1423

The construction of his house of brick, foam and wood frame — compare cost

When building a house (house, cottage), the future owner should make the decision on the basic material from which he will build his house.

Today the choice of materials is very wide. However, the main materials are: brick, foam concrete (aerated concrete), wooden beams or logs and panel-frame construction of several types.

Concrete as a material for the walls of your home, we do not consider the combination of reasons.

The material used for construction walls must be uniform since it allows you to perform homogeneous Foundation (not counting terraces). In such a house will not crack and will not break the Foundation for a daily and seasonal humidity and temperature changes.

The cost of construction of the Foundation, bearing walls, i.e., the power frame of the house, and the roof is from 30% to 40% of the total cost of a house under construction. Therefore, we will compare the cost of brick building, aerated concrete, wood, and frame houses built to the stage of "the house is ready for finishing".

Consider also the advantages and disadvantages of each of the wall materials, namely:

-assessment of the cost of construction of brick houses;

-assessment of the cost of building a house of foam concrete (aerated concrete);

-assessment of the cost of building a house of timber;

-assessment of the cost of construction of frame panel houses in different versions;

-comparative table of all the options, taking into account the cost of future maintenance and repair.

Construction of a brick house. Valuation, advantages and disadvantages

Brick walls are very durable, but they have a large weight, high heat capacity, low thermal insulation properties. Consider the advantages and disadvantages of a brick house.

The advantages of brick buildings include:

the strength of the walls;

flame-resistant material;

good sound insulation;

the material does not rot;

brick allows you to apply W/concrete slab, although for some people this combination is unacceptable.

The disadvantages of brick buildings include:

expensive construction;

the Foundation shall be constructed to the full depth of frost penetration (for the middle band 1.5 m) see foundations;

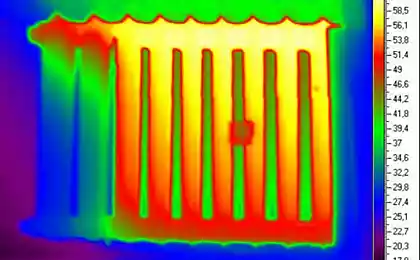

the brick must be warm, brick walls turn out wide (walls 2,5 bricks about 63 cm + 10 cm insulation, if you build from a clean brick, for the Moscow region the thickness of brick walls shall be not less than 1.5 m). Read more about thermal conductivity of the wall see a warm home;

long construction – a minimum of two seasons, the best three, because the Foundation needs to gain strength, the wall needs to dry and the house needs to settle down before the finish;

the unsuitability of a brick building for seasonal use (walls pick up moisture as the brick is hygroscopic, which is undesirable for temperature changes). In the winter of uninhabited brick house "warmed up" at least three days and "dry out" for about a month.

The cost of building a house of bricks

Many construction firms show beautiful booklets brick houses with outer and inner trim, while naming the price of building a box at home "or for finishing or" turnkey. As a rule, it is not very high. But what is meant by these phrases, and what else awaits You in the further construction of his house of brick.

So, we understand.

Work for finishing brick houses, "turnkey" include:

The construction of the box house;

Device at home for finishing.

Decipher these concepts.

The construction of the box house is:

excavation work is under communication and the area of the house (no landscaping);

structure and basement waterproofing, as a rule, without a basement;

the construction of the house in 2 or 2.5 bricks (the project), the thickness of the walls 510 or 630 mm, internal partitions in the brick floor;

the device window and door openings;

construction of reinforced concrete or wooden floors (project);

device stove or chimney;

device natural ventilation inside channel wall;

the device of a wooden truss system roof sheathing and insulation.

Ie getting the box of your home, You have not insulated frame walls, not made of facing bricks, requiring insulation and exterior sheathing, a roof without a roof, a house without Windows and doors.

For example, here is the cost of construction of the box is a brick building of various projects from construction companies (Moscow):

one-story brick house with an area of 52.m. precast reinforced concrete Foundation (no basement), concrete floors, precast reinforced concrete roof attic, tile – 800 000 RUB. or 15 500 RUB/sq. m.;

one-story brick house with an area of 89кв.m. precast reinforced concrete Foundation (no basement), concrete floors, precast reinforced concrete roof attic, metal roofing cost 1 400 000 RUB. or 15 700 RUB./sq. m.;

attic brick house, area 170kv.m. slab Foundation (no basement), concrete floors, precast reinforced concrete roof attic, metal – 2 800 000 rubles, or 16 500 RUB/sq. m.

Next you need to include the cost of the work the construction company on the brick house for finishing.

Device at home for finishing, is:

rough finish of the house (with external wall insulation, internal plaster, ...);

electrical wiring without installation of the devices;

wiring and plumbing – pipes only to conclusions without installing sanitary equipment;

the heating system with radiators and boiler (boiler and radiators – separate account);

the system of water – distributing pipes, without instruments;

the device roofing (economy version – metal or soft roof);

window – a separate account;

the device blind area of the Foundation at the perimeter of the house 1 meter wide.

For example, here is the cost of the device at home for finishing from construction companies (Moscow):

minimum: 7 000 RUB/sq. m.;

most: 8 000 RUB/sq. m. (max say no).

Total cost of building a house of brick "turn-key" will be from 22 500 RUB/sq. m. to 25,000 RUB./sq. m.

ATTENTION.

In the construction of houses " turnkey ", that is, for finishing does not include:

finishing the house, ie its facing;

finishing of walls and ceilings (plaster and painting);

trim staircases, porches, etc.;

device flooring with skirting;

the device and installation of plumbing fittings;

purchase and installation of the fireplace;

purchase and installation of interior doors with frames.

Total cost of building a brick house will be no less than 30 000 RUB./sq. m.

Building a house of foam concrete (aerated concrete). Valuation, advantages and disadvantages

The advantages of building a house of foam concrete (aerated concrete) are:

walls of foam concrete (aerated concrete) refractory;

the wall material does not rot;

the relative ease of processing, lightweight concrete, allows you to perform a wall with a complex configuration;

the rate of heat conduction is much better than brick, and the heat capacity (inertia of the heating) is lower than that of the brick walls in the winter so this house can be warm for a day;

the work on the masonry walls of aerated concrete requires less skilled labor, but there are works related to the reinforcement and concreting of lintels over window and door openings, and the reinforced concrete belt between the first and second floor;

the turnaround time is shorter;

the budget for the wall, by reducing the weight of the material, time and material costs, is much lower.

The disadvantages of building a house of foam concrete (aerated concrete) are:

aerated concrete (foam concrete) is hygroscopic and absorbs moisture. This requires the storage conditions of the material and protect the walls from moisture. If the walls gain moisture in the autumn, in the winter they can crack. Therefore, the house should be warm;

the walls of the foam are afraid of deformation, so I need a continuous footing or Foundation reinforced concrete plate;

after the masonry walls before they finish, it is desirable that the house passed the warm season and the walls are completely dry and " settled ", as a rule, normal life building a house of foam is 12-18 months.

the use of aerated concrete requires strict observance of technology of a laying of foam concrete, the device of the reinforcements and expansion joints. Not knowing the "masons" technology and lack of control by the "superintendents" or the host often leads to cracks in the walls;

the thickness of the walls of aerated concrete for the Moscow region without insulation should be between 600 to 1000 mm (depending on material density). Really laying the foam is, as a rule, unit 300/350mm and insulated the outside of the Styrofoam under the plaster.

House of foam concrete (aerated concrete) are recommended for year-round use. When seasonal operation service life is dramatically reduced, and the repair of the walls can be inevitable in 15-20 years.

The cost of building a house of foam concrete (aerated concrete)

The cost of building a house of foam concrete (aerated concrete) "turnkey" or "finishing" includes:

The cost of the box house from foam concrete (aerated concrete);

Device at home for finishing.

For example, here is the cost of construction of the box house from foam concrete (aerated concrete) of different projects from builders (Moscow):

one-storey house of foam concrete (aerated concrete), area of 86 sq. m., precast reinforced concrete Foundation (no basement), roof, attic, metal – cost 912 000 RUB. or 10 600 RUB/sq. m.;

mansard house from foam concrete (aerated concrete) with an area of 107 sq. m., precast reinforced concrete Foundation (no basement), roof, mansard, metal – 1 142 000 RUB. or 10 700rub./sq. m.;

2-storey house of foam concrete (aerated concrete) with an area of 240 sq. m, monolithic reinforced concrete Foundation (no basement), concrete floors, precast reinforced concrete roof attic, shingles – 3 276 000 rubles, or 13 650 RUB/sq. m.

For example, here is the cost of the device houses from foam concrete (aerated concrete) for finishing from the builders (Moscow):

minimum: 6 000 RUB./sq m;

most: 7 000 RUB/sq. m. (the maximum is not talking).

Details on the composition of works performed in the house "turnkey" and a list of works not included in this concept is described in the article on the analysis of the cost of construction of brick houses – link.

Total cost of construction of the box house from foam concrete (aerated concrete) " turnkey ", will be 17 000 rubles/sq. m to 21 000 RUB./sq. m.

Savings compared to a brick house is achieved due to lighter foundations reduce excavation, less loading and unloading, material cost.

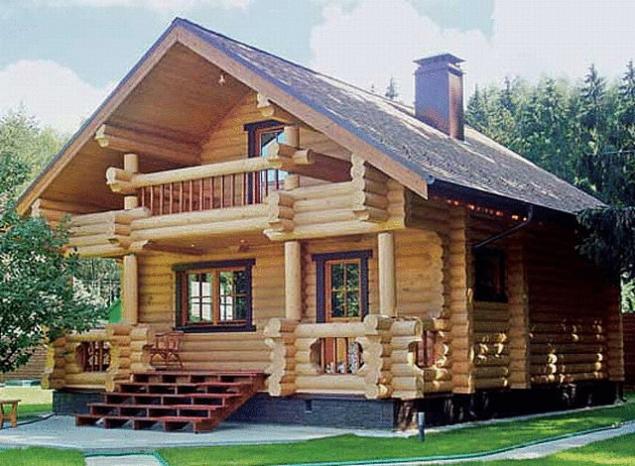

Construction of wooden houses. Valuation, advantages and disadvantages

Wooden homes are quite diverse. The most popular are home from a simple timber, profiled timber, simple beams and profiled beams. Sometimes the wooden houses are made of sharnika (deadwood).

Hardwood timber or timber with a thickness of 150 – 250 mm without additional insulation can be applied to the construction of wooden houses a seasonal residence.

For permanent living wall of wood, without insulation, for the Moscow region should be more than 50 cm.

The advantages of wooden houses include:

wooden walls can withstand an infinite number of cycles of freezing and thawing (temperature changes);

have low thermal conductivity (requires minimal insulation);

warm up after freezing for a few hours;

the house can be build on the pier or lightweight Foundation;

after drying, practically not subject to deformation;

a wooden house breathes well, people feel comfortable in it.

The disadvantages of wooden houses include:

if you are using a live tree (not sharnika) the first years maintenance — konopatka. It is time-consuming and expensive procedure;

when you use unseasoned wood, warping is inevitable;

the weak point is the lower crown — it requires protection from moisture and decay;

the tree is afraid of insects and fire, and during chemical processing of wood, lost his " spirit ".

The cost of construction of wooden houses

Usually, with the Customer specifying the cost of construction of wooden houses, carpentry companies use the term " warm loop ", which includes:

the device base;

assembling frame construction with insulation only the floors (the wall insulation is not included!);

the Assembly of the roof structure with insulation and covering it with a roofing material;

installation of Windows and doors;

device rough sex.

For example, here is the cost of building a "warm loop" wooden houses in different designs of wall material (timber, rounded log, glued laminated timber).

Mansard house, the area 100 — 110 sq. m., monolithic tape reinforced concrete Foundation (no basement), roof Dormer:

timber (softwood) 150*150 – 12 700 RUB/sq. m.;

round log (Russia), with a diameter of 240 mm – 16 500 rubles/sq. m.;

round log (Russia), with a diameter of 300 — 350 mm. – 21 000 RUB./sq m;

laminated Board (Russia), 210*270mm. – 35 400 RUB/sq. m.

Prices are for pine and spruce. If You want your house made of cedar or larch, then multiply by 1.5.

The cost of construction of wooden houses from imported kits – just space...

The tree should be used for the construction of their home for seasonal use, without additional insulation of the walls and of timber or logs of pine or spruce, diameter up to 200mm.

Construction of frame panel house. The cost of construction of a frame house

Construction of frame panel house produced using different technologies. They differ in materials used and the degree of readiness of the home kit.

For the cladding panels are used the following materials: OSB, DSP, gypsum fiber Board, plywood, isoplot. The most popular fillers panels: basalt wool, polystyrene, cellulose fibre insulation. Based on the variety of possible combinations of materials and readiness of the package frame house, on the Russian market there are different offers for every taste. The most comfortable of them are the houses in which the maximum volume of used natural materials – wood, basalt wool.

On the readiness of proposals from manufacturers can be divided into three main categories:

Complete sets of frame houses (under full commitment from the manufacturer for imported technologies: Finnish, German);

Sets frame houses — semi-finished products;

Sets frame houses — the designers.

Complete sets of frame houses.

Western producers, who have been advocating for maximum service, when the house comes complete with all the materials up to the outlet, deliver finished houses at fairly high prices. They will not be considered because they contain a high value added manufacturer (kit building area of 150 m2 costs more than 4 million rubles).

We believe that such proposals are not interesting for those who wish to build his own house with his own hands, and are not the most common practice frame construction in the world. That is to say – this is an option for the rich and lazy.

Sets frame houses – semi-finished products.

These include the products of those manufacturers whose technological process to a predetermined limit for the designs and applied the insulation. This home features a fully finished panels and ceiling elements.

As the insulation in them is most often used polystyrene because of its low cost and good insulating properties. Panels of this type are referred to as SIP panels. The most popular is the so-called "canadian pie" or " canadian sandwich." This three-layer plate, which consists of two of two layers of OSB with a thickness of 10-12mm., between them, as insulation, pressure bonded layer of expanded polystyrene.

The cost of construction a frame house without a Foundation and finish, but with the installation (do not collect) with an area of 150m2 on technology SIP is from 1 725 000 1 870 000 rubles (including installation will range from 375 000), i.e. about 12000 RUB/sq. m.

The advantages of timber frame construction of houses from SIP panels, with the use of polystyrene foam include ease of construction, good insulation, speed of production and installation, all season construction, no deformation, seismic, price.

The downside is the "thermos effect" because the house is almost not breathing. So they need a good air conditioning system.

Inconvenience is the necessity of laying out the walls.

In addition, doubts over their longevity, because the panel manufacturers guarantee them for 20 years.

They are almost not maintainable, as technologically accomplished as a whole. All of the above in equal measure can be attributed to homes built with the use of permanent formwork of polystyrene foam. Also open is the question of rodents.

Sets frame houses – the designers.

This category should include offers of manufacturers, which means the possibility of different configuration, the minimum offer is the framing of the house with the design documentation.

In this category is the most traditional methods of building a timber frame house based on a wooden frame. As insulation is mainly made of basalt wool of different density. The recommended density of the wool 50kg/m3. As a material for the cladding panels the most popular is OSB, though there are alternative solutions in the form of DSPS, plywood, isoplaate and even plastic.

The cost of the carrier frame (load-bearing walls and trusses) is about 3000 rubles/sq. m., further equipment in the construction of your home can be performed by the developer.

The cost of construction a frame house with basement for finishing made according to traditional methods ranges from 11000 to 14000 RUB/sq. m.

If we exclude the options of plating with the use of DSP, plywood, plastic and consider only the classics: wooden frame + OSB + basalt wool, you can highlight the following strengths and weaknesses of this category.

The advantages of classic wooden frame house:

environmentally friendly;

ease of construction;

no shrinkage and deformation;

good insulation (a sufficient wall thickness of 150mm), the house does not require additional insulation;

the only option is a "breathing" frame house;

high speed production and installation, the ability to assemble a house with his own hands;

seismic resistance;

low price.

The disadvantages of the classic timber-framed house — like wooden house, timber frame requires fire protection and treatment against decay and insects.

House – economy.

When you select the basic material from which You are going to build your house — economy, should be provided in addition to the cost of building a house, the cost of operating buildings and the cost of his detention.

House – economy, is a house that will not hold You money on the heating, repair and maintenance for decades.

Comparative table of variants of the construction cost of his house.Below is a table to compare the cost of building and owning their home with different versions of the power frame. Consider the cost of building a house for finishing, maintenance and repair of your home based on the home life of 100 years.

The type of walls. The cost stroit-VA, rbl./sq. m. Total cost of heating and ventilation, RUB/sq. m/year Total cost of repairs, RUB./sq m/year Cost of ownership, RUB/sqm/year the Rating of the Brick 510mm. with plaster 22450 332 45 601,50 7 630 mm Brick with plaster on insulation 27750 146 85 508,50 6 aerated Concrete block with insulation and plaster 20700 140 55 of 402.00 3 Cylindro-

bath rail 350mm (Angarska pine) 22970 177 59 465,70 5 Glued laminated timber 279*210 without insulation 35400 215 60 of 629.00 8 Panel-frame (SIP panel 174mm) 12000 115 151 of 386.00 2 Frame panel ("classic" panel 174mm) 12500 112 85 322,00 1 Wooden timber 200x200 without insulation 12700 231 65 of 423.00 4

Source: green-dom.info/%D1%81%D1%82%D1%80%D0%BE%D0%B8%D1%82%D0%B5%D0%BB%D1%8C%D1%81%D1%82%D0%B2%D0%BE-%D1%81%D0%BE%D0%B1%D1%81%D1%82%D0%B2%D0%B5%D0%BD%D0%BD%D0%BE%D0%B3%D0%BE-%D0%B4%D0%BE%D0%BC%D0%B0/%D1%81%D1%80%D0%B0%D0%B2%D0%BD%D0%B5%D0%BD%D0%B8%D0%B5-%