1055

Subtle complexity of rocketry: Part 5.

Subtle complexity of missile technology, Part 5: Initial construction

Previous parts:

Subtle complexity rocketry

Solid engines

Liquid fuels

Engines and tanks

Initial construction - a separate interesting aspect of space technology. In fact, it is necessary to assemble the rocket, take on the launch pad, check again, season, put the crew (if manned launch) and run. And each of the tasks a challenge of engineering ingenuity, material science, strength of materials, and a variety of other disciplines.

Introduction

In order to make it clear what is at stake, it is necessary to explain the terms used and explain in general how the launch rocket.

First of all, the carrier rocket and the payload is delivered to the launch site. Booster almost always delivered in parts, because that it is easier to transport. Then the rocket and payload are collected into one and checked in a special building, which for various missiles in different countries has many different names: MIC (assembly and testing facility), technical position technical complex, VAB (Vertical Assembly Building, Assembly Building ), assembly building (assembly building), etc. Then, booster, typically in assembly with the payload transported to a special area from which the trigger. This area also has many names - launch pad, launch pad, launch facilities, etc. The rocket, set vertically, a very high thing, so there is usually a so-called Tower of service that allows access to the desired location on the installed rocket.

When rockets were small

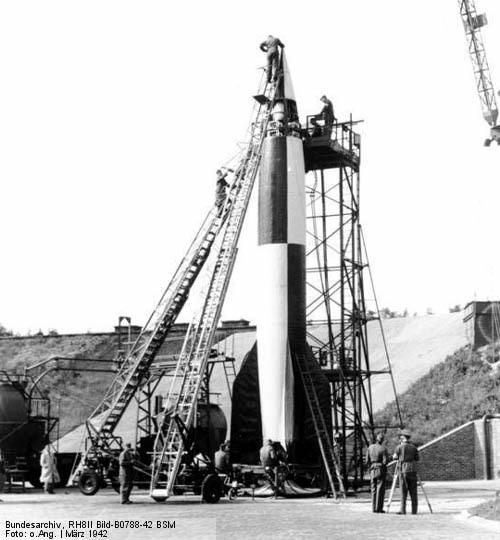

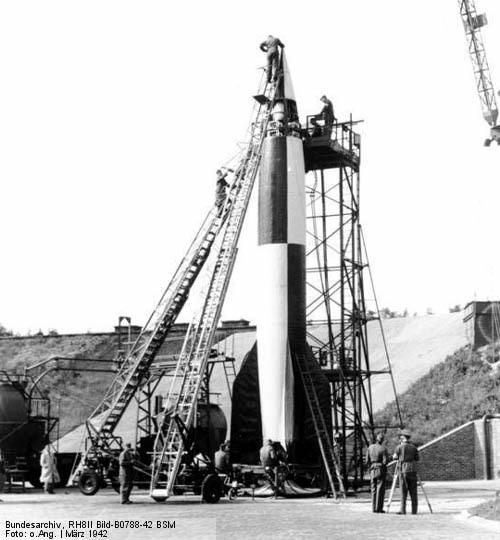

The smaller rocket launch pad the easier and less difficulty with it. At the dawn of the whole rocket launch complex consisted of a flat concrete pad, the support for the rocket on small legs and unpretentious service tower.

V-2 and ladders.

A more advanced version of the service tower. The cone is mounted at the bottom for uniform gas ejection part.

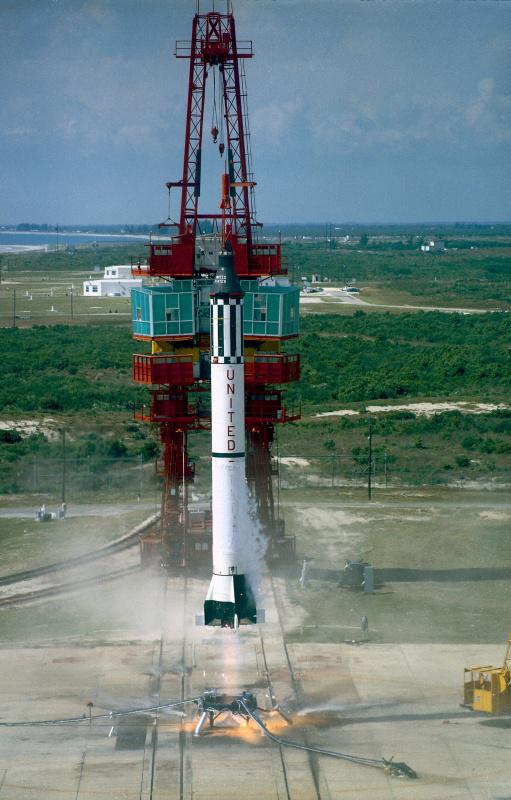

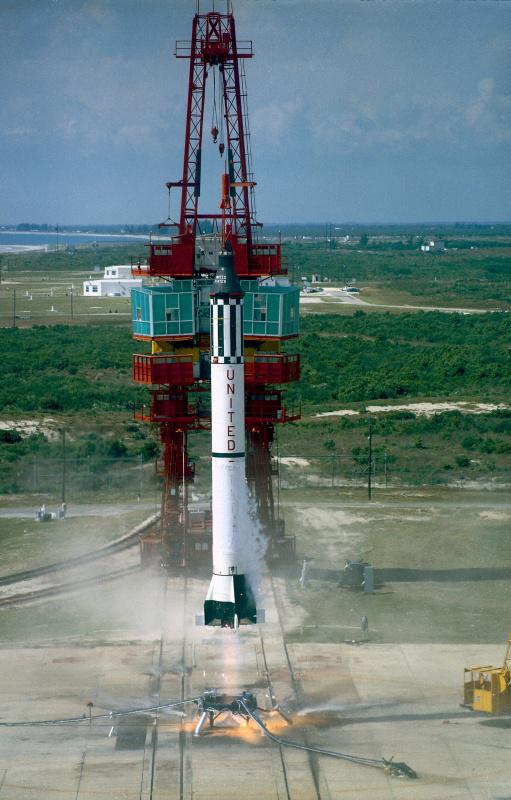

Even in manned launches from the launch complex of small rockets did not have too much difficulty.

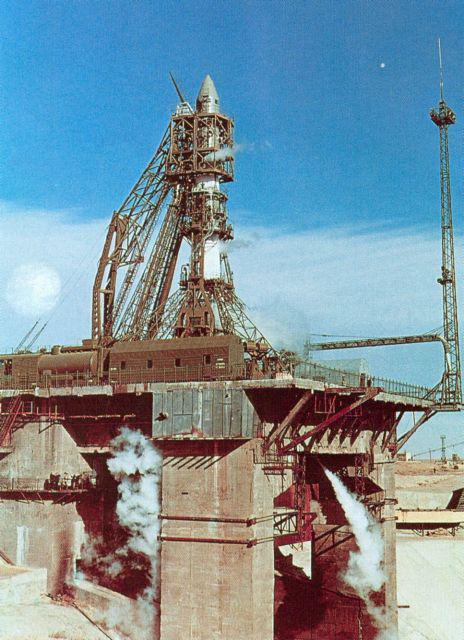

1961, the first manned mission program "Mercury» - «Mercury-Redstone 3". Tower moves on rails, the technology is similar to a construction crane. Under the home support can see a cone for a uniform gas dispersion.

In principle, small rockets, this approach is alive today. A small launch weight is relatively small engine power and the absence of problems with the evacuation of the gases is relatively short exposure to high temperatures, which reduces material requirements.

"Cosmos-3M", recently decommissioned. On the left is visible service tower, on the right - a simple launch pad.

In the West, about the same - small missile can be put at the start of an industrial crane.

Left Taurus, the right Minotaur V.

And let a higher, but still a simple launching facility.

Left Taurus, the right Minotaur V.

As bloomed tulip

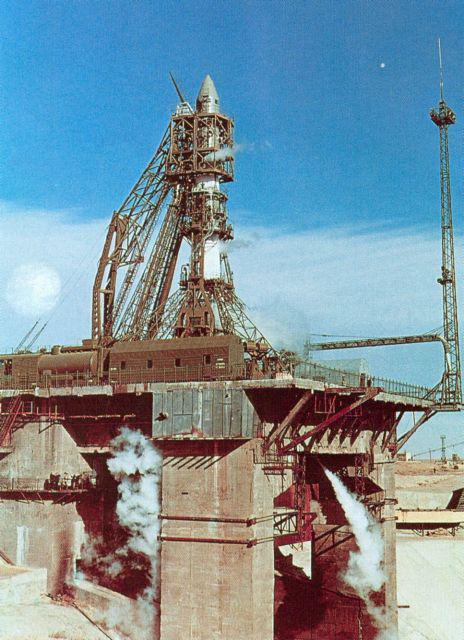

Perhaps the most unusual launch complex - the family of missiles' P-7. " Firstly, it is the only complex in which the missile is not on the table, and hung over the middle. Second, in early versions of the launch pad turns completely before starting. And third, instead of the service tower made two "polubashni", which, moreover, are moving away from the rocket by turning in a vertical plane. Why were such decisions taken?

The decision on the first point is very well described by BE Chertok. At missile family F-7, the first and second stages are assembled into a package. And this package is very poorly installed on the launch pad - required serious enhancement tail section, and is overweight, and increased wind resistance. Even had the idea to build a wall around the start. Sketch transport device that is exporting the rocket and put into four starting table, one for each side block, too, no one encouraged. And then there was a very beautiful idea of engineering. In flight, the efforts of the side blocks are transmitted to the central unit through their tops. So why not hang a rocket at the start of these same police units? In this case, the rocket at the start experiencing the same load as in-flight, and do not need special measures to enhance the design. A dive into the rocket launch facility solves problems with wind load.

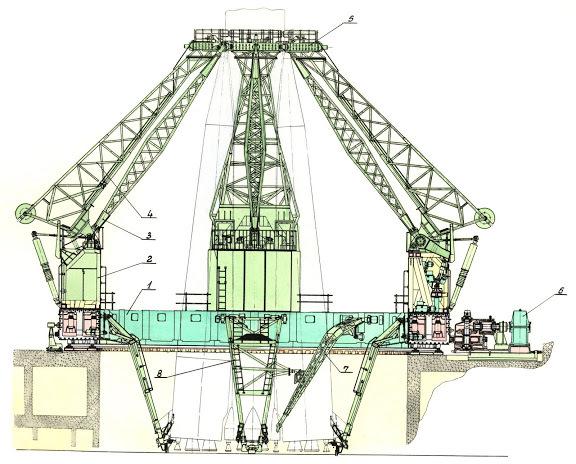

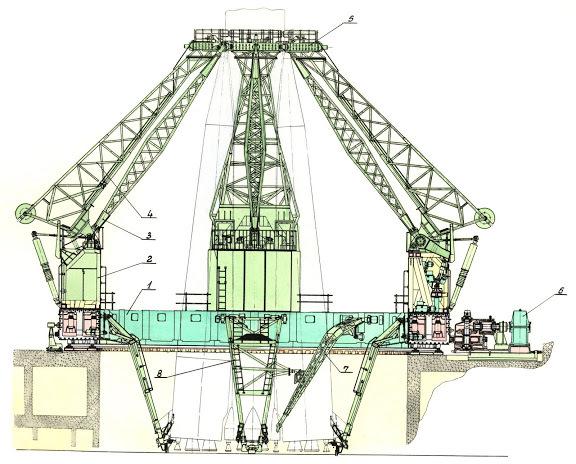

Driving launch pad. At the bottom there is a sliding table for personnel access, not shown here.

Paragraph two of the problem came from the ease of the control system. While deploy a missile with launch pad before the start it was easier to set up than a turn after the start of the analog control system. Now, in the age of computers, it is an anachronism. Baikonur able to turn the tables and use it as inherited, and new starting complexes (Kura East) tables without the rotary device.

Photos launch facility in Kourou.

The third point is due to constant upgrades missiles family of "P-7." First it was a simple one-level area:

When the "R-7" was the "East", a single-level court added mobile service tower:

For the "Sunrise" and "Lightning" More levels added:

The result is predictable bit :)

It Plesetsk, then 9 levels at Baikonur 8.

Despite the beautiful view, the construction is not very comfortable. Grounds open, windswept and work in cold or hot weather - it is unobtrusive heroism starting calculations. Therefore, when they began to build the start of "unions" in Kourou, designed conventional mobile tower (there was another factor, it will be a little later).

Good result of operation of the new tower has led to the fact that in the "East" will be the same.

Guns for battle go back to

Own an interesting dilemma - is the transportation of the rocket on the launch pad. And, of course, there are many possible solutions, with its pluses and minuses. Firstly, the rocket assembly can generally will not take - to gather immediately at launch, test and start up. Secondly, the rocket can be assembled horizontally, the drive to start, set it vertically, and empty. Third, the missile can be assembled vertically, and the drive to start immediately in an upright position. And, you can mix these options.

The first embodiment is realized mainly for small rockets (because it is simple).

Advantages:

No need to carry a rocket at the start.

Disadvantages:

We need to take away from the start of assembly and testing facility.

Again Taurus. On the left, covered in blue, the first stage.

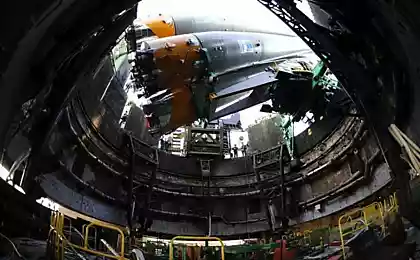

The second option - a Soviet / Russian school, and SpaceX. "Unions", "Proton", "Space", "H-1", "Energy", "Zenit" and "Falcon'y" going to start in a horizontal position. The carrier is also the installer and vertikalizuet rocket.

Advantages:

Long MIC build easier than high.

Carry horizontally easier.

Disadvantages:

From the rocket payload and required additional bending strength.

Option three - a school of the United States. Then they were joined by India, China and Europe.

Advantages:

On the rocket and payload force acts only in the direction of "top-down».

No need for the installer and the process of verticalization.

Disadvantages:

Need higher MIC.

A somewhat more complicated transportation.

"Long March," a manned version of China.

The fourth option - is the Kourou spaceport. The fact that European satellites often simply not designed for transporting in a horizontal position. To save weight, they lack the strength to bending. But what if the "Union" is designed for horizontal transport? We decided to make a hybrid method - the first three stages go as usual, horizontally, and the payload with the upper stage is already set at the start. This - the second reason for the creation of the mobile service tower.

Advantages:

It combines the convenience of the horizontal transport and vertical assembly.

Disadvantages:

It requires clean room, mini-MIC tower maintenance.

Dilemma tower

The next question is - is it necessary to service tower? Let all the checks carried out in the MIK, and start-up operations produce automatic. In this case, there is no one and no need to walk in the tower of service, and it does not need to build. The idea attractive, but as it turned out, it has its drawbacks. Her first implemented in the Soviet Union for the rocket "Zenit". The installation process, fueling, prelaunch processing and launch was fully automated and does not require anything other than a man of work and head pressing. Start to get a simple and minimal:

All is good, but a start in the first place, is not suitable for manned launches. For the same "Zenith", who decided to make a manned, had to build a "birdhouse" service tower.

The second drawback - at the start you can not fix. If there is a small failure, which in the presence of the tower could be remedied within half an hour, the rocket have to shoot from the start and to carry back to the MIC. The tower is also absent from SpaceX, and those who watch starts Falcon'ov probably noticed that starts regularly postponed to a later date. Of course, the problem may be different, and not all can be eliminated on the spot, but the presence of the tower makes it possible to correct minor faults quickly.

Dilemma Tower 2

Another question, again associated with the tower - it is a question of mobility. As far as is necessary and justified to spend money to ensure that the tower could move off from the start? There are guided engineering expediency. Fixed tower must withstand the explosion of a rocket at the start. The mobile must have the same engines, wheels and rails, as well as a system of stretching and collecting communications and pipelines. What happens easier, cheaper and more familiar, then it does. There is no national schools in each project engineers do believe more comfortable. For example, "Proton" make mobile tower:

And for "Angara" - is stationary:

Throne Gulliver

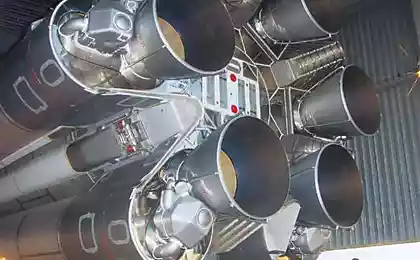

You can not ignore the launch complexes for superheavy missiles. The size and complexity of these systems, and the technical solutions chosen simply amazing.

The Americans acted in the tradition of his school - vertical assembly and transport. A key element was the tractor-transporter that carried the rocket together with part of the launch pad and tower maintenance. It is less well known, but was still the second half of the tower, which drove the same truck.

"Saturn-V» with the top of the launch pad and one tower was going to start the service. The second tower is waiting for their turn in a "dead end" road to the tractor. In the distance you can see the building of vertical assembly.

Small engineering curiosity. Mission "Apollo" to the station "Skylab" and the mission of "Soyuz-Apollo" use the same launch pad LC39, but a smaller rocket - Saturn-IB. To rocket stood opposite poles of the same on a much larger launch construction was made "chair" - truss, raised the rocket to an altitude of "Saturn-V»:

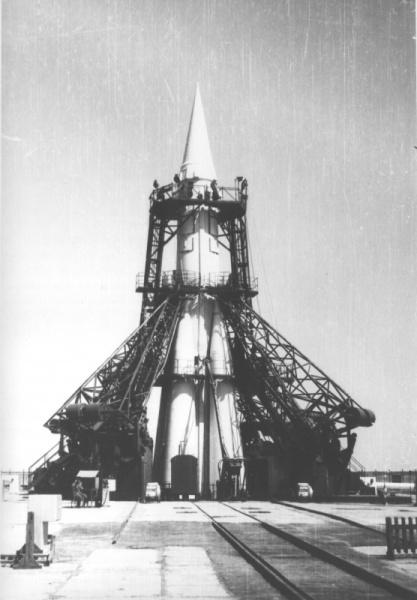

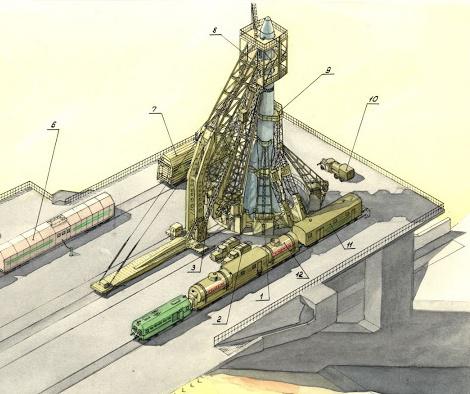

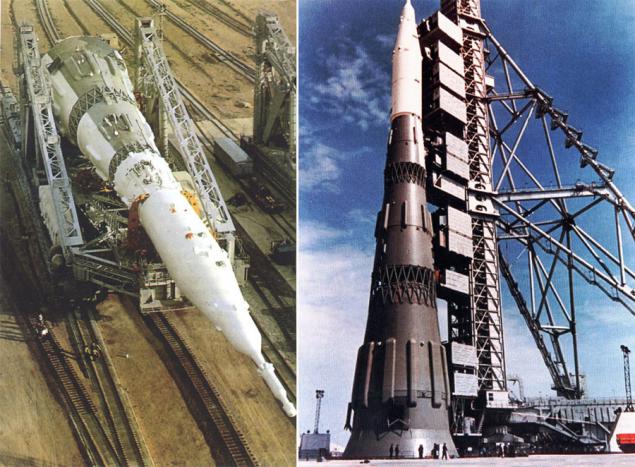

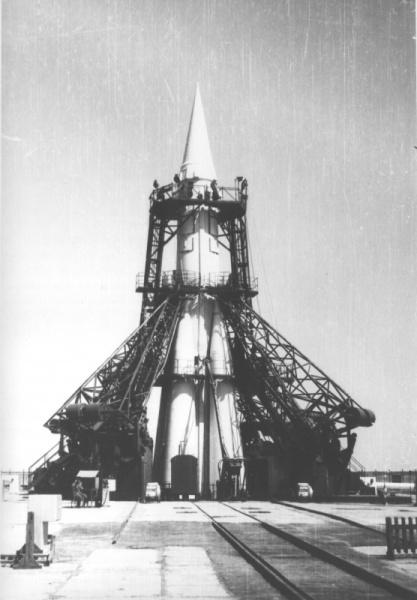

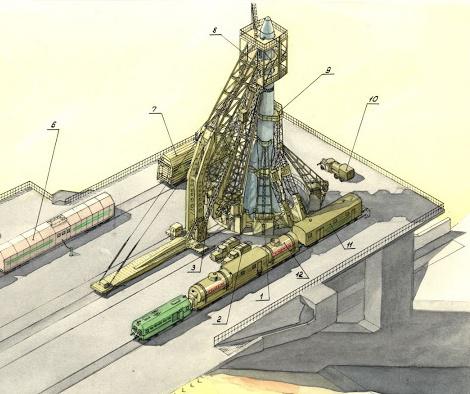

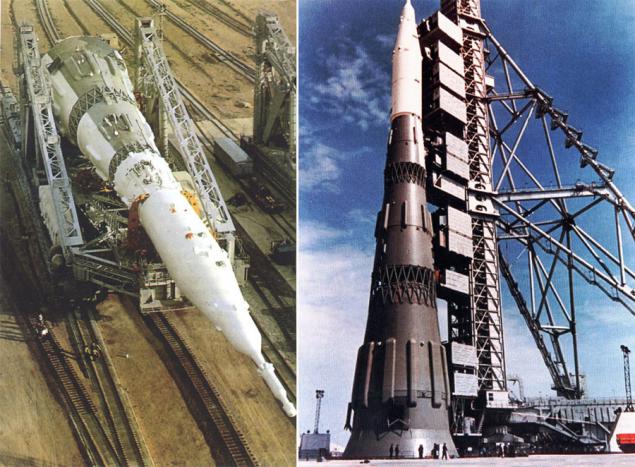

Soviet rocket "H-1" was also made in the native tradition, it was carried in a horizontal position on a giant locomotive of the installer, two parallel rails. Is that service tower was somewhat unusual - quite small.

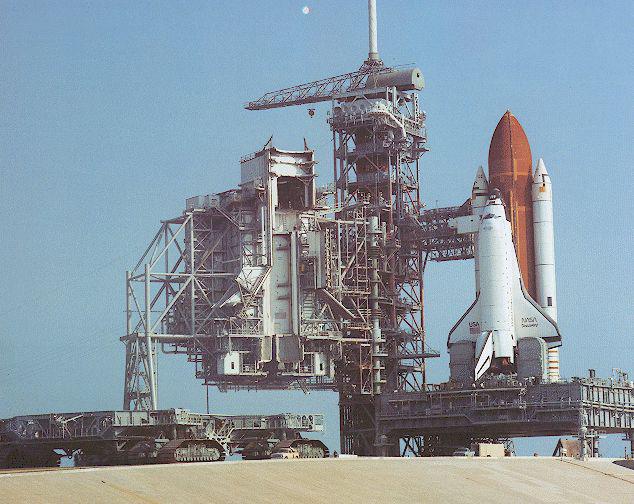

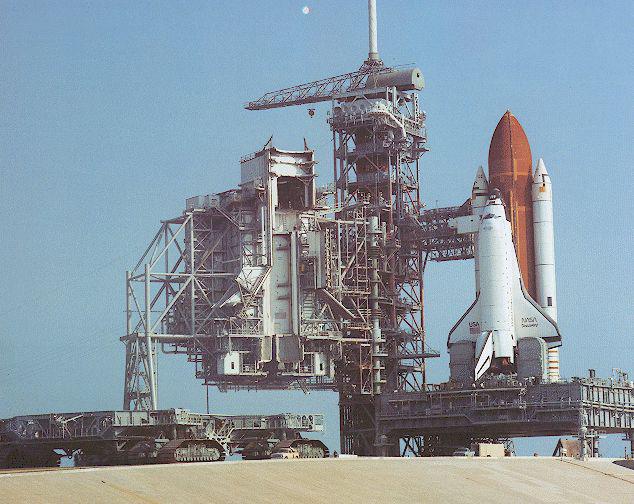

Since the beginning of the development of the shuttle launch facilities waiting for the same fate - they were converted under the reusable ships on both sides of the ocean.

The US has made very graceful service tower with a rotating element:

In the USSR it was made complex of two towers side by side.

Large pipes in the left tower - landing system and the emergency evacuation of the crew.

Gazovody

If you take a close look at the surface of a launch pad in the photos, you probably noticed the tunnels, openings, recesses. It gazovody they needed to divert the gases emitted by the rocket. For powerful engines of heavy missiles a simple cone at the bottom is not enough. The design of them can be different in the United States often use a bulk starter table with irrigated water gazovodami at ground level. The water softens the shock wave and reduce the thermal load on the wall. We gazovody usually dry and located below ground level. The April launch «Falcon'a» showed that in the case of irrigated groundwater gazovodov should monitor the level of liquid in them - the rocket was launched through the mud fountain, well, it did not cause problems.

Posted in [mergetime] 1398759603 [/ mergetime]

Conclusion

Finally, a beautiful video slow start "Zenith" in the "Sea Launch". Visible work starting mechanisms and evaporation of falling ice.

The end. Thank you for attention!

Source:

Previous parts:

Subtle complexity rocketry

Solid engines

Liquid fuels

Engines and tanks

Initial construction - a separate interesting aspect of space technology. In fact, it is necessary to assemble the rocket, take on the launch pad, check again, season, put the crew (if manned launch) and run. And each of the tasks a challenge of engineering ingenuity, material science, strength of materials, and a variety of other disciplines.

Introduction

In order to make it clear what is at stake, it is necessary to explain the terms used and explain in general how the launch rocket.

First of all, the carrier rocket and the payload is delivered to the launch site. Booster almost always delivered in parts, because that it is easier to transport. Then the rocket and payload are collected into one and checked in a special building, which for various missiles in different countries has many different names: MIC (assembly and testing facility), technical position technical complex, VAB (Vertical Assembly Building, Assembly Building ), assembly building (assembly building), etc. Then, booster, typically in assembly with the payload transported to a special area from which the trigger. This area also has many names - launch pad, launch pad, launch facilities, etc. The rocket, set vertically, a very high thing, so there is usually a so-called Tower of service that allows access to the desired location on the installed rocket.

When rockets were small

The smaller rocket launch pad the easier and less difficulty with it. At the dawn of the whole rocket launch complex consisted of a flat concrete pad, the support for the rocket on small legs and unpretentious service tower.

V-2 and ladders.

A more advanced version of the service tower. The cone is mounted at the bottom for uniform gas ejection part.

Even in manned launches from the launch complex of small rockets did not have too much difficulty.

1961, the first manned mission program "Mercury» - «Mercury-Redstone 3". Tower moves on rails, the technology is similar to a construction crane. Under the home support can see a cone for a uniform gas dispersion.

In principle, small rockets, this approach is alive today. A small launch weight is relatively small engine power and the absence of problems with the evacuation of the gases is relatively short exposure to high temperatures, which reduces material requirements.

"Cosmos-3M", recently decommissioned. On the left is visible service tower, on the right - a simple launch pad.

In the West, about the same - small missile can be put at the start of an industrial crane.

Left Taurus, the right Minotaur V.

And let a higher, but still a simple launching facility.

Left Taurus, the right Minotaur V.

As bloomed tulip

Perhaps the most unusual launch complex - the family of missiles' P-7. " Firstly, it is the only complex in which the missile is not on the table, and hung over the middle. Second, in early versions of the launch pad turns completely before starting. And third, instead of the service tower made two "polubashni", which, moreover, are moving away from the rocket by turning in a vertical plane. Why were such decisions taken?

The decision on the first point is very well described by BE Chertok. At missile family F-7, the first and second stages are assembled into a package. And this package is very poorly installed on the launch pad - required serious enhancement tail section, and is overweight, and increased wind resistance. Even had the idea to build a wall around the start. Sketch transport device that is exporting the rocket and put into four starting table, one for each side block, too, no one encouraged. And then there was a very beautiful idea of engineering. In flight, the efforts of the side blocks are transmitted to the central unit through their tops. So why not hang a rocket at the start of these same police units? In this case, the rocket at the start experiencing the same load as in-flight, and do not need special measures to enhance the design. A dive into the rocket launch facility solves problems with wind load.

Driving launch pad. At the bottom there is a sliding table for personnel access, not shown here.

Paragraph two of the problem came from the ease of the control system. While deploy a missile with launch pad before the start it was easier to set up than a turn after the start of the analog control system. Now, in the age of computers, it is an anachronism. Baikonur able to turn the tables and use it as inherited, and new starting complexes (Kura East) tables without the rotary device.

Photos launch facility in Kourou.

The third point is due to constant upgrades missiles family of "P-7." First it was a simple one-level area:

When the "R-7" was the "East", a single-level court added mobile service tower:

For the "Sunrise" and "Lightning" More levels added:

The result is predictable bit :)

It Plesetsk, then 9 levels at Baikonur 8.

Despite the beautiful view, the construction is not very comfortable. Grounds open, windswept and work in cold or hot weather - it is unobtrusive heroism starting calculations. Therefore, when they began to build the start of "unions" in Kourou, designed conventional mobile tower (there was another factor, it will be a little later).

Good result of operation of the new tower has led to the fact that in the "East" will be the same.

Guns for battle go back to

Own an interesting dilemma - is the transportation of the rocket on the launch pad. And, of course, there are many possible solutions, with its pluses and minuses. Firstly, the rocket assembly can generally will not take - to gather immediately at launch, test and start up. Secondly, the rocket can be assembled horizontally, the drive to start, set it vertically, and empty. Third, the missile can be assembled vertically, and the drive to start immediately in an upright position. And, you can mix these options.

The first embodiment is realized mainly for small rockets (because it is simple).

Advantages:

No need to carry a rocket at the start.

Disadvantages:

We need to take away from the start of assembly and testing facility.

Again Taurus. On the left, covered in blue, the first stage.

The second option - a Soviet / Russian school, and SpaceX. "Unions", "Proton", "Space", "H-1", "Energy", "Zenit" and "Falcon'y" going to start in a horizontal position. The carrier is also the installer and vertikalizuet rocket.

Advantages:

Long MIC build easier than high.

Carry horizontally easier.

Disadvantages:

From the rocket payload and required additional bending strength.

Option three - a school of the United States. Then they were joined by India, China and Europe.

Advantages:

On the rocket and payload force acts only in the direction of "top-down».

No need for the installer and the process of verticalization.

Disadvantages:

Need higher MIC.

A somewhat more complicated transportation.

"Long March," a manned version of China.

The fourth option - is the Kourou spaceport. The fact that European satellites often simply not designed for transporting in a horizontal position. To save weight, they lack the strength to bending. But what if the "Union" is designed for horizontal transport? We decided to make a hybrid method - the first three stages go as usual, horizontally, and the payload with the upper stage is already set at the start. This - the second reason for the creation of the mobile service tower.

Advantages:

It combines the convenience of the horizontal transport and vertical assembly.

Disadvantages:

It requires clean room, mini-MIC tower maintenance.

Dilemma tower

The next question is - is it necessary to service tower? Let all the checks carried out in the MIK, and start-up operations produce automatic. In this case, there is no one and no need to walk in the tower of service, and it does not need to build. The idea attractive, but as it turned out, it has its drawbacks. Her first implemented in the Soviet Union for the rocket "Zenit". The installation process, fueling, prelaunch processing and launch was fully automated and does not require anything other than a man of work and head pressing. Start to get a simple and minimal:

All is good, but a start in the first place, is not suitable for manned launches. For the same "Zenith", who decided to make a manned, had to build a "birdhouse" service tower.

The second drawback - at the start you can not fix. If there is a small failure, which in the presence of the tower could be remedied within half an hour, the rocket have to shoot from the start and to carry back to the MIC. The tower is also absent from SpaceX, and those who watch starts Falcon'ov probably noticed that starts regularly postponed to a later date. Of course, the problem may be different, and not all can be eliminated on the spot, but the presence of the tower makes it possible to correct minor faults quickly.

Dilemma Tower 2

Another question, again associated with the tower - it is a question of mobility. As far as is necessary and justified to spend money to ensure that the tower could move off from the start? There are guided engineering expediency. Fixed tower must withstand the explosion of a rocket at the start. The mobile must have the same engines, wheels and rails, as well as a system of stretching and collecting communications and pipelines. What happens easier, cheaper and more familiar, then it does. There is no national schools in each project engineers do believe more comfortable. For example, "Proton" make mobile tower:

And for "Angara" - is stationary:

Throne Gulliver

You can not ignore the launch complexes for superheavy missiles. The size and complexity of these systems, and the technical solutions chosen simply amazing.

The Americans acted in the tradition of his school - vertical assembly and transport. A key element was the tractor-transporter that carried the rocket together with part of the launch pad and tower maintenance. It is less well known, but was still the second half of the tower, which drove the same truck.

"Saturn-V» with the top of the launch pad and one tower was going to start the service. The second tower is waiting for their turn in a "dead end" road to the tractor. In the distance you can see the building of vertical assembly.

Small engineering curiosity. Mission "Apollo" to the station "Skylab" and the mission of "Soyuz-Apollo" use the same launch pad LC39, but a smaller rocket - Saturn-IB. To rocket stood opposite poles of the same on a much larger launch construction was made "chair" - truss, raised the rocket to an altitude of "Saturn-V»:

Soviet rocket "H-1" was also made in the native tradition, it was carried in a horizontal position on a giant locomotive of the installer, two parallel rails. Is that service tower was somewhat unusual - quite small.

Since the beginning of the development of the shuttle launch facilities waiting for the same fate - they were converted under the reusable ships on both sides of the ocean.

The US has made very graceful service tower with a rotating element:

In the USSR it was made complex of two towers side by side.

Large pipes in the left tower - landing system and the emergency evacuation of the crew.

Gazovody

If you take a close look at the surface of a launch pad in the photos, you probably noticed the tunnels, openings, recesses. It gazovody they needed to divert the gases emitted by the rocket. For powerful engines of heavy missiles a simple cone at the bottom is not enough. The design of them can be different in the United States often use a bulk starter table with irrigated water gazovodami at ground level. The water softens the shock wave and reduce the thermal load on the wall. We gazovody usually dry and located below ground level. The April launch «Falcon'a» showed that in the case of irrigated groundwater gazovodov should monitor the level of liquid in them - the rocket was launched through the mud fountain, well, it did not cause problems.

Posted in [mergetime] 1398759603 [/ mergetime]

Conclusion

Finally, a beautiful video slow start "Zenith" in the "Sea Launch". Visible work starting mechanisms and evaporation of falling ice.

The end. Thank you for attention!

Source: