomoskyner equipped independent from engine heat generators operating on the principle of a heat gun and placed inside the volume. Thus, even in case of failure of motor thermal balance is maintained. Moreover, additional heating is carried out through a separate heat exchanger.

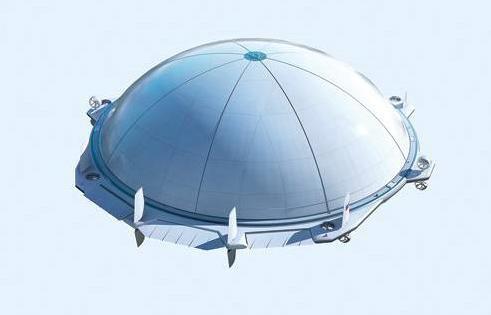

8. Today "LocomoSky" starts kstroitelstvu second prototype "Locomoskyner-03" carrying capacity of 3 tons. Compared with the planned 600-tonner nothing more than a toy, but in reality - a serious truck, allowing delivering heavy loads in remote areas. Design documentation on Locomoskyner fully prepared, and the management of the Ulyanovsk region has allocated space for the production of the first sample.

Power Torr at "Locomoskyner-03" metal, it is planned to establish four engines (possible to install six and eight - depending on the need). The casing is designed for comfortable operation in a temperature range from -50 to + 50 ° C, but there is one thing to stipulate. The fact that warm air can be fed inside almost any portion of the shell and maintain its temperature at any level. Because of this even Antarctic -80 ° C to Locomoskyner problem will not. Safety device is also higher than that of the airship. Even if the damage to the 16 series tanks with helium, it can still hold on to the place comfortable fit just hot air. That's what thermoballasted.

9. Locomoskyner there is another major difference from the airship. Remember the story about Cargolifter and the famous hangar? So, Locomoskyner hangar does not require at all. Inside a small room and collect items torus powertrain. The final assembly is made in an open area, because Locomoskyner not afraid of crosswinds. When Thor is fully assembled, it pull the top part of the shell, which serves as the hangar itself. Further works are in Locomoskyner. This reduces the cost of construction of such devices in comparison with the airship at least twice.

The planned range 3-tonner - 500 km, and 60 have tonnika- 3000. The mightiest Locomoskyner in the line would be free to move half of the rig from Moscow to Kamchatka, and no rivers and mountains will not be an obstacle to it.

Three-ton machine will show the public already at the MAKS-2011, and subsequent to it 60-tonner planning to build by 2016. However, can immediately take over and the 600-ton crane, why the 'Net?

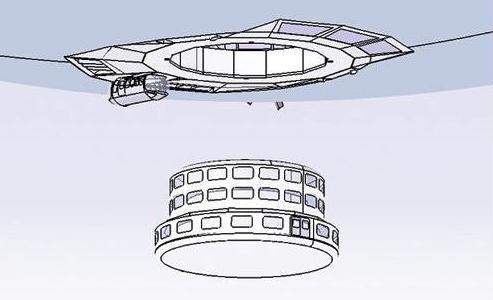

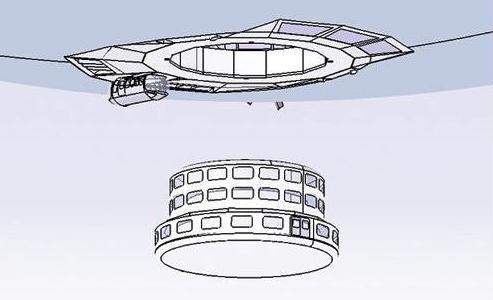

10. Locomoskyner can be equipped with various units - not only cargo. In "LocomoSky" developed Extinguishing unit, as well as a passenger. The latter has three floors, two of which are located inside Locomoskyner, and the bottom is a circular observation deck, articulated to the cockpit. Locomoskyner develop options for 120, 240, 400 and 600 tonnes. Locomoskyner-600 Diameter 250 m // maximum range of 5,000 km // // Payload 600 tons Year of completion of construction in 2016

Construction of the 600-tonne sample will cost about $ 120 million. However, if we analyze the situation Locomoskyner this size completely pay for itself within just a couple of years, and then only in any one activity. For example, the 1200-ton service rig or on delivery of equipment for reconstruction of the Sayano-

11. Termoplan in

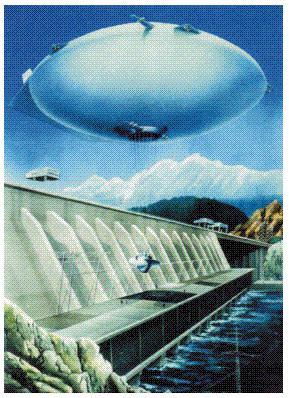

Suppose termoplan brings a payload of 100 tonnes in the taiga. It is completely painless hangs over the trees (because of the round form a unit, as opposed to the airship, not afraid of crosswind) and works in a helicopter, that is, lowers the load on the ropes down.

To compensate for the sharp increase in lift, from termoobema release of the heated air is pumped directly from the cold of the board. And yet - the airship again poised and ready to fly further. Thus, the ballast is due to changes in temperature termoobema, and the termoplan is a fully autonomous machine that is independent of the people at the bottom. Theoretically, it can safely deliver the goods in a bare field and unload it without any help from the ground.

The development termoplana involved a number of leading design bureaus of the Soviet Union. For example, one of the institutions has been seriously developed version of the draft with a nuclear power plant (though it was more a tribute to the nuclear arms race, not the functionality termoplana). Subsequently, the development of this branch was closed.

12. To date, potential customers at "Lokomoskaya" enough. It almost any firm or factory, engaged in the production of heavy equipment. Moreover, construction is already of the first 600-ton crane will automatically create a new clientele. For example, today in the far north nobody is building plants in the block-modular design for failure to deliver heavy equipment units. Using Locomoskyner will allow for the installation of the plant practically from the air, just a few tricks, and win tens of millions of dollars. In addition, Locomoskyner relieve the budget from the need to build roads in the northern villages of temporary settlement: huge air machines easily deliver and people and all the necessary equipment by air.

13. aerial vehicles of this type anywhere in the world. The urgency of the project is prominently due to the simultaneous development of this trend in several countries. Despite the negative example of a company Cargolifter, problems sverhgruzopodemnogo airship engaged in the United States, Japan, Germany. Who will be the first - to the cards. After all, the world is real enough 25-30 similar devices. Consumers can become Locomoskyner country sobshirnoy territory, difficult terrain and weather conditions - China, Brazil, India, Canada.

Therefore, we can only wish the company "LocomoSky 'progress and monitor developments. You'll see, in ten years, and over Moscow swims like this, man-made 250-meter flying saucer.

Dobavleno1 in [mergetime] 1277716197 [/ mergetime]

Instead of an epilogue.

There are a few very interesting articles on non-standard aeronautical devices. If you are interested, I'll post. Thank you for attention! That's all I wanted to say.

Source:

Source: Journal of the PM and the Internet

1. Several years ago, the specialists of "Metaprocess" was given the task of logistics. It was necessary to bring in the Ryazan region 600-ton hydrocracking reactor built at the Izhora plant near St. Petersburg. It was purchased 500-tonne truck and special barge port on the river Izhorka deepened. Send to a distance of 1,000 km cost of $ 5 million and took 45 days. Then the engineers asked themselves the question: is it possible to deliver such goods by air?

It turned out that it is theoretically possible. However, the most difficult to date, cargo aircraft An-225 "Mriya" has a capacity of "only" 250 tons, so we immediately turned to the airships. First, the limits for the carrying capacity of the airship is not theoretically, secondly, the energy giant aircraft engines almost spent on the maintenance of the lift, and finally, to a cargo airship can be hung, that is no problem with the size. But the classic airship has a number of disadvantages: it can not be unloaded from the air, it is prone to icing in the northern regions, its construction is very expensive. It was then and still remembered the Soviet project "Termoplan" - disc-shaped airship, in which the role of ballast carries the heated air. And breathed new life into the project.

2. In 1996, the German company has already tried to build Cargolifter sverhgruzopodemny airship capable of transporting up to 160 tons of cargo. The project CL 160 has been shown to investors, have gathered a huge amount iinzhenery started the construction of the hangar. Hangar was built and was 360 m in length and 220 in width and 106 (!) In height. At the investors' money ran out and the company went bankrupt Cargolifter safely and hangar that can accommodate the Eiffel Tower, still empty in the suburbs of Wiesbaden.

3. There is one "but." The point is that the delivery of heavy loads - drilling rigs, reactors, machine tools - needed more often in remote areas such as Siberia and Kamchatka, where the relevant plants and wells. A blimp can not fly without ballast. If the airship unloaded 20 tons, it must take on board 20t anything else in return. If no ground (especially if it is chilled) or sand or water? Moreover, demands for unloading the airship landing. And go and plant a large object length of 250 m, for example, in the taiga forest. In the same hovering blimp can not load because it is afraid of the side wind just blows it aside privately. It was then, and remembered the old Soviet project called "Termoplan."

4. What came up with Soviet engineers (Design Bureau "Termoplan", which was headed by Yury A. Ryzhov)? Termoplan was a "flying saucer", consisting of two halves. At the top of the container placed with helium as a conventional airship, and the bottom to perform the functions of so-called termoobema. He was filled with normal air, which is heated by the exhaust gas of engines. Why he needed a hybrid? It was then that he could dispense with the usual ballast: this function is performed in the air termoobeme.

Termoplana device was simple: the circumference of the torus was the power of fiberglass reinforced uglelentami, stretched over a torus shell and the inner cavity of the separation membrane and the volume on termoobem sgeliem. The prototype of the estimated carrying capacity of 3 tons began to build in Ulyanovsk Aviation Industry Complex named Ustinova (now the factory "Aviastar") in 1989. Front engine installed on the Yak-18, and vkachestve cab to the car hung redesigned fuselage of the helicopter MI-2, stuffed with equipment. Termoplan called ALA-40 completed by 1992.

5. The problem was the same: Union collapsed and the funding ceased. We managed to order another power Torr and a set of shells, but the assembly of the second unit of extra money was not - it was necessary to test first. In August 1992, Soviet UFO was taken out of the hangar and took him to the test.

Money for the restoration was not, but CB "Termoplan" existed until 2001. It was developed several original and highly successful catamarans WIG 2EU on the basis of AN-2. In 2008 the factory "Aviastar" needed new production facilities, and the remains of termoplana were finally sent to recycling. But by this time it has already begun a new chapter.

6. Thus, in 2005 Cyril Lyats, CEO of the group of companies "Metaprocess" through their own channels found the very Yuri Ryzhov, who in the 1980s led the project "Termoplan." It turned out that the staff of the former Bureau scattered in different places: Ulyanovsk part of the team who worked on "Aviastar" who Tupolev and Moscow formed CB "aerostatics", develops cigar-shaped airships. Lyats Ryzhov with both teams gathered together in a boarding house Golitsyn, brainstorm and decided: sverhgruzopodemnomu airship - be. The new company was named "LocomoSky" and the unit itself - Locomoskyner. General Designer Alexander became Harchikov, former Deputy General Designer "Termoplana."

7. Over 15 years have changed almost everything - materials, equipment, the level of computerization. Locomoskyner termoplan similar to the appearance, but they have in common - a principle. For example, in termoplane cavity with helium it was only one, but big. The project also includes a set of Locomoskyner helium bags (16 containers), then there is damage to one or two will not affect the progress and capacity giant.

Striking changes were the principles of heating termoobema. In the original design the exhaust gases from the engine directly flows into the shell, resulting in soot and formed termoplan was necessary to regularly clean the inside. Furthermore, the gas temperature was about 700 ° C, creating a significant risk - you could burn through the shell. Modern Locomoskyner equipped independent from engine heat generators operating on the principle of a heat gun and placed inside the volume. Thus, even in case of failure of motor thermal balance is maintained. Moreover, additional heating is carried out through a separate heat exchanger.

8. Today "LocomoSky" starts kstroitelstvu second prototype "Locomoskyner-03" carrying capacity of 3 tons. Compared with the planned 600-tonner nothing more than a toy, but in reality - a serious truck, allowing delivering heavy loads in remote areas. Design documentation on Locomoskyner fully prepared, and the management of the Ulyanovsk region has allocated space for the production of the first sample.

Power Torr at "Locomoskyner-03" metal, it is planned to establish four engines (possible to install six and eight - depending on the need). The casing is designed for comfortable operation in a temperature range from -50 to + 50 ° C, but there is one thing to stipulate. The fact that warm air can be fed inside almost any portion of the shell and maintain its temperature at any level. Because of this even Antarctic -80 ° C to Locomoskyner problem will not. Safety device is also higher than that of the airship. Even if the damage to the 16 series tanks with helium, it can still hold on to the place comfortable fit just hot air. That's what thermoballasted.

9. Locomoskyner there is another major difference from the airship. Remember the story about Cargolifter and the famous hangar? So, Locomoskyner hangar does not require at all. Inside a small room and collect items torus powertrain. The final assembly is made in an open area, because Locomoskyner not afraid of crosswinds. When Thor is fully assembled, it pull the top part of the shell, which serves as the hangar itself. Further works are in Locomoskyner. This reduces the cost of construction of such devices in comparison with the airship at least twice.

The planned range 3-tonner - 500 km, and 60 have tonnika- 3000. The mightiest Locomoskyner in the line would be free to move half of the rig from Moscow to Kamchatka, and no rivers and mountains will not be an obstacle to it.

Three-ton machine will show the public already at the MAKS-2011, and subsequent to it 60-tonner planning to build by 2016. However, can immediately take over and the 600-ton crane, why the 'Net?

10. Locomoskyner can be equipped with various units - not only cargo. In "LocomoSky" developed Extinguishing unit, as well as a passenger. The latter has three floors, two of which are located inside Locomoskyner, and the bottom is a circular observation deck, articulated to the cockpit. Locomoskyner develop options for 120, 240, 400 and 600 tonnes. Locomoskyner-600 Diameter 250 m // maximum range of 5,000 km // // Payload 600 tons Year of completion of construction in 2016

Construction of the 600-tonne sample will cost about $ 120 million. However, if we analyze the situation Locomoskyner this size completely pay for itself within just a couple of years, and then only in any one activity. For example, the 1200-ton service rig or on delivery of equipment for reconstruction of the Sayano-

11. Termoplan in

Suppose termoplan brings a payload of 100 tonnes in the taiga. It is completely painless hangs over the trees (because of the round form a unit, as opposed to the airship, not afraid of crosswind) and works in a helicopter, that is, lowers the load on the ropes down.

To compensate for the sharp increase in lift, from termoobema release of the heated air is pumped directly from the cold of the board. And yet - the airship again poised and ready to fly further. Thus, the ballast is due to changes in temperature termoobema, and the termoplan is a fully autonomous machine that is independent of the people at the bottom. Theoretically, it can safely deliver the goods in a bare field and unload it without any help from the ground.

The development termoplana involved a number of leading design bureaus of the Soviet Union. For example, one of the institutions has been seriously developed version of the draft with a nuclear power plant (though it was more a tribute to the nuclear arms race, not the functionality termoplana). Subsequently, the development of this branch was closed.

12. To date, potential customers at "Lokomoskaya" enough. It almost any firm or factory, engaged in the production of heavy equipment. Moreover, construction is already of the first 600-ton crane will automatically create a new clientele. For example, today in the far north nobody is building plants in the block-modular design for failure to deliver heavy equipment units. Using Locomoskyner will allow for the installation of the plant practically from the air, just a few tricks, and win tens of millions of dollars. In addition, Locomoskyner relieve the budget from the need to build roads in the northern villages of temporary settlement: huge air machines easily deliver and people and all the necessary equipment by air.

13. aerial vehicles of this type anywhere in the world. The urgency of the project is prominently due to the simultaneous development of this trend in several countries. Despite the negative example of a company Cargolifter, problems sverhgruzopodemnogo airship engaged in the United States, Japan, Germany. Who will be the first - to the cards. After all, the world is real enough 25-30 similar devices. Consumers can become Locomoskyner country sobshirnoy territory, difficult terrain and weather conditions - China, Brazil, India, Canada.

Therefore, we can only wish the company "LocomoSky 'progress and monitor developments. You'll see, in ten years, and over Moscow swims like this, man-made 250-meter flying saucer.

Dobavleno1 in [mergetime] 1277716197 [/ mergetime]

Instead of an epilogue.

There are a few very interesting articles on non-standard aeronautical devices. If you are interested, I'll post. Thank you for attention! That's all I wanted to say.

Source: