1154

An interesting way of oil from sand

What do you know about oil, except that today the whole world is literally sitting on the "oil needle"? This product is even more than a lot of money - it is the source of our civilized life with you. Therefore I suggest to read about an alternative method of extracting oil from sand. Look further!

Alberta (Canada) there are huge reserves of oil. At last count bituminozemnyh sands reserves in this province are 2, 0 bln. barrels. There are oil reserves in the Orinoco and Venezuela. Unfortunately, the world's oil reserves are estimated just one trillion. barrels (data for 2006). Therefore, the oil reserves in Alberta, the hoped. By 2020 it is planned to increase oil production in these areas in three times. And almost fivefold increase them by 2030.

With huge potential, the field, or rather oil production from these fields in the near future is not yet able to cover global demand for oil. This is explained by the fact that the currently existing technologies require large amounts of energy and fresh water. Energy consumption according to one account for 2/3 of the total costs for oil, others estimate their energy potential of oil in 1/5. Scientists are now dealing with this problem, but it is - the question of the future.

Although oil reserves in the sands bituminozemnyh great expectations.

Alberta Oil has a feature that distinguishes it from most of the oil-producing countries. In the province there are two types of oil, different from each other their origin, age and place of occurrence.

The first - a "conventional" oil, its age about 350 million years. It lies on the large, several kilometers deep in the so-called oil traps in the foothills of the Rocky Mountains and in the central parts of the province. For the first time this oil reserves found in 1947, 20 km south of Edmonton. This was the beginning of the oil boom in Alberta.

The second - is produced from oil, rather, the tar sands - Tar Sand. Sands of the (ancient river delta) saturated with bitumen, the average content of which reaches 82%. Their age - about 125 million. Years. They lie at depths of 50 to 500 meters. Stocks in terms of crude oil estimated at 1.6 trilionov barrels (1 barrel of oil = 160 liters) or 250 kub.km, of which about 200 billion barrels is possible to extract at suschestvuyuschth technologies. But, as is known, the latter does not stand still. At the moment of the Alberta oil sands receive more than 1.6-million barrels of oil per day.

The total area spread oil sands reaches 140 million square kilometers. They are divided into three fields, different bitumen content, depth and other parameters. The largest of them - Athabasca (name of a river flowing in the area) or, in fact, Tar Sand, located near the capital of oil sands - the town of Fort McMurrey.

Overhead, in the northern bright blue sky, but from the cab of the excavator Bucyrus 495 can not see it. Excavator John Martin hovers at the height of the third floor above the morass of mud and sand. In the air, though the ax hang from sulfuric stinks. But inside the cabin environment in a spacecraft, Martin conjures both hands on the remote control, such as those which are used in computer games. Deft movement of his fingers forced to move the entire backhoe - steel behemoth weighing a half thousand tons. Martin takes only 25 seconds to scoop up again about 70 tons of oily brown sand, turn 90 degrees, and dumped the whole bucket into the back of a yellow dump truck.

He scooped up, turned around, pour. Five buckets - and the body is full. He does not have time to dump drive off, and the right side by side-excavator is already waiting for the next car. A few minutes later, and she drives off with a full body, but on the left side there is another.

Scooped up, turned around, pour ...

Excavator repeats memorized movements almost round the clock for 365 days a year. The unit Bucyrus 495 worth more than $ 15 million. There are five of these, and they all work in the career of "Maskeg river" in 80 km from Fort Makmyurreya, Alberta. Yellow dump trucks Caterpillar 797B, which carry the extracted oil and dredge sand mixture - one of the world's largest machines of this class, and they cost under $ 5 million., But the cost of each pays for itself in the first week of work. On the career "Maskeg River" runs both 25 such trucks.

The whole modern world works almost exclusively on oil. All easily accessible deposits have exhausted promising only a few sources, but they are either located in the deep ocean, or in remote regions, or the raw material is in such forms that require large investments in the mining and processing. From 2000 to 2005, crude oil prices have pushed to the miners to invest in the development of deposits as much as $ 86 billion.

The epicenter of the gold rush of the XXI century is in the Canadian province of Alberta. Where the 140 000 km2 spread circumpolar forests, mineral wealth stored 174 billion. Barrels of oil. It discovered deposits is considered to be second in size in the world after Saudi Arabia's oil fields. However, it represents a reservoir of wet sand, mixed with bitumen - one of viscous hydrocarbons. Oil herein may contain from 10 to 12% of bitumen. Besides minerals covered 70-meter layer of clay soil, not counting sprawled on top of wetlands and woodlands.

The main industrial process to extract bitumen from the sand mixture is quite simple: tar sand is mixed with hot water and agitated, as a result of bitumen, water and sand are split into separate fractions. However, this method is not cheap. Development neftepeschanyh deposits cost-effective only at high world oil prices.

The largest companies operating in Alberta, - Suncor and Syncrude - began production in 1967 and 1968. Now they produce in the day about 560,000 barrels of oil. If you add a production company Shell, which is prey here since 2002, figures reached 720,000 barrels. Some experts predict that by the year 2020 of the oil sands will be produced on a daily basis up to 3 million. Barrels of clean oil.

"Capital" new "oil fever" - Fort McMurray. Once it was a sleepy little town, located 440 kilometers north of Edmonton and surrounded by dense forests. Now here it is based a whole army of 58 000 people. On the highway №63 pickups and buses transporting work crews, crawling slowly along the congested city. But after a few kilometers to the north taiga wilderness begins again. On the mean road sign: "Then you go at your own risk - the next 280 km on the road does not provide any service." It may seem that you have got away from the last frontiers of civilization.

But over the bend in the road begins a real nightmare industrial - endless brown desert quagmire of sand and mud. Here and there, from metal towers erupt into the sky in flames, clouds of steam and smoke in the mud are seen puddles of waste water and of toxic waste that around constantly popping special air gun, driving nearby birds, so they do not sit on a shiny oily water surface. In the midst of the lifeless kingdom rows stand-bedroom cabins for shift workers and their background crowded taken the break wheel steel giants.

Quarry "Maskeg river" is relatively small, but its area of 5 km2 pit could accommodate 120 stadiums mediocre. Many roads are twisted snakes down to the bottom. They are destined to remain in an unfinished state, since the failure of a giant is constantly expanding and deepening. Bulldozer shovel all the new heap the soil graders leveled them, go after them water tank and poured a brand new primer to nail dust and immediately let the roaring dump. The whole landscape - constantly moving and lumbering Symphony in the orchestra of the grandiose arrangements.

At the bottom of the man-made chasm geologists every 50 meters hit the pits and extract cores from layers deeper bedding. The office can be seen on the screens of all the cut plan, which is superimposed on a red grid. Each node of the grid are the number - the ratio of bitumen and sand at different depths. These relationships are called "ore grade". Four excavator working in a quarry at different levels (the fifth unit is used to remove the top layers of soil covering and expose the oil horizons). Trucks - 24 3-cylinder, 5-tysyachesilnye monster - do not stop for a minute.

By filling the body once again, trotting truck to the crusher: rents backing to the rocky cliffs and shakes his load into the mouth with a lot of giant steel rotating teeth. Every hour they milled nearly 15 000 tonnes of compact sandstone. "Hammer" semi-finished product is poured onto a conveyor belt (the largest in the world) and rides on it to the storage height with five-storey building.

From the tower elevator three pipeline will carry the raw materials to the family of radial drum crushers - there will mix with a relatively small lumps, in which hot water is added. The resulting slurry is pumped into the two-kilometer pipeline and further agitated on the way, so that the bitumen begins to emerge, and the sand - to settle. From pipe slurry is discharged into the primary separation capacity. Here, it will add more water and separation continues. At this stage, the mixture is called "white meadowfoam" - it 60% bitumen, 30% water and 10% total solids.

"Pennick" mixed with a special solvent (usually "heavy fuel") and receive "dilbit" ("diluted bitumen") - it is already possible to drive through the line almost to Edmonton. There, in the town of Fort Saskatchewan, are refining installation company Shell. Using hydrogen long hydrocarbon molecule bitumen torn to pieces in a cracking process to obtain a range of synthetic oil. On the oil sand deposits of Alberta there are 33 000 people. The usual mode - 12-hour shifts, 4 days and 5 days of rest.

Quarrying requires a lot of energy. On Maskege specially built 172-megawatt power plant operating on natural gas. It gives energy to work excavators, conveyors and other energy consuming equipment. Here, every day is burnt 17 million. M3 of gas, and it is only 10% of the total cost of the work. Such of daily energy would be enough to heat 3, 2 million. Canadian homes. Add that to produce each barrel of oil has to spend two to five barrels of water. Mining companies have a permit for the annual selection of 500 mln. Tons of water from the Athabasca River. According to Dan Voynilovich, leading analyst of a Canadian environmental activist, "no one yet knows where it all will lead».

Only 10% of the oil sands of Alberta, you can develop an open method. The rest of this field lies too deep, it is located in porous rocks and should be produced directly within the formation. It is much more complicated technology - earner couples should inject into the field, and then pumped to the surface, "mash" of water and bitumen. Environmentalists concerned about such technology is more than open development.

So are worth these hydrocarbon resources spent for these resources? Proponents of the theory known as "peak oil" (nominated by petroleum geologist King Hubbert), warned that we are approaching the top of the dynamics of world oil consumption and, as soon reach that peak, the remaining stocks will melt before our eyes, and no measures will not save the world from the global economic turmoil.

Of course, the manufacturers have their own opinion. Rayol Daughtery, senior analyst at the American Petroleum Institute, says: "We do not believe that the notorious rush will come until 2044. Perhaps they will be able to push back the horizon of the next century. High oil prices and the development of new technologies allows us to seek new frontiers. On this planet untold amounts of oil - the only question is, at what price and in what form ».

Meanwhile, in the town of Fort McMurray mansions and apartment buildings are mushrooming. Cash River Gold Rush act like a drug. "For all of us, - says John Martin excavator - a real Klondike. However, there is, of course ... come home, go to bed and dream still - scooped up, turned around, pour ... »

Where did these unusual sands and whether they like anywhere else on earth?

A bit of history

Yes, these sands and approximately the same kollichestve are in Venezuela.

And they were formed in the Cretaceous period, about 130 - 120 million years ago. While the climate of Alberta, however, as all of North America, was quite Warm humid. Almost the entire province was a bottom of the shallow and warm sea. And in this sea from the northeast runs a huge river, which forms a vast delta, constantly filling it with fine and clean sand - a product of the destruction of the Canadian-crystal panel.

You can envy - Tropical, warm, gentle, calm sea, clean, velvety sand and hundreds of kilometers of no man. And on land, in water and in the air full of life - among impenetrable forests and swamps of various dinosaurs roam, swim in the warm waters of ichthyosaurs and ammonites crawling, flying pterodactyls. All that is born, lives and dies ... and covered with new sediments of sand and sea mud.

And so, over the years, the Indians are in the steep banks of rivers have modern unusual, strange smelling something which is very good caulk their canoes. Later white settlers realized what it was and tried to extract oil from the sands. The first commercial production began in the 30 years of the twentieth century. But there was unprofitable - the technology was rather primitive. And only with the use of new methods of extraction and processing of sand mining industry has become urgent for Alberta. And it all began in the late 60s - early 70s of last century.

Who, Where and How to produces and processes oil sands?

As mentioned above, the first attempts to extract oil from the sands were undertaken in the first half of the twentieth century. It was a small quarry, used low-power technology, and rather primitive technology. All this makes getting oil uneconomical. But the human mind is not in place. Always replace the old comes the new, especially when the thought nothing and no one interferes. And on the "horizon" always loomed something like a mountain of petro-dollars.

And in the sixties of the last century roshlogo millennium with the direct support of the Government of Alberta began a new stage of development of the deposit TarSand. Create two oil companies "Syncrude" and "Suncor", which starts in the first place to develop deposits of sand open way - in large pits. Indeed, in some places the oil sands are deposited at a depth of 50-70 m. But these little places. Later, other oil companies have joined them. But the latter is already necessary to conduct underground mining.

The latest technology and research and development, immediately introduced into production, heavy and powerful machinery - excavators, dump trucks, bulldozers and graders, cranes and forklifts, etc.. Done the extraction and processing of oil, not only economically viable, but also quite profitable. Of course, not least in the economic benefits of developing sands plays and the price of oil.

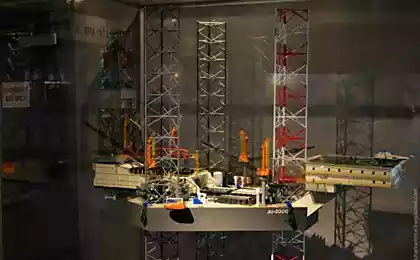

I would like to briefly talk about the unique technique with which has exploration and production, but also the construction of enrichment plants and refineries. For example, in quarries and construction sites operating the world's largest dump gruzopoemnostyu 400 m and a capacity of 3550 hp, bulldozers power of 935 hp, graders - up to 265 hp, shovels - bucket capacity up to 100 tons. But by the Giants used machinery and smaller - in the hundreds of names and modifications, which greatly facilitates the hard work of oil producers.

In the Canadian province of Alberta is an active industrial exploitation of forest areas. Along with forestry and mining are developing oil and gas fields. Getting There booming oil sands development further exacerbates the situation.

This is most clearly illustrated by the situation in Fort McMurray, a small town in the north of the province, where soaring housing prices. Until a few decades ago, it really was a real bear corner, and now is considered to be the center of the Canadian oil industry. Fort McMurray attracts thousands of people. But to get there appears to housing because of its lack of highly problematic.

And why?

Alberta (Canada) there are huge reserves of oil. At last count bituminozemnyh sands reserves in this province are 2, 0 bln. barrels. There are oil reserves in the Orinoco and Venezuela. Unfortunately, the world's oil reserves are estimated just one trillion. barrels (data for 2006). Therefore, the oil reserves in Alberta, the hoped. By 2020 it is planned to increase oil production in these areas in three times. And almost fivefold increase them by 2030.

With huge potential, the field, or rather oil production from these fields in the near future is not yet able to cover global demand for oil. This is explained by the fact that the currently existing technologies require large amounts of energy and fresh water. Energy consumption according to one account for 2/3 of the total costs for oil, others estimate their energy potential of oil in 1/5. Scientists are now dealing with this problem, but it is - the question of the future.

Although oil reserves in the sands bituminozemnyh great expectations.

Alberta Oil has a feature that distinguishes it from most of the oil-producing countries. In the province there are two types of oil, different from each other their origin, age and place of occurrence.

The first - a "conventional" oil, its age about 350 million years. It lies on the large, several kilometers deep in the so-called oil traps in the foothills of the Rocky Mountains and in the central parts of the province. For the first time this oil reserves found in 1947, 20 km south of Edmonton. This was the beginning of the oil boom in Alberta.

The second - is produced from oil, rather, the tar sands - Tar Sand. Sands of the (ancient river delta) saturated with bitumen, the average content of which reaches 82%. Their age - about 125 million. Years. They lie at depths of 50 to 500 meters. Stocks in terms of crude oil estimated at 1.6 trilionov barrels (1 barrel of oil = 160 liters) or 250 kub.km, of which about 200 billion barrels is possible to extract at suschestvuyuschth technologies. But, as is known, the latter does not stand still. At the moment of the Alberta oil sands receive more than 1.6-million barrels of oil per day.

The total area spread oil sands reaches 140 million square kilometers. They are divided into three fields, different bitumen content, depth and other parameters. The largest of them - Athabasca (name of a river flowing in the area) or, in fact, Tar Sand, located near the capital of oil sands - the town of Fort McMurrey.

Overhead, in the northern bright blue sky, but from the cab of the excavator Bucyrus 495 can not see it. Excavator John Martin hovers at the height of the third floor above the morass of mud and sand. In the air, though the ax hang from sulfuric stinks. But inside the cabin environment in a spacecraft, Martin conjures both hands on the remote control, such as those which are used in computer games. Deft movement of his fingers forced to move the entire backhoe - steel behemoth weighing a half thousand tons. Martin takes only 25 seconds to scoop up again about 70 tons of oily brown sand, turn 90 degrees, and dumped the whole bucket into the back of a yellow dump truck.

He scooped up, turned around, pour. Five buckets - and the body is full. He does not have time to dump drive off, and the right side by side-excavator is already waiting for the next car. A few minutes later, and she drives off with a full body, but on the left side there is another.

Scooped up, turned around, pour ...

Excavator repeats memorized movements almost round the clock for 365 days a year. The unit Bucyrus 495 worth more than $ 15 million. There are five of these, and they all work in the career of "Maskeg river" in 80 km from Fort Makmyurreya, Alberta. Yellow dump trucks Caterpillar 797B, which carry the extracted oil and dredge sand mixture - one of the world's largest machines of this class, and they cost under $ 5 million., But the cost of each pays for itself in the first week of work. On the career "Maskeg River" runs both 25 such trucks.

The whole modern world works almost exclusively on oil. All easily accessible deposits have exhausted promising only a few sources, but they are either located in the deep ocean, or in remote regions, or the raw material is in such forms that require large investments in the mining and processing. From 2000 to 2005, crude oil prices have pushed to the miners to invest in the development of deposits as much as $ 86 billion.

The epicenter of the gold rush of the XXI century is in the Canadian province of Alberta. Where the 140 000 km2 spread circumpolar forests, mineral wealth stored 174 billion. Barrels of oil. It discovered deposits is considered to be second in size in the world after Saudi Arabia's oil fields. However, it represents a reservoir of wet sand, mixed with bitumen - one of viscous hydrocarbons. Oil herein may contain from 10 to 12% of bitumen. Besides minerals covered 70-meter layer of clay soil, not counting sprawled on top of wetlands and woodlands.

The main industrial process to extract bitumen from the sand mixture is quite simple: tar sand is mixed with hot water and agitated, as a result of bitumen, water and sand are split into separate fractions. However, this method is not cheap. Development neftepeschanyh deposits cost-effective only at high world oil prices.

The largest companies operating in Alberta, - Suncor and Syncrude - began production in 1967 and 1968. Now they produce in the day about 560,000 barrels of oil. If you add a production company Shell, which is prey here since 2002, figures reached 720,000 barrels. Some experts predict that by the year 2020 of the oil sands will be produced on a daily basis up to 3 million. Barrels of clean oil.

"Capital" new "oil fever" - Fort McMurray. Once it was a sleepy little town, located 440 kilometers north of Edmonton and surrounded by dense forests. Now here it is based a whole army of 58 000 people. On the highway №63 pickups and buses transporting work crews, crawling slowly along the congested city. But after a few kilometers to the north taiga wilderness begins again. On the mean road sign: "Then you go at your own risk - the next 280 km on the road does not provide any service." It may seem that you have got away from the last frontiers of civilization.

But over the bend in the road begins a real nightmare industrial - endless brown desert quagmire of sand and mud. Here and there, from metal towers erupt into the sky in flames, clouds of steam and smoke in the mud are seen puddles of waste water and of toxic waste that around constantly popping special air gun, driving nearby birds, so they do not sit on a shiny oily water surface. In the midst of the lifeless kingdom rows stand-bedroom cabins for shift workers and their background crowded taken the break wheel steel giants.

Quarry "Maskeg river" is relatively small, but its area of 5 km2 pit could accommodate 120 stadiums mediocre. Many roads are twisted snakes down to the bottom. They are destined to remain in an unfinished state, since the failure of a giant is constantly expanding and deepening. Bulldozer shovel all the new heap the soil graders leveled them, go after them water tank and poured a brand new primer to nail dust and immediately let the roaring dump. The whole landscape - constantly moving and lumbering Symphony in the orchestra of the grandiose arrangements.

At the bottom of the man-made chasm geologists every 50 meters hit the pits and extract cores from layers deeper bedding. The office can be seen on the screens of all the cut plan, which is superimposed on a red grid. Each node of the grid are the number - the ratio of bitumen and sand at different depths. These relationships are called "ore grade". Four excavator working in a quarry at different levels (the fifth unit is used to remove the top layers of soil covering and expose the oil horizons). Trucks - 24 3-cylinder, 5-tysyachesilnye monster - do not stop for a minute.

By filling the body once again, trotting truck to the crusher: rents backing to the rocky cliffs and shakes his load into the mouth with a lot of giant steel rotating teeth. Every hour they milled nearly 15 000 tonnes of compact sandstone. "Hammer" semi-finished product is poured onto a conveyor belt (the largest in the world) and rides on it to the storage height with five-storey building.

From the tower elevator three pipeline will carry the raw materials to the family of radial drum crushers - there will mix with a relatively small lumps, in which hot water is added. The resulting slurry is pumped into the two-kilometer pipeline and further agitated on the way, so that the bitumen begins to emerge, and the sand - to settle. From pipe slurry is discharged into the primary separation capacity. Here, it will add more water and separation continues. At this stage, the mixture is called "white meadowfoam" - it 60% bitumen, 30% water and 10% total solids.

"Pennick" mixed with a special solvent (usually "heavy fuel") and receive "dilbit" ("diluted bitumen") - it is already possible to drive through the line almost to Edmonton. There, in the town of Fort Saskatchewan, are refining installation company Shell. Using hydrogen long hydrocarbon molecule bitumen torn to pieces in a cracking process to obtain a range of synthetic oil. On the oil sand deposits of Alberta there are 33 000 people. The usual mode - 12-hour shifts, 4 days and 5 days of rest.

Quarrying requires a lot of energy. On Maskege specially built 172-megawatt power plant operating on natural gas. It gives energy to work excavators, conveyors and other energy consuming equipment. Here, every day is burnt 17 million. M3 of gas, and it is only 10% of the total cost of the work. Such of daily energy would be enough to heat 3, 2 million. Canadian homes. Add that to produce each barrel of oil has to spend two to five barrels of water. Mining companies have a permit for the annual selection of 500 mln. Tons of water from the Athabasca River. According to Dan Voynilovich, leading analyst of a Canadian environmental activist, "no one yet knows where it all will lead».

Only 10% of the oil sands of Alberta, you can develop an open method. The rest of this field lies too deep, it is located in porous rocks and should be produced directly within the formation. It is much more complicated technology - earner couples should inject into the field, and then pumped to the surface, "mash" of water and bitumen. Environmentalists concerned about such technology is more than open development.

So are worth these hydrocarbon resources spent for these resources? Proponents of the theory known as "peak oil" (nominated by petroleum geologist King Hubbert), warned that we are approaching the top of the dynamics of world oil consumption and, as soon reach that peak, the remaining stocks will melt before our eyes, and no measures will not save the world from the global economic turmoil.

Of course, the manufacturers have their own opinion. Rayol Daughtery, senior analyst at the American Petroleum Institute, says: "We do not believe that the notorious rush will come until 2044. Perhaps they will be able to push back the horizon of the next century. High oil prices and the development of new technologies allows us to seek new frontiers. On this planet untold amounts of oil - the only question is, at what price and in what form ».

Meanwhile, in the town of Fort McMurray mansions and apartment buildings are mushrooming. Cash River Gold Rush act like a drug. "For all of us, - says John Martin excavator - a real Klondike. However, there is, of course ... come home, go to bed and dream still - scooped up, turned around, pour ... »

Where did these unusual sands and whether they like anywhere else on earth?

A bit of history

Yes, these sands and approximately the same kollichestve are in Venezuela.

And they were formed in the Cretaceous period, about 130 - 120 million years ago. While the climate of Alberta, however, as all of North America, was quite Warm humid. Almost the entire province was a bottom of the shallow and warm sea. And in this sea from the northeast runs a huge river, which forms a vast delta, constantly filling it with fine and clean sand - a product of the destruction of the Canadian-crystal panel.

You can envy - Tropical, warm, gentle, calm sea, clean, velvety sand and hundreds of kilometers of no man. And on land, in water and in the air full of life - among impenetrable forests and swamps of various dinosaurs roam, swim in the warm waters of ichthyosaurs and ammonites crawling, flying pterodactyls. All that is born, lives and dies ... and covered with new sediments of sand and sea mud.

And so, over the years, the Indians are in the steep banks of rivers have modern unusual, strange smelling something which is very good caulk their canoes. Later white settlers realized what it was and tried to extract oil from the sands. The first commercial production began in the 30 years of the twentieth century. But there was unprofitable - the technology was rather primitive. And only with the use of new methods of extraction and processing of sand mining industry has become urgent for Alberta. And it all began in the late 60s - early 70s of last century.

Who, Where and How to produces and processes oil sands?

As mentioned above, the first attempts to extract oil from the sands were undertaken in the first half of the twentieth century. It was a small quarry, used low-power technology, and rather primitive technology. All this makes getting oil uneconomical. But the human mind is not in place. Always replace the old comes the new, especially when the thought nothing and no one interferes. And on the "horizon" always loomed something like a mountain of petro-dollars.

And in the sixties of the last century roshlogo millennium with the direct support of the Government of Alberta began a new stage of development of the deposit TarSand. Create two oil companies "Syncrude" and "Suncor", which starts in the first place to develop deposits of sand open way - in large pits. Indeed, in some places the oil sands are deposited at a depth of 50-70 m. But these little places. Later, other oil companies have joined them. But the latter is already necessary to conduct underground mining.

The latest technology and research and development, immediately introduced into production, heavy and powerful machinery - excavators, dump trucks, bulldozers and graders, cranes and forklifts, etc.. Done the extraction and processing of oil, not only economically viable, but also quite profitable. Of course, not least in the economic benefits of developing sands plays and the price of oil.

I would like to briefly talk about the unique technique with which has exploration and production, but also the construction of enrichment plants and refineries. For example, in quarries and construction sites operating the world's largest dump gruzopoemnostyu 400 m and a capacity of 3550 hp, bulldozers power of 935 hp, graders - up to 265 hp, shovels - bucket capacity up to 100 tons. But by the Giants used machinery and smaller - in the hundreds of names and modifications, which greatly facilitates the hard work of oil producers.

In the Canadian province of Alberta is an active industrial exploitation of forest areas. Along with forestry and mining are developing oil and gas fields. Getting There booming oil sands development further exacerbates the situation.

This is most clearly illustrated by the situation in Fort McMurray, a small town in the north of the province, where soaring housing prices. Until a few decades ago, it really was a real bear corner, and now is considered to be the center of the Canadian oil industry. Fort McMurray attracts thousands of people. But to get there appears to housing because of its lack of highly problematic.

And why?