2387

The largest dump truck in the world (24 photos)

The company "BelAZ" has created the world's largest dump truck BelAZ-75710 with carrying capacity of 450 tons, which is equivalent to trёmstam Ford Focus, 37 double-decker buses and a half or two blue whales. By the way, Airbus A380 - the largest passenger aircraft in the world - weighs much less, only 277 tonnes.

Let's look at this machine more ...

September 25 at the test site was presented to the world's largest dump truck BelAZ-75710. Capacity of the new machine is 450 tons. Prior to that, the largest trucks BelAZ-75601 were considered (created in the Belarusian Automobile Plant in 2007) and the Swiss Liebherr T282B (appeared in 2003) - both carrying capacity of 360 tons. Overall vehicle weight is 810 tons. Soon the car will be entered in the Guinness Book of Records.

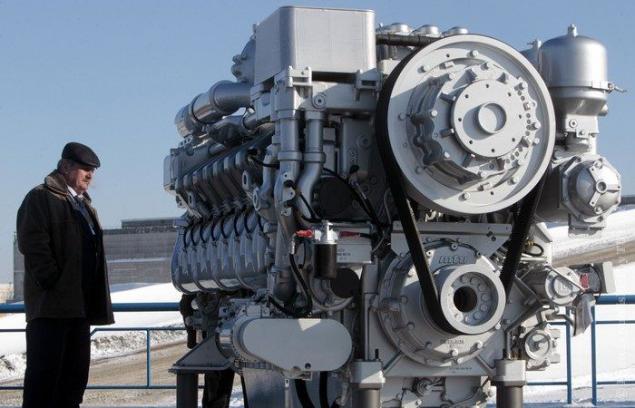

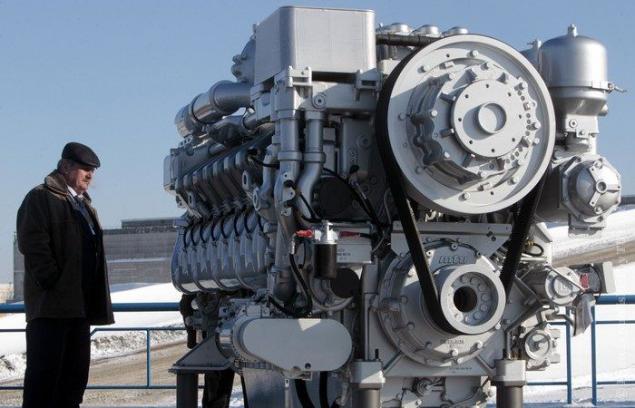

Powerplant record BelAZ-75710 includes two diesel engines with a total capacity of 8500 hp, designed to power the electric motors that drive the wheels of the truck giant. Maximum speed sverhmashiny is 64 km / h.

Equipment BelAZ-75710 includes a system for monitoring the dead zone air conditioning, signaling the approach of a high-voltage line, and the fire-fighting system. The largest dump truck in the world is designed to work in difficult conditions at open-pit and deep pits at temperatures from -50 to +50 degrees. 8-wheel truck equipped with tubeless tires, allow the heavy vehicle to easily move around on technological roads.

BelAZ-75710 was introduced in the town of Zhodino, in honor of the 65th anniversary of the Belarusian Automobile Plant, known worldwide for heavy equipment manufactured and Dumpers. The emergence of the largest truck in the world is dictated by modern conditions when the mining industry requires an increasingly heavy and powerful technique. In recent years, the production of ultra-high load-carrying capacity mining trucks increased by 2 times, and the growth trend is maintained. Taking into account market demand BelAZ will produce about 1,000 such vehicles per year.

To increase the rate of production at the Belarusian company for the past year and a half actively pursued development program, in which were built the new plant area of over 30 thousand sq. Meters. There was a lot of new equipment, and in the near future is planned to install about 700 machines and special process plants. Currently, BelAZ produces a wide range of dump trucks. A similar number of models no one producer in the world. In addition, the resource of machines increased from 400 thousand. Up to 1 mln. Km. Overall, in its history, Belarusian Automobile Plant has produced more than 500 different models with lifting capacity from 30 to 450 tons. For all the time it was produced 136 thousand. Machines, which are operated in 72 countries.

Belarusian Automobile Plant, whose construction began near the town of Zhodino near Minsk (then as the peat plant engineering) in 1948, today produces, world analogues which can be counted on the fingers of one hand.

For more than half a century history of the Belarusian automobile enterprises of Minsk was released more than 120 000 units of mining equipment. BelAZ working in almost 50 countries around the world. A history of the plant began in the Soviet casually: in 1946 the government decided to build the plant peat Engineering (Resolution of the Supreme Council of the BSSR 11.09.1946 № 137/308). Just 2 years Belpromproekt already completed the development and coordination of the project plant. So from the planning phase, the Belarusians went to the construction of the buildings.

His first production, the company showed Zhodino in 1950, and the following year the peat plant engineering has been redeveloped into a factory of road and reclamation machines "Dormash". In 1958 the company received a new name that is known so far - "Belarusian Autoworks." From the gates of the company with a new name he rolled out the first 25-ton dump truck MAZ-525.

Further more. In the same year in Zhodino transferred to Minsk Automobile production of 25-ton trucks MAZ-525. And in 1960, in Minsk region began to produce the first samples of MAZ-530 dump truck with carrying capacity of 40 tons. By the time the production line in Zhodino descended thousand MAZ-525.

But the company, bore the proud name of the automobile plant, a assembly of trucks under license, by itself, was not enough. Therefore, in 1960 it started to design trucks radically new design for the development of mineral deposits by open way.

However, in April 1960 at BelAZ created its own design bureau, headed by ZL Sirotkin, who arrived in Zhodino Minsk together with a group of designers MAZ. Just create a department it had to solve a complex problem. Until recently considered a model of new technology, MAZ-525 ceased to meet the growing demands of operatives. The powerful mining and coal quarries, large hydraulic construction projects, enterprises of the construction industry needed a high-performance trucks, the most adapted primarily to working conditions in the quarries.

Design services and management of the company decided not to improve the existing model of the truck, and create a completely new car. This period can be called a landmark in the history of the Belarusian Automobile Plant. Factory designers studied the operating conditions and the required technical specifications of the future dump on the drawing boards were created vertical contours of the future of the machine on test benches to verify the correctness of technical solutions adopted.

Perhaps now it may seem incredible, but then, in a time of unprecedented labor enthusiasm of the first postwar five-year plans, was an event almost ordinary: in less than one year at a young plant created a fundamentally new dump truck carrying capacity 27 tons under the name of BelAZ-540, a prototype of which He was released in September 1961.

The design of this car was laid a lot of new technical solutions for mechanical engineering, high-performance operation at a later date in a dump pits. It was first used in the practice of the domestic automotive pneumohydraulic suspension ensures high running smoothness both laden and unladen, hydromechanical transmission, which is also the first time in the practice of our engineering has been used to mass-produced machines, the original layout: the location of the cabin near the engine allowed receive a minimum base and minimum dimensions, thereby increasing maneuverability and increase its stability, the platform enabled the bucket and lower center of gravity and improve stability of the vehicle. Original solutions for the steering system and tilting platform, feathers and other sites have become a tradition in the creation of regular class-duty trucks.

BelAZ-540 was the progenitor of a whole family of heavy-duty trucks. In 1967, the company has mastered production of 40-ton dump truck BelAZ-548A, designed with the greatest possible unification of basic units and parts of the two cars.

1968 was the year of birth of the prototype BelAZ-549 - the base class-duty truck 75-80 tons, the first sample with electromechanical transmission. In 1977 he was released prototypes truck BelAZ-7519 - the base class-duty truck 110-120 tons. Six years later, the plant started serial production of BelAZ-75211 - the base class-duty truck 170-220 tons.

By 1986, the plant could produce up to 6,000 units of such equipment in the year, which is half the world's production.

This at BelAZ not going to stop. In 1963, coming off the assembly line of the second prototype of the design of the plant designers - BelAZ truck-carrying capacity of 40 548 tonnes.

In 1966, the Belarusian Automobile Plant started serial production of dump trucks BelAZ-548A - the base class-duty truck 40-45 tons. The plant itself was awarded the Order of the Red Banner and received a gold medal at the International Exhibition in Plovdiv for BelAZ-540.

Another novelty was the Belarusian autoenterprise truck BelAZ-carrying capacity of 75 549 t. The first prototype of this machine class load-carrying capacity of 75-80 tons was released in 1968. The unique development of Belarusians seriously declared themselves for the whole Union, proving that a small country can create such giants.

The next phase of construction took place already in the 70s. In 1977, there were prototypes truck BelAZ-7519 carrying capacity of 110 tonnes - the base class-duty truck 110-120 tons. So the Belarusian enterprise in one leap jumped over several weight categories.

In 1978, the plant develops new technique - aircraft tugs for towing aircraft with a takeoff weight of 100 tons. Fortunately, the chassis for the Belarusians are already there. But in the race for the increase of draft properties of BelAZ it was still too early to put an end. In 1982, a pipeline Zhodino gone prototype 170-ton dump truck BelAZ-75211, the representative of the class of load-carrying capacity of 170-200 tons.

In the early 1990s, marked by the collapse of the Soviet Union and the sharp decline in production, BelAZ has not stopped the release of any of the models of dump trucks, covering a range of capacities from 30 to 220 tons. Moreover, it included in the production program of other special heavy transport equipment, production of which is mastered from the nineties of the last century: dump terrain with hydromechanical transmission, construction machinery and machinery for the maintenance of mining and transport operations, such as loaders, bulldozers, tractor tugs and polivoorositelnye machines; machinery for underground works, machines for metallurgical plants, etc.

In 1990, BelAZ and did furor, build a huge truck carrying capacity of 280 t. The car has turned so serious that after her appearance slightly cooled the ardor of Engineers. In 1994 Belarusians turned again to the "small" class: a prototype truck BelAZ-7555 capacity of 55 tons, the head of a new model of family haulers with hydro mechanical transmission. Behind her, two years later, followed by the release of the 130-ton BelAZ-75131, which became the first-born in a new family of trucks with electromechanical transmission.

However, by 1998, the crisis in Zhodino realized that without a serious modernization of production plant vague future prospects. BelAZ on the reconstruction of existing production-oriented upgrade of mining equipment, the development of new models to improve the quality and technical level of both individual components and systems, and produced technology in general.

As a consequence, in 2000 the production association (the plant received this status in 1995) awarded the "Crystal Nika" for the international program "Partnership for Progress", and the general director of BelAZ PA? L. Mariev was awarded the title of "Director of the Year", and later the title of "Hero of Belarus».

Flattered success Belarusians set to work with renewed energy, and built in 2002, all-wheel drive Articulated dump truck BelAZ-7528 carrying capacity of 36 tons and 77-tonner, BelAZ-7555G.

In the early 1990s, marked by the collapse of the Soviet Union and the sharp decline in production, BelAZ has not stopped the release of any of the models of dump trucks, covering a range of capacities from 30 to 220 tons. Moreover, it included in the production program of other special heavy transport equipment, production of which is mastered from the nineties of the last century: dump terrain with hydromechanical transmission, construction machinery and machinery for the maintenance of mining and transport operations, such as loaders, bulldozers, tractor tugs and polivoorositelnye machines; machinery for underground works, machines for metallurgical plants, etc.

Innovative solutions incorporated into the design of the first Belarusian dump trucks, allowed to further improve the components and systems of cars of all classes of load capacity, introduce new components and materials, gradually modernize trucks with the creation of new versions based on the use of diesel engines, transmissions and tires production of various firms. Particular attention is always paid to factory experts fitness equipment to the operating environment, creating in each class dump options in the north and tropical version, for transporting light loads, etc.

Lineup equipment manufactured by the Belarusian Automobile Plant, joined as new generation of machines - 55-ton dump truck BelAZ-7555, dump truck BelAZ-75131 with carrying capacity of 130 tons, which was designed based on more than 15 years of operating experience predecessor - the 120-ton truck, as well as the largest in the history of the domestic automotive dump truck BelAZ-75600 with carrying capacity of 320 tons.

In total in the history of management chief designer of Belarusian Automobile Plant has developed over 600 modifications of dump trucks with capacity from 27 to 320 tons, the company produced more than 130 million units of dump trucks, which in the history of the plant were sent to more than 70 countries.

Significantly expanded the production line of BelAZ, primarily due to an underground theme, to take in the Mogilev Automobile Plant. Department underground and road construction equipment, conducting production design support at the branch in Mogilev, also joined in the engineering service of the Belarusian Automobile Plant. Special Design Bureau of UGC BelAZ is developing the design of freight rolling stock, manufactured at Mogilev Carriage Works also recently logged in the «BelAZ».

Only recently at BelAZ been designed and manufactured pilot batches:

- 90-ton dump trucks BelAZ-75570 with 6-speed hydromechanical transmission; according to test results finalized mass production, pilot batch of dump trucks shipped in Belogorsk of "Rusal Achinsk Transportation»;

- 45-ton dump trucks BelAZ-75450 with increased to 600 thousand. Kilometers resource exploitation, the prototype of which has been successfully tested in the Chelyabinsk region of Russia on "Uzhuralzoloto»;

- 320-ton dump trucks BelAZ-75600. The first machine of this series has passed acceptance tests in operation at JSC "MC" KRU "" in the Kemerovo region, which showed that the use of dump trucks BelAZ-75600 provides increased productivity by 35-40%, and a corresponding decrease in the cost of transport works. On the basis of the basic units of 320-tonner designed by dump truck BelAZ-75601 with carrying capacity of 360 tons, the prototype of which was made for the anniversary of UGC.

However, it would be wrong to claim that its birth mining machinery, for half a century to develop and produce at BelAZ, obliged only to Belarus. A huge amount of research and development work to create machines with hydromechanical transmission in the 60s of the last century BelAZ failed due to the wide community of the plant with many organizations, including the US, the Institute of Electric Welding, Barnaul Plant of Transport Engineering, Yaroslavl Engine Plant and others.

Creation of the first sample dump truck with electromechanical transmission BelAZ-carrying capacity of 75 549 tonnes was conducted according to the program of the State Committee of Science and Technology of the USSR with the participation of co-authors, among whom were Turbomotor Ural plant, "Dinamo", SRI heavy tires (Dnepropetrovsk), the plant " Sibelektroprivod ».

Start in life for a new generation of appliances received at the largest mining companies, which were tested prototypes and verify that the adopted technical solutions: to Bachatskom and Neryungri coal mines, Olenegorsky, Lebedinsky and Balkhash GOKah MMC "Pechenganikel" and other enterprises.

IB

Let's look at this machine more ...

September 25 at the test site was presented to the world's largest dump truck BelAZ-75710. Capacity of the new machine is 450 tons. Prior to that, the largest trucks BelAZ-75601 were considered (created in the Belarusian Automobile Plant in 2007) and the Swiss Liebherr T282B (appeared in 2003) - both carrying capacity of 360 tons. Overall vehicle weight is 810 tons. Soon the car will be entered in the Guinness Book of Records.

Powerplant record BelAZ-75710 includes two diesel engines with a total capacity of 8500 hp, designed to power the electric motors that drive the wheels of the truck giant. Maximum speed sverhmashiny is 64 km / h.

Equipment BelAZ-75710 includes a system for monitoring the dead zone air conditioning, signaling the approach of a high-voltage line, and the fire-fighting system. The largest dump truck in the world is designed to work in difficult conditions at open-pit and deep pits at temperatures from -50 to +50 degrees. 8-wheel truck equipped with tubeless tires, allow the heavy vehicle to easily move around on technological roads.

BelAZ-75710 was introduced in the town of Zhodino, in honor of the 65th anniversary of the Belarusian Automobile Plant, known worldwide for heavy equipment manufactured and Dumpers. The emergence of the largest truck in the world is dictated by modern conditions when the mining industry requires an increasingly heavy and powerful technique. In recent years, the production of ultra-high load-carrying capacity mining trucks increased by 2 times, and the growth trend is maintained. Taking into account market demand BelAZ will produce about 1,000 such vehicles per year.

To increase the rate of production at the Belarusian company for the past year and a half actively pursued development program, in which were built the new plant area of over 30 thousand sq. Meters. There was a lot of new equipment, and in the near future is planned to install about 700 machines and special process plants. Currently, BelAZ produces a wide range of dump trucks. A similar number of models no one producer in the world. In addition, the resource of machines increased from 400 thousand. Up to 1 mln. Km. Overall, in its history, Belarusian Automobile Plant has produced more than 500 different models with lifting capacity from 30 to 450 tons. For all the time it was produced 136 thousand. Machines, which are operated in 72 countries.

Belarusian Automobile Plant, whose construction began near the town of Zhodino near Minsk (then as the peat plant engineering) in 1948, today produces, world analogues which can be counted on the fingers of one hand.

For more than half a century history of the Belarusian automobile enterprises of Minsk was released more than 120 000 units of mining equipment. BelAZ working in almost 50 countries around the world. A history of the plant began in the Soviet casually: in 1946 the government decided to build the plant peat Engineering (Resolution of the Supreme Council of the BSSR 11.09.1946 № 137/308). Just 2 years Belpromproekt already completed the development and coordination of the project plant. So from the planning phase, the Belarusians went to the construction of the buildings.

His first production, the company showed Zhodino in 1950, and the following year the peat plant engineering has been redeveloped into a factory of road and reclamation machines "Dormash". In 1958 the company received a new name that is known so far - "Belarusian Autoworks." From the gates of the company with a new name he rolled out the first 25-ton dump truck MAZ-525.

Further more. In the same year in Zhodino transferred to Minsk Automobile production of 25-ton trucks MAZ-525. And in 1960, in Minsk region began to produce the first samples of MAZ-530 dump truck with carrying capacity of 40 tons. By the time the production line in Zhodino descended thousand MAZ-525.

But the company, bore the proud name of the automobile plant, a assembly of trucks under license, by itself, was not enough. Therefore, in 1960 it started to design trucks radically new design for the development of mineral deposits by open way.

However, in April 1960 at BelAZ created its own design bureau, headed by ZL Sirotkin, who arrived in Zhodino Minsk together with a group of designers MAZ. Just create a department it had to solve a complex problem. Until recently considered a model of new technology, MAZ-525 ceased to meet the growing demands of operatives. The powerful mining and coal quarries, large hydraulic construction projects, enterprises of the construction industry needed a high-performance trucks, the most adapted primarily to working conditions in the quarries.

Design services and management of the company decided not to improve the existing model of the truck, and create a completely new car. This period can be called a landmark in the history of the Belarusian Automobile Plant. Factory designers studied the operating conditions and the required technical specifications of the future dump on the drawing boards were created vertical contours of the future of the machine on test benches to verify the correctness of technical solutions adopted.

Perhaps now it may seem incredible, but then, in a time of unprecedented labor enthusiasm of the first postwar five-year plans, was an event almost ordinary: in less than one year at a young plant created a fundamentally new dump truck carrying capacity 27 tons under the name of BelAZ-540, a prototype of which He was released in September 1961.

The design of this car was laid a lot of new technical solutions for mechanical engineering, high-performance operation at a later date in a dump pits. It was first used in the practice of the domestic automotive pneumohydraulic suspension ensures high running smoothness both laden and unladen, hydromechanical transmission, which is also the first time in the practice of our engineering has been used to mass-produced machines, the original layout: the location of the cabin near the engine allowed receive a minimum base and minimum dimensions, thereby increasing maneuverability and increase its stability, the platform enabled the bucket and lower center of gravity and improve stability of the vehicle. Original solutions for the steering system and tilting platform, feathers and other sites have become a tradition in the creation of regular class-duty trucks.

BelAZ-540 was the progenitor of a whole family of heavy-duty trucks. In 1967, the company has mastered production of 40-ton dump truck BelAZ-548A, designed with the greatest possible unification of basic units and parts of the two cars.

1968 was the year of birth of the prototype BelAZ-549 - the base class-duty truck 75-80 tons, the first sample with electromechanical transmission. In 1977 he was released prototypes truck BelAZ-7519 - the base class-duty truck 110-120 tons. Six years later, the plant started serial production of BelAZ-75211 - the base class-duty truck 170-220 tons.

By 1986, the plant could produce up to 6,000 units of such equipment in the year, which is half the world's production.

This at BelAZ not going to stop. In 1963, coming off the assembly line of the second prototype of the design of the plant designers - BelAZ truck-carrying capacity of 40 548 tonnes.

In 1966, the Belarusian Automobile Plant started serial production of dump trucks BelAZ-548A - the base class-duty truck 40-45 tons. The plant itself was awarded the Order of the Red Banner and received a gold medal at the International Exhibition in Plovdiv for BelAZ-540.

Another novelty was the Belarusian autoenterprise truck BelAZ-carrying capacity of 75 549 t. The first prototype of this machine class load-carrying capacity of 75-80 tons was released in 1968. The unique development of Belarusians seriously declared themselves for the whole Union, proving that a small country can create such giants.

The next phase of construction took place already in the 70s. In 1977, there were prototypes truck BelAZ-7519 carrying capacity of 110 tonnes - the base class-duty truck 110-120 tons. So the Belarusian enterprise in one leap jumped over several weight categories.

In 1978, the plant develops new technique - aircraft tugs for towing aircraft with a takeoff weight of 100 tons. Fortunately, the chassis for the Belarusians are already there. But in the race for the increase of draft properties of BelAZ it was still too early to put an end. In 1982, a pipeline Zhodino gone prototype 170-ton dump truck BelAZ-75211, the representative of the class of load-carrying capacity of 170-200 tons.

In the early 1990s, marked by the collapse of the Soviet Union and the sharp decline in production, BelAZ has not stopped the release of any of the models of dump trucks, covering a range of capacities from 30 to 220 tons. Moreover, it included in the production program of other special heavy transport equipment, production of which is mastered from the nineties of the last century: dump terrain with hydromechanical transmission, construction machinery and machinery for the maintenance of mining and transport operations, such as loaders, bulldozers, tractor tugs and polivoorositelnye machines; machinery for underground works, machines for metallurgical plants, etc.

In 1990, BelAZ and did furor, build a huge truck carrying capacity of 280 t. The car has turned so serious that after her appearance slightly cooled the ardor of Engineers. In 1994 Belarusians turned again to the "small" class: a prototype truck BelAZ-7555 capacity of 55 tons, the head of a new model of family haulers with hydro mechanical transmission. Behind her, two years later, followed by the release of the 130-ton BelAZ-75131, which became the first-born in a new family of trucks with electromechanical transmission.

However, by 1998, the crisis in Zhodino realized that without a serious modernization of production plant vague future prospects. BelAZ on the reconstruction of existing production-oriented upgrade of mining equipment, the development of new models to improve the quality and technical level of both individual components and systems, and produced technology in general.

As a consequence, in 2000 the production association (the plant received this status in 1995) awarded the "Crystal Nika" for the international program "Partnership for Progress", and the general director of BelAZ PA? L. Mariev was awarded the title of "Director of the Year", and later the title of "Hero of Belarus».

Flattered success Belarusians set to work with renewed energy, and built in 2002, all-wheel drive Articulated dump truck BelAZ-7528 carrying capacity of 36 tons and 77-tonner, BelAZ-7555G.

In the early 1990s, marked by the collapse of the Soviet Union and the sharp decline in production, BelAZ has not stopped the release of any of the models of dump trucks, covering a range of capacities from 30 to 220 tons. Moreover, it included in the production program of other special heavy transport equipment, production of which is mastered from the nineties of the last century: dump terrain with hydromechanical transmission, construction machinery and machinery for the maintenance of mining and transport operations, such as loaders, bulldozers, tractor tugs and polivoorositelnye machines; machinery for underground works, machines for metallurgical plants, etc.

Innovative solutions incorporated into the design of the first Belarusian dump trucks, allowed to further improve the components and systems of cars of all classes of load capacity, introduce new components and materials, gradually modernize trucks with the creation of new versions based on the use of diesel engines, transmissions and tires production of various firms. Particular attention is always paid to factory experts fitness equipment to the operating environment, creating in each class dump options in the north and tropical version, for transporting light loads, etc.

Lineup equipment manufactured by the Belarusian Automobile Plant, joined as new generation of machines - 55-ton dump truck BelAZ-7555, dump truck BelAZ-75131 with carrying capacity of 130 tons, which was designed based on more than 15 years of operating experience predecessor - the 120-ton truck, as well as the largest in the history of the domestic automotive dump truck BelAZ-75600 with carrying capacity of 320 tons.

In total in the history of management chief designer of Belarusian Automobile Plant has developed over 600 modifications of dump trucks with capacity from 27 to 320 tons, the company produced more than 130 million units of dump trucks, which in the history of the plant were sent to more than 70 countries.

Significantly expanded the production line of BelAZ, primarily due to an underground theme, to take in the Mogilev Automobile Plant. Department underground and road construction equipment, conducting production design support at the branch in Mogilev, also joined in the engineering service of the Belarusian Automobile Plant. Special Design Bureau of UGC BelAZ is developing the design of freight rolling stock, manufactured at Mogilev Carriage Works also recently logged in the «BelAZ».

Only recently at BelAZ been designed and manufactured pilot batches:

- 90-ton dump trucks BelAZ-75570 with 6-speed hydromechanical transmission; according to test results finalized mass production, pilot batch of dump trucks shipped in Belogorsk of "Rusal Achinsk Transportation»;

- 45-ton dump trucks BelAZ-75450 with increased to 600 thousand. Kilometers resource exploitation, the prototype of which has been successfully tested in the Chelyabinsk region of Russia on "Uzhuralzoloto»;

- 320-ton dump trucks BelAZ-75600. The first machine of this series has passed acceptance tests in operation at JSC "MC" KRU "" in the Kemerovo region, which showed that the use of dump trucks BelAZ-75600 provides increased productivity by 35-40%, and a corresponding decrease in the cost of transport works. On the basis of the basic units of 320-tonner designed by dump truck BelAZ-75601 with carrying capacity of 360 tons, the prototype of which was made for the anniversary of UGC.

However, it would be wrong to claim that its birth mining machinery, for half a century to develop and produce at BelAZ, obliged only to Belarus. A huge amount of research and development work to create machines with hydromechanical transmission in the 60s of the last century BelAZ failed due to the wide community of the plant with many organizations, including the US, the Institute of Electric Welding, Barnaul Plant of Transport Engineering, Yaroslavl Engine Plant and others.

Creation of the first sample dump truck with electromechanical transmission BelAZ-carrying capacity of 75 549 tonnes was conducted according to the program of the State Committee of Science and Technology of the USSR with the participation of co-authors, among whom were Turbomotor Ural plant, "Dinamo", SRI heavy tires (Dnepropetrovsk), the plant " Sibelektroprivod ».

Start in life for a new generation of appliances received at the largest mining companies, which were tested prototypes and verify that the adopted technical solutions: to Bachatskom and Neryungri coal mines, Olenegorsky, Lebedinsky and Balkhash GOKah MMC "Pechenganikel" and other enterprises.

IB