1195

War industries (15 photos)

The Second World War was a war not only the countries and peoples, ideologies, generals and soldiers, and the war industries. All the leading member countries and their satellites has a powerful military industry (which implies complex technological and logistics networks, the availability of research institutes and design bureaus, a large number of mechanical engineering and mining industries).

Unlike modern local wars, in which the struggle is primarily accumulated in peacetime weapon in the long war between the most powerful countries of the world fleet of vehicles of the armed forces dozens updated view of its release failure and destroy the enemy. For example, out of nearly 5,000 aircraft of Germany and its allies, launched a war against the Soviet Union, more than 70% of this fleet was lost in 1941. A similar situation exists with the Wehrmacht armored vehicles. The situation with aircraft and armored vehicles of the USSR in this fateful year was a much more sad, leaving the Red Army during the 1942 number of techniques has been in the minority, despite all efforts to the rear.

Such a significant loss in the total war of annihilation (namely this was a war the Soviet Union and the Third Reich) needed to urgently fill. USSR, in this situation was in a very dangerous position - a significant portion of the European part of the country was occupied. It should be understood that in Russia and the Soviet Union, despite the vast territory of almost all industrial and human resources are located in the European part of the country, while tending to the western borders. Forced industrial colonization of Siberia began in the course of the war, therefore, rely on the fact that "something like that because we take the Urals and the win" was not necessary.

Moreover, the Siberian oil then was not even close (what many modern "onalitegi" forget), and 85% of oil in the Soviet Union during the war produced in Azerbaijan. The latter circumstance determined the southern direction of the German offensive in 1942 as a priority and strategically important - the capture or block oil fields (the war in the Caucasus), and cutting the traffic flow across the Volga River and the surrounding area (Stalingrad). Actually, the full success of this offensive in at least one direction almost guaranteed defeat of the USSR in the war - oil reserves, as required tanks, vehicles and aircrafts, have dried up to within a few weeks, and lend-lease deliveries in any way could not provide Soviet demand for fuel. But at Stalingrad, German troops are bogged down and the city has not mastered, and to the oil fields of the Caucasus arm of the Wehrmacht did not even have reached. And that's good.

Total - at the beginning of the war a large part of the defense enterprises of the USSR was located close to the western borders of the country during the war, these territories were occupied as well as territories and cities to which the Wehrmacht had no chance, we could easily reach the Luftwaffe. These circumstances could lead to the inevitable defeat of the USSR in the war (it is only in wet fantasies of some citizens of German tanks and planes piled with corpses, in reality, they swamped by Soviet tanks, planes and missiles), and the threat to be no industry in the Kremlin understood much better than ours . In the 1941-1942 year, thousands of businesses were evacuated to the Urals, Siberia, the Volga region and Central Asia.

This evacuation was unprecedented in history, either before or after it is nothing comparable in scale has not been done anywhere in the world. Only in July and November 1941, were evacuated to the east of the enterprise in 2593, including 1523 large factory 18 million. Workers, employees and members of their families. And all the years of war, the number of evacuees was about 25 million. People, with 17 million. - Only in June-December 1941

To present such very difficult. If you've ever moved from apartment to apartment, you know, how many difficulties it causes. And then it was necessary to evacuate hundreds of thousands of people, machinery plant to build a new place shops and accommodations to provide all this electricity to completely reshape the logistics (you can not just go and build a new railway line) - and it's all under the constant bombing. Moreover, the evacuation was to be carried out as soon as possible, because every hour of downtime of the plant - is a foregone front of tanks, planes, hundreds submachine guns or rifles. Therefore, while one plant was evacuated, another shop under the bombs produced a much-needed edge product and country.

Of course, just go and build a military factory in a new place can be only in Command & Conquer. In fact, the evacuated enterprises could not immediately reach the rate of production, which was before the war - affected the problems of logistics and personnel. Moreover, the evacuation of all the equipment and all the machines was often physically impossible and subjected to removal of only the most valuable equipment. A huge number of companies to evacuate, in principle, not time, many infrastructure and facilities (for example, important for the Soviet aluminum industry Dneproges) were blown up or otherwise destroyed, so they do not fall into the hands of the enemy and not provided with tanks and planes of his army.

Blown up during the retreat Dneproges

Related evacuation degradation of the production base and facilities could not affect the quality of products. Often the development of production of the desired weapon was impossible, and instead went to the front ersatz equipment - for example, a light tank T-60, which is produced instead of a much more perfect T-50. In the future, T-60 has been gradually replaced by the T-70, which is, again, in some ways (book boards, for example) lost in 1940 developed the T-50. Similarly fared in other industries - for exactly the same reasons, it was not deployed mass production Polikarpov I-185, which demanded deficit duralumin and improved (compared to commercially available) air-cooled engines. These and many other situations where instead of better produced more primitive and inferior to the characteristics of a sample of arms, only at first glance seem silly or sabotage - but in reality all this is a forced decision, dictated by the conditions and the situation on the war front. Better to have a mediocre tank and mediocre aircraft than none at all.

The situation in the first years of the war and exacerbated by the problem of human resources - a significant portion of the working population has been called to the front, and their machine took place at the old men, women and children. Skilled workers were only on the most critical areas of production. Of course, the replacement of skilled labor for unskilled labor accordingly affected the quality of the art.

All of the above reasons have led to the fact that machinery manufactured by the Soviet Union during the early years of the war, had low reliability and poor quality in comparison with pre-war samples and copies issued in the last years of the war when the production technology has been established, and the deficit of many strategic material has been eliminated.

At the same time the position of the industry of the Third Reich in 1941 was more than winning - under the control of Hitler proved to the whole of Europe, its material and human resources, as well as industrial enterprises. Even those countries that are not directly subordinate to Hitler and were not occupied, provided Germany and its industry its resources. There was no need to evacuate the plant. Buyers front during the first years of the war with the Soviet Union, though significantly higher than expected, but did not require a general mobilization, resulting in factories operated by qualified workers. Design offices Germany is free "creative search for" new weapons without regard to the front, which was then in many hundreds of kilometers away from the walls of Berlin. This creative search led to a truly breakthrough technologies in samolёto- and rocket, the relevance of which persist for decades after the war.

By the end of the 1930s. German tank building was in charge of at least nine major corporations involved in the supply of tanks and armored hulls. They controlled 32 companies belonging to 27 different companies. The characteristic is that these firms specialize in several areas. For example, the eight companies Daimler-Benz only one engaged in the production of tanks. The other four were producing avtomobileyesche three - aircraft engines. During the war years, the situation has not changed much.

Workshop for production of gun barrels of the German plant-Borzing Rheinmetall (Rheinmetall-Borsig) before the war

Start of the third and probably the most interesting period - 1940. World War II unfolded in Europe, required adjustments in the industry. Formation of new pieces suffer from a lack of equipment and weapons. Manufacture of tanks lagged behind the needs of the Wehrmacht in them. Yes, probably in a different way and could not be, because the mobilization of the economy has been limited. Moreover, almost all the economic use rather peculiar: endlessly surfing the release of one product to another. This plan is usually to fit the priorities of the military-strategic activities. In addition, it was necessary to urgently solve many other organizational issues related to the more efficient use of production capacity, productivity and reallocation of labor contingents.

Out of this situation was found. March 17, 1940 created Reichsministerium die Waffe und Munition (special Reich Ministry of arms and ammunition), the head of which was the engineer F. Todt. Russian readers he is better known as the founder and leader of the national building organization "Todt". It was through his effort to build a famous reyhsavtobany. The same pressure energy is probably needed in the military industry. Soon, however, Todt was killed in a plane crash.

After him, the ministry was headed by no less talented organizer - the architect Speer. Over a relatively short period of time - two years - Speer failed three times to increase the output of armored vehicles. It is not surprising that during his leadership of the Ministry is often called the "era of Speer».

Descended from the conveyor of the German tanks Pz.Kpfw. V Ausf. D «Panther" and Pz.Kpfw. VI ausf.H «Tiger" in the courtyard of the factory of the company "Henschel»

- Now the Ministry of arms and ammunition involved in the planning of supply, the issuance of orders, work through the guidance of experienced commander of tank building. About rigorous approach can be judged by the main committee structural divisions: manufacture and repair of tanks, design and monitoring of production, improvement of armor manufacture light armored vehicles, engines, and other supplies.

Consider a new scheme of "birth" of armored vehicles. General Staff of the Army with the wishes of the front-line practitioners were frequently rough tactical and technical project management of arms (general staff also determined the amount of equipment required). In WaPruf-6 mission worked out in detail, after which it was transferred to the Commander of tank development, which, in turn, picked up two or three companies of the designer. A special commission consisting of representatives of interested parties, studied completed projects from which to choose the best. Design Bureau, submitted a project selected, appointed leading on this structure, although the company could not obtain an order for mass production of their own offspring.

The test specimens were subjected to a comprehensive run-in Kummersdorfskom central test site, located near Berlin. Also, tests were carried out in the branches of the landfill: a mountain range in Thuringia, as well as in the Tyrolean Alps on the so-called snow site. And only then determine whether to surrender or self-propelled tank on stream. Total output was determined by the supreme command of the German army. Distribution of orders to the factories and firms engaged in the Ministry of arms and ammunition. Armored vehicles in the Ministry was in charge of the main group for the production of tanks. If the plan of production of tanks was more or less stable, the production program towers, felling for self-propelled guns and armored hulls, which also accounts for a year, can often be corrected.

"Geography" German tank industry is mainly determined by strategic considerations. Production facilities in order to reduce their vulnerability to aerial bombardments deliberately dispersed. Also take into account the principle of duplication supplies of basic units and units from different companies.

Note that how a similar co-operation has been developed, and as much complicated. For example, for the production of "Panther" was drawn 136 subcontractors. Enclosures supplied 6 factories, towers - 5, gearboxes - 3 motors - 2 tracks - 4 optics - 1, armament - 1, forgings - 15, cast steel - 14, other - finished parts, assemblies and fasteners. < br />

Assembly shop of German medium tanks Pz.Kpfw. III

- Due to the success, to designate the results of the first year of the campaign against the Soviet Union, the tendency of movement of tank to the east of Germany. Special Commission for the production of tanks and parts in December, 41-year examined the possibility of attracting industry occupied Ukraine for their own needs. Excellent prospects for the production of hulls of tanks opened at the Mariupol plant them. Illich captured by the Germans. However, the rapidly changing situation on the German-Soviet front in the region is not possible to realize these ambitious plans. And once the Wehrmacht was defeated on the Volga and Kursk, ceased production of armored units, even in Poland and Silesia.

Since the second half of the 43rd, the large tank plants located in Germany, became the object of attacks by Allied aircraft. Thus, for example, to the end, the capacities Daimler-Benz, located in Berlin, thrice subjected bombed. In the 44th year, they added plants of MAN, as well as almost all the companies located in the Rhine-Westphalian industrial area, and engaged in the production hulls.

To avoid disruptions of the established system of tank orders for important assemblies and parts had to be transferred to small producers. In large enterprises also began to move some of the management group of machines together with staff in a safe place, and under the earth .... For example, in September 44th, almost half of the structural units of Daimler-Benz, which specialized in the production control mechanisms, turret boxes and chassis for the "Panther", was moved to small towns Falkensee near Berlin, Fitz had Kiistrin, Kzerits in Pomerania, Teltow, Oberprausnits in the Sudetenland, and even in the wine cellar of Deulivag. We are considering the option of placing production facilities in the potash mines in former strongholds in Czechoslovakia, in the caves ...

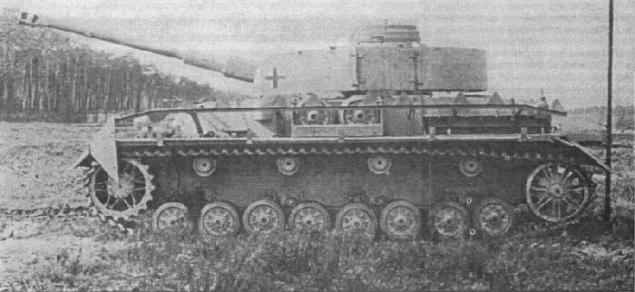

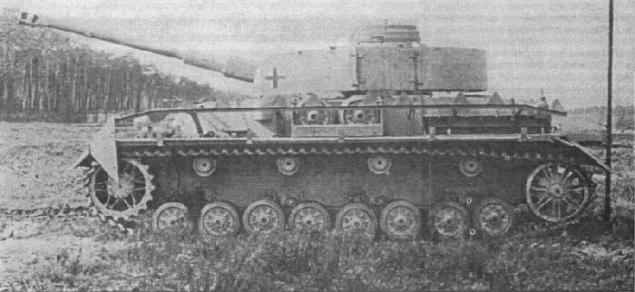

The tank Pz IV is an example of a fairly successful design. Its production in the factories of the Reich lasted until the end of the war. In this photo submitted tank modifications H, tested for kummersdorf in 1944

- The measures taken to relocate production, of course, did not contribute to the implementation of the advantages of modern mass-stream production, and only increased traffic flows and so intense. Despite this, Speer these circumstances represented as a virtue, saying that "the German arms production rejects conveyor method the US and the USSR, and relies heavily on skilled German labor". Although it is the absence of large companies did not allow the German tank development to sustain competition with tank production of the anti-fascist coalition. German serial armor divided into several groups according to the steel grade and thickness. Along with heterogeneous still more homogeneous armor was issued. Armor plate production technology bronelisty divided into a surface hardened and evenly tempered. After the loss of Nikopol basin decreased intake of manganese in Germany. Nickel is delivered only to the north of Finland.

The result of constant shortage of alloying elements was the deterioration of the quality of the armor series.

Germany

Unlike modern local wars, in which the struggle is primarily accumulated in peacetime weapon in the long war between the most powerful countries of the world fleet of vehicles of the armed forces dozens updated view of its release failure and destroy the enemy. For example, out of nearly 5,000 aircraft of Germany and its allies, launched a war against the Soviet Union, more than 70% of this fleet was lost in 1941. A similar situation exists with the Wehrmacht armored vehicles. The situation with aircraft and armored vehicles of the USSR in this fateful year was a much more sad, leaving the Red Army during the 1942 number of techniques has been in the minority, despite all efforts to the rear.

Such a significant loss in the total war of annihilation (namely this was a war the Soviet Union and the Third Reich) needed to urgently fill. USSR, in this situation was in a very dangerous position - a significant portion of the European part of the country was occupied. It should be understood that in Russia and the Soviet Union, despite the vast territory of almost all industrial and human resources are located in the European part of the country, while tending to the western borders. Forced industrial colonization of Siberia began in the course of the war, therefore, rely on the fact that "something like that because we take the Urals and the win" was not necessary.

Moreover, the Siberian oil then was not even close (what many modern "onalitegi" forget), and 85% of oil in the Soviet Union during the war produced in Azerbaijan. The latter circumstance determined the southern direction of the German offensive in 1942 as a priority and strategically important - the capture or block oil fields (the war in the Caucasus), and cutting the traffic flow across the Volga River and the surrounding area (Stalingrad). Actually, the full success of this offensive in at least one direction almost guaranteed defeat of the USSR in the war - oil reserves, as required tanks, vehicles and aircrafts, have dried up to within a few weeks, and lend-lease deliveries in any way could not provide Soviet demand for fuel. But at Stalingrad, German troops are bogged down and the city has not mastered, and to the oil fields of the Caucasus arm of the Wehrmacht did not even have reached. And that's good.

Total - at the beginning of the war a large part of the defense enterprises of the USSR was located close to the western borders of the country during the war, these territories were occupied as well as territories and cities to which the Wehrmacht had no chance, we could easily reach the Luftwaffe. These circumstances could lead to the inevitable defeat of the USSR in the war (it is only in wet fantasies of some citizens of German tanks and planes piled with corpses, in reality, they swamped by Soviet tanks, planes and missiles), and the threat to be no industry in the Kremlin understood much better than ours . In the 1941-1942 year, thousands of businesses were evacuated to the Urals, Siberia, the Volga region and Central Asia.

This evacuation was unprecedented in history, either before or after it is nothing comparable in scale has not been done anywhere in the world. Only in July and November 1941, were evacuated to the east of the enterprise in 2593, including 1523 large factory 18 million. Workers, employees and members of their families. And all the years of war, the number of evacuees was about 25 million. People, with 17 million. - Only in June-December 1941

To present such very difficult. If you've ever moved from apartment to apartment, you know, how many difficulties it causes. And then it was necessary to evacuate hundreds of thousands of people, machinery plant to build a new place shops and accommodations to provide all this electricity to completely reshape the logistics (you can not just go and build a new railway line) - and it's all under the constant bombing. Moreover, the evacuation was to be carried out as soon as possible, because every hour of downtime of the plant - is a foregone front of tanks, planes, hundreds submachine guns or rifles. Therefore, while one plant was evacuated, another shop under the bombs produced a much-needed edge product and country.

Of course, just go and build a military factory in a new place can be only in Command & Conquer. In fact, the evacuated enterprises could not immediately reach the rate of production, which was before the war - affected the problems of logistics and personnel. Moreover, the evacuation of all the equipment and all the machines was often physically impossible and subjected to removal of only the most valuable equipment. A huge number of companies to evacuate, in principle, not time, many infrastructure and facilities (for example, important for the Soviet aluminum industry Dneproges) were blown up or otherwise destroyed, so they do not fall into the hands of the enemy and not provided with tanks and planes of his army.

Blown up during the retreat Dneproges

Related evacuation degradation of the production base and facilities could not affect the quality of products. Often the development of production of the desired weapon was impossible, and instead went to the front ersatz equipment - for example, a light tank T-60, which is produced instead of a much more perfect T-50. In the future, T-60 has been gradually replaced by the T-70, which is, again, in some ways (book boards, for example) lost in 1940 developed the T-50. Similarly fared in other industries - for exactly the same reasons, it was not deployed mass production Polikarpov I-185, which demanded deficit duralumin and improved (compared to commercially available) air-cooled engines. These and many other situations where instead of better produced more primitive and inferior to the characteristics of a sample of arms, only at first glance seem silly or sabotage - but in reality all this is a forced decision, dictated by the conditions and the situation on the war front. Better to have a mediocre tank and mediocre aircraft than none at all.

The situation in the first years of the war and exacerbated by the problem of human resources - a significant portion of the working population has been called to the front, and their machine took place at the old men, women and children. Skilled workers were only on the most critical areas of production. Of course, the replacement of skilled labor for unskilled labor accordingly affected the quality of the art.

All of the above reasons have led to the fact that machinery manufactured by the Soviet Union during the early years of the war, had low reliability and poor quality in comparison with pre-war samples and copies issued in the last years of the war when the production technology has been established, and the deficit of many strategic material has been eliminated.

At the same time the position of the industry of the Third Reich in 1941 was more than winning - under the control of Hitler proved to the whole of Europe, its material and human resources, as well as industrial enterprises. Even those countries that are not directly subordinate to Hitler and were not occupied, provided Germany and its industry its resources. There was no need to evacuate the plant. Buyers front during the first years of the war with the Soviet Union, though significantly higher than expected, but did not require a general mobilization, resulting in factories operated by qualified workers. Design offices Germany is free "creative search for" new weapons without regard to the front, which was then in many hundreds of kilometers away from the walls of Berlin. This creative search led to a truly breakthrough technologies in samolёto- and rocket, the relevance of which persist for decades after the war.

By the end of the 1930s. German tank building was in charge of at least nine major corporations involved in the supply of tanks and armored hulls. They controlled 32 companies belonging to 27 different companies. The characteristic is that these firms specialize in several areas. For example, the eight companies Daimler-Benz only one engaged in the production of tanks. The other four were producing avtomobileyesche three - aircraft engines. During the war years, the situation has not changed much.

Workshop for production of gun barrels of the German plant-Borzing Rheinmetall (Rheinmetall-Borsig) before the war

Start of the third and probably the most interesting period - 1940. World War II unfolded in Europe, required adjustments in the industry. Formation of new pieces suffer from a lack of equipment and weapons. Manufacture of tanks lagged behind the needs of the Wehrmacht in them. Yes, probably in a different way and could not be, because the mobilization of the economy has been limited. Moreover, almost all the economic use rather peculiar: endlessly surfing the release of one product to another. This plan is usually to fit the priorities of the military-strategic activities. In addition, it was necessary to urgently solve many other organizational issues related to the more efficient use of production capacity, productivity and reallocation of labor contingents.

Out of this situation was found. March 17, 1940 created Reichsministerium die Waffe und Munition (special Reich Ministry of arms and ammunition), the head of which was the engineer F. Todt. Russian readers he is better known as the founder and leader of the national building organization "Todt". It was through his effort to build a famous reyhsavtobany. The same pressure energy is probably needed in the military industry. Soon, however, Todt was killed in a plane crash.

After him, the ministry was headed by no less talented organizer - the architect Speer. Over a relatively short period of time - two years - Speer failed three times to increase the output of armored vehicles. It is not surprising that during his leadership of the Ministry is often called the "era of Speer».

Descended from the conveyor of the German tanks Pz.Kpfw. V Ausf. D «Panther" and Pz.Kpfw. VI ausf.H «Tiger" in the courtyard of the factory of the company "Henschel»

- Now the Ministry of arms and ammunition involved in the planning of supply, the issuance of orders, work through the guidance of experienced commander of tank building. About rigorous approach can be judged by the main committee structural divisions: manufacture and repair of tanks, design and monitoring of production, improvement of armor manufacture light armored vehicles, engines, and other supplies.

Consider a new scheme of "birth" of armored vehicles. General Staff of the Army with the wishes of the front-line practitioners were frequently rough tactical and technical project management of arms (general staff also determined the amount of equipment required). In WaPruf-6 mission worked out in detail, after which it was transferred to the Commander of tank development, which, in turn, picked up two or three companies of the designer. A special commission consisting of representatives of interested parties, studied completed projects from which to choose the best. Design Bureau, submitted a project selected, appointed leading on this structure, although the company could not obtain an order for mass production of their own offspring.

The test specimens were subjected to a comprehensive run-in Kummersdorfskom central test site, located near Berlin. Also, tests were carried out in the branches of the landfill: a mountain range in Thuringia, as well as in the Tyrolean Alps on the so-called snow site. And only then determine whether to surrender or self-propelled tank on stream. Total output was determined by the supreme command of the German army. Distribution of orders to the factories and firms engaged in the Ministry of arms and ammunition. Armored vehicles in the Ministry was in charge of the main group for the production of tanks. If the plan of production of tanks was more or less stable, the production program towers, felling for self-propelled guns and armored hulls, which also accounts for a year, can often be corrected.

"Geography" German tank industry is mainly determined by strategic considerations. Production facilities in order to reduce their vulnerability to aerial bombardments deliberately dispersed. Also take into account the principle of duplication supplies of basic units and units from different companies.

Note that how a similar co-operation has been developed, and as much complicated. For example, for the production of "Panther" was drawn 136 subcontractors. Enclosures supplied 6 factories, towers - 5, gearboxes - 3 motors - 2 tracks - 4 optics - 1, armament - 1, forgings - 15, cast steel - 14, other - finished parts, assemblies and fasteners. < br />

Assembly shop of German medium tanks Pz.Kpfw. III

- Due to the success, to designate the results of the first year of the campaign against the Soviet Union, the tendency of movement of tank to the east of Germany. Special Commission for the production of tanks and parts in December, 41-year examined the possibility of attracting industry occupied Ukraine for their own needs. Excellent prospects for the production of hulls of tanks opened at the Mariupol plant them. Illich captured by the Germans. However, the rapidly changing situation on the German-Soviet front in the region is not possible to realize these ambitious plans. And once the Wehrmacht was defeated on the Volga and Kursk, ceased production of armored units, even in Poland and Silesia.

Since the second half of the 43rd, the large tank plants located in Germany, became the object of attacks by Allied aircraft. Thus, for example, to the end, the capacities Daimler-Benz, located in Berlin, thrice subjected bombed. In the 44th year, they added plants of MAN, as well as almost all the companies located in the Rhine-Westphalian industrial area, and engaged in the production hulls.

To avoid disruptions of the established system of tank orders for important assemblies and parts had to be transferred to small producers. In large enterprises also began to move some of the management group of machines together with staff in a safe place, and under the earth .... For example, in September 44th, almost half of the structural units of Daimler-Benz, which specialized in the production control mechanisms, turret boxes and chassis for the "Panther", was moved to small towns Falkensee near Berlin, Fitz had Kiistrin, Kzerits in Pomerania, Teltow, Oberprausnits in the Sudetenland, and even in the wine cellar of Deulivag. We are considering the option of placing production facilities in the potash mines in former strongholds in Czechoslovakia, in the caves ...

The tank Pz IV is an example of a fairly successful design. Its production in the factories of the Reich lasted until the end of the war. In this photo submitted tank modifications H, tested for kummersdorf in 1944

- The measures taken to relocate production, of course, did not contribute to the implementation of the advantages of modern mass-stream production, and only increased traffic flows and so intense. Despite this, Speer these circumstances represented as a virtue, saying that "the German arms production rejects conveyor method the US and the USSR, and relies heavily on skilled German labor". Although it is the absence of large companies did not allow the German tank development to sustain competition with tank production of the anti-fascist coalition. German serial armor divided into several groups according to the steel grade and thickness. Along with heterogeneous still more homogeneous armor was issued. Armor plate production technology bronelisty divided into a surface hardened and evenly tempered. After the loss of Nikopol basin decreased intake of manganese in Germany. Nickel is delivered only to the north of Finland.

The result of constant shortage of alloying elements was the deterioration of the quality of the armor series.

Germany