2777

Museum of the oil industry

Throughout the XX century in the XXI century oil is one of the most important for humanity minerals. I suggest you go to a museum of the oil industry in Galveston, Texas, and learn about the process of oil production and the life of the well during drilling

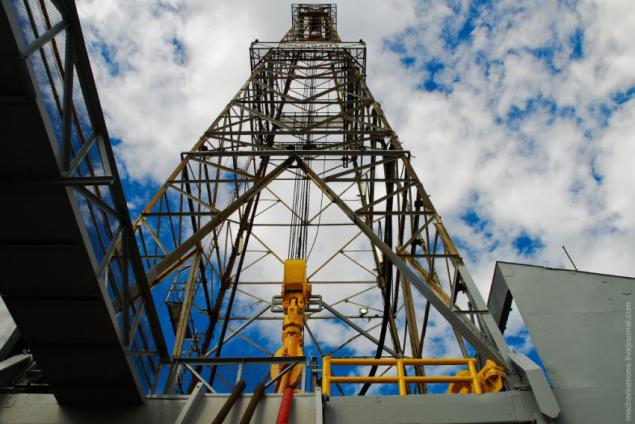

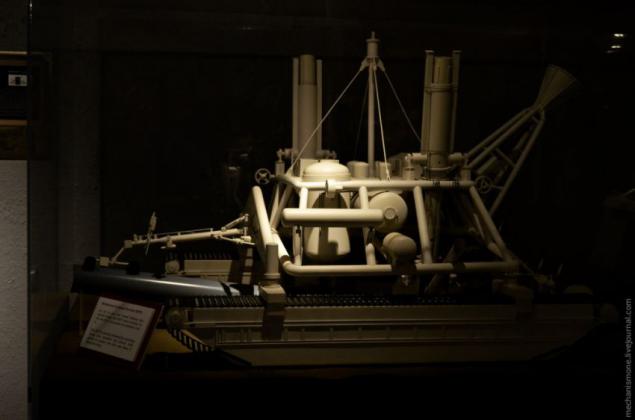

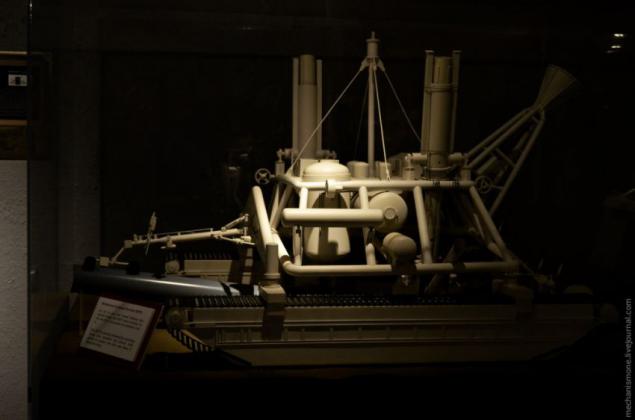

First of all, I will say a few words about the museum. The museum is located on a decommissioned mobile offshore platform with retractable legs «Ocean Star». Actually, this is the layout of the platform.

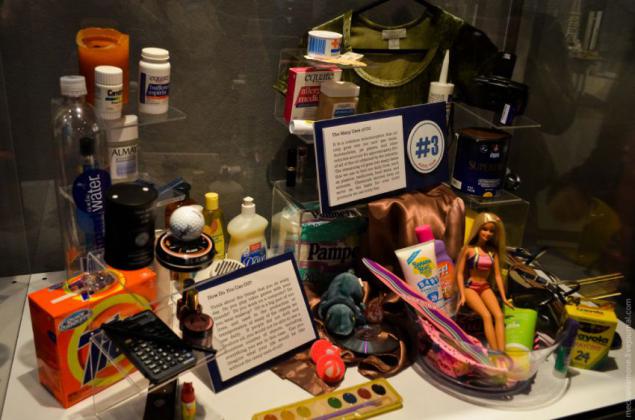

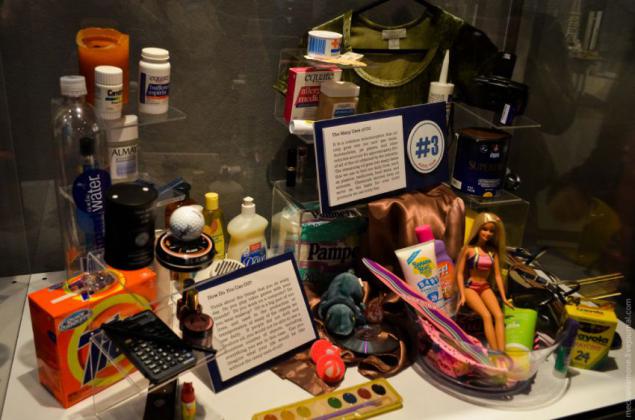

Today a lot of people, for some reason, the word is associated with the word oil gasoline, but not everyone knows that oil can now be found in almost all the things that surround us, and not only in things, as well as medications, food and household chemicals. Only about 70% of its oil goes to energy production, the remaining 30% are converted into a variety of things around us. This exhibition features items containing a mineral oil.

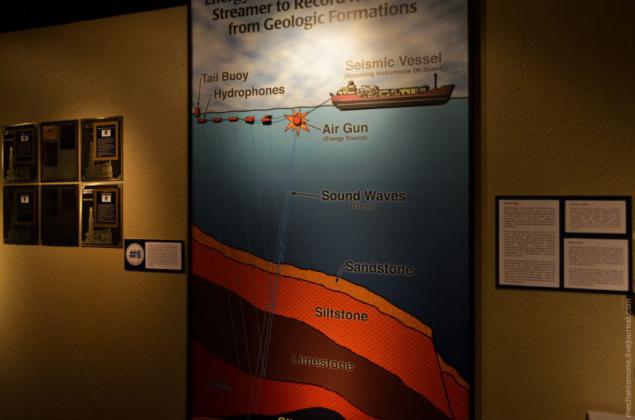

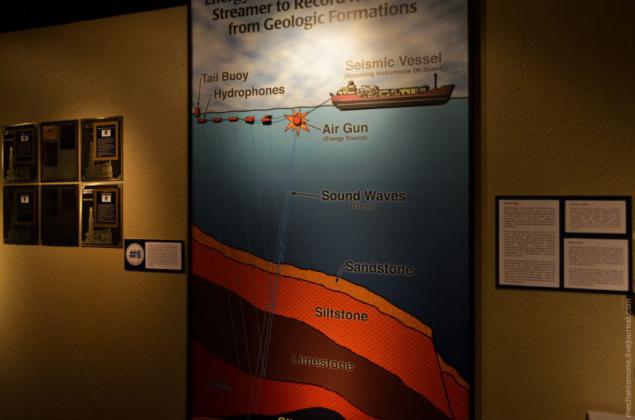

The process begins with the extraction of oil exploration seismic. In the sea seismic survey is conducted with the help of special ships, usually displacement of up to 3,000 tons. Such vessels unwound for a seismic streamers, which are located hydrophones (receivers) and create acoustic waves with the help of an oscillation source (airgun). Who are interested in the life and work on the ship - look cool video, tyts-tyts.

Acoustic shock waves are reflected from the layers of the earth, and returning to the surface captured by hydrophones. Incidentally, the very spit towed at a speed of 5 to 20 knots, a normal length of the spit is 3-4 km, the transport state braids are stored on the coils inside the ship.

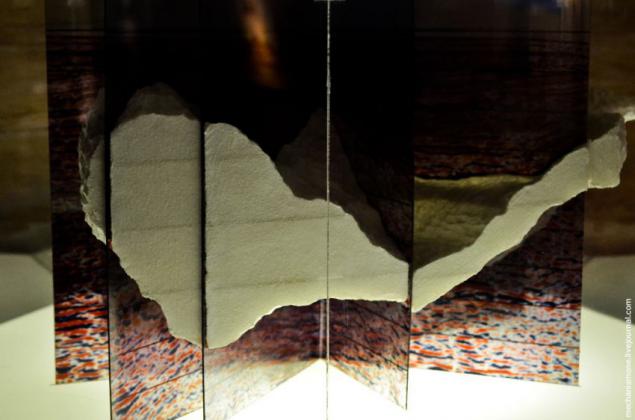

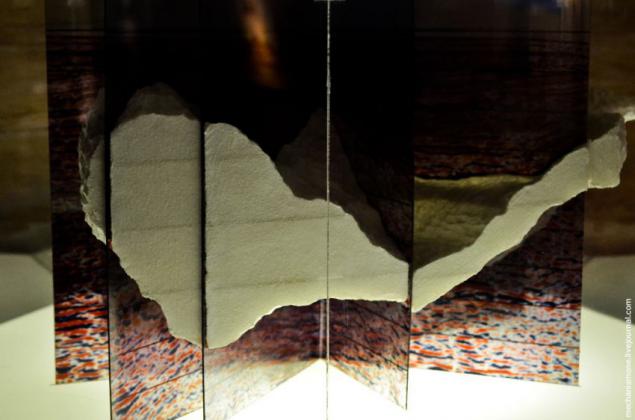

Thanks to these data it is possible to create two-dimensional and three-dimensional seismic maps that you can see the potential reservoirs of hydrocarbons.

On the ground, installed seismic streamers with receivers and acoustic oscillations are created with explosives or here are vibration machines.

Once a potential reservoir is found, start drilling exploration wells. The drilling process - it is a complex activity, which involves a 20 to 60 suppliers.

But before to drill in the sea, you need to prepare the site for it, the goal of the anchor (anchor) to the sea floor and stretch the cables fixing towers (if semi-submersible rig). These works deal with the special support vessels and divers.

Of course, in reality such vessels are somewhat different from the layout and size are huge barge-village, with a "population" of up to 100 people.

Without divers such a thing can not do. Here in such suits, divers are able to produce work to a depth of 100 meters. To work at great depths, divers suits slightly modified.

And that's become such. In such a space suit diver is able to produce work to a depth of 1000 meters. This range of models suit in 1978. By the way, plus such suits is that the diver does not feel pressure because inside this suit is maintained at normal atmospheric pressure, thus saving a lot of time going up and down divers to the place of work. On his back with a diver can carry a variety of tools.

What to do if you want to work on the pipeline at a depth of two kilometers? Do not worry, this is the case in the arsenal of oil workers have a squad of different robots. Such a robot can operate at depths of up to three kilometers and has on all the necessary equipment. And can be located at a depth of a few days.

Then the marine tower transported to the place of its setting by the sea tug, if drilling location is situated near the coastline, or tower carrying on board transporter.

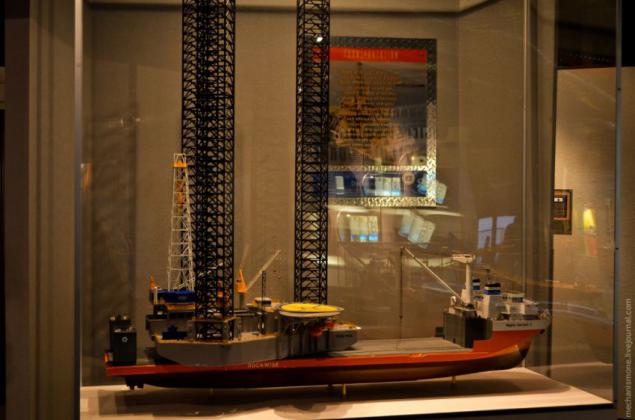

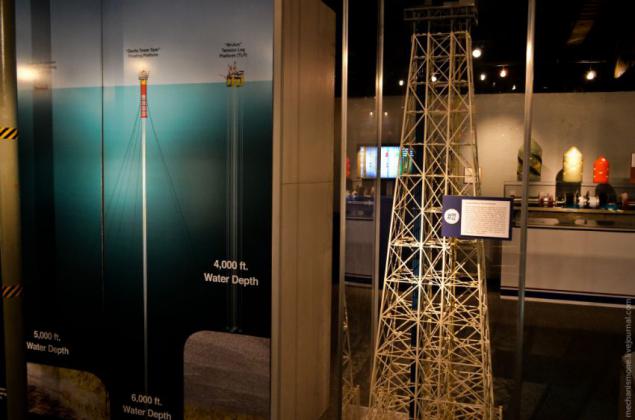

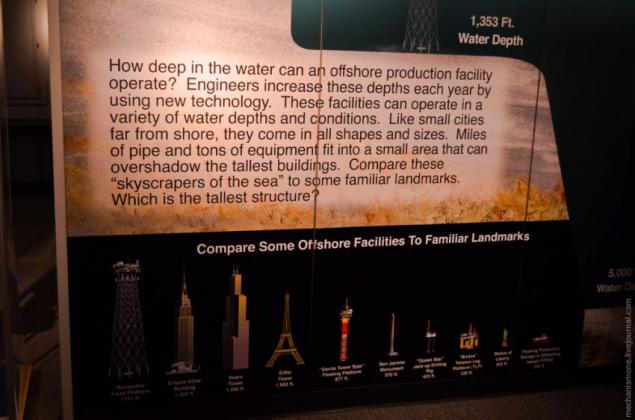

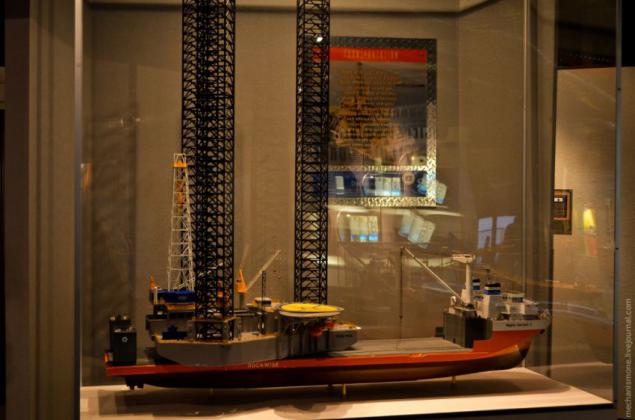

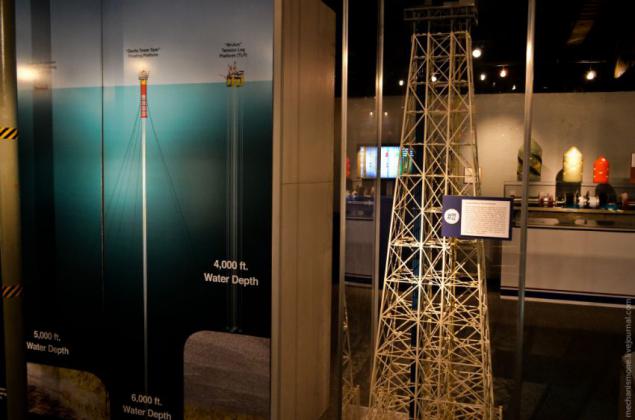

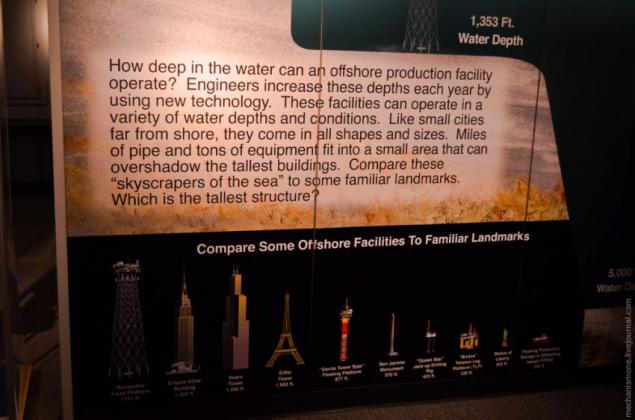

Offshore platforms are available in various types: fixed, fixed to the bottom freely, semi-submersible mobile with retractable legs. Not all are scale drilling platforms, here are some interesting comparisons. This model is the base platform Bullwinkle, located in the Gulf of Mexico. Height of the base platform - 533 meters, of which 412 are under water. The diameter of the main pipe - 3 meters, the base area - 1.8 ha and the drilling rig deck - 3350 meters. 28 piles were scored through the tube base to a depth of 122 meters into the seabed to keep the structure from sea currents. The total weight of the base - 69 854 metric tonnes.

Semi-submersible platforms are not smaller. This refining platform Devils Tower, operating in the Gulf of Mexico. The platform operates at a depth of 1,706 meters, producing about 90,000 barrels of oil per day. The total length of the submersible platform is 267 meters. For better stabilization of towers, tanks platform is oil, providing ultra center of gravity, making the tower is very resistant to storm waves and gale-force winds at sea.

Comparison of drilling platforms with famous buildings in the world.

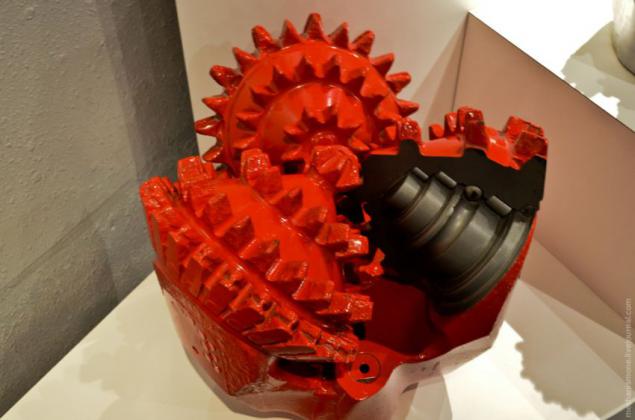

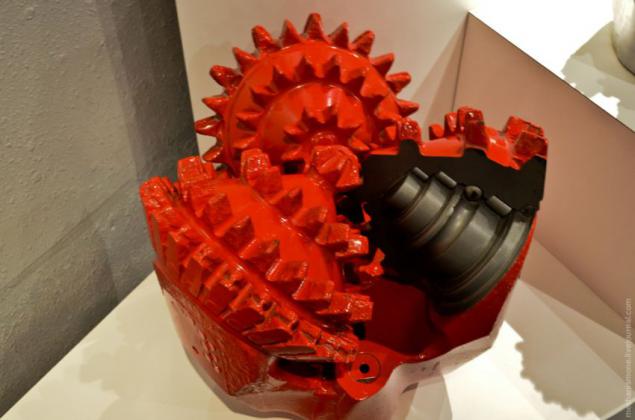

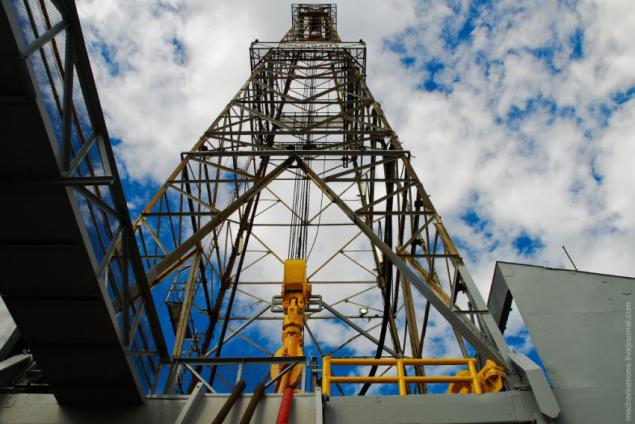

After installing the rig begins excavation hole through rock breaking chisel. Well take place not on the "one go", as many think, but in several stages.

Drilling may be carried out in the same drill ship. Ships in the drilling process has several advantages, but the main thing - mobility, after the drilling vessel can be easily replaced by processing platform. Drilling vessels are capable of producing clay to a depth of 3700 meters and 6-8 screws steer the ship remain exactly the position of the coordinates of the satellite, up to half a meter. Team members usually has 150-200 people.

With each step drill bit size is changed to smaller, in a sense, well - it matryoshka.

First, the largest bit traversed the upper section of the well, which is called the direction of its diameter is usually from 16 to 34 inches, and the depth of penetration of about 50-100 meters.

This prevents erosion of the slaughter of the well, and also allows you to set preventer. After drilling, the drill string is raised and lowered into the well casing, and then the annulus is cemented. About cementing describe below.

After that, the smaller the bit is passed and upset the conductor, then the intermediate or technical pipe, and finally the production string. By the time the production casing drilling bit usually has a diameter of 12.25, 8.75, or 7.875 inches. As I mentioned above, at each stage of rainfall occurs pipe cementing the annulus. This is done for several reasons: firstly, to liquid natural not "walk" up and down the annulus. Few people know that usually at a depth of 1500 meters water becomes salty and impure hydrogen sulfide, so mixing this water with pure underground sources of undesirable. Secondly, the cement column will prevent corrosion and pressure reservoirs, thus significantly extends the life of the column.

There are many ways and forms of well cementing, but they are essentially reduced by one. With compressors of special cement mortar is fed into the casing, and then the pressure "squeezes" down and entering the annular space through the well bottom, the cement begins to rise upward now cementing casing and insulating. Actually that's what a mixer and pump slurry feed to the wellhead.

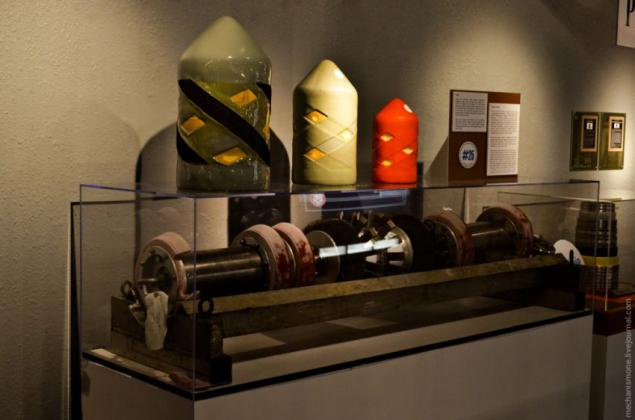

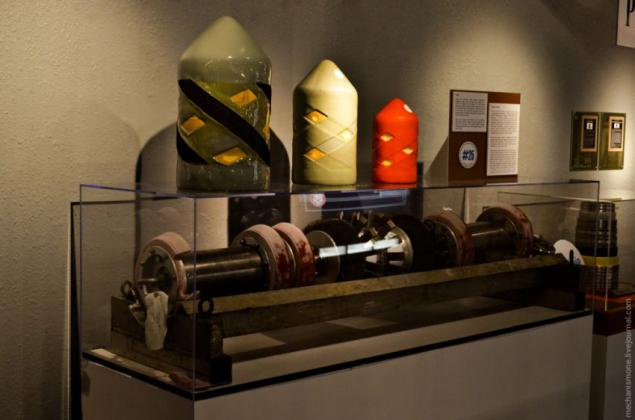

This cement "pig" or plug. It is thrown into the well before cementing, then top starts to be supplied grout, and then, when the piglet reaches the bottom of the face, it will pave the way mortar, which passes through the pig in the annulus. After cementing the wellbore throw another pig for cleaning the walls and replacement mortar inside the casing a drilling fluid (white mass at the bottom - is a cement). Through them grout stored in pure form or mixed with the drilling fluid.

Once completed the drilling of an oil reservoir, the drill string to the bit raised from the borehole geophysical logging and conduct an open hole. Open, because in the well until nothing. Logging is carried out with the help of special lifts, both mobile and stationary.

During a logging cable to a well drained geophysical string which is composed of various instruments (magnetic, radioactive, acoustic, etc.), and determine the geophysical characteristics of the various species (permeability resistance, oil saturation, etc.). In addition to direct research conducted secondary species, such as determined by the required amount of cement for further cementing the well or accurately determined depth of the well and the depth of the previous casing.

Just in the drilling process can take soil samples for laboratory tests.

They may be taken in the process by means of geophysical logging string.

Logging occurs just after cementing wells for the determination of the integrity of the cement in the annulus. Generally, modern tools can immediately tell if the oil in the rocks or not, determine the pressure, take samples of fluids and rocks, make a three-dimensional model for subsequent fracturing and to do a lot of things previously unimaginable.

After precipitation and cementing production casing, the well is completely isolated from the external environment, as then the oil gets into the well? On cable lift is lowered into the borehole with an explosive charge, and then to the desired depth, thanks to a particular open hole logging detaniruetsya it. Explosives creates holes in the steel casing pipe, and then penetrates the cement rocks. Modern explosives can penetrate rocks to a depth of 2 meters. Actually, the above cycle is presented in this picture with captions.

After the well is drilled, the process does not end there, now we need to lay pipelines to plants. Engaged in this special pipelay vessels. Their deck is continuous pipeline welding, whereupon the finished pipe is lowered to the seabed. By the way, do not think that such a sturdy steel, under its own weight it bends like straw, and a pipe with a wall thickness of a few centimeters bend very easily.

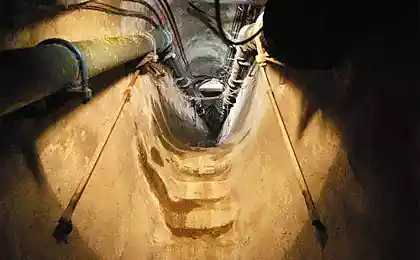

For Pipelayers usually creeps "digger". Such a robot hides laid pipe in the trench, as they say, from sin away.

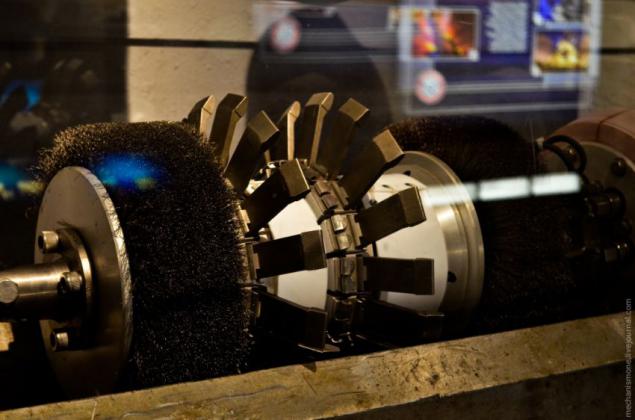

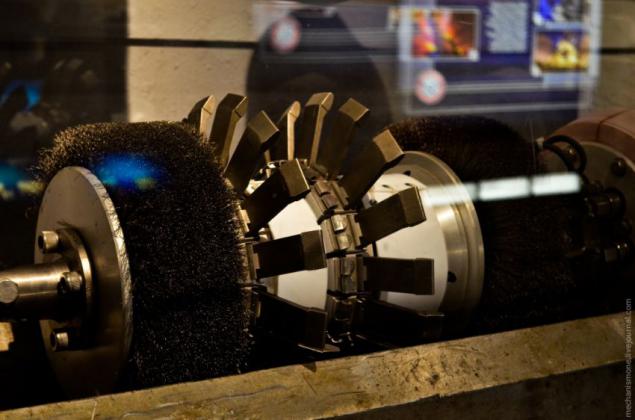

Well, after the pipeline is laid, its clean before starting. For this purpose, another pig, not to be confused with the cement pig. This pig is forced through the pipe water pressure along the way it cleans and inspects the pipe joints and the integrity of the pipe.

These pigs "crawl" through the pipes and pipelines in operation, it is done for cleaning pipes of paraffin deposits, their examination, changes in liquid flows through pipes and many other purposes.

In addition to the pipelines of the wells is necessary to lay a large number of communication cables and control. Cable just fit in the pipes, as a rule. In addition to cable carries a wide variety of hydraulic lines and communication lines are heated with steam. On the seabed rather cold, and no heating hydraulics can freeze, so the operating temperature of the mechanisms supported by means of steam.

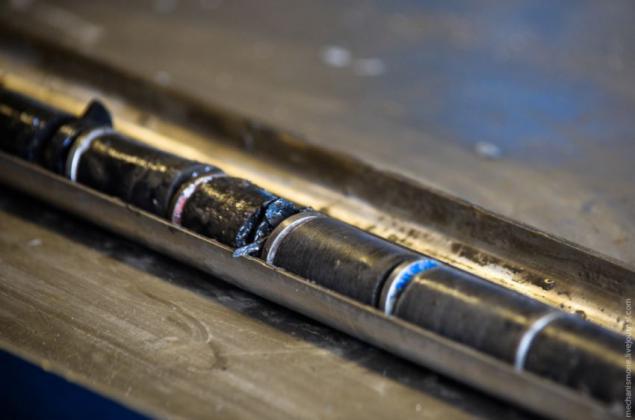

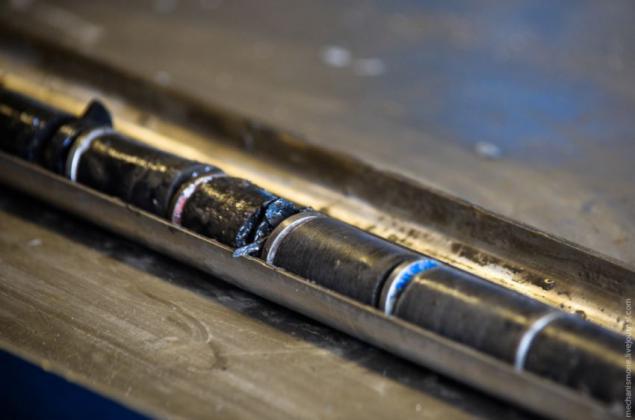

Communication cable in the cut. One meter of the cable, depending on the materials and equipment, may be worth up to $ 2 000. It is very expensive.

After the wells were drilled, a drilling platform or a floating vessel replaced tower storage and refining.

Such vessel or platform is connected to the wells drilled in the bottom of the sea, followed by purification of crude oil from impurities and provides shipment of finished products in tankers or delivers oil to refineries through pipelines.

It looks something like this.

Here is the processing platform. This model platform Harvest. By the way, all the pipes in the towers painted not arbitrary, color tubes associated with the type of liquid. White tube - air, black - drainage, yellow - gas, gold - oil, green - mud, etc ...

Drilling - very expensive. I already wrote the price, but I will repeat again (approximate prices per day of work):

- $ 7000 - Vessel delivery personnel at the tower or towers;

- $ 40,000 - supply ship;

- $ 50 000- tug;

- $ 77,000 - Support barge with a crane;

- $ 160,000 - offshore platform with retractable legs;

- $ 314,000 - offshore platforms, freely fixed to the bottom;

- $ 480,000 - a drilling ship.

Well, a couple of interesting points. A lot of talk about the dangers of oil spills during drilling. I am with this view is not entirely agree. Since 1975, drilling in the Gulf of Mexico has a safety rating of 99.999%, ie but only 0.001% of crude oil was spilled into the sea. During the period from 1993 to 2007 was recorded 651 spills, the total amount of 47,800 barrels, with production of 7.5 billion barrels. In other words, the oil spill in the Gulf are negligible in comparison with the volume extracted.

Another point. Teleportation from the deck of the ship on deck offshore platform happens here in this basket, which is lifted by crane. If you think that you have to sit inside - you're wrong. Sit, or rather hang, you have the outside of the basket and will lie inside your stuff. This is done for security in the event of breakage baskets, you do not become entangled in the net and drowned.

From time to time I am asked about the strength of attachment of drilling pipes, this incision mounting drill pipe diameter of 5.5 inches. Typically, the threaded fixation of the pipe is much stronger, and in which case, the tube "burst" is not the point of attachment.

Wall of Honor.

Source: kak-eto-sdelano.livejournal.com

First of all, I will say a few words about the museum. The museum is located on a decommissioned mobile offshore platform with retractable legs «Ocean Star». Actually, this is the layout of the platform.

Today a lot of people, for some reason, the word is associated with the word oil gasoline, but not everyone knows that oil can now be found in almost all the things that surround us, and not only in things, as well as medications, food and household chemicals. Only about 70% of its oil goes to energy production, the remaining 30% are converted into a variety of things around us. This exhibition features items containing a mineral oil.

The process begins with the extraction of oil exploration seismic. In the sea seismic survey is conducted with the help of special ships, usually displacement of up to 3,000 tons. Such vessels unwound for a seismic streamers, which are located hydrophones (receivers) and create acoustic waves with the help of an oscillation source (airgun). Who are interested in the life and work on the ship - look cool video, tyts-tyts.

Acoustic shock waves are reflected from the layers of the earth, and returning to the surface captured by hydrophones. Incidentally, the very spit towed at a speed of 5 to 20 knots, a normal length of the spit is 3-4 km, the transport state braids are stored on the coils inside the ship.

Thanks to these data it is possible to create two-dimensional and three-dimensional seismic maps that you can see the potential reservoirs of hydrocarbons.

On the ground, installed seismic streamers with receivers and acoustic oscillations are created with explosives or here are vibration machines.

Once a potential reservoir is found, start drilling exploration wells. The drilling process - it is a complex activity, which involves a 20 to 60 suppliers.

But before to drill in the sea, you need to prepare the site for it, the goal of the anchor (anchor) to the sea floor and stretch the cables fixing towers (if semi-submersible rig). These works deal with the special support vessels and divers.

Of course, in reality such vessels are somewhat different from the layout and size are huge barge-village, with a "population" of up to 100 people.

Without divers such a thing can not do. Here in such suits, divers are able to produce work to a depth of 100 meters. To work at great depths, divers suits slightly modified.

And that's become such. In such a space suit diver is able to produce work to a depth of 1000 meters. This range of models suit in 1978. By the way, plus such suits is that the diver does not feel pressure because inside this suit is maintained at normal atmospheric pressure, thus saving a lot of time going up and down divers to the place of work. On his back with a diver can carry a variety of tools.

What to do if you want to work on the pipeline at a depth of two kilometers? Do not worry, this is the case in the arsenal of oil workers have a squad of different robots. Such a robot can operate at depths of up to three kilometers and has on all the necessary equipment. And can be located at a depth of a few days.

Then the marine tower transported to the place of its setting by the sea tug, if drilling location is situated near the coastline, or tower carrying on board transporter.

Offshore platforms are available in various types: fixed, fixed to the bottom freely, semi-submersible mobile with retractable legs. Not all are scale drilling platforms, here are some interesting comparisons. This model is the base platform Bullwinkle, located in the Gulf of Mexico. Height of the base platform - 533 meters, of which 412 are under water. The diameter of the main pipe - 3 meters, the base area - 1.8 ha and the drilling rig deck - 3350 meters. 28 piles were scored through the tube base to a depth of 122 meters into the seabed to keep the structure from sea currents. The total weight of the base - 69 854 metric tonnes.

Semi-submersible platforms are not smaller. This refining platform Devils Tower, operating in the Gulf of Mexico. The platform operates at a depth of 1,706 meters, producing about 90,000 barrels of oil per day. The total length of the submersible platform is 267 meters. For better stabilization of towers, tanks platform is oil, providing ultra center of gravity, making the tower is very resistant to storm waves and gale-force winds at sea.

Comparison of drilling platforms with famous buildings in the world.

After installing the rig begins excavation hole through rock breaking chisel. Well take place not on the "one go", as many think, but in several stages.

Drilling may be carried out in the same drill ship. Ships in the drilling process has several advantages, but the main thing - mobility, after the drilling vessel can be easily replaced by processing platform. Drilling vessels are capable of producing clay to a depth of 3700 meters and 6-8 screws steer the ship remain exactly the position of the coordinates of the satellite, up to half a meter. Team members usually has 150-200 people.

With each step drill bit size is changed to smaller, in a sense, well - it matryoshka.

First, the largest bit traversed the upper section of the well, which is called the direction of its diameter is usually from 16 to 34 inches, and the depth of penetration of about 50-100 meters.

This prevents erosion of the slaughter of the well, and also allows you to set preventer. After drilling, the drill string is raised and lowered into the well casing, and then the annulus is cemented. About cementing describe below.

After that, the smaller the bit is passed and upset the conductor, then the intermediate or technical pipe, and finally the production string. By the time the production casing drilling bit usually has a diameter of 12.25, 8.75, or 7.875 inches. As I mentioned above, at each stage of rainfall occurs pipe cementing the annulus. This is done for several reasons: firstly, to liquid natural not "walk" up and down the annulus. Few people know that usually at a depth of 1500 meters water becomes salty and impure hydrogen sulfide, so mixing this water with pure underground sources of undesirable. Secondly, the cement column will prevent corrosion and pressure reservoirs, thus significantly extends the life of the column.

There are many ways and forms of well cementing, but they are essentially reduced by one. With compressors of special cement mortar is fed into the casing, and then the pressure "squeezes" down and entering the annular space through the well bottom, the cement begins to rise upward now cementing casing and insulating. Actually that's what a mixer and pump slurry feed to the wellhead.

This cement "pig" or plug. It is thrown into the well before cementing, then top starts to be supplied grout, and then, when the piglet reaches the bottom of the face, it will pave the way mortar, which passes through the pig in the annulus. After cementing the wellbore throw another pig for cleaning the walls and replacement mortar inside the casing a drilling fluid (white mass at the bottom - is a cement). Through them grout stored in pure form or mixed with the drilling fluid.

Once completed the drilling of an oil reservoir, the drill string to the bit raised from the borehole geophysical logging and conduct an open hole. Open, because in the well until nothing. Logging is carried out with the help of special lifts, both mobile and stationary.

During a logging cable to a well drained geophysical string which is composed of various instruments (magnetic, radioactive, acoustic, etc.), and determine the geophysical characteristics of the various species (permeability resistance, oil saturation, etc.). In addition to direct research conducted secondary species, such as determined by the required amount of cement for further cementing the well or accurately determined depth of the well and the depth of the previous casing.

Just in the drilling process can take soil samples for laboratory tests.

They may be taken in the process by means of geophysical logging string.

Logging occurs just after cementing wells for the determination of the integrity of the cement in the annulus. Generally, modern tools can immediately tell if the oil in the rocks or not, determine the pressure, take samples of fluids and rocks, make a three-dimensional model for subsequent fracturing and to do a lot of things previously unimaginable.

After precipitation and cementing production casing, the well is completely isolated from the external environment, as then the oil gets into the well? On cable lift is lowered into the borehole with an explosive charge, and then to the desired depth, thanks to a particular open hole logging detaniruetsya it. Explosives creates holes in the steel casing pipe, and then penetrates the cement rocks. Modern explosives can penetrate rocks to a depth of 2 meters. Actually, the above cycle is presented in this picture with captions.

After the well is drilled, the process does not end there, now we need to lay pipelines to plants. Engaged in this special pipelay vessels. Their deck is continuous pipeline welding, whereupon the finished pipe is lowered to the seabed. By the way, do not think that such a sturdy steel, under its own weight it bends like straw, and a pipe with a wall thickness of a few centimeters bend very easily.

For Pipelayers usually creeps "digger". Such a robot hides laid pipe in the trench, as they say, from sin away.

Well, after the pipeline is laid, its clean before starting. For this purpose, another pig, not to be confused with the cement pig. This pig is forced through the pipe water pressure along the way it cleans and inspects the pipe joints and the integrity of the pipe.

These pigs "crawl" through the pipes and pipelines in operation, it is done for cleaning pipes of paraffin deposits, their examination, changes in liquid flows through pipes and many other purposes.

In addition to the pipelines of the wells is necessary to lay a large number of communication cables and control. Cable just fit in the pipes, as a rule. In addition to cable carries a wide variety of hydraulic lines and communication lines are heated with steam. On the seabed rather cold, and no heating hydraulics can freeze, so the operating temperature of the mechanisms supported by means of steam.

Communication cable in the cut. One meter of the cable, depending on the materials and equipment, may be worth up to $ 2 000. It is very expensive.

After the wells were drilled, a drilling platform or a floating vessel replaced tower storage and refining.

Such vessel or platform is connected to the wells drilled in the bottom of the sea, followed by purification of crude oil from impurities and provides shipment of finished products in tankers or delivers oil to refineries through pipelines.

It looks something like this.

Here is the processing platform. This model platform Harvest. By the way, all the pipes in the towers painted not arbitrary, color tubes associated with the type of liquid. White tube - air, black - drainage, yellow - gas, gold - oil, green - mud, etc ...

Drilling - very expensive. I already wrote the price, but I will repeat again (approximate prices per day of work):

- $ 7000 - Vessel delivery personnel at the tower or towers;

- $ 40,000 - supply ship;

- $ 50 000- tug;

- $ 77,000 - Support barge with a crane;

- $ 160,000 - offshore platform with retractable legs;

- $ 314,000 - offshore platforms, freely fixed to the bottom;

- $ 480,000 - a drilling ship.

Well, a couple of interesting points. A lot of talk about the dangers of oil spills during drilling. I am with this view is not entirely agree. Since 1975, drilling in the Gulf of Mexico has a safety rating of 99.999%, ie but only 0.001% of crude oil was spilled into the sea. During the period from 1993 to 2007 was recorded 651 spills, the total amount of 47,800 barrels, with production of 7.5 billion barrels. In other words, the oil spill in the Gulf are negligible in comparison with the volume extracted.

Another point. Teleportation from the deck of the ship on deck offshore platform happens here in this basket, which is lifted by crane. If you think that you have to sit inside - you're wrong. Sit, or rather hang, you have the outside of the basket and will lie inside your stuff. This is done for security in the event of breakage baskets, you do not become entangled in the net and drowned.

From time to time I am asked about the strength of attachment of drilling pipes, this incision mounting drill pipe diameter of 5.5 inches. Typically, the threaded fixation of the pipe is much stronger, and in which case, the tube "burst" is not the point of attachment.

Wall of Honor.

Source: kak-eto-sdelano.livejournal.com