1255

How to make stove water heating with his own hands

In any private house, a very acute problem of uninterrupted hot water and General heating. For these purposes, use a variety of options, but the easiest and most efficient is the heating system that is connected to the furnace. Currently, it is possible to buy on the market for fabricated metal stove, although you can save money through a heating device, making the system on the basis of a kiln of bricks. This water heating system is not very costly, as the oven can easily lay their hands. To build a water boiler, use a metal conventional pipe or sheet metal. Sheet metal weld capacity, which is used for water, and after it is connected to a common heating circuit.

Due to the relatively simple process of installation and affordable price oven remains the best option for heating homes. It is especially useful for heating when it is combined with a water circuit. The advantages and disadvantages of a water heating furnace,Today it is often possible to meet the application of the heating circuit on the basis of the furnace. This option is most popular for holiday houses small sizes, where there is no point in installing expensive gas or electric boilers.

Among the advantages of such a heating system are the following:

A simple and quick process of installation of the furnace. You can buy a small metal furnace which is capable of providing independent heating effectively, but you can lay down a conventional oven made of brick, which wakes last a long time. Easy maintenance of the furnace, which requires only regular cleaning. This setup is ideal for private homes, since there is no need for costly maintenance. This fairly effective system, if the equipment is installed correctly, the efficiency will be approximately 60% when operating on liquid fuel. The possibility of combining a furnace with a fireplace, so you can perform for a private home, not only heating, but also improve interior decor. Possibility of regulation of combustion through the usual valve. The disadvantages of such systems are the following:

For installation of furnace design need a lot of space, because the amount of heat transfer depends directly on the size of the furnace itself. The system is observed for a long period of heating process that makes it impossible for a sudden temperature increase. For full heating of a private house requires a lot of time. For use with furnaces of this type are quite strict sanitary standards, as the products of combustion can quickly contaminate a room. For this reason, requires constant cleaning of the equipment. Supposed to use special means for care. However, such independent means of heating do not cause any serious problems if a regular Shoe design, moreover, with constant care it takes not much time. Water furnace performs the uneven heating of the house, with the highest temperature observed near the furnace and in the back rooms of a private house heating is not so good. Important when using the kiln system to pay special attention to fire-prevention measures. The types of the furnace with a water circuit for heating

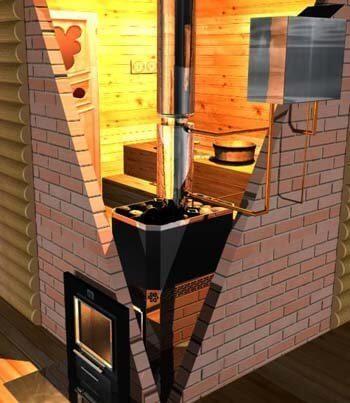

This type of equipment is made in two versions. Take already mounted oven and set it on the coil. This option is considered time-consuming sandstorm, which is used less frequently. This is due to the fact that making the coil, it is necessary to rely on already existing dimensions of the firebox.

The source of the warmth you spread with your hands in accordance with the size of the register. Built properly, the stove will serve as a guarantee that will last for a long time and serve reliably.

Definitely you must ensure that the internal value of the shirt started from 4-5 inches. Otherwise, it will start to boil the water, more likely in the case of weak circulation. To fix this flaw, sets the pump. The heat exchanger shall have a wall the size of at least five millimeters. If it is smaller, then the case simply burned, which will lead to his forced substitution. To replace it requires parsing of the floor of the furnace, therefore, such negligence would cost dearly.Walls should have a thickness of, directly corresponding to the kind of fuel used, its calorific value and specific abilities. Thus, for example, if the firebox is made only with wood, the walls can be performed less than three millimeters. In the case of coal it is better to make the walls a minimum thickness of five millimeters. In this case you need to leave a gap between the wall and register approximately ten to twenty millimeters. This should be done in order to offset the thermal expansion of the applied metal, thus preserving its integrity.

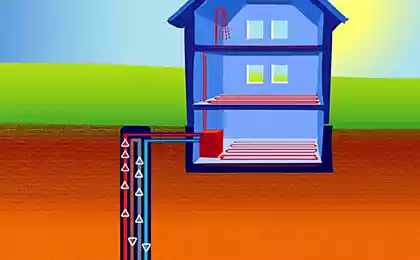

The combination of water and furnace heatingHave the classic wood house with the presence of the heating furnace has one important drawback: the room is heated by the heater is extremely uneven. Above the stove and near it is constantly heated air, and the room, away from her cold. For this reason, in big houses have to do several furnaces to provide uniform heat flow.

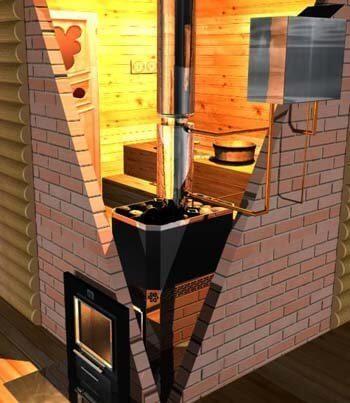

However, water and stove heating in a private house can be combined. The usual traditional oven made of brick supply register, that is, the heat exchanger from steel or plastic pipes, which resembles the shape of a coil.

It is located at the base of the chimney or in the fuel room and the water inside it is heated by furnace heat. Then pipe the water flows into the radiator, evenly warming up the house. Such a system has several clear advantages:

Furnace heating in a wooden house, which is combined with a water contour gives you the opportunity to save on fuel consumption, although you will need to heat the oven daily. One of the few downsides of this system is its inability to work without direct supervision and involvement of the people.

Preparations for the construction and designing of furnace water heating

The first thing required to develop a project that better to discuss with the relevant specialists in this field. For stove heating in the house with a water circuit, generally supposed location of the furnace in the Central portion in the house so that the furnace went out, for example, in the kitchen or other non-residential premises and housing W e have is in the living room. This arrangement allows you to warm multiple rooms efficiently

The value of the furnace is determined by the dimensions of the house. When one meter square of the kiln is able to heat about 35 square meters in the house, therefore, according to this indicator, you can calculate its value for a specific structure or home.

In certain cases, acquire the register for ready furnace, however, it happens quite rarely. Often the first thing to make or acquire the register required area, and after it going to a furnace of a given magnitude.

The register can be made from a sheet or from the pipes, but in any case, the thickness of the metal should be at least 3-5 mm. Thinner metal will burn through quickly, which will have to change the heat exchanger, which will lead to large financial costs.

In the fuel Department establish a register, while leaving between the wall and him the gap of a small size to compensate for thermal expansion and allow more efficient heat transfer. Besides, you need to provide access to carry out periodic cleaning as ash and other combustion products reduce the efficiency of the heater.

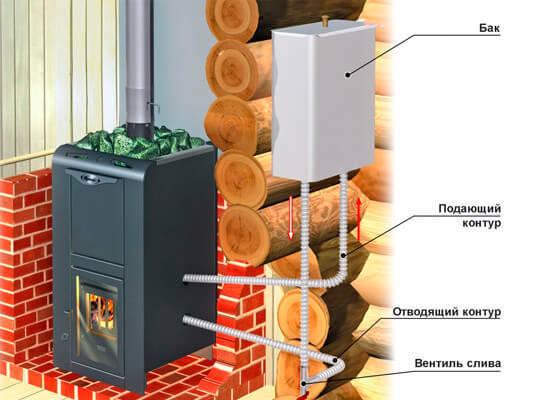

It is important to note that when mounting the register decreases the value of the fuel chamber, and therefore the coal or wood you need to put if. It is possible to provide in the case to build the firebox for the size of the coil and make it large enough to warm the whole house.Essential to the health of the system is a constant process of circulation in the pipes of water, for which they should be placed under the slope, it is also desirable to set the circulating pump to ensure uninterrupted stable job and not being able to boil the coolant.

It is important to know that not allowed the arrangement of the structure without bias, while focusing only on the operation of the pump. In the event of power outages, the pump fails and the coolant boils in the pipes, and the whole system will fail. Also the system needs to provide an expansion tank to compensate for expansion of water from temperature changes.After completing the design work, it is recommended to show the completed scheme to the concerned professionals as any mistake can make the entire structure unstable, and therefore to neglect the safety rules in any case impossible.

The necessary tools

To work in advance to prepare the necessary tools:

To build a furnace, you need properly mixed the mortar and bricks of high quality. Some professionals are oriented not to the exhaust ratio, but rather on intuition. But if the wizard is not a great experience, it is better to buy mortar already in a ready kind.On the basis of lay the waterproofing layer, the bricks are soaked in water. After they begin to spread according to the lining on the Foundation. The lining is called the series arrangement of bricks. If the dimensions of the furnace are accurately known, you can easily find the lining on the Internet, scheduling the pre-construction phase.

In the design lay the coil is the register to which further attach the pipe to the output and input of the coolant. Collect the oven at the seams, the size of maximum 4 mm, moreover, you must ensure that inside diodelaser channels and firebox was not sharp edges. Need rounded corners without sacrificing a quiet smoke, so that the firebox will be collected less soot.

The construction of the furnace there are some important rules:

Clearance required between the stove and walls, besides, it is necessary to lay before a furnace sheet metal. The floor and walls will protect from fire a simple wall. To every 4 rows of masonry be reinforced to make it maximum strength. Reinforcement is carried out using metal pins. The clay mortar should be of medium plasticity. If the solution is made with your own hands, you need to roll a ball of small size and throw it on the floor. Solution of normal consistency would not give a large crack and crumble. The chimney must have a height of at least 5 meters. It completes the headband element, protecting the pipe from debris and rain into and which allows enhancing traction and are an additional element of the decor of the building. The installation process water circuit

Register for water heating furnace

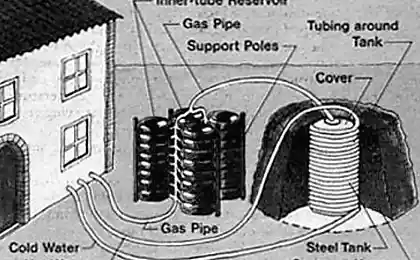

For the effective operation of equipment for heating water system should be installed so-called register, which is a boiler or heat exchanger. It is often called the coil. A register placing in the furnace firebox.

Diagram of a water heating furnace for a private home consists of the following elements:

Also, building a heat exchanger for a private home, you must consider the wall thickness of the installed designs. If you plan stove wood, its walls can be thinner and run, but if running water is heated by coal briquettes, it is better to make the thickness thicker. If you ignore this detail, the boiler very quickly burned, and hence, will have soon to change it. This, in turn, will have to disassemble the oven. Thus, in fact, will need to collect the oven again after the replacement.Installation of furnaces and heating systems your own hands

Self-stacking kiln is not that difficult, although it is possible to apply and finish is really metal structure. But the oven made of bricks, looks much more aesthetically pleasing. If the employee knows how to deal with this material, the masonry stove for heating can be performed independently.

The process begins with the selection of suitable bricks. In this case, you need to take only the red ceramic bricks, which had previously been annealed. Brick it is recommended to choose only high quality. In order to perform the stacking ovens will not work:

For heating in this case it is possible to use refractory fire brick:

Carefully sifted sand. In a container filled with the clay for rstore and filled with water, and then, kneaded by hand. Formed the clay solution is left for three days, and after that time it is advisable to strain through a sieve. The mixture should be the consistency like thick cream. Next is a trial solution. If used skinny clay, then you need to mix different 4 test portions, each of 0.5 liter. This clay solution was added to the sand. Each piece of clay has the following proportion – 1, of 0.75, 0.25 and 0.1, if the clay used is oily, then the next is 2, and 1.5, 1 and 0.5. Then it checks which one to use mortar for the heating furnace. Each part osipyants piece and made from a ball having a diameter of 5 centimeters. Next, the ball is rotated between the smooth straps and shrink. Thus, appreciate the result: if the ball formed large cracks, and the whole is compressed to 1/3, it indicates medium plasticity. Such a solution should be used for the device of the furnace. Following the inspection, preparing a solution in the prescribed proportions, focusing on the number of a hundred pieces of bricks. It takes two buckets of clay and half a bucket of sand. Mix ka to mix. The mixture should not be spread on the trowel for masonry and smoothly with it sliding.

To lay out laying under the stove equipment, on the sides, you can install a special wooden otfugovannymi bars to control the verticality of the walls at the future of the furnace.For self-laying of the furnace it is assumed that the joints will have a thickness of not more than 3-4 millimeters. Today quite a lot of options of masonry stoves of brick for a heating system in a private home. Among the General requirements that they imposed, are the following:

This article describes the basic rules for the construction of the heating furnace from a private home. Here you specify only part of the requirements for self-erecting device of the furnace, and it is recommended to see complete list. It is advisable to consult with the professional potters, and it is better to follow the process of his work, while receiving invaluable knowledge, which are not in the appropriate books and manuals.

The combination of new solutions and familiar traditions allows you to create durable and effective heater, fully independent from the Central source. Supporting the heating unit and furnace in good condition and order, on the years not to worry about the heating and the heat in the house.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

published

Source: normdom.ru/otoplenie/pechnoe-vodyanoe-otoplenie.html

Due to the relatively simple process of installation and affordable price oven remains the best option for heating homes. It is especially useful for heating when it is combined with a water circuit. The advantages and disadvantages of a water heating furnace,Today it is often possible to meet the application of the heating circuit on the basis of the furnace. This option is most popular for holiday houses small sizes, where there is no point in installing expensive gas or electric boilers.

Among the advantages of such a heating system are the following:

A simple and quick process of installation of the furnace. You can buy a small metal furnace which is capable of providing independent heating effectively, but you can lay down a conventional oven made of brick, which wakes last a long time. Easy maintenance of the furnace, which requires only regular cleaning. This setup is ideal for private homes, since there is no need for costly maintenance. This fairly effective system, if the equipment is installed correctly, the efficiency will be approximately 60% when operating on liquid fuel. The possibility of combining a furnace with a fireplace, so you can perform for a private home, not only heating, but also improve interior decor. Possibility of regulation of combustion through the usual valve. The disadvantages of such systems are the following:

For installation of furnace design need a lot of space, because the amount of heat transfer depends directly on the size of the furnace itself. The system is observed for a long period of heating process that makes it impossible for a sudden temperature increase. For full heating of a private house requires a lot of time. For use with furnaces of this type are quite strict sanitary standards, as the products of combustion can quickly contaminate a room. For this reason, requires constant cleaning of the equipment. Supposed to use special means for care. However, such independent means of heating do not cause any serious problems if a regular Shoe design, moreover, with constant care it takes not much time. Water furnace performs the uneven heating of the house, with the highest temperature observed near the furnace and in the back rooms of a private house heating is not so good. Important when using the kiln system to pay special attention to fire-prevention measures. The types of the furnace with a water circuit for heating

This type of equipment is made in two versions. Take already mounted oven and set it on the coil. This option is considered time-consuming sandstorm, which is used less frequently. This is due to the fact that making the coil, it is necessary to rely on already existing dimensions of the firebox.

The source of the warmth you spread with your hands in accordance with the size of the register. Built properly, the stove will serve as a guarantee that will last for a long time and serve reliably.

Definitely you must ensure that the internal value of the shirt started from 4-5 inches. Otherwise, it will start to boil the water, more likely in the case of weak circulation. To fix this flaw, sets the pump. The heat exchanger shall have a wall the size of at least five millimeters. If it is smaller, then the case simply burned, which will lead to his forced substitution. To replace it requires parsing of the floor of the furnace, therefore, such negligence would cost dearly.Walls should have a thickness of, directly corresponding to the kind of fuel used, its calorific value and specific abilities. Thus, for example, if the firebox is made only with wood, the walls can be performed less than three millimeters. In the case of coal it is better to make the walls a minimum thickness of five millimeters. In this case you need to leave a gap between the wall and register approximately ten to twenty millimeters. This should be done in order to offset the thermal expansion of the applied metal, thus preserving its integrity.

The combination of water and furnace heatingHave the classic wood house with the presence of the heating furnace has one important drawback: the room is heated by the heater is extremely uneven. Above the stove and near it is constantly heated air, and the room, away from her cold. For this reason, in big houses have to do several furnaces to provide uniform heat flow.

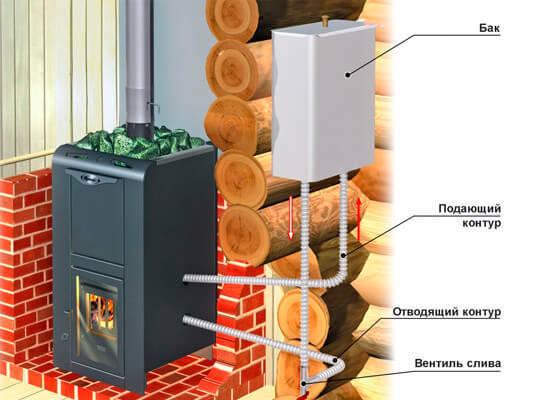

However, water and stove heating in a private house can be combined. The usual traditional oven made of brick supply register, that is, the heat exchanger from steel or plastic pipes, which resembles the shape of a coil.

It is located at the base of the chimney or in the fuel room and the water inside it is heated by furnace heat. Then pipe the water flows into the radiator, evenly warming up the house. Such a system has several clear advantages:

- The uniformity and efficiency of heating. It is possible to place the radiators in each room, providing constant heat during firing. Since the house is from the wood itself holds heat good, also it is possible to heat, such heating system is quite effective.

- Absolute independence. The Central pipeline is not everywhere, besides, not uncommon for rural area power outages. In this regard, in the winter you can suddenly be left without heat at the most inopportune moment. Wood or coal heating depends only on the wishes of the owners of the house. Classic oven can serve for decades without creating any interruption of heat supply, if pre-packaged fuel.

- For a country house with stove heating does not require additional costs for maintenance of equipment professionals. For the Russian stove requires only periodic cleaning of the furnace with soot and ash, the rest of the system to run smoothly.

Furnace heating in a wooden house, which is combined with a water contour gives you the opportunity to save on fuel consumption, although you will need to heat the oven daily. One of the few downsides of this system is its inability to work without direct supervision and involvement of the people.

Preparations for the construction and designing of furnace water heating

The first thing required to develop a project that better to discuss with the relevant specialists in this field. For stove heating in the house with a water circuit, generally supposed location of the furnace in the Central portion in the house so that the furnace went out, for example, in the kitchen or other non-residential premises and housing W e have is in the living room. This arrangement allows you to warm multiple rooms efficiently

The value of the furnace is determined by the dimensions of the house. When one meter square of the kiln is able to heat about 35 square meters in the house, therefore, according to this indicator, you can calculate its value for a specific structure or home.

In certain cases, acquire the register for ready furnace, however, it happens quite rarely. Often the first thing to make or acquire the register required area, and after it going to a furnace of a given magnitude.

The register can be made from a sheet or from the pipes, but in any case, the thickness of the metal should be at least 3-5 mm. Thinner metal will burn through quickly, which will have to change the heat exchanger, which will lead to large financial costs.

In the fuel Department establish a register, while leaving between the wall and him the gap of a small size to compensate for thermal expansion and allow more efficient heat transfer. Besides, you need to provide access to carry out periodic cleaning as ash and other combustion products reduce the efficiency of the heater.

It is important to note that when mounting the register decreases the value of the fuel chamber, and therefore the coal or wood you need to put if. It is possible to provide in the case to build the firebox for the size of the coil and make it large enough to warm the whole house.Essential to the health of the system is a constant process of circulation in the pipes of water, for which they should be placed under the slope, it is also desirable to set the circulating pump to ensure uninterrupted stable job and not being able to boil the coolant.

It is important to know that not allowed the arrangement of the structure without bias, while focusing only on the operation of the pump. In the event of power outages, the pump fails and the coolant boils in the pipes, and the whole system will fail. Also the system needs to provide an expansion tank to compensate for expansion of water from temperature changes.After completing the design work, it is recommended to show the completed scheme to the concerned professionals as any mistake can make the entire structure unstable, and therefore to neglect the safety rules in any case impossible.

The necessary tools

To work in advance to prepare the necessary tools:

- building level;

- gon;

- brush to perform the grouting;

- masonry trowel;

- hammer;

- kirk.

To build a furnace, you need properly mixed the mortar and bricks of high quality. Some professionals are oriented not to the exhaust ratio, but rather on intuition. But if the wizard is not a great experience, it is better to buy mortar already in a ready kind.On the basis of lay the waterproofing layer, the bricks are soaked in water. After they begin to spread according to the lining on the Foundation. The lining is called the series arrangement of bricks. If the dimensions of the furnace are accurately known, you can easily find the lining on the Internet, scheduling the pre-construction phase.

In the design lay the coil is the register to which further attach the pipe to the output and input of the coolant. Collect the oven at the seams, the size of maximum 4 mm, moreover, you must ensure that inside diodelaser channels and firebox was not sharp edges. Need rounded corners without sacrificing a quiet smoke, so that the firebox will be collected less soot.

The construction of the furnace there are some important rules:

Clearance required between the stove and walls, besides, it is necessary to lay before a furnace sheet metal. The floor and walls will protect from fire a simple wall. To every 4 rows of masonry be reinforced to make it maximum strength. Reinforcement is carried out using metal pins. The clay mortar should be of medium plasticity. If the solution is made with your own hands, you need to roll a ball of small size and throw it on the floor. Solution of normal consistency would not give a large crack and crumble. The chimney must have a height of at least 5 meters. It completes the headband element, protecting the pipe from debris and rain into and which allows enhancing traction and are an additional element of the decor of the building. The installation process water circuit

Register for water heating furnace

For the effective operation of equipment for heating water system should be installed so-called register, which is a boiler or heat exchanger. It is often called the coil. A register placing in the furnace firebox.

Diagram of a water heating furnace for a private home consists of the following elements:

- combustion chamber;

- ash pan;

- hermetic door for the furnace;

- cleaning hatch of the furnace;

- special surface for reheating furnace;

- injector;

- gate;

- cutter;

- convection tubes;

- the grate bar.

Also, building a heat exchanger for a private home, you must consider the wall thickness of the installed designs. If you plan stove wood, its walls can be thinner and run, but if running water is heated by coal briquettes, it is better to make the thickness thicker. If you ignore this detail, the boiler very quickly burned, and hence, will have soon to change it. This, in turn, will have to disassemble the oven. Thus, in fact, will need to collect the oven again after the replacement.Installation of furnaces and heating systems your own hands

Self-stacking kiln is not that difficult, although it is possible to apply and finish is really metal structure. But the oven made of bricks, looks much more aesthetically pleasing. If the employee knows how to deal with this material, the masonry stove for heating can be performed independently.

The process begins with the selection of suitable bricks. In this case, you need to take only the red ceramic bricks, which had previously been annealed. Brick it is recommended to choose only high quality. In order to perform the stacking ovens will not work:

- brick nedogony pale pink color;

- brick perelozhenie with the presence on the surface of the glassy film.

For heating in this case it is possible to use refractory fire brick:

- for heating kamnem uglum better to take fireclay bricks;

- for heating with wood or peat – white Gzhel or Borovichi brick.

Carefully sifted sand. In a container filled with the clay for rstore and filled with water, and then, kneaded by hand. Formed the clay solution is left for three days, and after that time it is advisable to strain through a sieve. The mixture should be the consistency like thick cream. Next is a trial solution. If used skinny clay, then you need to mix different 4 test portions, each of 0.5 liter. This clay solution was added to the sand. Each piece of clay has the following proportion – 1, of 0.75, 0.25 and 0.1, if the clay used is oily, then the next is 2, and 1.5, 1 and 0.5. Then it checks which one to use mortar for the heating furnace. Each part osipyants piece and made from a ball having a diameter of 5 centimeters. Next, the ball is rotated between the smooth straps and shrink. Thus, appreciate the result: if the ball formed large cracks, and the whole is compressed to 1/3, it indicates medium plasticity. Such a solution should be used for the device of the furnace. Following the inspection, preparing a solution in the prescribed proportions, focusing on the number of a hundred pieces of bricks. It takes two buckets of clay and half a bucket of sand. Mix ka to mix. The mixture should not be spread on the trowel for masonry and smoothly with it sliding.

To lay out laying under the stove equipment, on the sides, you can install a special wooden otfugovannymi bars to control the verticality of the walls at the future of the furnace.For self-laying of the furnace it is assumed that the joints will have a thickness of not more than 3-4 millimeters. Today quite a lot of options of masonry stoves of brick for a heating system in a private home. Among the General requirements that they imposed, are the following:

- reinforcement every fourth row of masonry with metal rods;

- all internal parts of the furnace should run and rounded with no protrusions and, therefore, do not use bricks with chips;

- for private one-storey house pipe should be from iron pipe at a height of at least 5 meters;

- with the passage of the roof, you need to perform brick “fuzz”, but rather a gradual build-up of bricks;

- should be installed above the exit chimney of the headband that protects against snow, moisture and debris, and amplifies thrust.

This article describes the basic rules for the construction of the heating furnace from a private home. Here you specify only part of the requirements for self-erecting device of the furnace, and it is recommended to see complete list. It is advisable to consult with the professional potters, and it is better to follow the process of his work, while receiving invaluable knowledge, which are not in the appropriate books and manuals.

The combination of new solutions and familiar traditions allows you to create durable and effective heater, fully independent from the Central source. Supporting the heating unit and furnace in good condition and order, on the years not to worry about the heating and the heat in the house.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

published

Source: normdom.ru/otoplenie/pechnoe-vodyanoe-otoplenie.html