322

One night my work

Good evening YaPovtsy. Tonight will tell you how to connect the rails in Europe. Probably none of you driving the train did not think that the rails require constant repairs or even replacement, depending on the traffic at the site.

So one of the types of rail connections after replacing just have thermal welding. I'll tell you and show you the whole process, so to speak directly to the workplace. Maybe someone will seem interesting.

There will be 25 pictures and a description of the characteristics of the process.

01.Pered start welding crucible heats gorelkoy.V gas is already prepared the necessary clearance between the rails.

While still hot crucible rails are put on a level

03. Here it is! Place seam.

04. On the rails mounted mold.

05. And the warmed honey agaric gas burner

06. Top mounted crucible.

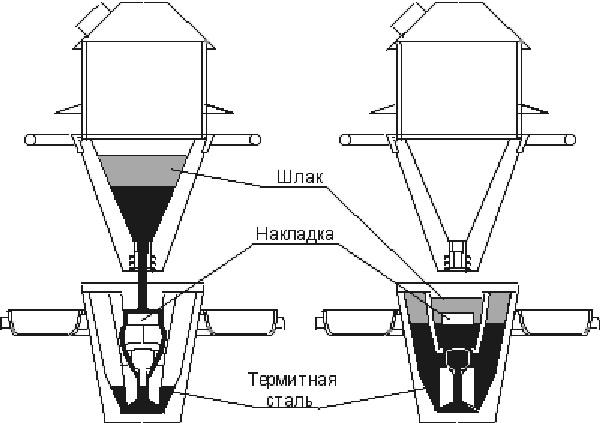

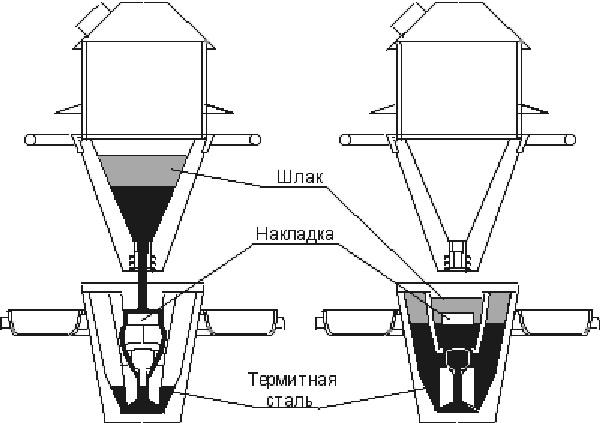

07. To make it ponyatno.Vot process diagram.

After the release of the steel crucible gap in rail joints filled from the bottom up. In contrast to standard thermite steel, when used with respect to the two-component welding low alloy melting part, which provides high viscosity of the weld metal. In the area of the working surface of the rail in this case, the wear resistance was not enough high. In this regard, additional doping is needed, at least in the upper part of the railhead. For this dopants are placed on the underside of the ceramic lining. During casting alloy contact with additional dopants is impossible, but as the upward joint filling molten steel is suited to the bottom ceramic plates, alloying additions fall into the melt and the weld metal in the zone of the rail head. As a result, the weld zone of the sole and the rail web has a high viscosity and a high wear resistance of the head area.

08. Driving

09.Spets mixture is ignited in the crucible

10.

11. The metal begins to fill in the form

12. The process went

13. Excess flow into special woks at the edges of the crucible

14. here is best seen

15. Cools down the metal in the form of

16. aside to cool red-hot crucible

17. While the metal is hot and soft cut its manual hydraulic press, in the form of rails (figs knows the name of Russian)

18. In

19. Now, wait until cool down and solidify

20. slugger excess metal, mostly porous and shlakoobrazny

21. Here's a Pribluda gasoline-powered rails polished

22. The process of

23.

24.

25. As a result, we get here is a nice strong seam. That's all I wanted to say.

Source:

So one of the types of rail connections after replacing just have thermal welding. I'll tell you and show you the whole process, so to speak directly to the workplace. Maybe someone will seem interesting.

There will be 25 pictures and a description of the characteristics of the process.

01.Pered start welding crucible heats gorelkoy.V gas is already prepared the necessary clearance between the rails.

While still hot crucible rails are put on a level

03. Here it is! Place seam.

04. On the rails mounted mold.

05. And the warmed honey agaric gas burner

06. Top mounted crucible.

07. To make it ponyatno.Vot process diagram.

After the release of the steel crucible gap in rail joints filled from the bottom up. In contrast to standard thermite steel, when used with respect to the two-component welding low alloy melting part, which provides high viscosity of the weld metal. In the area of the working surface of the rail in this case, the wear resistance was not enough high. In this regard, additional doping is needed, at least in the upper part of the railhead. For this dopants are placed on the underside of the ceramic lining. During casting alloy contact with additional dopants is impossible, but as the upward joint filling molten steel is suited to the bottom ceramic plates, alloying additions fall into the melt and the weld metal in the zone of the rail head. As a result, the weld zone of the sole and the rail web has a high viscosity and a high wear resistance of the head area.

08. Driving

09.Spets mixture is ignited in the crucible

10.

11. The metal begins to fill in the form

12. The process went

13. Excess flow into special woks at the edges of the crucible

14. here is best seen

15. Cools down the metal in the form of

16. aside to cool red-hot crucible

17. While the metal is hot and soft cut its manual hydraulic press, in the form of rails (figs knows the name of Russian)

18. In

19. Now, wait until cool down and solidify

20. slugger excess metal, mostly porous and shlakoobrazny

21. Here's a Pribluda gasoline-powered rails polished

22. The process of

23.

24.

25. As a result, we get here is a nice strong seam. That's all I wanted to say.

Source: