2726

Russian traditional furnace - working principle, advantages and disadvantages, the construction of their own

Russian stove is not extinguished never. She slowly flickered in his area in the industrialization, electrification, gasification, and has always been the object of attention of specialists due to its wonderful qualities.

Now Russian stove is experiencing a rebirth; a significant role was played by her efficiency, omnivorous and the opportunity to build with their hands, expensive materials and complex industrial equipment is not required. What good is it, what her secrets where it is impossible to build?

From personal experience

The author of this article in childhood and early youth, many was visiting his grandmother in the village, in the Russian Outback in the summer and winter vacations. Relish namaw side to the Russian stove with stove bench, he was eager to build the same in a city apartment. It was absolutely feasible, but was accumulated fairly extensive material on Russian stoves of different types, that had very useful when writing the article. The observations were carried out from 1961 to 1972, the Furnace was built after the liberation of those places (Orel) from the Nazis in 1943-45.

Classic Russian stove

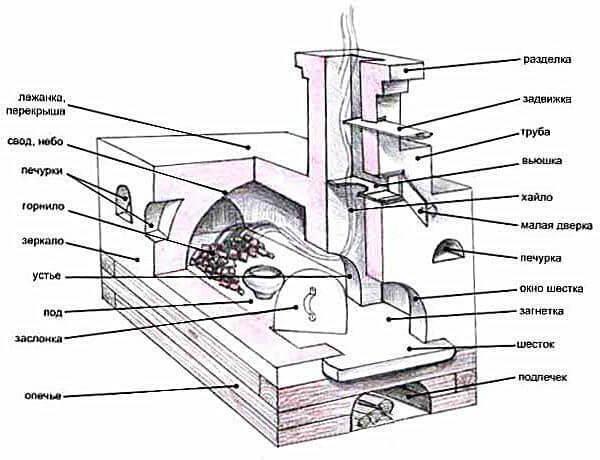

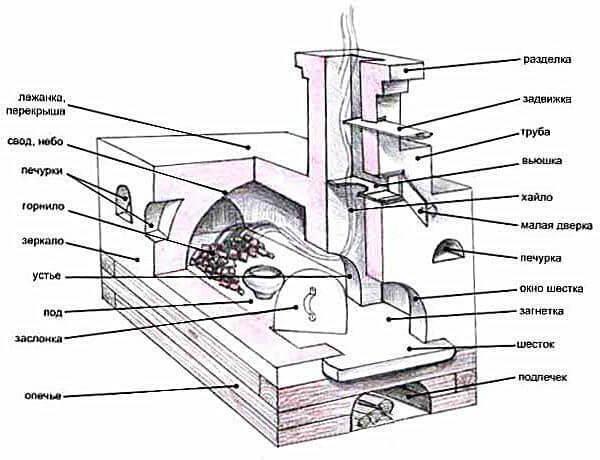

Russian stove was highly polymorphic design. Only traditional stoves were different, even from hut to hut in the same village. And the works of unknown but savvy stove-makers and scientists, especially Podgorodnikov I. S. and I. V. Kuznetsova, has created many designs based on common principles. All of their survey in the same publication it is impossible even briefly, therefore, further concerns mainly the classical Russian furnace (see Fig.), and improvements are described in General terms.

Curious: the vault of the crucible of one of the kilns were made from the halves of the large cylinder of the internal combustion engine. Tank or jet, our or German – is unknown.

Theory and the secrets

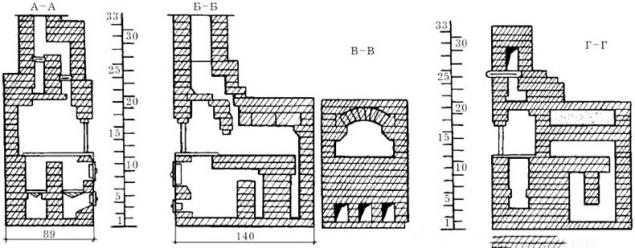

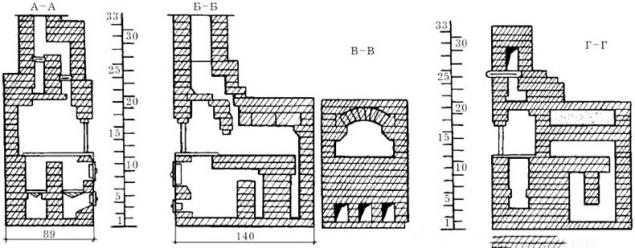

The fundamental unit of the Russian furnace is shown in the figure. From a lateral incision to understand its secrets. Understanding them, will receive its advantages/disadvantages, and then move on to the description of the structure. In conclusion describes modern high-performance designs.

The scheme of the Russian stove

Russian stove rests on a Foundation – Apache, wood, stone, brick or concrete. Podpack used to store fuel that it dries "to the gunpowder" and easily erupted during heating. Top podpack closed semicircular arch (set-trough). The arch is filled with water from thermal material: sand, brick chips on a clay solution, and the bedding dry, without mortar, is laid under the cooking chamber constituting the front part of the furnace.

Important: if you lay under the bedding without hearth baking will never get "real". By the way, for "nastasescu" bread and pies to bake on cabbage leaves. With fresh milk – m-m-mmm!!!

Russian stove – the heating device of periodic action: while not a very long firing it accumulates heat and then about a day warm, giving, and bringing it up to standard culinary delights. To understand her work, follow the flow of air.

Secrets begin to zagnetko (some say "zinetac or zagnetko") with its finial – peretrube – ending tapering nozzle – YAP. The side walls in zagnetko made caverns – ash to ash collection and storage of embers for the next fire.

Notes:

1. Often the hole for the ash and coals do the hearth – stone or cast-iron stove, a prominent brow (face) of the furnace. Then it is called celcom.

2. Mansion window surrounds in furnaces purity's sake, but in the poorest, to reduce the cost of the work, ocelot and ash pan did not. Ash raked the coals and kept in pors'k – inside the cavern-side of the mouth, see below. In this case, the coals kept the heat of the day, only when using birch, oak, fazovymi or maple wood, on which was superimposed on top of aspen. Perhaps because of this, and the conviction has remained in the nicety of the Russian stove. In fact, she eats any solid fuel: firewood, brushwood, straw, twigs (dry weeds), dung, anthracite, coal seed, peat briquettes, corpocracy, sawdust. But to make bread you only need wood or charcoal. Otherwise the taste will be shopping.

In General zinetac, scientifically speaking, gas economizer, which recovers energy: flue gases (diveboat) preheat the incoming furnace air, not taking away his oxygen. Mixing of streams does not occur: a paper strip of the zone of turbulence is not detected. The thermometer on the hearth zagnetko showed the increase of temperature from the throat to the mouth from room to more than 76 degrees (column reaches the limit, the alcohol was boiling and the thermometer burst).

Important: to oven not smoked, did not work voracious and quickly cooling, to withstand indicated in the figure, the size and especially the smoothness of the walls haila. Plastering zinetac not, so the bricks of the walls haila chip and grind until smooth. In fuming furnaces a piece of paper, especially when using bulk glow fuel, found turbulence in peretrube. In furnaces with a smooth current of gases YAP was always laminar. It is easy to understand that the turbulence in zagnetko the air will go into the furnace oxygen-depleted.

The heart of the Russian stove – furnace. It is divided into the cooking chamber (bakery) and the furnace firebox. In a small furnace (2,5x1,75 feet in plan; 1780х1240 mm) under entire furnace spread with a uniform rise posteriorly at 60-90 mm. In large (3,25x2,25 feet; 2310х1600 mm) and mostly in the middle (3x2 feet; 2130х1470 mm) experienced potters spread it with a kink in the middle (large) or third (in the middle) to the cast iron stood smoothly and steadily. But under the crucible must be sloping, and size, as specified, and not on an angle. By the way, the height of the shelf (cots) from the floor in the "Domostroy" – 2.5 feet.

Dimensions are approximate Russian stoves. The length of the yard in different regions ranged. Potters dancing with bricks in length, width and height of the furnace has to meet a whole number of them, given the layers of mortar.

The hot air is already involved in cooking, warming dishes below. He then goes to the fuel; the flue gases rise to the ceiling of the furnace. He is also inclined, but it should be, than under. Best heated furnace, in which furnace, in plan, tapers to the mouth of the same 60-90 mm.

A strip of foil on a stick found under the arch of the furnace two stable in any mode of combustion of oppositely directed vortex (circulation). Two of the vortex, presumably, this is the most important secret of Russian furnace. Their torques cancel each other, and zagnetko, despite the presence of the nut, visible turbulence is not formed. In the ovens too low or high sill circulation was weak and unstable.

The second assignment of vortices in the furnace – delay unburned fuel particles. Before leaving the mouth, they are doing a few (maybe a lot of turns) and completely burned at a relatively low temperature. Emitted by the IR evenly heats the cookware with cooking. In the middle of the height of the bakery moving gases were not detected.

Important: the food is prepared WITHOUT CONTACT WITH FIRE AND OVERHEATED GASES at the optimum temperature, therefore, the pyrolysis products is suppressed, carcinogens, toxins it is not formed.

Notes:

1. Potters-aces the vault of the crucible do not semicircular, and the three-center barrel, as shown in the figure are smoothed by a dotted line. Also at 90 mm at the same userauth the crucible in the middle. In such a furnace burning 100%: she never smokes and does not give sparks.

2. The infrared rays in the crucible – one of the secrets of Russian cuisine. Dishes such as daily soup or pie Paglia, must then. and remove the coal for a long time to languish in the crucible. To achieve such a mode of cooking in the gas oven or impossible. And crust so no grill does not get it. But the hostess needs to know that the temperature in the furnace varies from 350 to 150 degrees, counting from the fire to the mouth. Depending on the desired cooking mode you need to place the dishes and move them with tongs or a dovetail. So cooking in the Russian oven requires skill and dexterity, the townspeople know.

Finally, return to zinetac. Here we not only heat up the air, but and maintain hot cooked food for today (the hostess until the next morning to do other things), and the remainder of the heat give up the body furnace in peretrube with YAP. To started (the chimney pipe) will leave only a tiny amount of it. As the temperature of dymooborotah over its entire length to a sharp jump in never falling, but in the crucible it burns almost all that can burn, smoke and soot if deposited, the most minuscule. The danger of soot fire does not arise, and the services of a chimney sweep will not take decades.

The main secret

In the Russian oven without any partitions and corners, complicating and even making it impossible to repair or cleansing, a virtual complex smoke channel, effectiveness superior to any labyrinth. It remains to regret only one thing: the name or names of the geniuses who created it remain in obscurity.

About mini-ovens

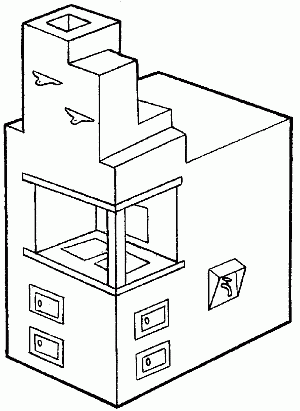

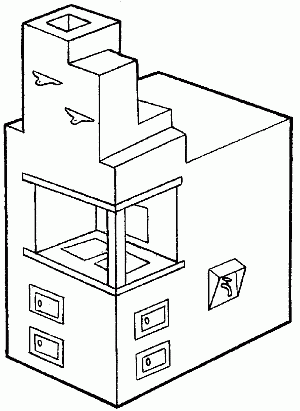

Now Russian stove has steadily moved from the sticks. Due to the high technology and new materials appeared Russian mini-oven, see Fig. This one person can easily lift, stacks in the trunk, puts in the gazebo at the cottage or just on the lawn. Most useful qualities a mini oven saves. One trouble with them: there is no prophet in his own country. Shows the model of the Italian production and domestic market something difficult to see.

Russian mini oven

Some of the features

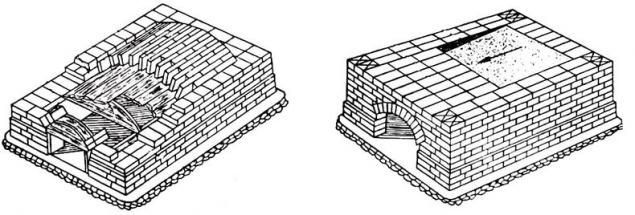

The following figure is the same basic furnace, in isometric view. Here you can see the stove – niches for drying herbs, mushrooms, berries. The stove shown in the cross section in Fig. right. Between it and the crucible is just one brick. Dry infrared rays, and depending on the location of the stove relative to the fire changes its mode. Also in this "budget" furnace no brick potpecka; it is the role of Apache.

Russian stove without potpecka

Under the hearth is often, especially in outdoor furnaces, little stove – podapok. Drown him in black, and the smoke capture hood above the hearth; the mouth of the cap goes to the started on the view. Podapok allows to save fuel during the summer when heating is not needed, or quickly cooking something, not waiting for an hour and a half until warms up the whole oven.

Sometimes podpack put forward flush with the hearth across the width of the brow. Sometimes, on the contrary, Zev started with and zagnetko push back due to the length of the shelf; the depth of the crucible on the physics of the processes in a furnace has little effect, and the result is a broad and durable, comfortable last. In this podapok you can make a niche and sink in white, moving it started in zinetac.

You must also mention the different kinds of additional material, based on the experience of personal observation. Signs of destruction at the end of the observation period was not noticeable only in Russian stoves of brick entirely. From the corners of panels and cross members of metal and concrete from year to year, crawled cracks. Wooden inserts on the forehead (for fire safety can be done only on the outside) was cracked and fell out.

No repair does not require a kiln, the surface layer of the masonry and the shelf was laid in lime mortar; furnace entirely on the clay had to grease and plastering. But the inside of the furnace, is exposed to alternating thermal strains, was kept posted on a very fat clay (see below) – TCR, temperature coefficient of expansion, such a masonry mortar exactly equal to the same red brick.

Couches, built on clay, never failed, if they had parquet flooring made of wood. They're not baked sides, like oven or "ghalili".The arches of the even number of bricks in 20-25 years began to collapse. However, what is a castle vault, the builders do not need to explain.

Interesting fact: one Joseph Dzhugashvili, known in history as Stalin, was a zealous champion of the Russian furnace. For flooring the loft of his beloved stove carved hand-piece Board made of Siberian pine, which a dictator in the allotted hour and died. More in Siberia, a huge cedar had never seen.

Summary of properties

What's in the oven right?

Efficiency

When calculating according to prepared formulas and simplified methods, the efficiency of the Russian stove goes somewhere 25-30% of This value has long inspired the question, and in 1927 the people's Commissariat of the USSR has conducted full-scale tests. The result stunned professionals: the precisely measured value was 68%! This higher efficiency of the large CHP! At the same time, a competition was announced for the improvement of the furnace. Samples, developed at the VTI (all-Union thermal engineering Institute), Grumm-Grzhimailo and Podgorodnikov, showed an efficiency of about 80%. The Russian research furnaces maintained to this day: yet it is not clear how such efficiency is achieved.

Sleep

These properties of sleep in the loft belong to the slow wystawowa per night furnace. Similar but much weaker effect is the use of good branded electric blanket with auto on videoparameters.

Fire safety

The reader, not penetrating deeply into the topic, the question may arise: what about the devastating fires that were "famous" wooden Russia? It is appropriate to tell the following.

In the beginning of XVIII century Peter I, Moscow asatani from another fire, gave to one of his closest associates, the chief of the Order of secret Affairs boyar Prince Romodanovsky, the task to find out: "What-is packing hail this damned can't burn can't?" The response was soon received:

— Ordinary people, even to cloth merchants hundreds, drowning in black, inasmuch as the household apply for do not want to pay.

— Revel restrictie, vodka moonshine, like beasts obscene, because and burn.

Peter's reforms touched and furnace business, and by the end of his reign a massive fire almost ceased. Catherine II continued improvement of fire safety, and its Board fires even in smoky huts have become extremely rare; in Russia now burned no more often than in Europe.

What's wrong with it?

Russian stove in the interior

In General, we must admit that Russian stove is only suitable for detached housing.

And in the interior?

But not archaic if Russian stove and mind? If she could be entered in a modern interior? Quite, as the basis of design of the Russian stove – simple forms. They allow as an independent aesthetic use, and the artsy decor. Technically the design of the Russian stove is quite compatible with the modern finishing materials, see Fig.

Video: craft and decorating masonry Russian stoves

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Build oven

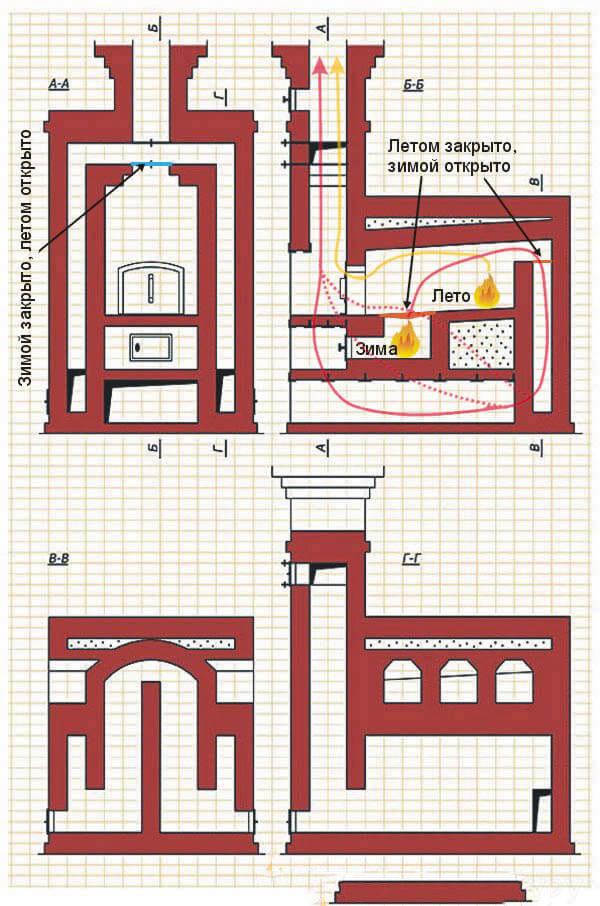

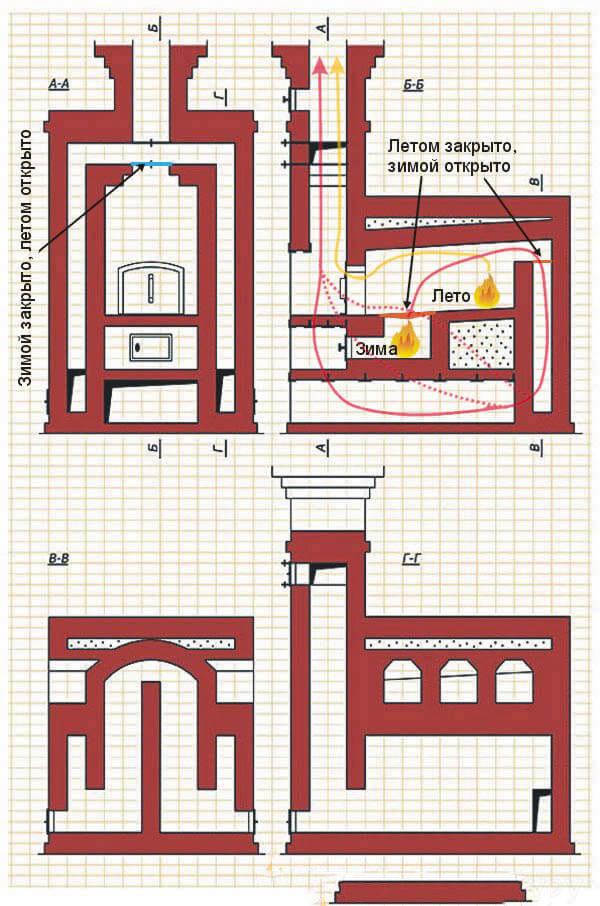

The complete circuit of the Russian furnace shown in the figure below, with a list of positions. To the above there is a Supplement – dushnik. This gas-air heat exchanger: dymooborotov through the wall heats the air, which is drawn at the bottom. Outlet dushnika out into the room at the top, then comes the choke, and her mouth opens in dushnik started on the view.

In the summer the damper is open and the flow of air in the dushnik outputs excess heat of flue gases, at the same time providing good ventilation. In winter the damper is closed; the heated air enters the room and warms it.

Dushnik – the easiest and safest way to get from the furnace bottom heating without excessively complicating its design.

Podpeche; Pedsector; Hearth; Dushnik; Brow; gate Valve; Fireplace; Peritricha; Flap; Mouth; Cutting; a Warm stove; Hot stove; Nut; Backfilling; the arch of the crucible; the Crucible; Under; Cheek; Porson; Podpack; Arch potpecka; pharynx; pharyngeal Arch; YAP; the Arch of the mouth; Ledge of masonry; Channel dushnika; Mouth dumnica.

Note: cheek (side) of the furnace, facing the wall, called the deaf, and facing the room mirror.

What is the lining?

Oven spread by horizontal layers of bricks – rows. A set of instructions for the laying of each row – this is the lining. Sometimes called lead series (the first lining, spread porjadovki, etc.). It is, generally, wrong.

For each type of furnace lining, of course, will have their own. Modern poryadovki are accompanied by drawings. Construction of furnaces it is possible to start only if its lining is absolutely clear.

Materials

Brick

Masonry Russian stove made of red ceramic bricks. The bricks should be well burnt and of very high quality, dense, smooth. Overburnt brick (dark inside, if it is broken) is absolutely unusable. Also not good hollow brick: heat will not flow through the body of the furnace, her insides would overheat and the whole furnace will soon begin to fall apart.

Especially carefully it is necessary to select bricks for the hearth: they must be flat, smooth, exactly the same height. In the old days potters chose the hearth bricks from batches procured and stored separately. In our time, can be ironed after a masonry grinder with a pan around. The idea is that this oven does not become worse, but experienced no data.

Facing the furnace and the upper row of benches can be built of facing bricks in lime mortar. Then the shelf will never fail, and finish ovens will not cause difficulties – masonry on clay with the widened seams (see below), though heat resistant, but is not very durable and smooth, and the plaster and tile on it holding up no matter.

Solution

The mortar for the Russian stove is not quite normal; it is important the combination of heat resistance, high heat capacity, and the same brick TKR. The composition of the solution is:

Good clay for masonry stoves ever presented a serious problem. Now the structure of the Russian oven is simplified: there are ready-made dry mixes for masonry stoves and separately – rich clay.

When dry oily solution often crack. In this case, cracks obscure to the average or lean clay solution, but in any case, no lime, gypsum or cement.

Work

Opecia

Wood stove keeps opecia weighing up to 1600 pounds (about 750 kg), i.e. low or medium without potpecka. Perform it in a frame in two zones, with the filling booth and decking of the bars. The flooring is covered with felt, as it should have been soaked in a liquid solution fat clay, and the roofing iron.

Wooden opecia fire and the now-banned. Now Russian stoves are put on a Foundation of brick or concrete blocks, or simply on the concrete floor. If the furnace in the basement and assumed its veneer, the Foundation on the perimeter need to produce a half-brick-brick subject mortar layer.

Arches and vaults

Arches and vaults are laid out from an ODD number of bricks on the mould in a wooden template of the wheel. First life-size, make a drawing of the arch in the cut, then it otesyvajut wedge-locking bricks. Put a arch with straight lock or without the homebrew you don't try, it may not everyone experienced bricklayer.

Next, prepare the centres, taking into account the thickness of the formwork planks and it spread a vault without a lock. Then you need to heavily grease the grooves of the locks solution and locks to invest in the groove. The next stage – the locks in turn and in several passes, gradually clog the groove. Mallet will not do here, you have to wield a stick. But peel that is dope, you need to use the inertia of the heavy piece of wood, not power sharp blow.

Quality controlled circuit set by squeezing the sausage of mortar from joints: it should be more or less uniform over the entire surface. The dense solution flows slowly, so you need to take breaks between passages. The end result is pre-tensioned; only such a set and will last for many decades.

How to learn?

Just from the above it is clear that Russian stove to build a very, very difficult, and we haven't got to porjadovki. In the book, even to the experienced and skilled craftsmen will get the result, vividly described in Makarenko's "Pedagogical poem". Is it possible to learn to put the furnace itself? There is a way.

First, slice the foam in the scale of small blocks of about 2500 pieces To be the same and equal, need to cut not with a knife, and the simple machine: over a plywood shield is stretched height-adjustable nichrome wire 0.3-0.4 mm. it Heats up the current low, 2-12, voltage.

Attention! To take the current from Later is impossible – it is an autotransformer and does not isolate the phase!

Then take the lining and on the table drops on the PVA collected model furnace. In the winter it's not so boring. After a week of drying... reset it on the bare floor. Not broke – you can go further.

And then fold in the cottage or in the courtyard of the smallest, which are the lining, the stove. Very useful, simulating winter, to understand how the whole design, and to develop the lining independently. If after the initial firing furnace no smoke and somehow bakes can be taken for real. But strictly keeping the rule: measure twice, cut once.

Material consumption

Classic brick oven, as described above, depending on the size requires approximately such quantity of materials:

1. Small – 1500 bricks and 0.8 cubic metres of solution.

2. Middle – 2100 bricks and 1.1 cubic meters of solution.

3. Large – 2500 bricks and 1.35 cubic meters of a solution.

Is it worth it yourself?

Does it make sense to take on such a difficult job yourself? How much is the work of an experienced and reliable Builder? If 100% of the cost of materials, as is customary in General construction work, it is still not too expensive.

And certainly not twice against the material. You can find deals put the stove in 20 000, but it is an obvious absurdity. Try to figure yourself.

A Russian stove with a stove

Setter works in the mid-latitudes half a year, and always with an assistant-apprentice. Considering their employment of 100% of the time, the salary of the master in 25 000 rubles, and the assistant 15,000 and the lead time is 7 working days (this is a real term), get a simple microwave oven will cost not less 45 000 rubles, and the Russian stove with a stove and photograhy (see Fig.) 55 000-60 000.

But after a week it will be possible to drown. Only one condition: the master must indicate where, when and to whom he had already put the furnace, and they need to inspect personally. Good master be sure to stock up on references, and if turns and mumbles – it is better to go to another.

To give a more complete picture of the complexity of the work, let us consider briefly how to lay out the above described furnace. For example only; detailed lining of the Russian stove – a rather bulky pamphlet.

The lining

Note: the first three rows (the lining), you can put a brick perekladnyh (iron ore) in cement mortar. They are not heat almost. But oven with bottom heat the whole to be of high quality bricks.

1-6 series

Screed on waterproofing the basement do not put dry – sweating is eliminated. Start with the front-left corner (POS. a-1 in Fig.) In the corner of the brick 3/4 poke out. From a range of 12 Panamera to the corner and-2. The seam is widened to 13 mm; this will be everywhere in the first 3 rows, because row 4 is formed by a ledge of masonry.

In the corner of a-2 – two butting 3/4 and double the range of Panamera to the corner and-3. To the corner of the a-4 come similarly a-1 to a-2. Rounding out the number 1 two polemarchi forming an aperture 540 mm. Masonry check rule and the diagonals.

In the second row (POS. b) on the sides butting 1 number of closed spoons. In the corners, 2 trehchetvertki stacked spoons. Frame the opening polemarchi butting 3/4 covered with bandaging of seams. The third row (POS. C) identical to the first.

Note: stretcher bond brick has nothing to spoon with which to eat. Stretcher bond bricks laid along the wall of the long side horizontal, and the bonder is orthogonal to it. He and the other can put horizontally, on its side, on end (upright, on end).

Number 4 – according to the POS. on the brace. The location of the bricks – as in the 2nd row. The seam is narrowed to 5 mm, to obtain a ledge of 25 mm on the sides. Check the clutch level.

Number 5 – POS. D. In d-2 and d-3 3/4, two; between them, the two stretcher bond series. The side walls are bonded. Of the wall opening of podpeca stesyvat under the heel arch. Mounted on legs of its centres, and put the number 6 is identical to 4-mu.

The first arch

Laying out the arch, in addition need to observe the following; for subsequent arches/vaults, too:

7-10 rows

7 a number laid out as 5; 8 – 6 th (left Fig.) In the sidewalls of the inside shots are squared under the heel of the arch. On the 8-th row begin to lay out podlesok: three rows bonder Panamera, counting back from the brow. Average poke bottom need to cut under the arch of podpiska. 9 the number is put as the 7th, but the 2nd number of podsachka put spoons. Put a set of podpiska.

10 a number of special, in Fig. right: the corners of the 3/4, sides of stretcher bond Panamera; the rear of the bonder Panamera. From the brow of deep – 3 series bonded Panamera. In a series of 7 pieces, laid flat. This will be the last hearth zagnetko.

The crust

The filling of the crucible do of broken bricks in clay mortar. Tamp and tie, as indicated by the arrow. Do yourself under a Jag is better not to try – it turns out not every setter.

11-17 rows

Even the ranks of the spread as 10 minutes. In odd-numbered sides are tychkovye numbers; rear – stretcher bond. 15-th and 16-th otesyvajut under the heel of the arches. At the end of the 17th series of the walls, around the crucible to interrupt, until all laid out in front of the furnace, to the vertical plane passing through the rear wall of the mouth.

Zev, zinetac, the mouth, the crucible

Arches and vaults erected by the wheel arch potpecka with formwork. The side walls of zagnetko go to the brick; the brow and mouth in a half-brick. Heel arch of the throat will be in the 15th row; the heel of the arch of the mouth – on the 16th. Especially it will be difficult for the beginner to iron the inner walls haila: the top is not see what you are doing, and from within the dust and grit in the eye flying. So YAP needs to handle from the top, verifying a template.

18 and above

Odd-numbered rows are put as either 1 or 11; even as 2 or 10, see Fig. If the shelf will be stacked on clay, Dating from the 19th number of bricks inside protesilaus at the place the arch of the furnace. But it does not always save the clay from falling through the shelf, so the best masters erected around the crucible box, make the filling of brick dust on the clay, level it and tamp, and it allowed a continuous pavement from a spoon, framed by junkies with trehchetvertkami in the corners. Below the shelf lasted forever and not pushed through the arch, the future depends on the prosperity and generosity of the customer: whether the wooden Board flooring, whether the number of face bricks in lime with bandaging of seams.

The latter method is not as simple as it seems: because the arch is tilted anteriorly. So it locks, put a row of bricks flat and prodol with bandaging of seams relative to the keyhole. Then stesyvajut on a wedge, this crossmember came out flush with the walls.

Backfilling will dvuhstoronka, and the shelf will fall on the wedge and the wall. The point here is what? Remember structural mechanics: a set is much harder to crush on top, than to punch in the side. The load of the shelf will be transmitted to the castle, and from him to set on the cheeks of the furnace. Arch arch will only work in compression and if the shelf and fail to remain intact, and the shelf is easy to recover.

If you cut the bricks at the top, the load from the shelf will give a lateral shear load on the arch. Shift building materials holding bad. Failed the shelf – would fail, and the arch and the furnace need to shift.

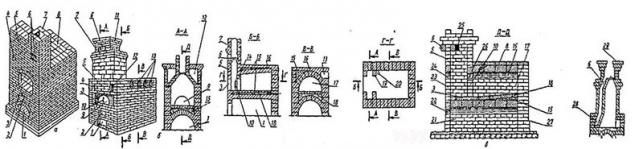

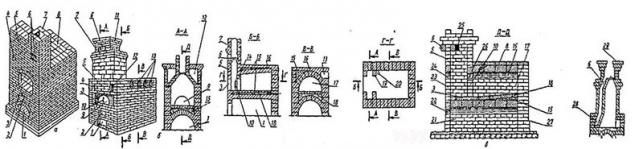

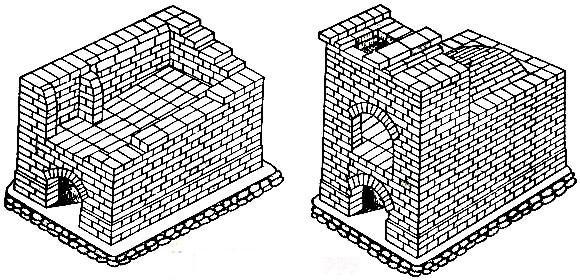

Evolution

Diagram furnace Podgorodnikov

The development of the Russian stove was on four interwoven branches: the lower heating plate, saving, compactness. The huge contribution it has made I. S. Podgorodnikov, developed a series of furnace "Housekeeper" and "the Van" today. The scheme of "the Van" Podgorodnikov shown in the figure. It improved I. V. Kuznetsov; Kuznetsov oven – Fig. below.

The point is that the firebox and cooking chamber are separated, and podpeche sealed. The flue gases down through the hole in podpeche (which is equipped with a second low bed, comfortable old and small, and the furnace in the most natural way works like a stove. Accumulation of soot in podpeche eliminated through careful design. What works it was worth in the age of adding machines and slide rules, we'd better not guess.

Oven Kuznetsova

However, this oven has held up much space and has increased the fire hazard: the fire burned close to the mouth of the furnace. Further improvements to the 90-ies of sense and gave little oven too complicated. The following figure is a compact housekeeper 70-x – 80-ies in the context. Its efficiency is above 80%, but to lay down such a maze will take not just a stove, and to understand the purpose and order of use of all these doors and dampers will not immediately be able and heating engineer with a diploma, not something that an ordinary housewife. In addition, there are nooks and crannies that are inaccessible for inspection and cleaning.

Compact oven-housekeeper a difficult design

Modern Russian stove

With the development of computer modeling Russian stove has gone the way of quality improvements: all the creativity you can draw on wit and intelligence. The following figure (right) – a good modern brick oven. The feature of design is that instead of filling under the bakery (where she turned out to be, it's still not working as intended) gave winter the furnace. Increasing the height of podsachka allowed to increase the volume of rockfill under the crucible to the optimum.

The drawback of such a furnace is only one: to switch "winter – summer" to move not one but two dampers, and in addition to put/remove the heavy plate covering the mouth of the winter the furnace. If this plate is something to think of, such a furnace can already be automated for the winter: winter furnace can run on gas.

What's next?

We know how to construct a brick oven. But how it works – there is still a lot unclear. And in an age of dwindling energy supplies the heat generator with an efficiency of as with electric cars – discovery is priceless. And here opens a wide field for both veteran professionals and DIY.

Video: example of construction of the Russian stove with bench

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS! www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: clubpechnikov.ru/russkaya-pech/

Now Russian stove is experiencing a rebirth; a significant role was played by her efficiency, omnivorous and the opportunity to build with their hands, expensive materials and complex industrial equipment is not required. What good is it, what her secrets where it is impossible to build?

From personal experience

The author of this article in childhood and early youth, many was visiting his grandmother in the village, in the Russian Outback in the summer and winter vacations. Relish namaw side to the Russian stove with stove bench, he was eager to build the same in a city apartment. It was absolutely feasible, but was accumulated fairly extensive material on Russian stoves of different types, that had very useful when writing the article. The observations were carried out from 1961 to 1972, the Furnace was built after the liberation of those places (Orel) from the Nazis in 1943-45.

Classic Russian stove

Russian stove was highly polymorphic design. Only traditional stoves were different, even from hut to hut in the same village. And the works of unknown but savvy stove-makers and scientists, especially Podgorodnikov I. S. and I. V. Kuznetsova, has created many designs based on common principles. All of their survey in the same publication it is impossible even briefly, therefore, further concerns mainly the classical Russian furnace (see Fig.), and improvements are described in General terms.

Curious: the vault of the crucible of one of the kilns were made from the halves of the large cylinder of the internal combustion engine. Tank or jet, our or German – is unknown.

Theory and the secrets

The fundamental unit of the Russian furnace is shown in the figure. From a lateral incision to understand its secrets. Understanding them, will receive its advantages/disadvantages, and then move on to the description of the structure. In conclusion describes modern high-performance designs.

The scheme of the Russian stove

Russian stove rests on a Foundation – Apache, wood, stone, brick or concrete. Podpack used to store fuel that it dries "to the gunpowder" and easily erupted during heating. Top podpack closed semicircular arch (set-trough). The arch is filled with water from thermal material: sand, brick chips on a clay solution, and the bedding dry, without mortar, is laid under the cooking chamber constituting the front part of the furnace.

Important: if you lay under the bedding without hearth baking will never get "real". By the way, for "nastasescu" bread and pies to bake on cabbage leaves. With fresh milk – m-m-mmm!!!

Russian stove – the heating device of periodic action: while not a very long firing it accumulates heat and then about a day warm, giving, and bringing it up to standard culinary delights. To understand her work, follow the flow of air.

Secrets begin to zagnetko (some say "zinetac or zagnetko") with its finial – peretrube – ending tapering nozzle – YAP. The side walls in zagnetko made caverns – ash to ash collection and storage of embers for the next fire.

Notes:

1. Often the hole for the ash and coals do the hearth – stone or cast-iron stove, a prominent brow (face) of the furnace. Then it is called celcom.

2. Mansion window surrounds in furnaces purity's sake, but in the poorest, to reduce the cost of the work, ocelot and ash pan did not. Ash raked the coals and kept in pors'k – inside the cavern-side of the mouth, see below. In this case, the coals kept the heat of the day, only when using birch, oak, fazovymi or maple wood, on which was superimposed on top of aspen. Perhaps because of this, and the conviction has remained in the nicety of the Russian stove. In fact, she eats any solid fuel: firewood, brushwood, straw, twigs (dry weeds), dung, anthracite, coal seed, peat briquettes, corpocracy, sawdust. But to make bread you only need wood or charcoal. Otherwise the taste will be shopping.

In General zinetac, scientifically speaking, gas economizer, which recovers energy: flue gases (diveboat) preheat the incoming furnace air, not taking away his oxygen. Mixing of streams does not occur: a paper strip of the zone of turbulence is not detected. The thermometer on the hearth zagnetko showed the increase of temperature from the throat to the mouth from room to more than 76 degrees (column reaches the limit, the alcohol was boiling and the thermometer burst).

Important: to oven not smoked, did not work voracious and quickly cooling, to withstand indicated in the figure, the size and especially the smoothness of the walls haila. Plastering zinetac not, so the bricks of the walls haila chip and grind until smooth. In fuming furnaces a piece of paper, especially when using bulk glow fuel, found turbulence in peretrube. In furnaces with a smooth current of gases YAP was always laminar. It is easy to understand that the turbulence in zagnetko the air will go into the furnace oxygen-depleted.

The heart of the Russian stove – furnace. It is divided into the cooking chamber (bakery) and the furnace firebox. In a small furnace (2,5x1,75 feet in plan; 1780х1240 mm) under entire furnace spread with a uniform rise posteriorly at 60-90 mm. In large (3,25x2,25 feet; 2310х1600 mm) and mostly in the middle (3x2 feet; 2130х1470 mm) experienced potters spread it with a kink in the middle (large) or third (in the middle) to the cast iron stood smoothly and steadily. But under the crucible must be sloping, and size, as specified, and not on an angle. By the way, the height of the shelf (cots) from the floor in the "Domostroy" – 2.5 feet.

Dimensions are approximate Russian stoves. The length of the yard in different regions ranged. Potters dancing with bricks in length, width and height of the furnace has to meet a whole number of them, given the layers of mortar.

The hot air is already involved in cooking, warming dishes below. He then goes to the fuel; the flue gases rise to the ceiling of the furnace. He is also inclined, but it should be, than under. Best heated furnace, in which furnace, in plan, tapers to the mouth of the same 60-90 mm.

A strip of foil on a stick found under the arch of the furnace two stable in any mode of combustion of oppositely directed vortex (circulation). Two of the vortex, presumably, this is the most important secret of Russian furnace. Their torques cancel each other, and zagnetko, despite the presence of the nut, visible turbulence is not formed. In the ovens too low or high sill circulation was weak and unstable.

The second assignment of vortices in the furnace – delay unburned fuel particles. Before leaving the mouth, they are doing a few (maybe a lot of turns) and completely burned at a relatively low temperature. Emitted by the IR evenly heats the cookware with cooking. In the middle of the height of the bakery moving gases were not detected.

Important: the food is prepared WITHOUT CONTACT WITH FIRE AND OVERHEATED GASES at the optimum temperature, therefore, the pyrolysis products is suppressed, carcinogens, toxins it is not formed.

Notes:

1. Potters-aces the vault of the crucible do not semicircular, and the three-center barrel, as shown in the figure are smoothed by a dotted line. Also at 90 mm at the same userauth the crucible in the middle. In such a furnace burning 100%: she never smokes and does not give sparks.

2. The infrared rays in the crucible – one of the secrets of Russian cuisine. Dishes such as daily soup or pie Paglia, must then. and remove the coal for a long time to languish in the crucible. To achieve such a mode of cooking in the gas oven or impossible. And crust so no grill does not get it. But the hostess needs to know that the temperature in the furnace varies from 350 to 150 degrees, counting from the fire to the mouth. Depending on the desired cooking mode you need to place the dishes and move them with tongs or a dovetail. So cooking in the Russian oven requires skill and dexterity, the townspeople know.

Finally, return to zinetac. Here we not only heat up the air, but and maintain hot cooked food for today (the hostess until the next morning to do other things), and the remainder of the heat give up the body furnace in peretrube with YAP. To started (the chimney pipe) will leave only a tiny amount of it. As the temperature of dymooborotah over its entire length to a sharp jump in never falling, but in the crucible it burns almost all that can burn, smoke and soot if deposited, the most minuscule. The danger of soot fire does not arise, and the services of a chimney sweep will not take decades.

The main secret

In the Russian oven without any partitions and corners, complicating and even making it impossible to repair or cleansing, a virtual complex smoke channel, effectiveness superior to any labyrinth. It remains to regret only one thing: the name or names of the geniuses who created it remain in obscurity.

About mini-ovens

Now Russian stove has steadily moved from the sticks. Due to the high technology and new materials appeared Russian mini-oven, see Fig. This one person can easily lift, stacks in the trunk, puts in the gazebo at the cottage or just on the lawn. Most useful qualities a mini oven saves. One trouble with them: there is no prophet in his own country. Shows the model of the Italian production and domestic market something difficult to see.

Russian mini oven

Some of the features

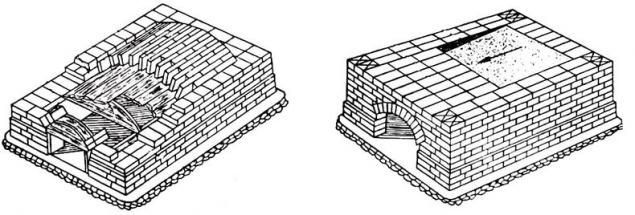

The following figure is the same basic furnace, in isometric view. Here you can see the stove – niches for drying herbs, mushrooms, berries. The stove shown in the cross section in Fig. right. Between it and the crucible is just one brick. Dry infrared rays, and depending on the location of the stove relative to the fire changes its mode. Also in this "budget" furnace no brick potpecka; it is the role of Apache.

Russian stove without potpecka

Under the hearth is often, especially in outdoor furnaces, little stove – podapok. Drown him in black, and the smoke capture hood above the hearth; the mouth of the cap goes to the started on the view. Podapok allows to save fuel during the summer when heating is not needed, or quickly cooking something, not waiting for an hour and a half until warms up the whole oven.

Sometimes podpack put forward flush with the hearth across the width of the brow. Sometimes, on the contrary, Zev started with and zagnetko push back due to the length of the shelf; the depth of the crucible on the physics of the processes in a furnace has little effect, and the result is a broad and durable, comfortable last. In this podapok you can make a niche and sink in white, moving it started in zinetac.

You must also mention the different kinds of additional material, based on the experience of personal observation. Signs of destruction at the end of the observation period was not noticeable only in Russian stoves of brick entirely. From the corners of panels and cross members of metal and concrete from year to year, crawled cracks. Wooden inserts on the forehead (for fire safety can be done only on the outside) was cracked and fell out.

No repair does not require a kiln, the surface layer of the masonry and the shelf was laid in lime mortar; furnace entirely on the clay had to grease and plastering. But the inside of the furnace, is exposed to alternating thermal strains, was kept posted on a very fat clay (see below) – TCR, temperature coefficient of expansion, such a masonry mortar exactly equal to the same red brick.

Couches, built on clay, never failed, if they had parquet flooring made of wood. They're not baked sides, like oven or "ghalili".The arches of the even number of bricks in 20-25 years began to collapse. However, what is a castle vault, the builders do not need to explain.

Interesting fact: one Joseph Dzhugashvili, known in history as Stalin, was a zealous champion of the Russian furnace. For flooring the loft of his beloved stove carved hand-piece Board made of Siberian pine, which a dictator in the allotted hour and died. More in Siberia, a huge cedar had never seen.

Summary of properties

What's in the oven right?

- Low cost materials – to build a Russian stove, you need a red brick, clay and sand.

- Efficiency – efficiency is the most simple Russian furnace exceeds 60%, and advanced designs give up to 80% or more, which thermal devices are simply incredible.

- Omnivorous – works on any solid fuels without compromising.

- Functionality – in addition to heating and cooking in the kitchen, as you know, sleep.

- Ease of use – in the morning I heated, and a day will be enough. Stoke the furnace does not need.

- The healing properties of food have already said; sleep on the shelf is strong and deep. 6 hours it's enough to relish sleep; Wake up, always cheerful, with a clear head.

- Security – the fire in the depths of the furnace, the coals die and fall it is highly unlikely even in case of incorrect use; spark gives only in exceptional cases from a very intense furnace in the dead of winter. With trehtsentrovye arch on sparks never.

Efficiency

When calculating according to prepared formulas and simplified methods, the efficiency of the Russian stove goes somewhere 25-30% of This value has long inspired the question, and in 1927 the people's Commissariat of the USSR has conducted full-scale tests. The result stunned professionals: the precisely measured value was 68%! This higher efficiency of the large CHP! At the same time, a competition was announced for the improvement of the furnace. Samples, developed at the VTI (all-Union thermal engineering Institute), Grumm-Grzhimailo and Podgorodnikov, showed an efficiency of about 80%. The Russian research furnaces maintained to this day: yet it is not clear how such efficiency is achieved.

Sleep

These properties of sleep in the loft belong to the slow wystawowa per night furnace. Similar but much weaker effect is the use of good branded electric blanket with auto on videoparameters.

Fire safety

The reader, not penetrating deeply into the topic, the question may arise: what about the devastating fires that were "famous" wooden Russia? It is appropriate to tell the following.

In the beginning of XVIII century Peter I, Moscow asatani from another fire, gave to one of his closest associates, the chief of the Order of secret Affairs boyar Prince Romodanovsky, the task to find out: "What-is packing hail this damned can't burn can't?" The response was soon received:

— Ordinary people, even to cloth merchants hundreds, drowning in black, inasmuch as the household apply for do not want to pay.

— Revel restrictie, vodka moonshine, like beasts obscene, because and burn.

Peter's reforms touched and furnace business, and by the end of his reign a massive fire almost ceased. Catherine II continued improvement of fire safety, and its Board fires even in smoky huts have become extremely rare; in Russia now burned no more often than in Europe.

What's wrong with it?

- Russian stove only works on slow burning solid fuel. Quickly-burning liquid and gas require a lot of air, the inflow of which Russian stove can not provide. Put into the furnace of the atomizer for fuel oil or gas burner is not only useless, but also dangerous to life.

- Solid waste – ash that needs to be put somewhere.

- Heavy, gives greater point load on the floor, so in multi-storey buildings is not applicable.

- Bulky, takes a lot of living space and volume.

- Heat transfer per unit surface is small: a large Russian stove can heat a room of 45 sq m is exactly the same as a radiator under the window.

- Sluggish diveboat (a byproduct of high efficiency) excludes the elimination of several Dymnikov one pipe oven, which stoked a little harder, squeezed the other smoke from the chimney at any traction, and they begin to smoke. Therefore unsuitable for apartment buildings.

- Long warming; after the summer of inactivity required daily Protoka.

- When the flaws of the structure could smoke.

- Absolutely not amenable to automation.

Russian stove in the interior

In General, we must admit that Russian stove is only suitable for detached housing.

And in the interior?

But not archaic if Russian stove and mind? If she could be entered in a modern interior? Quite, as the basis of design of the Russian stove – simple forms. They allow as an independent aesthetic use, and the artsy decor. Technically the design of the Russian stove is quite compatible with the modern finishing materials, see Fig.

Video: craft and decorating masonry Russian stoves

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Build oven

The complete circuit of the Russian furnace shown in the figure below, with a list of positions. To the above there is a Supplement – dushnik. This gas-air heat exchanger: dymooborotov through the wall heats the air, which is drawn at the bottom. Outlet dushnika out into the room at the top, then comes the choke, and her mouth opens in dushnik started on the view.

In the summer the damper is open and the flow of air in the dushnik outputs excess heat of flue gases, at the same time providing good ventilation. In winter the damper is closed; the heated air enters the room and warms it.

Dushnik – the easiest and safest way to get from the furnace bottom heating without excessively complicating its design.

Podpeche; Pedsector; Hearth; Dushnik; Brow; gate Valve; Fireplace; Peritricha; Flap; Mouth; Cutting; a Warm stove; Hot stove; Nut; Backfilling; the arch of the crucible; the Crucible; Under; Cheek; Porson; Podpack; Arch potpecka; pharynx; pharyngeal Arch; YAP; the Arch of the mouth; Ledge of masonry; Channel dushnika; Mouth dumnica.

Note: cheek (side) of the furnace, facing the wall, called the deaf, and facing the room mirror.

What is the lining?

Oven spread by horizontal layers of bricks – rows. A set of instructions for the laying of each row – this is the lining. Sometimes called lead series (the first lining, spread porjadovki, etc.). It is, generally, wrong.

For each type of furnace lining, of course, will have their own. Modern poryadovki are accompanied by drawings. Construction of furnaces it is possible to start only if its lining is absolutely clear.

Materials

Brick

Masonry Russian stove made of red ceramic bricks. The bricks should be well burnt and of very high quality, dense, smooth. Overburnt brick (dark inside, if it is broken) is absolutely unusable. Also not good hollow brick: heat will not flow through the body of the furnace, her insides would overheat and the whole furnace will soon begin to fall apart.

Especially carefully it is necessary to select bricks for the hearth: they must be flat, smooth, exactly the same height. In the old days potters chose the hearth bricks from batches procured and stored separately. In our time, can be ironed after a masonry grinder with a pan around. The idea is that this oven does not become worse, but experienced no data.

Facing the furnace and the upper row of benches can be built of facing bricks in lime mortar. Then the shelf will never fail, and finish ovens will not cause difficulties – masonry on clay with the widened seams (see below), though heat resistant, but is not very durable and smooth, and the plaster and tile on it holding up no matter.

Solution

The mortar for the Russian stove is not quite normal; it is important the combination of heat resistance, high heat capacity, and the same brick TKR. The composition of the solution is:

- Carefully sifted the fat, which are clay – 3 dimensional part.

- Sieved and calcined river sand is 3-5 ppm.

- Pure water is 1 volume part.

Good clay for masonry stoves ever presented a serious problem. Now the structure of the Russian oven is simplified: there are ready-made dry mixes for masonry stoves and separately – rich clay.

When dry oily solution often crack. In this case, cracks obscure to the average or lean clay solution, but in any case, no lime, gypsum or cement.

Work

Opecia

Wood stove keeps opecia weighing up to 1600 pounds (about 750 kg), i.e. low or medium without potpecka. Perform it in a frame in two zones, with the filling booth and decking of the bars. The flooring is covered with felt, as it should have been soaked in a liquid solution fat clay, and the roofing iron.

Wooden opecia fire and the now-banned. Now Russian stoves are put on a Foundation of brick or concrete blocks, or simply on the concrete floor. If the furnace in the basement and assumed its veneer, the Foundation on the perimeter need to produce a half-brick-brick subject mortar layer.

Arches and vaults

Arches and vaults are laid out from an ODD number of bricks on the mould in a wooden template of the wheel. First life-size, make a drawing of the arch in the cut, then it otesyvajut wedge-locking bricks. Put a arch with straight lock or without the homebrew you don't try, it may not everyone experienced bricklayer.

Next, prepare the centres, taking into account the thickness of the formwork planks and it spread a vault without a lock. Then you need to heavily grease the grooves of the locks solution and locks to invest in the groove. The next stage – the locks in turn and in several passes, gradually clog the groove. Mallet will not do here, you have to wield a stick. But peel that is dope, you need to use the inertia of the heavy piece of wood, not power sharp blow.

Quality controlled circuit set by squeezing the sausage of mortar from joints: it should be more or less uniform over the entire surface. The dense solution flows slowly, so you need to take breaks between passages. The end result is pre-tensioned; only such a set and will last for many decades.

How to learn?

Just from the above it is clear that Russian stove to build a very, very difficult, and we haven't got to porjadovki. In the book, even to the experienced and skilled craftsmen will get the result, vividly described in Makarenko's "Pedagogical poem". Is it possible to learn to put the furnace itself? There is a way.

First, slice the foam in the scale of small blocks of about 2500 pieces To be the same and equal, need to cut not with a knife, and the simple machine: over a plywood shield is stretched height-adjustable nichrome wire 0.3-0.4 mm. it Heats up the current low, 2-12, voltage.

Attention! To take the current from Later is impossible – it is an autotransformer and does not isolate the phase!

Then take the lining and on the table drops on the PVA collected model furnace. In the winter it's not so boring. After a week of drying... reset it on the bare floor. Not broke – you can go further.

And then fold in the cottage or in the courtyard of the smallest, which are the lining, the stove. Very useful, simulating winter, to understand how the whole design, and to develop the lining independently. If after the initial firing furnace no smoke and somehow bakes can be taken for real. But strictly keeping the rule: measure twice, cut once.

Material consumption

Classic brick oven, as described above, depending on the size requires approximately such quantity of materials:

1. Small – 1500 bricks and 0.8 cubic metres of solution.

2. Middle – 2100 bricks and 1.1 cubic meters of solution.

3. Large – 2500 bricks and 1.35 cubic meters of a solution.

Is it worth it yourself?

Does it make sense to take on such a difficult job yourself? How much is the work of an experienced and reliable Builder? If 100% of the cost of materials, as is customary in General construction work, it is still not too expensive.

And certainly not twice against the material. You can find deals put the stove in 20 000, but it is an obvious absurdity. Try to figure yourself.

A Russian stove with a stove

Setter works in the mid-latitudes half a year, and always with an assistant-apprentice. Considering their employment of 100% of the time, the salary of the master in 25 000 rubles, and the assistant 15,000 and the lead time is 7 working days (this is a real term), get a simple microwave oven will cost not less 45 000 rubles, and the Russian stove with a stove and photograhy (see Fig.) 55 000-60 000.

But after a week it will be possible to drown. Only one condition: the master must indicate where, when and to whom he had already put the furnace, and they need to inspect personally. Good master be sure to stock up on references, and if turns and mumbles – it is better to go to another.

To give a more complete picture of the complexity of the work, let us consider briefly how to lay out the above described furnace. For example only; detailed lining of the Russian stove – a rather bulky pamphlet.

The lining

Note: the first three rows (the lining), you can put a brick perekladnyh (iron ore) in cement mortar. They are not heat almost. But oven with bottom heat the whole to be of high quality bricks.

1-6 series

Screed on waterproofing the basement do not put dry – sweating is eliminated. Start with the front-left corner (POS. a-1 in Fig.) In the corner of the brick 3/4 poke out. From a range of 12 Panamera to the corner and-2. The seam is widened to 13 mm; this will be everywhere in the first 3 rows, because row 4 is formed by a ledge of masonry.

In the corner of a-2 – two butting 3/4 and double the range of Panamera to the corner and-3. To the corner of the a-4 come similarly a-1 to a-2. Rounding out the number 1 two polemarchi forming an aperture 540 mm. Masonry check rule and the diagonals.

In the second row (POS. b) on the sides butting 1 number of closed spoons. In the corners, 2 trehchetvertki stacked spoons. Frame the opening polemarchi butting 3/4 covered with bandaging of seams. The third row (POS. C) identical to the first.

Note: stretcher bond brick has nothing to spoon with which to eat. Stretcher bond bricks laid along the wall of the long side horizontal, and the bonder is orthogonal to it. He and the other can put horizontally, on its side, on end (upright, on end).

Number 4 – according to the POS. on the brace. The location of the bricks – as in the 2nd row. The seam is narrowed to 5 mm, to obtain a ledge of 25 mm on the sides. Check the clutch level.

Number 5 – POS. D. In d-2 and d-3 3/4, two; between them, the two stretcher bond series. The side walls are bonded. Of the wall opening of podpeca stesyvat under the heel arch. Mounted on legs of its centres, and put the number 6 is identical to 4-mu.

The first arch

Laying out the arch, in addition need to observe the following; for subsequent arches/vaults, too:

- Across the arch from the heel to the heel should not be any neperevyazannym seam (to the left in Fig. below).

- Seams from top to toe flat out smoothly from 13 to 5 mm.

- Kruzhala with formwork removed after drying of the solution.

7-10 rows

7 a number laid out as 5; 8 – 6 th (left Fig.) In the sidewalls of the inside shots are squared under the heel of the arch. On the 8-th row begin to lay out podlesok: three rows bonder Panamera, counting back from the brow. Average poke bottom need to cut under the arch of podpiska. 9 the number is put as the 7th, but the 2nd number of podsachka put spoons. Put a set of podpiska.

10 a number of special, in Fig. right: the corners of the 3/4, sides of stretcher bond Panamera; the rear of the bonder Panamera. From the brow of deep – 3 series bonded Panamera. In a series of 7 pieces, laid flat. This will be the last hearth zagnetko.

The crust

The filling of the crucible do of broken bricks in clay mortar. Tamp and tie, as indicated by the arrow. Do yourself under a Jag is better not to try – it turns out not every setter.

11-17 rows

Even the ranks of the spread as 10 minutes. In odd-numbered sides are tychkovye numbers; rear – stretcher bond. 15-th and 16-th otesyvajut under the heel of the arches. At the end of the 17th series of the walls, around the crucible to interrupt, until all laid out in front of the furnace, to the vertical plane passing through the rear wall of the mouth.

Zev, zinetac, the mouth, the crucible

Arches and vaults erected by the wheel arch potpecka with formwork. The side walls of zagnetko go to the brick; the brow and mouth in a half-brick. Heel arch of the throat will be in the 15th row; the heel of the arch of the mouth – on the 16th. Especially it will be difficult for the beginner to iron the inner walls haila: the top is not see what you are doing, and from within the dust and grit in the eye flying. So YAP needs to handle from the top, verifying a template.

18 and above

Odd-numbered rows are put as either 1 or 11; even as 2 or 10, see Fig. If the shelf will be stacked on clay, Dating from the 19th number of bricks inside protesilaus at the place the arch of the furnace. But it does not always save the clay from falling through the shelf, so the best masters erected around the crucible box, make the filling of brick dust on the clay, level it and tamp, and it allowed a continuous pavement from a spoon, framed by junkies with trehchetvertkami in the corners. Below the shelf lasted forever and not pushed through the arch, the future depends on the prosperity and generosity of the customer: whether the wooden Board flooring, whether the number of face bricks in lime with bandaging of seams.

The latter method is not as simple as it seems: because the arch is tilted anteriorly. So it locks, put a row of bricks flat and prodol with bandaging of seams relative to the keyhole. Then stesyvajut on a wedge, this crossmember came out flush with the walls.

Backfilling will dvuhstoronka, and the shelf will fall on the wedge and the wall. The point here is what? Remember structural mechanics: a set is much harder to crush on top, than to punch in the side. The load of the shelf will be transmitted to the castle, and from him to set on the cheeks of the furnace. Arch arch will only work in compression and if the shelf and fail to remain intact, and the shelf is easy to recover.

If you cut the bricks at the top, the load from the shelf will give a lateral shear load on the arch. Shift building materials holding bad. Failed the shelf – would fail, and the arch and the furnace need to shift.

Evolution

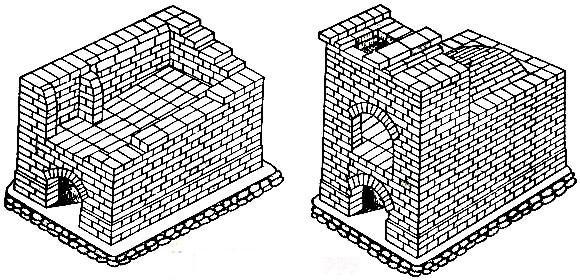

Diagram furnace Podgorodnikov

The development of the Russian stove was on four interwoven branches: the lower heating plate, saving, compactness. The huge contribution it has made I. S. Podgorodnikov, developed a series of furnace "Housekeeper" and "the Van" today. The scheme of "the Van" Podgorodnikov shown in the figure. It improved I. V. Kuznetsov; Kuznetsov oven – Fig. below.

The point is that the firebox and cooking chamber are separated, and podpeche sealed. The flue gases down through the hole in podpeche (which is equipped with a second low bed, comfortable old and small, and the furnace in the most natural way works like a stove. Accumulation of soot in podpeche eliminated through careful design. What works it was worth in the age of adding machines and slide rules, we'd better not guess.

Oven Kuznetsova

However, this oven has held up much space and has increased the fire hazard: the fire burned close to the mouth of the furnace. Further improvements to the 90-ies of sense and gave little oven too complicated. The following figure is a compact housekeeper 70-x – 80-ies in the context. Its efficiency is above 80%, but to lay down such a maze will take not just a stove, and to understand the purpose and order of use of all these doors and dampers will not immediately be able and heating engineer with a diploma, not something that an ordinary housewife. In addition, there are nooks and crannies that are inaccessible for inspection and cleaning.

Compact oven-housekeeper a difficult design

Modern Russian stove

With the development of computer modeling Russian stove has gone the way of quality improvements: all the creativity you can draw on wit and intelligence. The following figure (right) – a good modern brick oven. The feature of design is that instead of filling under the bakery (where she turned out to be, it's still not working as intended) gave winter the furnace. Increasing the height of podsachka allowed to increase the volume of rockfill under the crucible to the optimum.

The drawback of such a furnace is only one: to switch "winter – summer" to move not one but two dampers, and in addition to put/remove the heavy plate covering the mouth of the winter the furnace. If this plate is something to think of, such a furnace can already be automated for the winter: winter furnace can run on gas.

What's next?

We know how to construct a brick oven. But how it works – there is still a lot unclear. And in an age of dwindling energy supplies the heat generator with an efficiency of as with electric cars – discovery is priceless. And here opens a wide field for both veteran professionals and DIY.

Video: example of construction of the Russian stove with bench

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS! www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: clubpechnikov.ru/russkaya-pech/

Toyota first showed the interior of the hybrid crossover C-HR

Strawberries with ginger, chilli and Basil 2 recipes non-trivial jam