731

How to build a sauna from chopped logs: step by step instructions

The use of chopped logs in the construction process of the bath is quite justified by high costs. As the quality of such facilities is much higher applications of roundup materials. About how to build a sauna from a log will be discussed further.

Chopped log: features and benefitsMost popular material used in the construction of baths is a tree. Wooden buildings have the quality, durability, and spending time in a bath becomes healthy.

The use of wood allows you to maintain the necessary microclimate in the room, the walls in a bath is able under certain conditions to absorb moisture and at the right time to give it.

The duration of use and quality of the built bathhouse directly depend on the type of materials used in the process of its construction and the quality. When logging, you should follow certain rules, which we consider next:

1. Harvested wood is best between December to March.

2. After the tree is cut down, you should wait at least a month prior to its further processing.

3. Before storing the forest all the logs are cleaned of bark, only on the end portions remain of a small space, 15-20 cm, with bark, to prevent their cracking.

4. Logs are stored in piles. It is important to observe a ventilation gap between them, with a size of 50 mm.

5. All stacks sheltering slate, which will protect them from moisture.

If you adhere to all the conditions of the raw material, then this room will serve its owners for at least 50 years.

The logs are round materials which are formed after cutting of trees, which are cleared from branches and trunks.

Among the advantages of chopped logs release:

Among the shortcomings of chopped logs say:

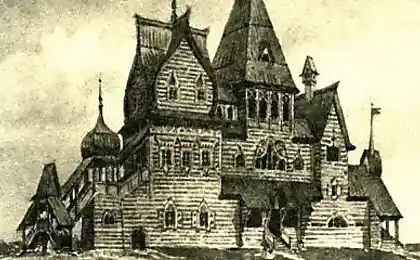

Baths of chopped logs — feature

Baths of chopped logs remain popular more than a dozen and even hundreds of years. This is due to the availability of the materials used in the process of their construction and ease of processing.

The use of wood in construction has such advantages:

In the construction of baths using different wood species, but the lower part of the bath, which is in contact with the Foundation, traditionally made of larch, as this material possesses high quality characteristics. In addition, widespread use of coniferous trees, pine and fir trees that fill the room with a special aroma, cleansing and healing the human body.

For heating it is better to give preference to the birch. In the construction of baths, the main thing — to choose the right type of wood. As it is the quality of the material depends on the end result.

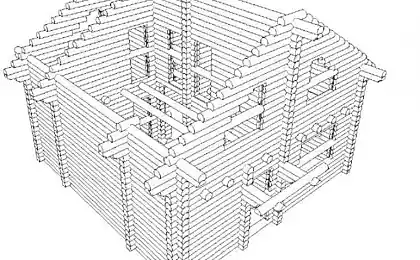

An important point is the construction of load-bearing structures of the building. They appear in the form of one of the wooden walls, which are longitudinally stacked logs or crowns.

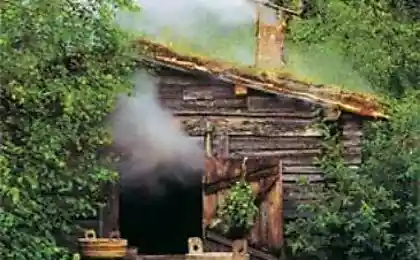

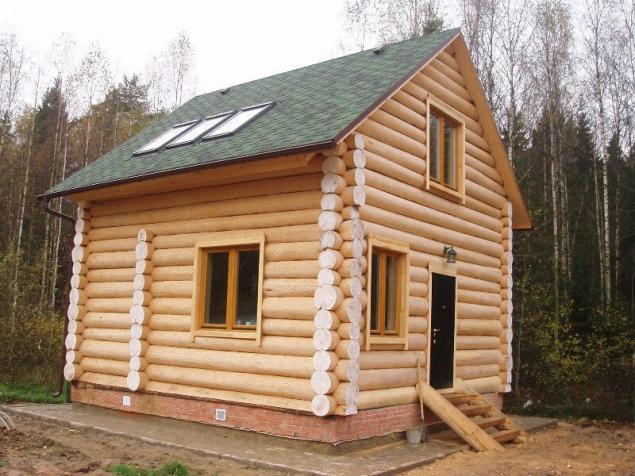

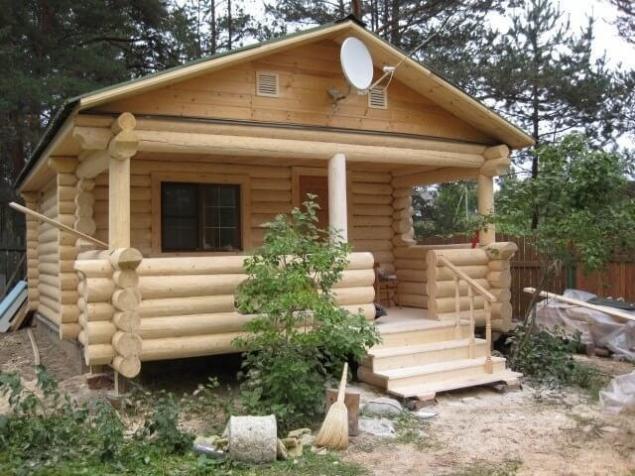

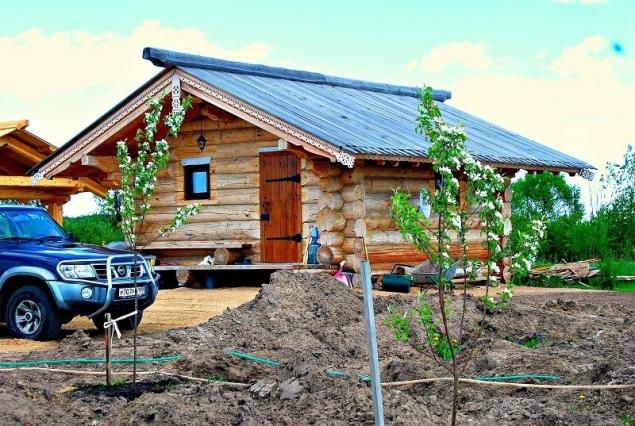

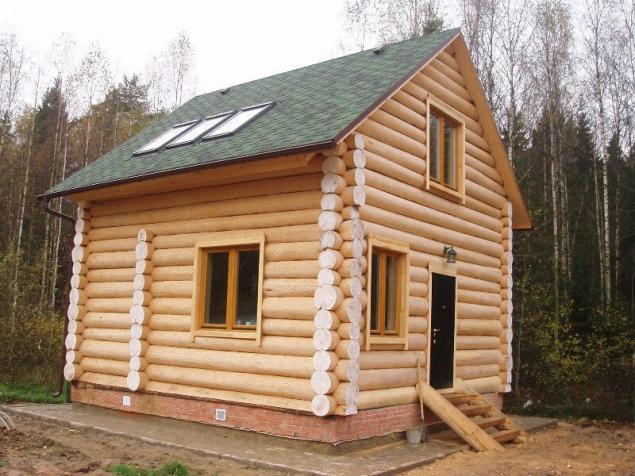

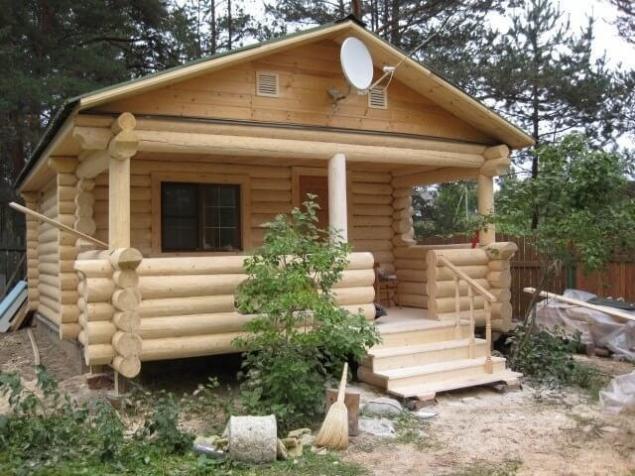

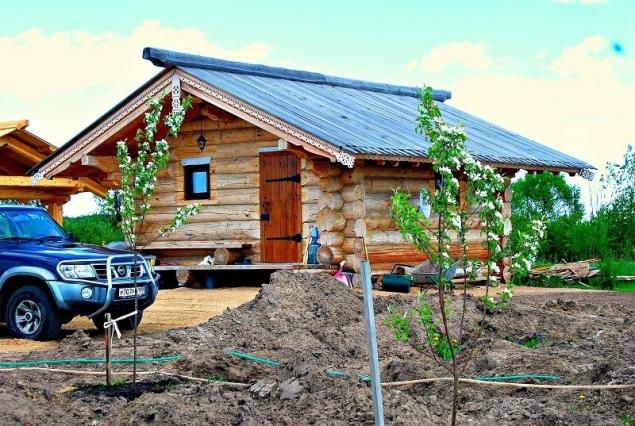

Chopped baths of logs photo:

The crown is a rectangular structure consisting of stacked in the direction perpendicular to the beams.

The final stage of works — cutting the baths, first the work on felling the tree in the forest or on the field. Next, the carcass is transported to the construction site and konoplitsy. After a year after installation and complete drying is made of inner and outer trim frame.

Construction of the baths of logs: step by step instructions

The procedure for the construction of baths with the use of chopped logs consists of several stages, namely:

1. Drafting baths of chopped logs.

2. Assembly and carcass materials used in the construction process.

3. Preparation and base construction.

4. The construction of the walls in the bath.

5. The equipment of the roof structure.

6. Installation of the stove.

7. Conduct internal finishing work.

8. Installation of the flue.

9. Insulation of floors and ceiling.

10. Installation of shelves in the room.

The first phase involves work on the design of baths. Development projects are carried out in relation to all the requirements of the owners. The option of independent development of the project, prepared the purchase of the project or individual project development experts who will take into account all the individual climatic and geological features of the area and will make an optimum variant of the project of the bath.

Bath begin to build by defining its size if we consider a standard size frame, which consists of three rooms, its area is about 60 square meters.

Another important factor is the height of the room, which will house shelves, and which must be comfortable to visit a certain number of people.

Note that too large size of the bath will help to improve heat loss and the heating of bath will need to spend a lot of fuel. Therefore, you should choose the minimum dimensions of the room that should be comfortable for the location of people in the bath.

The standard bath consists of predbannik the room where change and steam rooms, which are washed and steamed. The variant of the equipment room.

For a more efficient use of space door of the steam needs to go out into the hallway.

To improve the strength of the structure, to properly pick and build the Foundation. The depth of the bookmarks is determined by the depth of soil freezing, to which are added a minimum of 100 mm.

It is important to consider the correctness of the temperature distribution in the bath. The temperature in the steam room is from 51 to 57 degrees in the room for washing — 35-40 degrees and in the locker room, low of 22 degrees.

Another important factor is the correct location and installation of shelves. They should not be near the stove, as there is a risk of burns from too-hot steam.

Therefore, it is preferable to arrange the shelves near solid walls. Shelves should be arranged in two or three tiers, depending on the ceiling height.

Most often used in the bath of the furnace of the heater, which is located in the corner section of the room. This arrangement allows to provide optimal heating of the premises. In the inner part of the furnace is installed a reservoir in which water is heated. The principle of this furnace consists in using a special kind of stones, which when heated red-hot and emit steam in contact with water. As fuel for stoves in the used firewood, which she drowned in a long time.

Construction of the roof is another important issue, as the roof must have a minimum conductivity. If the room is in a separate building, then the most popular variant of the construction of the roof is a gable roof. In the regeneration baths in the form of an extension, rational use of single types of roofs.

The angle of the gable roof is from 18 to 44 degrees, and shed twenty to thirty degrees. Wooden bath requires heavy roof, as it needs to be very warm, to prevent heat loss. Quite popular are the Norwegian excavation of the roof on which surface is the ground and plants in the lawn.

For the construction of baths will require a minimum of two months. But, remember to have bath served efficiently, to begin its operation should be not earlier than a year after its construction. So how exactly after this period of time there is the first stage of shrinkage of the bath. The final shrinkage will occur after four to five years, depending on the type of tree.

The main construction phase of the bath is the thermal insulation of the floor and ceiling. To insulate the ceiling in the bath of chopped logs, you will need to nail lines, across the ceiling, then you set the ceiling out of wood, next is the installation of caulk, to prevent heat loss.

In addition, care should be taken about the correct arrangement of flooring and spillway. During the construction of the floor in the room for washing and steam, should be very concerned about ensuring a normal flow and drainage of water in the sewer system. Therefore, the floor should have a sloping surface, used for its manufacture exclusively insulating materials in the form of concrete, clay.

The slope should be directed to a sump, which is equipped with a water seal that connects the overflow pipe and the sewage pit.

Next is the flooring and wooden materials. For the product this process requires the installation log, which is mounted on the pre-gidroizolirovat surface with the supporting pillars. Between the boards, necessarily left a gap of at least 0.5 cm, because the wood swells when wet, and dries to a decrease in volume. In addition, you should worry about removing the longitudinal chamfer boards, so the top part becomes a little more bottom.

If a solid floor is constructed, the arrangement requires the presence of the pit directly in the room. To cover it establishes a special grille. The vent riser is used for equipment sanitation. For its arrangement you want to install asbestos-cement or metal pipe, the minimum diameter of which is 10 cm On the upper section sets the cap or deflector.

Technology of construction of a bath of chopped logsAfter the construction of baths is required to make laying between-joisting sealant between the logs. This eliminates the appearance of cracks through which heat losses occur.

As the seal used moss or oakum, but this method is less popular due to the complexity of the work and cost of material. Modern construction involves the use of lnovatin that offers the convenience of installation, as is done in the form of a roll.

The procedure of sealing joints called konopatkoy, it must have the same between-joisting sealant or linen rope — improves the appearance of the building.

Using caulk significantly improves the thermal insulation of the building. But, this process should be repeated after the shrinkage of the building, that is, after five years of its operation.

An important issue is the problem of docking logs since chopped materials have different diameter and for interfacing requires special skills.

The standard size of a log is 600 cm If the wall of the building longer, they are joined together at the place of cut. Thus, the joint portions become invisible. In the absence of perpendicular walls, the butt area is equipped with a cut that hides the joints.

In the absence of opportunities in the construction notches, joints are formed in a staggered manner, for more secure logs.

The manufacture of baths made of wood has one unpleasant consequence, such as the cracking of the logs. Since the tree is a living organism, inside which there is moisture, then, after some processing, it dries and loses its strength. As the moisture begins to evaporate from the Central part of the logs, that they bore the biggest burden, leading to cracking. To avoid this process, you want to make sawing deformation of destination, which will help take the moisture without consequences for the logs.

In addition, there is a danger of SIRENIA or darkening of wood. This procedure is due to the lower quality wood under the influence of moisture, sun, temperature changes and other factors. Particularly sensitive logs to fungi or mold, that are in the air and through it into the surface. The optimal conditions for reproduction of the fungus is temperature is +22 and 90% humidity, so in the bath it is recommended to install a good ventilation, which make it possible to prevent this process.

In addition, it is required to conduct periodic processing of wood with antiseptic preparations and treatment, If the blue has already appeared on the surface, it should be sanded well and apply the medication of bleaching action.

Before installing the boards, should be very concerned about their treatment by using drugs that will protect the wood from sun, moisture and other external influences. You should not save on the purchase of these materials, as they are able to extend the service life of wooden baths several times. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement . Put LIKES and share with your FRIENDS! www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Source: strport.ru/bani-sauny-i-basseiny/bani-iz-rublennogo-brevna-poshagovaya-instruktsiya

Chopped log: features and benefitsMost popular material used in the construction of baths is a tree. Wooden buildings have the quality, durability, and spending time in a bath becomes healthy.

The use of wood allows you to maintain the necessary microclimate in the room, the walls in a bath is able under certain conditions to absorb moisture and at the right time to give it.

The duration of use and quality of the built bathhouse directly depend on the type of materials used in the process of its construction and the quality. When logging, you should follow certain rules, which we consider next:

1. Harvested wood is best between December to March.

2. After the tree is cut down, you should wait at least a month prior to its further processing.

3. Before storing the forest all the logs are cleaned of bark, only on the end portions remain of a small space, 15-20 cm, with bark, to prevent their cracking.

4. Logs are stored in piles. It is important to observe a ventilation gap between them, with a size of 50 mm.

5. All stacks sheltering slate, which will protect them from moisture.

If you adhere to all the conditions of the raw material, then this room will serve its owners for at least 50 years.

The logs are round materials which are formed after cutting of trees, which are cleared from branches and trunks.

Among the advantages of chopped logs release:

- less creaking and cracking;

- lower level of moisture absorption;

- higher resistance to biological influences in the form of insects, fungus or mould;

- the duration of operation, not requiring special care;

- the ease and ease of Assembly;

- the presence of specific components of the slot;

- a variety of angular Brubeck in the form of paws, Russian bowls, exclusive triple.;

- a variety of styles to complete the bath;

- healthy indoor climate;

- a wide range of diameters of logs.

Among the shortcomings of chopped logs say:

- higher cost of execution of works on preparation of the material;

- the difference of diameters on opposite ends of the frame;

- the quality of work depends on the experience of professionals who perform them, when poor-quality installation of equipment, severely affecting the external appearance of buildings.

Baths of chopped logs — feature

Baths of chopped logs remain popular more than a dozen and even hundreds of years. This is due to the availability of the materials used in the process of their construction and ease of processing.

The use of wood in construction has such advantages:

- first of all, the capacity of wooden walls “breathe” — thanks to this in the bath easy to breathe, while indoors there is fresh air and healthy atmosphere;

- low level of conductivity provides excellent heat retention in the bath, even in winter time, which is very important for the adoption of bath procedures;

- construction walls in the bath wood in the summer allows you to avoid their overheating, as wood controls the temperature level in the room;

- cost is another advantage, as wooden bath does not require building a costly Foundation, and the tree is much cheaper than brick or concrete.

In the construction of baths using different wood species, but the lower part of the bath, which is in contact with the Foundation, traditionally made of larch, as this material possesses high quality characteristics. In addition, widespread use of coniferous trees, pine and fir trees that fill the room with a special aroma, cleansing and healing the human body.

For heating it is better to give preference to the birch. In the construction of baths, the main thing — to choose the right type of wood. As it is the quality of the material depends on the end result.

An important point is the construction of load-bearing structures of the building. They appear in the form of one of the wooden walls, which are longitudinally stacked logs or crowns.

Chopped baths of logs photo:

The crown is a rectangular structure consisting of stacked in the direction perpendicular to the beams.

The final stage of works — cutting the baths, first the work on felling the tree in the forest or on the field. Next, the carcass is transported to the construction site and konoplitsy. After a year after installation and complete drying is made of inner and outer trim frame.

Construction of the baths of logs: step by step instructions

The procedure for the construction of baths with the use of chopped logs consists of several stages, namely:

1. Drafting baths of chopped logs.

2. Assembly and carcass materials used in the construction process.

3. Preparation and base construction.

4. The construction of the walls in the bath.

5. The equipment of the roof structure.

6. Installation of the stove.

7. Conduct internal finishing work.

8. Installation of the flue.

9. Insulation of floors and ceiling.

10. Installation of shelves in the room.

The first phase involves work on the design of baths. Development projects are carried out in relation to all the requirements of the owners. The option of independent development of the project, prepared the purchase of the project or individual project development experts who will take into account all the individual climatic and geological features of the area and will make an optimum variant of the project of the bath.

Bath begin to build by defining its size if we consider a standard size frame, which consists of three rooms, its area is about 60 square meters.

Another important factor is the height of the room, which will house shelves, and which must be comfortable to visit a certain number of people.

Note that too large size of the bath will help to improve heat loss and the heating of bath will need to spend a lot of fuel. Therefore, you should choose the minimum dimensions of the room that should be comfortable for the location of people in the bath.

The standard bath consists of predbannik the room where change and steam rooms, which are washed and steamed. The variant of the equipment room.

For a more efficient use of space door of the steam needs to go out into the hallway.

To improve the strength of the structure, to properly pick and build the Foundation. The depth of the bookmarks is determined by the depth of soil freezing, to which are added a minimum of 100 mm.

It is important to consider the correctness of the temperature distribution in the bath. The temperature in the steam room is from 51 to 57 degrees in the room for washing — 35-40 degrees and in the locker room, low of 22 degrees.

Another important factor is the correct location and installation of shelves. They should not be near the stove, as there is a risk of burns from too-hot steam.

Therefore, it is preferable to arrange the shelves near solid walls. Shelves should be arranged in two or three tiers, depending on the ceiling height.

Most often used in the bath of the furnace of the heater, which is located in the corner section of the room. This arrangement allows to provide optimal heating of the premises. In the inner part of the furnace is installed a reservoir in which water is heated. The principle of this furnace consists in using a special kind of stones, which when heated red-hot and emit steam in contact with water. As fuel for stoves in the used firewood, which she drowned in a long time.

Construction of the roof is another important issue, as the roof must have a minimum conductivity. If the room is in a separate building, then the most popular variant of the construction of the roof is a gable roof. In the regeneration baths in the form of an extension, rational use of single types of roofs.

The angle of the gable roof is from 18 to 44 degrees, and shed twenty to thirty degrees. Wooden bath requires heavy roof, as it needs to be very warm, to prevent heat loss. Quite popular are the Norwegian excavation of the roof on which surface is the ground and plants in the lawn.

For the construction of baths will require a minimum of two months. But, remember to have bath served efficiently, to begin its operation should be not earlier than a year after its construction. So how exactly after this period of time there is the first stage of shrinkage of the bath. The final shrinkage will occur after four to five years, depending on the type of tree.

The main construction phase of the bath is the thermal insulation of the floor and ceiling. To insulate the ceiling in the bath of chopped logs, you will need to nail lines, across the ceiling, then you set the ceiling out of wood, next is the installation of caulk, to prevent heat loss.

In addition, care should be taken about the correct arrangement of flooring and spillway. During the construction of the floor in the room for washing and steam, should be very concerned about ensuring a normal flow and drainage of water in the sewer system. Therefore, the floor should have a sloping surface, used for its manufacture exclusively insulating materials in the form of concrete, clay.

The slope should be directed to a sump, which is equipped with a water seal that connects the overflow pipe and the sewage pit.

Next is the flooring and wooden materials. For the product this process requires the installation log, which is mounted on the pre-gidroizolirovat surface with the supporting pillars. Between the boards, necessarily left a gap of at least 0.5 cm, because the wood swells when wet, and dries to a decrease in volume. In addition, you should worry about removing the longitudinal chamfer boards, so the top part becomes a little more bottom.

If a solid floor is constructed, the arrangement requires the presence of the pit directly in the room. To cover it establishes a special grille. The vent riser is used for equipment sanitation. For its arrangement you want to install asbestos-cement or metal pipe, the minimum diameter of which is 10 cm On the upper section sets the cap or deflector.

Technology of construction of a bath of chopped logsAfter the construction of baths is required to make laying between-joisting sealant between the logs. This eliminates the appearance of cracks through which heat losses occur.

As the seal used moss or oakum, but this method is less popular due to the complexity of the work and cost of material. Modern construction involves the use of lnovatin that offers the convenience of installation, as is done in the form of a roll.

The procedure of sealing joints called konopatkoy, it must have the same between-joisting sealant or linen rope — improves the appearance of the building.

Using caulk significantly improves the thermal insulation of the building. But, this process should be repeated after the shrinkage of the building, that is, after five years of its operation.

An important issue is the problem of docking logs since chopped materials have different diameter and for interfacing requires special skills.

The standard size of a log is 600 cm If the wall of the building longer, they are joined together at the place of cut. Thus, the joint portions become invisible. In the absence of perpendicular walls, the butt area is equipped with a cut that hides the joints.

In the absence of opportunities in the construction notches, joints are formed in a staggered manner, for more secure logs.

The manufacture of baths made of wood has one unpleasant consequence, such as the cracking of the logs. Since the tree is a living organism, inside which there is moisture, then, after some processing, it dries and loses its strength. As the moisture begins to evaporate from the Central part of the logs, that they bore the biggest burden, leading to cracking. To avoid this process, you want to make sawing deformation of destination, which will help take the moisture without consequences for the logs.

In addition, there is a danger of SIRENIA or darkening of wood. This procedure is due to the lower quality wood under the influence of moisture, sun, temperature changes and other factors. Particularly sensitive logs to fungi or mold, that are in the air and through it into the surface. The optimal conditions for reproduction of the fungus is temperature is +22 and 90% humidity, so in the bath it is recommended to install a good ventilation, which make it possible to prevent this process.

In addition, it is required to conduct periodic processing of wood with antiseptic preparations and treatment, If the blue has already appeared on the surface, it should be sanded well and apply the medication of bleaching action.

Before installing the boards, should be very concerned about their treatment by using drugs that will protect the wood from sun, moisture and other external influences. You should not save on the purchase of these materials, as they are able to extend the service life of wooden baths several times. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement . Put LIKES and share with your FRIENDS! www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Source: strport.ru/bani-sauny-i-basseiny/bani-iz-rublennogo-brevna-poshagovaya-instruktsiya