2069

Rocket stove with their hands

Among the variety of wood-burning stoves, special attention deserves such a thermal device, such as a homemade rocket stove. It has an original design, does not require the manufacture of expensive materials and components.

To make this stove any person, even a little bit versed in the drawings and able to work with your hands. To help such home craftsmen and have come to our article where you will learn about the design and principle of operation of the furnace – rocket. Here are the recommendations for its manufacture from different materials.

THE PRINCIPLES OF OPERATION OF ROCKET FURNACE

Although the device of the rocket furnace is simple enough, but successfully uses two principle borrowed from other types of solid fuel heating appliances:

— the principle of reburning wood gas combustion (pyrolysis);

— the principle of free flow of gases through the channels (without any prompting from the natural draught of the chimney).

Note. In the simplest rocket stoves for cooking, including the portable type, operates only the second principle, since the flow of the pyrolysis process in them is not created favorable conditions.

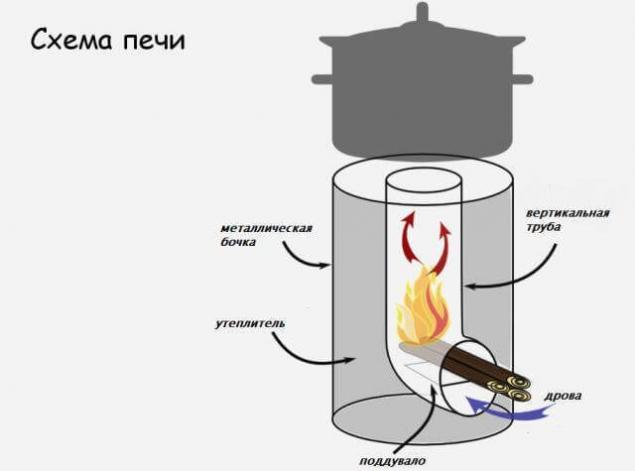

First, let us examine the device of rocket stoves direct combustion, is designed only for cooking food. Here the firebox is a short horizontal section of the pipe, which then turns upwards. The design is simple to a disgrace

The fuel is laid in the tube and ignited, resulting in an upward flow of hot gases, tends to rise in vertical section and go outside. Here at the cut pipe and installed capacity for food or water. Of course, between the pan and the tube provides clearance for the exit of combustion products. This is achieved by various metal supports.

For reference. The above device of a rocket stove – one of the first. It is because of a turned up nozzle from escaping from the flames device is called the rocket.

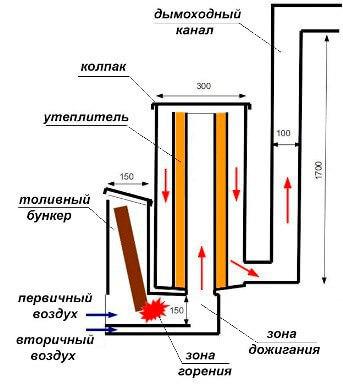

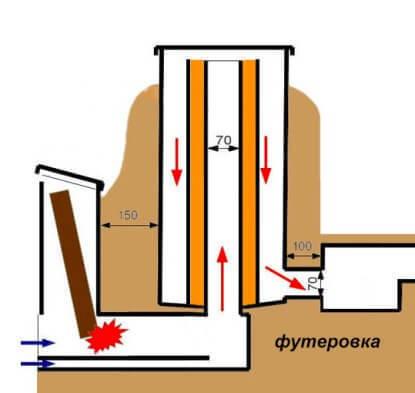

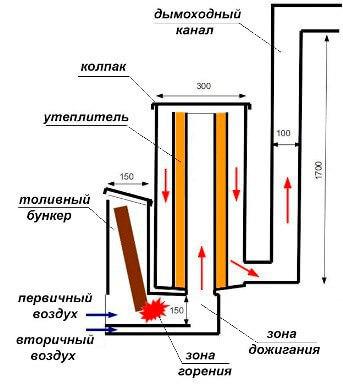

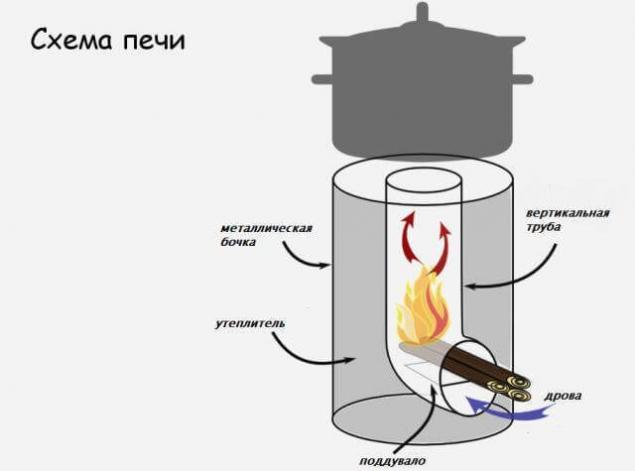

As to heat the premises in such a unit is impossible, the design of the heating rocket stoves were augmented heat exchange unit and the channels for the flue gases. To save on vertical pipe section high temperature, it is insulated from any refractory material. Further, for the intense heat the nozzle on top is covered with a cap, for example, conventional metallic barrel. At the bottom of the horizontal fire tube is a channel for secondary air.

Now the principle of operation of rocket furnace looks a little different. First, at the end of a horizontal firing channel is afterburning pyrolysis gases through the secondary air flow. Second, the products of combustion with high temperature accumulate under the top of hood (barrel), creating a slight overpressure. As the transfer of heat out through the metal walls, these gases cool down and come down.

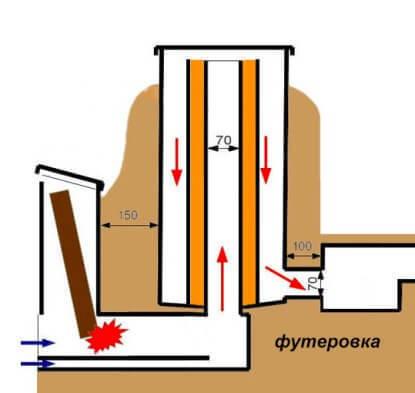

Since the cooling gases from below are the new hot stream, then descend the same way they can't, and pass through the space between the pipe walls and barrels safely connected to a chimney channel. The processes are well reflected in the scheme of the rocket furnace

So, due to the pyrolysis efficiency of burning wood increases, and the use of the free flow of gases creates a self-regulating system that restricts the entry of fresh air into the firebox. Air mixture is fed as the cooling of combustion products under the hood, frees up space for new portions. The excess pressure of hot gases forces the cooled part to the outside, so the furnace is little affected by the presence of draft in the chimney.

THE EFFECT OF HEAT

Gases entering the flue channel, still have a high temperature. Just throw them out is impractical, we may easily imagine that the efficiency of such installations is too low. Using the fact that the furnace-rocket literally pushing the products of combustion to the outside, craftsmen invented 2 ways of selection of heat:

— flowing the gases through the channels, arranged under the bench;

— setting on the stove water circuit.

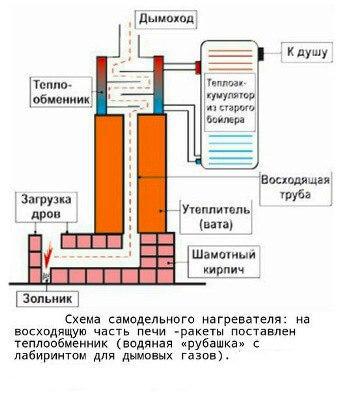

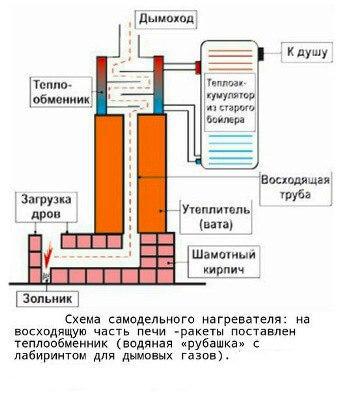

Rocket stove with a water circuit is done without the cap, the force of the upward flow of combustion products is used in multi-pass heat exchanger is made of metal. It is not recommended to enter in the gas flow coil with water, it will last long due to too high temperature. It would be correct to make a water jacket with metal fins inside the flue

Another way is to lay bricks horizontal flue channels directly on the floor and arrange on top of chic a mud stove heated by inserting a rocket stove type. Here it is important the correct selection of the length of the channels to excess pressure enough to overcome them, otherwise you will still have to take care of the natural draft.

ADVANTAGES AND DISADVANTAGES

Homemade rocket long burning ovens have many admirers, and here are the reasons:

— simplicity and low cost of installation: in order to build a similar thermal device, do not need to bear the large expense of purchasing expensive materials, fixtures and fittings. Experience in the heater business also requires minimal;

— self-regulation and undemanding to the natural draught of the chimney;

— Furnace efficiency – the rocket is variable and largely depends on the design, the main thing — to take away thermal energy from the flue gases;

— fuel can be added "on the fly".

Despite the attractiveness and simplicity of the unit, heating rocket stove has its negative points. It is a mistake to assume that it is possible to push in the firewood of any quality. Wet wood will not give the desired temperature in the chamber, the pyrolysis process to occur will not. In the worst case the smoke of a furnace can pour into the room. Also for the "rocket" constant supervision is necessary, especially in terms of fire safety.

Made with their own hands the rocket furnace unsuitable for baths because give relatively little heat in the infrared range, which is very important for a sauna. The surface of the furnace, radiant heat, have a very small area and to heat the bath should not succeed.

For reference. As a portable source of heat is frequently applied to a metal rocket stove Robinson prefabrication. Master craftsmen and then kept his head and quickly upgraded this product, making it, with the grate bars.

FURNACE FROM THE CYLINDER

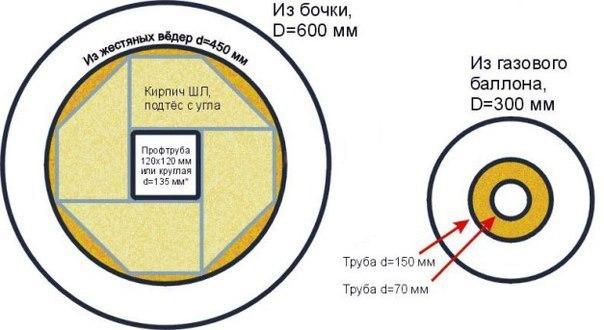

This is one of the easiest options to implement, you can use the drawing below. The container from under the propane with a diameter of 300 mm will be an excellent cap, but the role of the firebox and the hopper will play the role of a steel pipe size of 150 mm. Internal vertical channel is made of pipe diameter of 70 mm, and the chimney – 100 mm

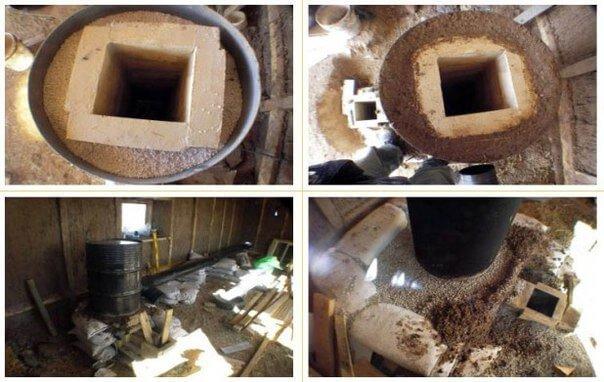

Design fully-welded pipes are cut to the desired length, and cut off tank top. Then the parts are welded according to the drawings, only the opening between vertical pipes with a diameter of 70 and 150 mm is filled with loose insulating material. The role itself can be a perlite or vermiculite, in extreme cases, is ordinary sand.

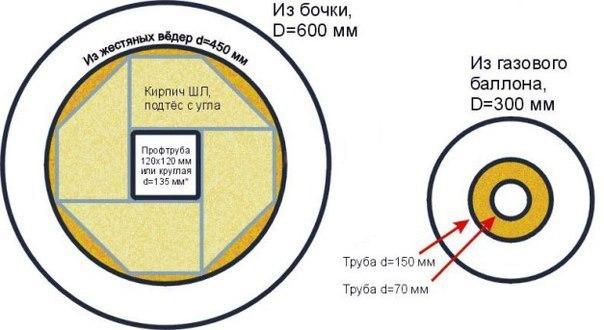

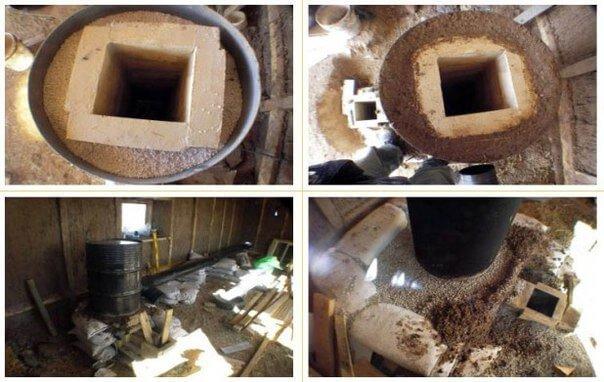

If you have the ability and desire to make a more powerful rocket oven, the cap uses the standard barrel of 200 l, then the dimensions of all the parts is also increased. Working inner tube is adopted with a diameter of 129 mm (or profile 120 x 120 mm), and outer – size of 450 mm. the Tube of such diameter is difficult to pick up, so usually find another barrel to the smaller capacity and cut off her bottom

The entire rocket stove from a gas cylinder Assembly has a great weight, so we should give her a massive Foundation is not necessary. When the unit is placed on the floor, legs are welded to it, and if subsequently planned unit couches, the design will have to coat the refractory composition, and then execute the outer lining. Then bottom on the floor lay a basalt cardboard and a sheet of roofing iron.

OF THE BRICK OVEN

Its device of rocket stove made of bricks not much different from metal, but requires more work. The difference is that all fire TV units are made of refractory brick, the hood is all from the same barrel.

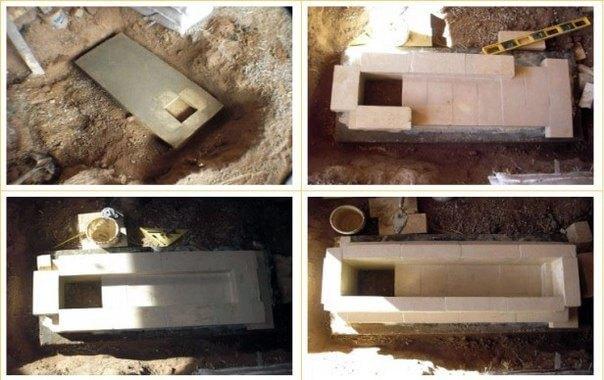

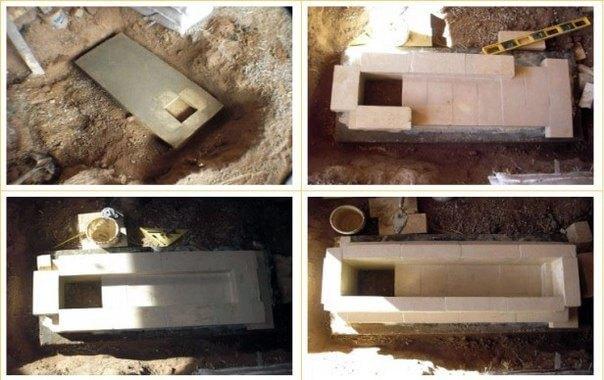

The entire structure, except for the projecting cap, we recommend that you lower below the floor level, which excavated a shallow pit. Its bottom is sealed, and then the mold is poured a small concrete Foundation with a thickness of 100 mm. After its solidification start laying, applying a solution of refractory clay.After laying and curing of the mortar pit covered, and on top of the firing channel wearing an iron barrel without a bottom, the cavity between it and the brick covered with insulation.

The end of the structure coated with the same solution, and then the top put on the big barrel – cap. Its lower part is welded chimney pipe for the exact dimensions used drawings of rocket stoves.

Conclusion

With all its advantages, the rocket oven made with your own hands, can not serve as an adequate source of heat to heat the whole house. To start this construction makes sense when you have to organise Parking a small cottage or similar building, especially that "rocket" is not afraid of periodic tasks. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: vk.com/gnezdo_paranoika?w=wall-38598449_115368

To make this stove any person, even a little bit versed in the drawings and able to work with your hands. To help such home craftsmen and have come to our article where you will learn about the design and principle of operation of the furnace – rocket. Here are the recommendations for its manufacture from different materials.

THE PRINCIPLES OF OPERATION OF ROCKET FURNACE

Although the device of the rocket furnace is simple enough, but successfully uses two principle borrowed from other types of solid fuel heating appliances:

— the principle of reburning wood gas combustion (pyrolysis);

— the principle of free flow of gases through the channels (without any prompting from the natural draught of the chimney).

Note. In the simplest rocket stoves for cooking, including the portable type, operates only the second principle, since the flow of the pyrolysis process in them is not created favorable conditions.

First, let us examine the device of rocket stoves direct combustion, is designed only for cooking food. Here the firebox is a short horizontal section of the pipe, which then turns upwards. The design is simple to a disgrace

The fuel is laid in the tube and ignited, resulting in an upward flow of hot gases, tends to rise in vertical section and go outside. Here at the cut pipe and installed capacity for food or water. Of course, between the pan and the tube provides clearance for the exit of combustion products. This is achieved by various metal supports.

For reference. The above device of a rocket stove – one of the first. It is because of a turned up nozzle from escaping from the flames device is called the rocket.

As to heat the premises in such a unit is impossible, the design of the heating rocket stoves were augmented heat exchange unit and the channels for the flue gases. To save on vertical pipe section high temperature, it is insulated from any refractory material. Further, for the intense heat the nozzle on top is covered with a cap, for example, conventional metallic barrel. At the bottom of the horizontal fire tube is a channel for secondary air.

Now the principle of operation of rocket furnace looks a little different. First, at the end of a horizontal firing channel is afterburning pyrolysis gases through the secondary air flow. Second, the products of combustion with high temperature accumulate under the top of hood (barrel), creating a slight overpressure. As the transfer of heat out through the metal walls, these gases cool down and come down.

Since the cooling gases from below are the new hot stream, then descend the same way they can't, and pass through the space between the pipe walls and barrels safely connected to a chimney channel. The processes are well reflected in the scheme of the rocket furnace

So, due to the pyrolysis efficiency of burning wood increases, and the use of the free flow of gases creates a self-regulating system that restricts the entry of fresh air into the firebox. Air mixture is fed as the cooling of combustion products under the hood, frees up space for new portions. The excess pressure of hot gases forces the cooled part to the outside, so the furnace is little affected by the presence of draft in the chimney.

THE EFFECT OF HEAT

Gases entering the flue channel, still have a high temperature. Just throw them out is impractical, we may easily imagine that the efficiency of such installations is too low. Using the fact that the furnace-rocket literally pushing the products of combustion to the outside, craftsmen invented 2 ways of selection of heat:

— flowing the gases through the channels, arranged under the bench;

— setting on the stove water circuit.

Rocket stove with a water circuit is done without the cap, the force of the upward flow of combustion products is used in multi-pass heat exchanger is made of metal. It is not recommended to enter in the gas flow coil with water, it will last long due to too high temperature. It would be correct to make a water jacket with metal fins inside the flue

Another way is to lay bricks horizontal flue channels directly on the floor and arrange on top of chic a mud stove heated by inserting a rocket stove type. Here it is important the correct selection of the length of the channels to excess pressure enough to overcome them, otherwise you will still have to take care of the natural draft.

ADVANTAGES AND DISADVANTAGES

Homemade rocket long burning ovens have many admirers, and here are the reasons:

— simplicity and low cost of installation: in order to build a similar thermal device, do not need to bear the large expense of purchasing expensive materials, fixtures and fittings. Experience in the heater business also requires minimal;

— self-regulation and undemanding to the natural draught of the chimney;

— Furnace efficiency – the rocket is variable and largely depends on the design, the main thing — to take away thermal energy from the flue gases;

— fuel can be added "on the fly".

Despite the attractiveness and simplicity of the unit, heating rocket stove has its negative points. It is a mistake to assume that it is possible to push in the firewood of any quality. Wet wood will not give the desired temperature in the chamber, the pyrolysis process to occur will not. In the worst case the smoke of a furnace can pour into the room. Also for the "rocket" constant supervision is necessary, especially in terms of fire safety.

Made with their own hands the rocket furnace unsuitable for baths because give relatively little heat in the infrared range, which is very important for a sauna. The surface of the furnace, radiant heat, have a very small area and to heat the bath should not succeed.

For reference. As a portable source of heat is frequently applied to a metal rocket stove Robinson prefabrication. Master craftsmen and then kept his head and quickly upgraded this product, making it, with the grate bars.

FURNACE FROM THE CYLINDER

This is one of the easiest options to implement, you can use the drawing below. The container from under the propane with a diameter of 300 mm will be an excellent cap, but the role of the firebox and the hopper will play the role of a steel pipe size of 150 mm. Internal vertical channel is made of pipe diameter of 70 mm, and the chimney – 100 mm

Design fully-welded pipes are cut to the desired length, and cut off tank top. Then the parts are welded according to the drawings, only the opening between vertical pipes with a diameter of 70 and 150 mm is filled with loose insulating material. The role itself can be a perlite or vermiculite, in extreme cases, is ordinary sand.

If you have the ability and desire to make a more powerful rocket oven, the cap uses the standard barrel of 200 l, then the dimensions of all the parts is also increased. Working inner tube is adopted with a diameter of 129 mm (or profile 120 x 120 mm), and outer – size of 450 mm. the Tube of such diameter is difficult to pick up, so usually find another barrel to the smaller capacity and cut off her bottom

The entire rocket stove from a gas cylinder Assembly has a great weight, so we should give her a massive Foundation is not necessary. When the unit is placed on the floor, legs are welded to it, and if subsequently planned unit couches, the design will have to coat the refractory composition, and then execute the outer lining. Then bottom on the floor lay a basalt cardboard and a sheet of roofing iron.

OF THE BRICK OVEN

Its device of rocket stove made of bricks not much different from metal, but requires more work. The difference is that all fire TV units are made of refractory brick, the hood is all from the same barrel.

The entire structure, except for the projecting cap, we recommend that you lower below the floor level, which excavated a shallow pit. Its bottom is sealed, and then the mold is poured a small concrete Foundation with a thickness of 100 mm. After its solidification start laying, applying a solution of refractory clay.After laying and curing of the mortar pit covered, and on top of the firing channel wearing an iron barrel without a bottom, the cavity between it and the brick covered with insulation.

The end of the structure coated with the same solution, and then the top put on the big barrel – cap. Its lower part is welded chimney pipe for the exact dimensions used drawings of rocket stoves.

Conclusion

With all its advantages, the rocket oven made with your own hands, can not serve as an adequate source of heat to heat the whole house. To start this construction makes sense when you have to organise Parking a small cottage or similar building, especially that "rocket" is not afraid of periodic tasks. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: vk.com/gnezdo_paranoika?w=wall-38598449_115368

Guryevskaya porridge — cooking Imperial dish

This simple and cheap tool to easily remove stains from iodine, oils and herbs!