810

How to make oven filings on their hands for the garden and home

Sawdust is a cheap and available fuel, but its use in ordinary furnaces it is impossible – it needs a focus of special design. To build the oven on the sawdust with their hands, not have to learn masonry – the case of such devices are always made from metal. Economical furnaces are perfect for heating greenhouses, garages, cottages and country houses. It all depends on how seriously the work and the money to be spent on materials.

The principle of operation of furnace for sawdust

Furnace, using as fuel waste wood, works on the principle of continuous burning. The fuel in these devices is not lit and smoldering, gradually producing a small but sufficient amount of thermal energy. The slow burning allows you to save on fuel and reduce the number of downloads. With this method costly heat is not emitted into the pipe, and the maximum is spent on heating the house.

Homemade oven slow combustion for sawdust

To exclude intense flame and to achieve a slow and long decay, it is necessary to restrict the access of oxygen to the fuel cell. The problem is solved by the tightness and compression of the fuel.

With the lid closed, the fuel is not burning and slow smoldering

How to make oven long burning

To make their own hands the oven on the sawdust, you can use the finished metal capacity: barrel, cans, empty gas cylinder or pipe of suitable diameter. To work need a welder, grinder and skills to work with them.

A simple furnace for sawdust from the barrel

If you have a metal barrel, you first need to cut off from it the top. This should be done carefully, because further detail will be used as intended, but as a removable cover.

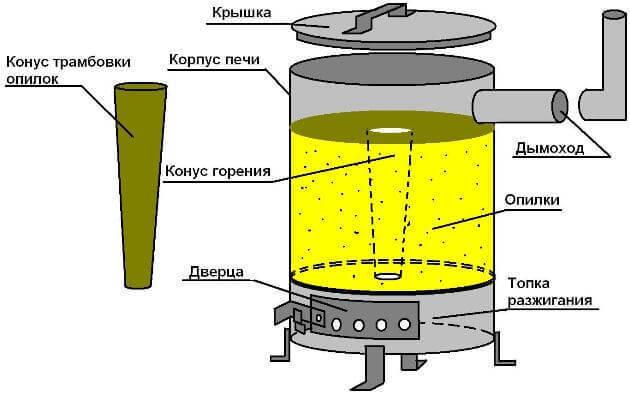

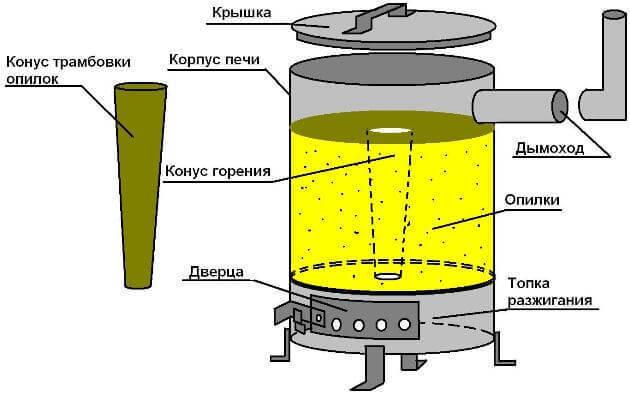

Diagram of homemade furnace for sawdust from the barrel

Further, from sheet metal with a minimum thickness of 3 mm cut out a circle with a diameter slightly smaller than the parameters of the barrel. In the center of the circle make a hole under the pipe with a diameter of 10 cm and carefully welded resulting billet to the inner walls, departing from the bottom 15-20 cm.

Just below the welded sheet cut a little window blew, for admission to the furnace is required for combustion of oxygen. In the upper part of the cylinder cut out the hole for the chimney – it is welded pipe, the outlet from the furnace, carbon monoxide.

The chimney requires special attention – too powerful thrust will contribute to the rapid withdrawal of the gases and reduction of thermal efficiency of the device. In low traction may be another problem – in the room begin to do life-threatening products of combustion.

Experienced masters recommend artificially lengthen fume pipe, dropping it on the perimeter of the room, or to adapt the chimney for hot water preparation, including the design of the boiler. All this will help to keep heat in the house and to extract from it the maximum benefit.

The oven of barrels for household premises

The cover is made from cut off tops, privaris to her side, or from sheet metal. It is important to ensure the integrity of the design, otherwise is corruption work burning. For the most of tight junction using a special heat-resistant seals for furnaces. For convenience, necessarily welded handle.

The rules of operation of a homemade furnace

For all its efficiency powered homemade device just:

In a hole in a metal sheet set the tube of a conical shape – this makes it easier to extract at the right time.

Capacity filled with sawdust to the level of the chimney in small portions, thoroughly ramming each layer.

The tube is carefully removed leaving a Central hole for admission to the fuel of oxygen and the exit of exhaust gases.

Oven cover with lid and light the fuel from the blower. To simplify the operation, it is possible to pour some flammable liquid on a metal partition to download the sawdust.

The process of decay in a barrel volume of about 200 liters lasts at least 8 hours – during this time the furnace lid is impossible to open and add the sawdust. A new download can be done only after complete combustion of the previous batch of fuel.

Fuel load from above

How to improve a budget model

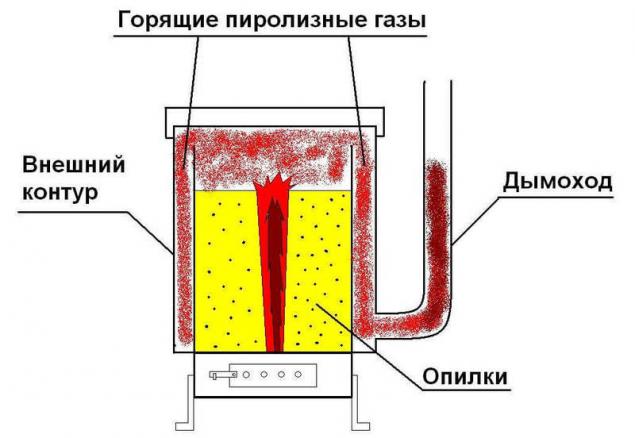

A simple stove out of a barrel suitable for the country house, garage or greenhouse. For residential buildings it is recommended to upgrade the design, increasing the heating surface of a flue construction of additional contour.

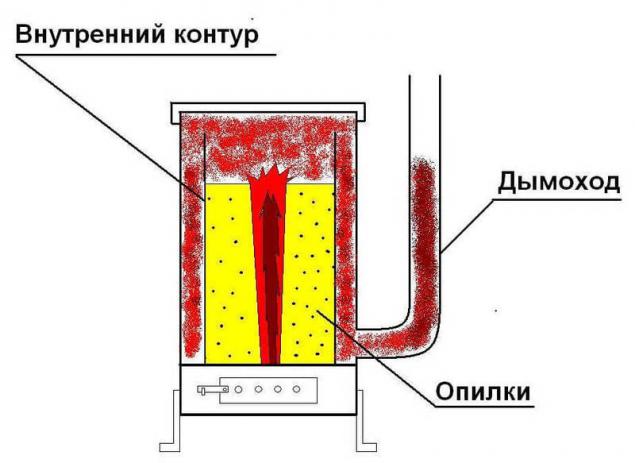

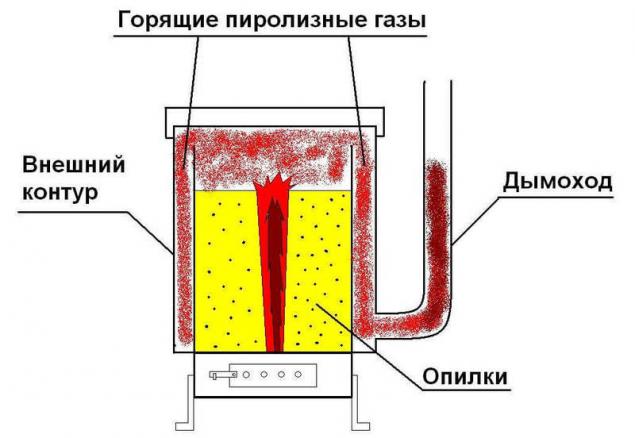

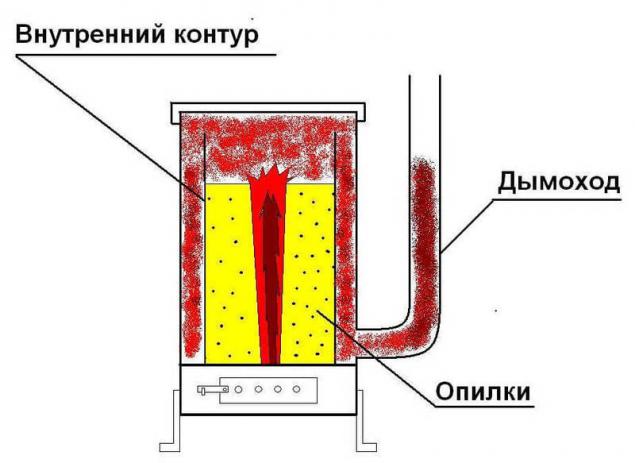

The circuit can be done internal or external. In the first case will require the same form of larger diameter and in the second you need to find the barrel a little smaller or make a suitable container made of metal.

The structure of the kiln with external smoke outline

The outer contour of the attractive increase the area of heat transfer and conservation of volume of the furnace chamber, and the interior easier to work with. In both cases, the chimney should be moved down.

The design of the stove in the filings with the internal contour

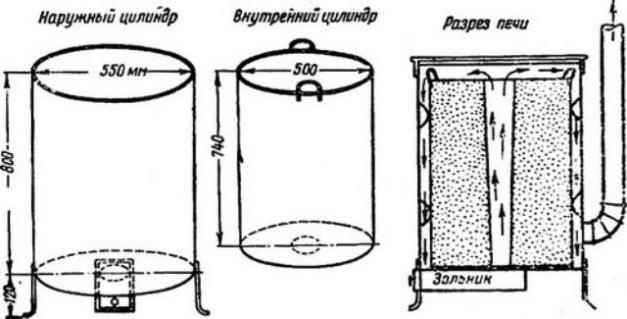

Diagram of the two cylinders

Better cover made of thick steel sheet with a minimum thickness of 5 mm and increase at the edges, otherwise it quickly gets deformed from the heat.

Sawdust boiler for water heating

If you go further, we can turn the furnace long burning in an efficient boiler. The boiler body is best done from a pipe with a diameter of 40 cm with a wall thickness of not less than 10 mm. the greater the size of the boiler, the longer the stove will last for one load. If you take the pipe the length of five feet, you won't have to think about the furnace in the next 40 hours.

The boiler from the pipe, running on sawdust

For blew will fit tubes with a diameter of 7.6 cm, and for the chimney – 10 cm Cover made from steel sheet of thickness 10 mm and necessarily reinforce its edges. In the lid, as in the model described above, provide for the handle. The bottom is cut from the same sheet and welded it to the end of the future of the boiler.

The device blew

To the pipe for the blower with one hand welded 4 steel pin with a length of 10-15 cm – it provides the oxygen and raises the detail above the boiler body. You also need to cut some holes with a length of 10 cm and a width of 0.5–0.7 mm in the lower part of the blower.

Corps of the heating boiler

Chimney pipe is welded to the upper housing, and the output of the chimney install a hot water tank. It is desirable to mount the tank as close as possible to the boiler – this will increase the work efficiency. To the tank connected by two pipes – flow and return connected to the heating system at home.

Before you begin to self-production on sawdust furnace for water heating, it is necessary to carry out all the calculations of the system. This option can only be experienced, confident in their knowledge and abilities. Others recommend ordering the boiler from specialists or buy ready-made model. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/9/3/2/89ulqz9eyp6t/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: teploguru.ru/pechi/pech-na-opilkax.html

The principle of operation of furnace for sawdust

Furnace, using as fuel waste wood, works on the principle of continuous burning. The fuel in these devices is not lit and smoldering, gradually producing a small but sufficient amount of thermal energy. The slow burning allows you to save on fuel and reduce the number of downloads. With this method costly heat is not emitted into the pipe, and the maximum is spent on heating the house.

Homemade oven slow combustion for sawdust

To exclude intense flame and to achieve a slow and long decay, it is necessary to restrict the access of oxygen to the fuel cell. The problem is solved by the tightness and compression of the fuel.

With the lid closed, the fuel is not burning and slow smoldering

How to make oven long burning

To make their own hands the oven on the sawdust, you can use the finished metal capacity: barrel, cans, empty gas cylinder or pipe of suitable diameter. To work need a welder, grinder and skills to work with them.

A simple furnace for sawdust from the barrel

If you have a metal barrel, you first need to cut off from it the top. This should be done carefully, because further detail will be used as intended, but as a removable cover.

Diagram of homemade furnace for sawdust from the barrel

Further, from sheet metal with a minimum thickness of 3 mm cut out a circle with a diameter slightly smaller than the parameters of the barrel. In the center of the circle make a hole under the pipe with a diameter of 10 cm and carefully welded resulting billet to the inner walls, departing from the bottom 15-20 cm.

Just below the welded sheet cut a little window blew, for admission to the furnace is required for combustion of oxygen. In the upper part of the cylinder cut out the hole for the chimney – it is welded pipe, the outlet from the furnace, carbon monoxide.

The chimney requires special attention – too powerful thrust will contribute to the rapid withdrawal of the gases and reduction of thermal efficiency of the device. In low traction may be another problem – in the room begin to do life-threatening products of combustion.

Experienced masters recommend artificially lengthen fume pipe, dropping it on the perimeter of the room, or to adapt the chimney for hot water preparation, including the design of the boiler. All this will help to keep heat in the house and to extract from it the maximum benefit.

The oven of barrels for household premises

The cover is made from cut off tops, privaris to her side, or from sheet metal. It is important to ensure the integrity of the design, otherwise is corruption work burning. For the most of tight junction using a special heat-resistant seals for furnaces. For convenience, necessarily welded handle.

The rules of operation of a homemade furnace

For all its efficiency powered homemade device just:

In a hole in a metal sheet set the tube of a conical shape – this makes it easier to extract at the right time.

Capacity filled with sawdust to the level of the chimney in small portions, thoroughly ramming each layer.

The tube is carefully removed leaving a Central hole for admission to the fuel of oxygen and the exit of exhaust gases.

Oven cover with lid and light the fuel from the blower. To simplify the operation, it is possible to pour some flammable liquid on a metal partition to download the sawdust.

The process of decay in a barrel volume of about 200 liters lasts at least 8 hours – during this time the furnace lid is impossible to open and add the sawdust. A new download can be done only after complete combustion of the previous batch of fuel.

Fuel load from above

How to improve a budget model

A simple stove out of a barrel suitable for the country house, garage or greenhouse. For residential buildings it is recommended to upgrade the design, increasing the heating surface of a flue construction of additional contour.

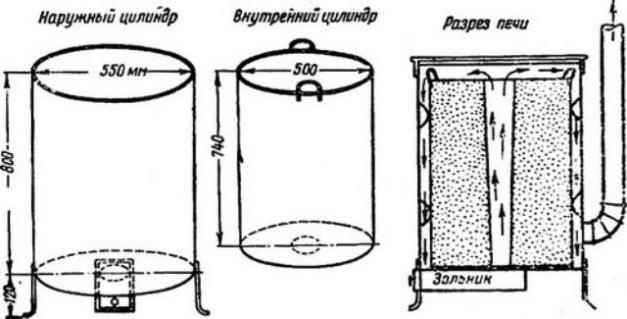

The circuit can be done internal or external. In the first case will require the same form of larger diameter and in the second you need to find the barrel a little smaller or make a suitable container made of metal.

The structure of the kiln with external smoke outline

The outer contour of the attractive increase the area of heat transfer and conservation of volume of the furnace chamber, and the interior easier to work with. In both cases, the chimney should be moved down.

The design of the stove in the filings with the internal contour

Diagram of the two cylinders

Better cover made of thick steel sheet with a minimum thickness of 5 mm and increase at the edges, otherwise it quickly gets deformed from the heat.

Sawdust boiler for water heating

If you go further, we can turn the furnace long burning in an efficient boiler. The boiler body is best done from a pipe with a diameter of 40 cm with a wall thickness of not less than 10 mm. the greater the size of the boiler, the longer the stove will last for one load. If you take the pipe the length of five feet, you won't have to think about the furnace in the next 40 hours.

The boiler from the pipe, running on sawdust

For blew will fit tubes with a diameter of 7.6 cm, and for the chimney – 10 cm Cover made from steel sheet of thickness 10 mm and necessarily reinforce its edges. In the lid, as in the model described above, provide for the handle. The bottom is cut from the same sheet and welded it to the end of the future of the boiler.

The device blew

To the pipe for the blower with one hand welded 4 steel pin with a length of 10-15 cm – it provides the oxygen and raises the detail above the boiler body. You also need to cut some holes with a length of 10 cm and a width of 0.5–0.7 mm in the lower part of the blower.

Corps of the heating boiler

Chimney pipe is welded to the upper housing, and the output of the chimney install a hot water tank. It is desirable to mount the tank as close as possible to the boiler – this will increase the work efficiency. To the tank connected by two pipes – flow and return connected to the heating system at home.

Before you begin to self-production on sawdust furnace for water heating, it is necessary to carry out all the calculations of the system. This option can only be experienced, confident in their knowledge and abilities. Others recommend ordering the boiler from specialists or buy ready-made model. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

http://cdn00.vidyomani.com/c/9/3/2/89ulqz9eyp6t/index.html

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: teploguru.ru/pechi/pech-na-opilkax.html