1134

How to make oven Lacireno their hands

Today we talk about the invention of engineer and innovator who did the unprecedented: they built a furnace, which is on the same download works for up to 7 days. Meet, pyrolysis oven Lecinena. Drawings of this miracle of the furnace laid out in free access and we will provide you with. We will tell you what is such a long and efficient combustion, more precisely, the decay of the fuel. Also the open secret developer Lecinena Sergei Surenovich regarding the products of the pyrolysis process.

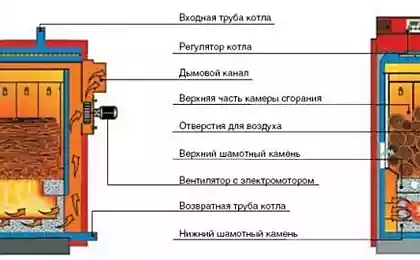

The principle of operation of the furnace Lecinena

Oven name Lecinena Sergei Surenovich

Pyrolysis furnace Lecinena Sergei Surenovich works by complete fuel combustion and products of pyrolysis. In other furnaces pyrolysis involves release of gas from solid fuel, but this design has some differences. In addition to gas, the pyrolysis process of fuel distinguished by the special liquid. In ordinary stoves it evaporates and goes into the chimney along with the combustion products.

What is special pyrolysis furnace Lachinyan? The drawings include a cooling tank in which the condensate gathers. The tank is installed in the flue pipe. After the tank has gathered the condensate it is fed into the combustion chamber. It contributes to:

For ignition of Macinanti can be used as firewood, and gas burner. Importantly, the coals flared and the stove went into the mode of pyrolysis.During operation, the housing cover is heated to 85 degrees, this allows you to use it as a surface for heating food or water. As the hob, unfortunately, it cannot be used, as the temperature is not so high.

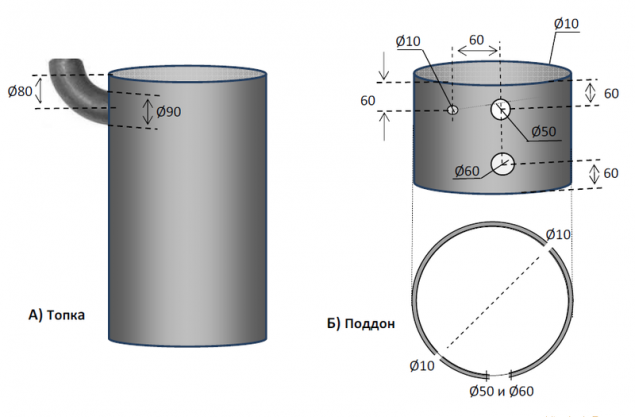

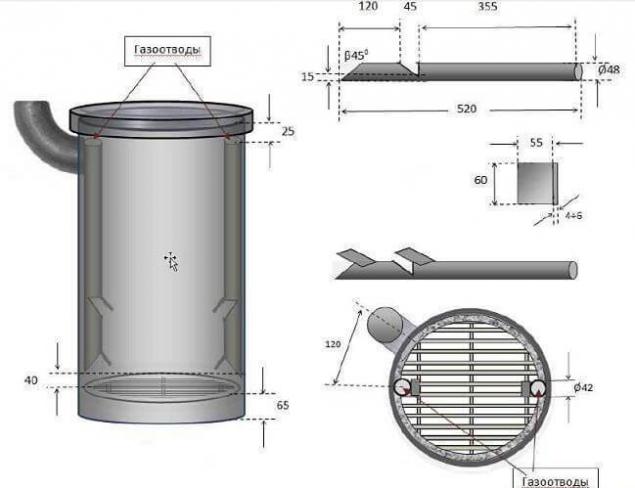

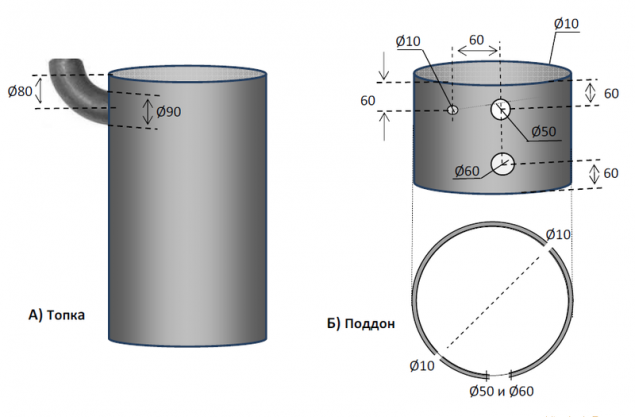

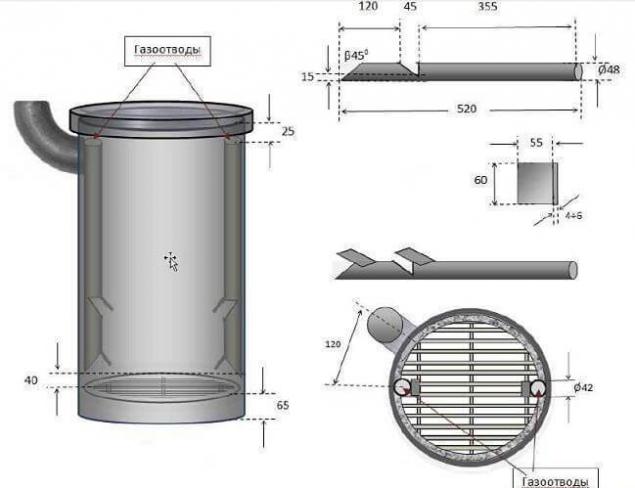

Design of pyrolysis furnace Lecinenato make baking Uchinanchu you will need instruction, which will be described in all components and stages of Assembly. This information is already on the Internet in free access. We will briefly focus on the key points. So, the design of the furnace Lecinena (drawings):

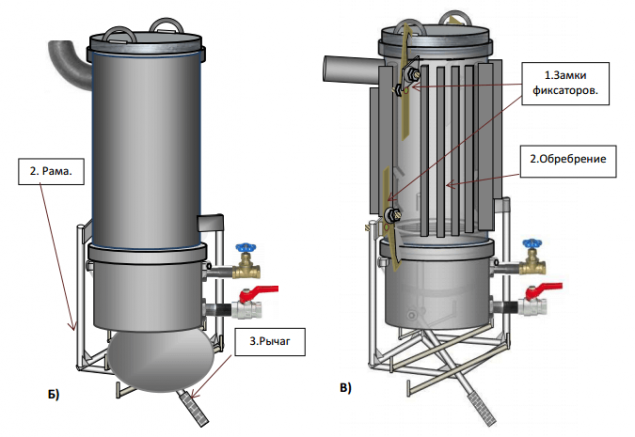

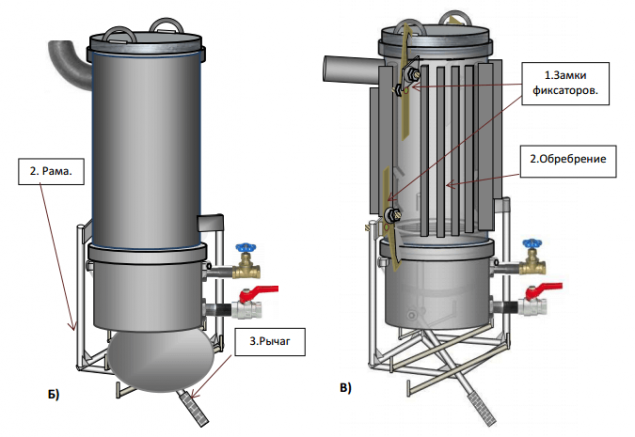

Some models of furnaces "Lacireno" made by their own hands, have fins of the housing and the chimney. Additionally, the housing may be wrapped with insulation. There are several models of furnaces, the main difference is the capacity, which depends on the size. Naturally, the larger the design, the more thermal energy it releases in the process. So, there are small units of 50 square meters, and has 300 sq. m.

Sergey Suren as the seals have decided to use river sand. It turns out that it is not breathable and the after edge of the flap down into the sand, the connection becomes tight. As we have said, integrity is a necessary condition for the aggregation operates in the specified mode for many days.

Stages of production of the furnace of Macinanti their hands

The layout of the holes in the furnace body.

Made baking Lacireno in sequence:

The stove to Lucinasco can be done even with the old barrel, as long as the metal wasn't too thin. This is important because when Rusalka and in the mode of "stove" the body becomes very hot.

Housing with tray and lid used pipe with the same diameter. To take thin-walled tube should not be, because to work in high temperature mode, the desired metal is somewhat stronger. The drawing furnace Lacireno designed for pipe with wall thickness 5 to 8 mm. in the manufacture of edges (grooves) for sand from two plates welded in a circle, first one should be to weld the inner part. This should be done so that the seam lay in the groove.

In the manufacture of grate furnaces Lecinena, use the steel bars and to avoid cast iron. When choosing valves for air supply, note that they have to work in high temperatures, hence they must be all metal, no plastic elements. Suitable water tap in one and a half inches with rubber seals. Rubber is quite efficient in these conditions.Housing with tray and lid used pipe with the same diameter.

Schematic layout for the installation of pipelines

To take thin-walled tube should not be, because to work in high temperature mode, the desired metal is somewhat stronger. The drawing furnace Lacireno designed for pipe with wall thickness 5 to 8 mm. in the manufacture of edges (grooves) for sand from two plates welded in a circle, first one should be to weld the inner part. This should be done so that the seam lay in the groove.

To avoid condensation, the chimney should be insulated or kept in a warm room. Pipe to chimney must not be horizontally positioned. You need to give a slight slope to the side of the heater so that the condensate can drain off, first into the condensate, and then in the oven Lecinena.

The furnace of MacinantiAfter you already have a pyrolysis oven Lecinena, you need to know how to handle it. Manual transmission manual we will divide into several sections:

When you close the lid or the tray, do not force to push it into the sand. Use the hammer. When tapped, the sand begins to move and the edge of the cover smoothly it's going.Furnace design Lecinena impossible without a chimney. It has the same requirements as for chimneys and other heating appliances to gas or solid fuel. It is also extremely important to correctly calculate the diameter of the chimney. It needs to be not less than the pipe section in a furnace, and neither in any places should not be saujani, or lost traction.

To inflame Lecinena furnace the furnace is filled with coal coarse fraction, dust. In the pan the fire gets divorced. You need to open both taps for the supply of air and a tray to close tightly. Once the coal will ignite the pan can be sealed and the furnace to fill the coal is full to the brim. After one hour the stove can be converted into pyrolysis mode. This is completely overlapped by the lower tap, and almost completely overlaps the top of the crane.

During the operation to remove the ash and periodically clean the boiler and chimney. Frequency of cleaning depends on the quality of coal. The higher it is, the less you need to carry out the cleaning procedure. In addition, the need to periodically change the sand in the grooves for sealing. It is necessary to use a clean, dry river sand, not too small fraction. To fill up the fuel by simply opening the top cover, it does not need to stop the burning process. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: utepleniedoma.com/otoplenie/otoplenie-doma/pech-lachinyanka

The principle of operation of the furnace Lecinena

Oven name Lecinena Sergei Surenovich

Pyrolysis furnace Lecinena Sergei Surenovich works by complete fuel combustion and products of pyrolysis. In other furnaces pyrolysis involves release of gas from solid fuel, but this design has some differences. In addition to gas, the pyrolysis process of fuel distinguished by the special liquid. In ordinary stoves it evaporates and goes into the chimney along with the combustion products.

What is special pyrolysis furnace Lachinyan? The drawings include a cooling tank in which the condensate gathers. The tank is installed in the flue pipe. After the tank has gathered the condensate it is fed into the combustion chamber. It contributes to:

- to increase the efficiency of the device;

- to reduce the amount of condensate in the chimney.

For ignition of Macinanti can be used as firewood, and gas burner. Importantly, the coals flared and the stove went into the mode of pyrolysis.During operation, the housing cover is heated to 85 degrees, this allows you to use it as a surface for heating food or water. As the hob, unfortunately, it cannot be used, as the temperature is not so high.

Design of pyrolysis furnace Lecinenato make baking Uchinanchu you will need instruction, which will be described in all components and stages of Assembly. This information is already on the Internet in free access. We will briefly focus on the key points. So, the design of the furnace Lecinena (drawings):

- valves for air supply;

- housing;

- housing cover;

- the firebox and the grate;

- connections for circulation of gases;

- tank for condensate collection;

- chimney;

- frame for installation;

- lever for pan;

- locks locking lid and tray.

Some models of furnaces "Lacireno" made by their own hands, have fins of the housing and the chimney. Additionally, the housing may be wrapped with insulation. There are several models of furnaces, the main difference is the capacity, which depends on the size. Naturally, the larger the design, the more thermal energy it releases in the process. So, there are small units of 50 square meters, and has 300 sq. m.

Sergey Suren as the seals have decided to use river sand. It turns out that it is not breathable and the after edge of the flap down into the sand, the connection becomes tight. As we have said, integrity is a necessary condition for the aggregation operates in the specified mode for many days.

Stages of production of the furnace of Macinanti their hands

The layout of the holes in the furnace body.

Made baking Lacireno in sequence:

- manufactured housing with a lid, and a reservoir for ash;

- made the necessary holes;

- prepare grooves, which will then be covered with river sand;

- made the gas and the grate;

- mounted two cranes, which are used for oxygen supply;

- you can then start making intake air;

- the whole structure is mounted on the frame and mounted the arm to the pallet;

- set the chimney with a reservoir for condensate collection.

The stove to Lucinasco can be done even with the old barrel, as long as the metal wasn't too thin. This is important because when Rusalka and in the mode of "stove" the body becomes very hot.

Housing with tray and lid used pipe with the same diameter. To take thin-walled tube should not be, because to work in high temperature mode, the desired metal is somewhat stronger. The drawing furnace Lacireno designed for pipe with wall thickness 5 to 8 mm. in the manufacture of edges (grooves) for sand from two plates welded in a circle, first one should be to weld the inner part. This should be done so that the seam lay in the groove.

In the manufacture of grate furnaces Lecinena, use the steel bars and to avoid cast iron. When choosing valves for air supply, note that they have to work in high temperatures, hence they must be all metal, no plastic elements. Suitable water tap in one and a half inches with rubber seals. Rubber is quite efficient in these conditions.Housing with tray and lid used pipe with the same diameter.

Schematic layout for the installation of pipelines

To take thin-walled tube should not be, because to work in high temperature mode, the desired metal is somewhat stronger. The drawing furnace Lacireno designed for pipe with wall thickness 5 to 8 mm. in the manufacture of edges (grooves) for sand from two plates welded in a circle, first one should be to weld the inner part. This should be done so that the seam lay in the groove.

To avoid condensation, the chimney should be insulated or kept in a warm room. Pipe to chimney must not be horizontally positioned. You need to give a slight slope to the side of the heater so that the condensate can drain off, first into the condensate, and then in the oven Lecinena.

The furnace of MacinantiAfter you already have a pyrolysis oven Lecinena, you need to know how to handle it. Manual transmission manual we will divide into several sections:

- installation rules;

- how to inflame the furnace;

- features of the application;

- preventive maintenance.

When you close the lid or the tray, do not force to push it into the sand. Use the hammer. When tapped, the sand begins to move and the edge of the cover smoothly it's going.Furnace design Lecinena impossible without a chimney. It has the same requirements as for chimneys and other heating appliances to gas or solid fuel. It is also extremely important to correctly calculate the diameter of the chimney. It needs to be not less than the pipe section in a furnace, and neither in any places should not be saujani, or lost traction.

To inflame Lecinena furnace the furnace is filled with coal coarse fraction, dust. In the pan the fire gets divorced. You need to open both taps for the supply of air and a tray to close tightly. Once the coal will ignite the pan can be sealed and the furnace to fill the coal is full to the brim. After one hour the stove can be converted into pyrolysis mode. This is completely overlapped by the lower tap, and almost completely overlaps the top of the crane.

During the operation to remove the ash and periodically clean the boiler and chimney. Frequency of cleaning depends on the quality of coal. The higher it is, the less you need to carry out the cleaning procedure. In addition, the need to periodically change the sand in the grooves for sealing. It is necessary to use a clean, dry river sand, not too small fraction. To fill up the fuel by simply opening the top cover, it does not need to stop the burning process. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: utepleniedoma.com/otoplenie/otoplenie-doma/pech-lachinyanka

Top 5 home remedies treatment of periodontal disease

Point hand massage to reduce appetite and not only