702

Oven-barbecued bricks with their hands: drawings and lining

Oven-BBQ E. Gudkova well unites in one design two functions — BBQ grill and a cooktop with griddle.

FoundationMaterialsthe Basic materials for monolithic slabs are the concrete, reinforcement mesh.

For the device of Foundation is enough to apply the concrete compressive strength B15 (M200). It may be cooked in the correct proportion:

Cement M 400 — 1 part. Crushed stone or gravel, the size of which should be less than 30 mm — 4 pieces. Sand — 2 parts. Impurities in sand clay, organic particles, mica, and dust inclusions shall not be more than 10% of its volume. In a large aggregate (gravel, crushed stone) the number of impurities, decreasing the strength properties of concrete, shall be less than 2%.

Consumption of concrete components by weight per 1 m3:

The size of the Foundation take more of the size of furnace 10 cm on each edge. If the furnace has a size of 1400х1000 mm, the Foundation is 1600 x 1200 mm.

Tools

Laying of concrete mix

Properly selected and made the Foundation is a guarantee of strength and durability of the whole structure. It is very important to know what the ground will be the basis for the furnace. Fairly dense soil may keep the design of the oven-barbecue. But there are pitfalls to be aware of.

There are soils that can change its volume due to soaking or temperature reduction. It is a swelling clay subsidence of loess and the content of soluble salts, water-saturated (the freezing of ice increases the volume of soil), with particles of biological origin (peat), etc. These soils require special measures for their strengthening.

Markup the future of the Foundation can be done, pulling the string on the pegs. The size of pits for sand shall be made at the size of base plate (160x120 cm). As the furnace-a barbecue will be on the street, the ground in the winter time will be subjected to freezing and thawing. Depending on the type of soil, depth of the sand cushion can reach 1000 mm.

Filling the pit with sand is necessary to carry out layer-by-layer (15 cm) by compaction or by pouring water to seal. On the ground before laying the sand you can lay the geotextile, which transmits water but prevents erosion of the sand by groundwater.

On the sand cushion to be laid in waterproofing, 2 layers of roofing material. This will protect the concrete from water in the soil and retain uncured concrete mixture from flowing into the sand.

Boards for formwork used softwood and hardwood with a minimum thickness of 2 cm and no wider than 15 cm posts, which will later be attached to the Board formwork, driven into the ground 50 cm, and then reinforce them with struts. Before you start laying the concrete mixture, it is necessary to clean the casing from dirt and wet.

Next is the installation of reinforcement into the formwork. The reinforcement mesh by means of vertical rods tied into surround frame, given the distance between them and the amount of the protective layer of the working armature 2 cm.

Concreting is desirable to make at one time. This will ensure uniform timing of hardening concrete. Also we should not forget about the compaction of the concrete mixture to remove the formed air bubbles and seal the concrete.

To maintain the humidity needed for normal hardening of the concrete, it is covered with damp burlap, canvas or other similar material. Can 3 hours after pouring the concrete on the surface to put a layer of damp sawdust or sand, which is moistened periodically (5 times per day). This is supported by 7-14 days until the concrete reaches 50-70% of its strength.

Important! When the outside temperature is below +5 °C fresh concrete needs to be insulated to comply with the uniform mode setting.

The formwork can be removed when the concrete attains at least 50% of the strength. In days it will depend on air temperature:

The furnace housing barbecue GudkovMaterials,refractory Brick (fireclay) GOST 390-96. Clay brick GOST 530-2012. The furnace body is laid of brick or a refractory or ceramic (required full-bodied). Fire brick can withstand 1300 °C and more. Ordinary clay bricks shall be well burnt. Nedozhzhenny, hollow, silicate, and brick, with cracks on chimney masonry not suitable.

On the stove you will need a brick — 465 PCs.

Furnace appliances:

Important! Before starting work, the clay is soaked for a day, and then gradually stirring, add a little sand.

You can also buy ready-mix mortar for the oven works. Such mixtures can withstand high temperature and will considerably reduce the time required for the preparation of the solution.

Tool setterChimney masonry is the same brickwork, so basically and tool her practically the same.

1 — kirk; 2 plastering trowel; 3 — mallet; 4 — jointing; 5 — plumb 6 — level 7 — gon

Case garden combined furnacethe erection of the furnace body should be carried out only when there is at least a temporary canopy over it. For the convenience of work you can put the body at first dry, picking up a brick.

Important! Not shot up the side of the brick to put inside the firebox or chimney.

Before laying clay bricks moistened, 1-2 minutes dropping into the water. Fireclay brick only rinse to remove the dust. The thickness of the clay bricks shall be less than 5 mm, and fireclay — 3 mm.

In the production of furnace work must comply with the strict horizontality of the surfaces of each row and vertical angles. Ligation joints shall be 1/2 bricks.

All oven devices are installed simultaneously with the masonry work. Metal and brick have a different value of linear expansion, so all the metal elements of the furnace are installed with a gap of 3-5 mm, then this space is filled with asbestos cord.

To the furnace door mounted steel wire to seal it to the walls.

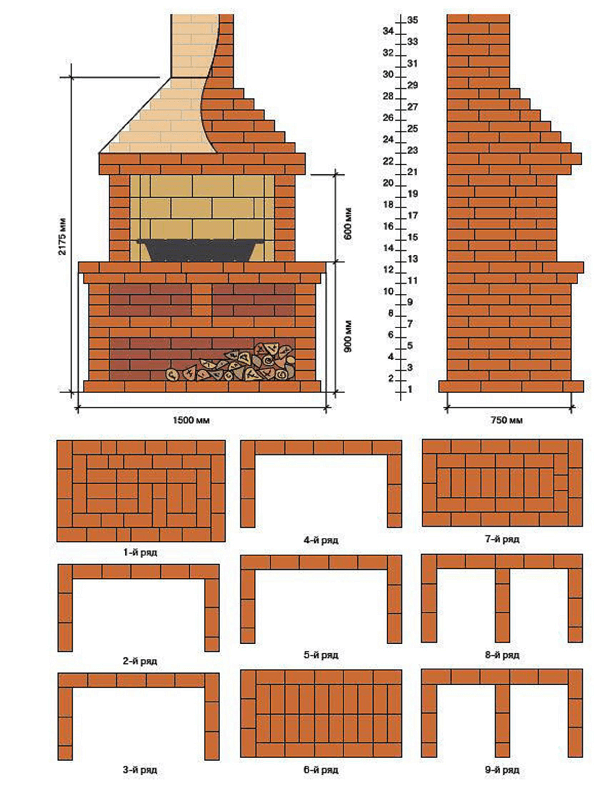

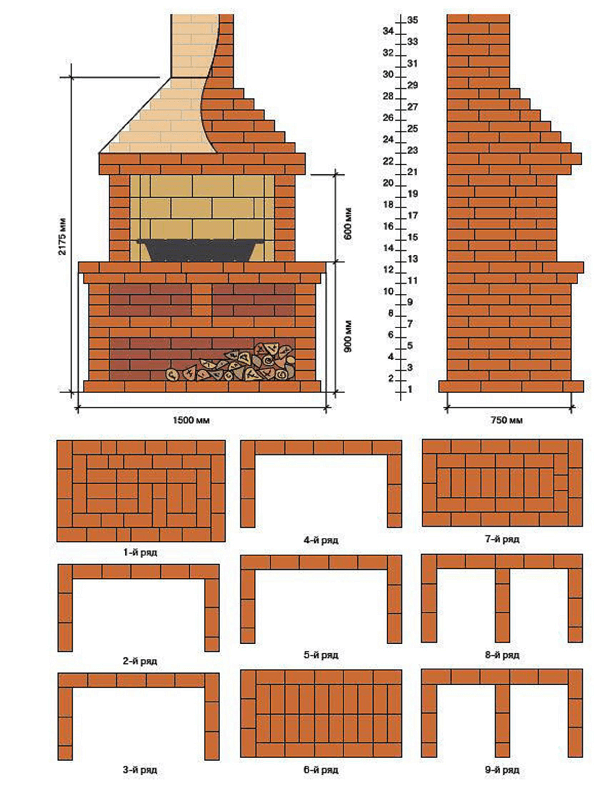

Porjadovki

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor in recovery — EN

Put LIKES and share with your FRIENDS!

https://www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

You can install a cast iron cooking stove, a can and a grill-grill as desired.

When the device of the arch over the cooking plate brick is mounted on steel angles. Also the corners are placed the grate or cast iron grill plate. The canal of the chimney for garden oven-barbecue you can do 270х140 mm, 270х270 mm and 400х140 mm. the Inner wall of the chimney must be plastered, so it was flat and not allowed to accumulate in the irregularities of soot.

For fire safety oven, barbecue set no closer than 7 m from the walls of the house. Finish this type of furnace is selected by the taste of the owner. It could be the pointing, plastering or finish tiles.

Drying oven is gently, slowly. A small amount of fuel it going for 3-8 days.

Any holiday outdoors is hardly complete without delicious food on the fire that fills it with natural energy. And oven made with your own hands will bring any prescriptions and hospitable. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: www.rmnt.ru/story/fireplaces/1086947.htm

FoundationMaterialsthe Basic materials for monolithic slabs are the concrete, reinforcement mesh.

For the device of Foundation is enough to apply the concrete compressive strength B15 (M200). It may be cooked in the correct proportion:

Cement M 400 — 1 part. Crushed stone or gravel, the size of which should be less than 30 mm — 4 pieces. Sand — 2 parts. Impurities in sand clay, organic particles, mica, and dust inclusions shall not be more than 10% of its volume. In a large aggregate (gravel, crushed stone) the number of impurities, decreasing the strength properties of concrete, shall be less than 2%.

Consumption of concrete components by weight per 1 m3:

- cement, 325 kg;

- sand — 1300 kg;

- gravel — 1300 kg;

- water 205 kg.

The size of the Foundation take more of the size of furnace 10 cm on each edge. If the furnace has a size of 1400х1000 mm, the Foundation is 1600 x 1200 mm.

Tools

- dipstick (for diamond);

- rammer (narrow), protected by a metal;

- rammer (round) with two handles;

- rammer (square), covered the bottom with metal;

- trowel (for leveling of concrete);

- scraper (to remove cement grout);

- poluterok;

- Board (for smoothing concrete);

- trowel;

- spade — straight cutting part;

- shovel — pointed lower section;

- the shovel solution.

Laying of concrete mix

Properly selected and made the Foundation is a guarantee of strength and durability of the whole structure. It is very important to know what the ground will be the basis for the furnace. Fairly dense soil may keep the design of the oven-barbecue. But there are pitfalls to be aware of.

There are soils that can change its volume due to soaking or temperature reduction. It is a swelling clay subsidence of loess and the content of soluble salts, water-saturated (the freezing of ice increases the volume of soil), with particles of biological origin (peat), etc. These soils require special measures for their strengthening.

Markup the future of the Foundation can be done, pulling the string on the pegs. The size of pits for sand shall be made at the size of base plate (160x120 cm). As the furnace-a barbecue will be on the street, the ground in the winter time will be subjected to freezing and thawing. Depending on the type of soil, depth of the sand cushion can reach 1000 mm.

Filling the pit with sand is necessary to carry out layer-by-layer (15 cm) by compaction or by pouring water to seal. On the ground before laying the sand you can lay the geotextile, which transmits water but prevents erosion of the sand by groundwater.

On the sand cushion to be laid in waterproofing, 2 layers of roofing material. This will protect the concrete from water in the soil and retain uncured concrete mixture from flowing into the sand.

Boards for formwork used softwood and hardwood with a minimum thickness of 2 cm and no wider than 15 cm posts, which will later be attached to the Board formwork, driven into the ground 50 cm, and then reinforce them with struts. Before you start laying the concrete mixture, it is necessary to clean the casing from dirt and wet.

Next is the installation of reinforcement into the formwork. The reinforcement mesh by means of vertical rods tied into surround frame, given the distance between them and the amount of the protective layer of the working armature 2 cm.

Concreting is desirable to make at one time. This will ensure uniform timing of hardening concrete. Also we should not forget about the compaction of the concrete mixture to remove the formed air bubbles and seal the concrete.

To maintain the humidity needed for normal hardening of the concrete, it is covered with damp burlap, canvas or other similar material. Can 3 hours after pouring the concrete on the surface to put a layer of damp sawdust or sand, which is moistened periodically (5 times per day). This is supported by 7-14 days until the concrete reaches 50-70% of its strength.

Important! When the outside temperature is below +5 °C fresh concrete needs to be insulated to comply with the uniform mode setting.

The formwork can be removed when the concrete attains at least 50% of the strength. In days it will depend on air temperature:

- +5 °C to 12 days;

- +10 °C — 8 days;

- +15 °C — 7 days;

- +20 °C — 6 days.

The furnace housing barbecue GudkovMaterials,refractory Brick (fireclay) GOST 390-96. Clay brick GOST 530-2012. The furnace body is laid of brick or a refractory or ceramic (required full-bodied). Fire brick can withstand 1300 °C and more. Ordinary clay bricks shall be well burnt. Nedozhzhenny, hollow, silicate, and brick, with cracks on chimney masonry not suitable.

On the stove you will need a brick — 465 PCs.

Furnace appliances:

- odnokomnatnaya stove cooking 420х500 mm;

- grille–grill 420х500 mm;

- sheet metal 500х600 mm;

- cleanout door 140х140 mm;

- ashbox's door 270х140 mm;

- furnace door 250х270 mm;

- grate 300x200 mm;

- the area of steel 32х32х4 mm length 500 mm — 4 pieces 600 mm — 6 pieces;

- steel wire 2 mm — 10 m;

- asbestos cord 5 mm — 10 M.

- fat — 2-4%;

- medium — 15%;

- skinny — 30%.

- fatty is 1:2.5;

- average — 1:1,5;

- skinny — 1:1.

Important! Before starting work, the clay is soaked for a day, and then gradually stirring, add a little sand.

You can also buy ready-mix mortar for the oven works. Such mixtures can withstand high temperature and will considerably reduce the time required for the preparation of the solution.

Tool setterChimney masonry is the same brickwork, so basically and tool her practically the same.

1 — kirk; 2 plastering trowel; 3 — mallet; 4 — jointing; 5 — plumb 6 — level 7 — gon

Case garden combined furnacethe erection of the furnace body should be carried out only when there is at least a temporary canopy over it. For the convenience of work you can put the body at first dry, picking up a brick.

Important! Not shot up the side of the brick to put inside the firebox or chimney.

Before laying clay bricks moistened, 1-2 minutes dropping into the water. Fireclay brick only rinse to remove the dust. The thickness of the clay bricks shall be less than 5 mm, and fireclay — 3 mm.

In the production of furnace work must comply with the strict horizontality of the surfaces of each row and vertical angles. Ligation joints shall be 1/2 bricks.

All oven devices are installed simultaneously with the masonry work. Metal and brick have a different value of linear expansion, so all the metal elements of the furnace are installed with a gap of 3-5 mm, then this space is filled with asbestos cord.

To the furnace door mounted steel wire to seal it to the walls.

Porjadovki

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor in recovery — EN

Put LIKES and share with your FRIENDS!

https://www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

You can install a cast iron cooking stove, a can and a grill-grill as desired.

When the device of the arch over the cooking plate brick is mounted on steel angles. Also the corners are placed the grate or cast iron grill plate. The canal of the chimney for garden oven-barbecue you can do 270х140 mm, 270х270 mm and 400х140 mm. the Inner wall of the chimney must be plastered, so it was flat and not allowed to accumulate in the irregularities of soot.

For fire safety oven, barbecue set no closer than 7 m from the walls of the house. Finish this type of furnace is selected by the taste of the owner. It could be the pointing, plastering or finish tiles.

Drying oven is gently, slowly. A small amount of fuel it going for 3-8 days.

Any holiday outdoors is hardly complete without delicious food on the fire that fills it with natural energy. And oven made with your own hands will bring any prescriptions and hospitable. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: www.rmnt.ru/story/fireplaces/1086947.htm