639

Kiln 2 X 2 bricks: a compact and efficient stove with your hands!

Unfavorable economic situation, the rapid rise in gas prices is forcing homeowners to think seriously about alternative options for heating their homes. In this article we consider the advantages, the technology to build a small kiln of brick.

They also provide several beneficial qualities, the main of which are: easy operation, low fuel price and high heating efficiency. They can also work on many cheap fuels, such as coal, wood, peat and so on.

Due to the simple design and small size, small-sized heating furnace of brick is easy to build with their hands. The project would not have a significant impact on your budget, as the construction of small furnaces do not require large expenditures for tools and materials.

If You choose to build with high quality materials, you will receive not only an economical way of heating your home, but also additional decorative element.

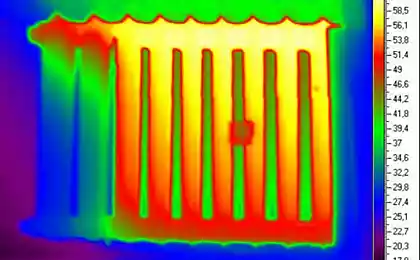

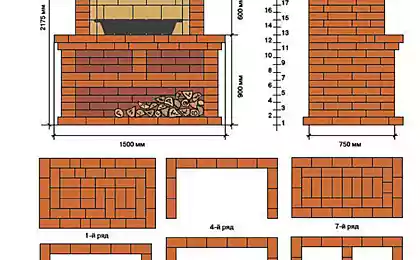

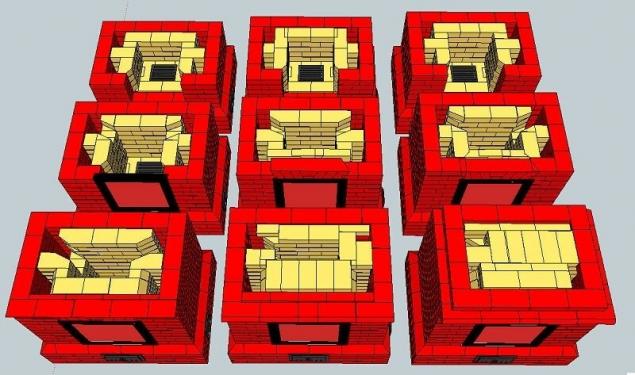

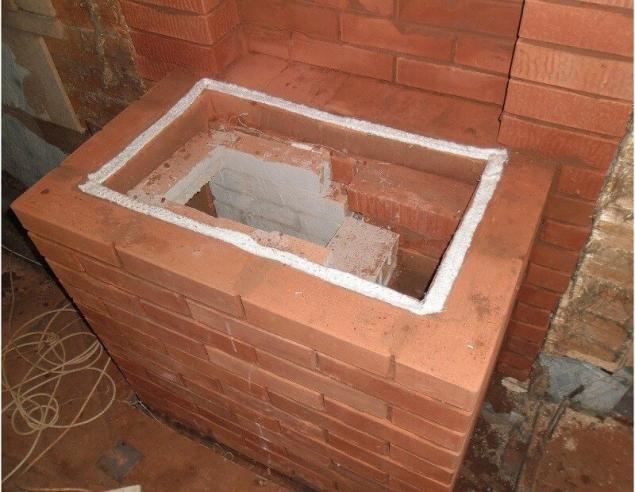

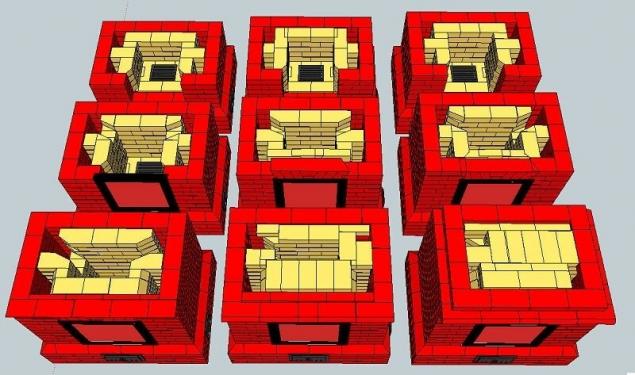

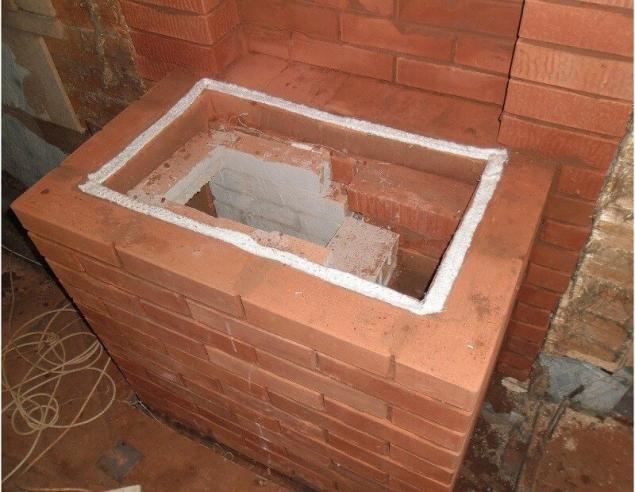

Device ovensgenerally compact oven with his own hands has a size of two by two or three bricks in the base, has the shape of an elongated rectangle. For heating efficiency most often it is placed in the center of the house, and due to its small size it usually is not much difficulty. It consists of a fuel chamber and top cap. Flue gases embark on a special channel at the top it makes a turn of 180 degrees, this system is called pass. Thus, the flue gases have time to give more energy to the walls, increasing its effectiveness.

For furnace, you must use fire-resistant materials. The Foundation usually do 5 cm above the base of the furnace. But thanks to lightweight construction, in some cases, you can do without Foundation. In front of the firedoor, as a rule, install a metal sheet 50x50 cm

Preparation and calculationsCarefully consider how best to position the small oven. For example, if it is built right next to the outer wall, most of the heat will go to heating the streets, so it is best to place it in the center of the house. Please note, in some parts of the house will be the door of the heating chamber. Drop the fuel and clean the oven will be easier if the door of the fuel chamber opens into a corridor or hallway. So you will have less problems with ash and dust.

Brick small oven does not require a large consumption of materials. Most likely, You will need the following:

Quickly and securely buildthe Foundation usually do rubble concrete or brick in cement mortar. Please note that the Foundation must be freestanding, not connected with the Foundation of the house. The size of Foundation is best done at 5-8 cm above the base of the furnace and 15 inches below the floor level.

For masonry use clay-sand mortar in proportion 1:3. The thickness of the seams should be about 5 millimeters. Don't forget about the bandaging of seams, this will give it the necessary strength. At each stage of the construction, measure the walls horizontally and vertically using a level. Remember, if the clutch is completed with no errors and of high quality brick, then the oven will eventually have great decorative qualities and will not require excessive additional finishing.

To the fuel chamber walls and ceilings are required to use only fire-resistant brick. The inner wall of the masonry must be perfectly smooth, so during the construction satilite exposed seams with a wet cloth.

Chimney pipe is constructed of the same brick, with the exception that the wall used cement-sand mortar. In the place where a chimney passes by a ceiling, you must do the cutting to increase the distance between the walls of the chimney and flammable materials floors.

The final stage of constructionafter completion of works fresh designs should be given time to dry. This will require from 3 to 5 days. Thereafter, the furnace is ready for decorating.

This article certainly provides information about some key moments of the construction of a small kiln, but to cover all the elements You'll need to not only reading more but also to do some independent tests.

For example, if in the past you had no experience with bricklaying, before building a small kiln at home, better work out and fold test the first stage of the furnace outside. This will give You the opportunity to better understand what tools you need, how to align and do the dressing of the masonry, and also helps to better match the proportions of the solution.

You should also be familiar with some of the issues associated with the construction. For example, in some cases, do not have to build the Foundation? How many rooms can heat a small oven?

The construction of a small kiln of brick this is a great project, even those who have never faced the brick masonry. Carefully planning each stage, You can complete the construction of the furnace 2 on 2 or 3 bricks in less than a week. And most importantly, You will have the opportunity to save on heating the house. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: idachi.ru/stroitelstvo-i-remont/pechi/pech-2-na-2-kirpicha.html

They also provide several beneficial qualities, the main of which are: easy operation, low fuel price and high heating efficiency. They can also work on many cheap fuels, such as coal, wood, peat and so on.

Due to the simple design and small size, small-sized heating furnace of brick is easy to build with their hands. The project would not have a significant impact on your budget, as the construction of small furnaces do not require large expenditures for tools and materials.

If You choose to build with high quality materials, you will receive not only an economical way of heating your home, but also additional decorative element.

Device ovensgenerally compact oven with his own hands has a size of two by two or three bricks in the base, has the shape of an elongated rectangle. For heating efficiency most often it is placed in the center of the house, and due to its small size it usually is not much difficulty. It consists of a fuel chamber and top cap. Flue gases embark on a special channel at the top it makes a turn of 180 degrees, this system is called pass. Thus, the flue gases have time to give more energy to the walls, increasing its effectiveness.

For furnace, you must use fire-resistant materials. The Foundation usually do 5 cm above the base of the furnace. But thanks to lightweight construction, in some cases, you can do without Foundation. In front of the firedoor, as a rule, install a metal sheet 50x50 cm

Preparation and calculationsCarefully consider how best to position the small oven. For example, if it is built right next to the outer wall, most of the heat will go to heating the streets, so it is best to place it in the center of the house. Please note, in some parts of the house will be the door of the heating chamber. Drop the fuel and clean the oven will be easier if the door of the fuel chamber opens into a corridor or hallway. So you will have less problems with ash and dust.

Brick small oven does not require a large consumption of materials. Most likely, You will need the following:

- Ceramic brick – 200 PCs.

- Refractory bricks – 70 PCs.

- Ordinary clay is 0.2 cubic meters.

- Fireclay – 15 kg.

- Furnace door 250х250 mm.

- Ashbox's door 130х140 mm.

- Cleanout door 130х140 mm.

- Valve Pushechnaya 130x130 mm.

- Roofing felt for waterproofing 800x500 mm.

Quickly and securely buildthe Foundation usually do rubble concrete or brick in cement mortar. Please note that the Foundation must be freestanding, not connected with the Foundation of the house. The size of Foundation is best done at 5-8 cm above the base of the furnace and 15 inches below the floor level.

For masonry use clay-sand mortar in proportion 1:3. The thickness of the seams should be about 5 millimeters. Don't forget about the bandaging of seams, this will give it the necessary strength. At each stage of the construction, measure the walls horizontally and vertically using a level. Remember, if the clutch is completed with no errors and of high quality brick, then the oven will eventually have great decorative qualities and will not require excessive additional finishing.

To the fuel chamber walls and ceilings are required to use only fire-resistant brick. The inner wall of the masonry must be perfectly smooth, so during the construction satilite exposed seams with a wet cloth.

Chimney pipe is constructed of the same brick, with the exception that the wall used cement-sand mortar. In the place where a chimney passes by a ceiling, you must do the cutting to increase the distance between the walls of the chimney and flammable materials floors.

The final stage of constructionafter completion of works fresh designs should be given time to dry. This will require from 3 to 5 days. Thereafter, the furnace is ready for decorating.

This article certainly provides information about some key moments of the construction of a small kiln, but to cover all the elements You'll need to not only reading more but also to do some independent tests.

For example, if in the past you had no experience with bricklaying, before building a small kiln at home, better work out and fold test the first stage of the furnace outside. This will give You the opportunity to better understand what tools you need, how to align and do the dressing of the masonry, and also helps to better match the proportions of the solution.

You should also be familiar with some of the issues associated with the construction. For example, in some cases, do not have to build the Foundation? How many rooms can heat a small oven?

The construction of a small kiln of brick this is a great project, even those who have never faced the brick masonry. Carefully planning each stage, You can complete the construction of the furnace 2 on 2 or 3 bricks in less than a week. And most importantly, You will have the opportunity to save on heating the house. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: idachi.ru/stroitelstvo-i-remont/pechi/pech-2-na-2-kirpicha.html