911

Any solid fuel boiler to choose for a private house

The solid fuel boiler runs on wood pellets and fuel-briquettes, or "eurowood".

Because the boilers are different, with different objectives and characteristics, we will help to choose the right model for your home. To solve this problem, start with studying information on all species, in order to understand what to choose.

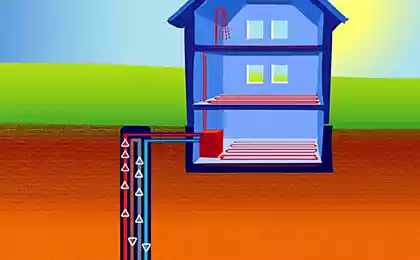

Guidance on selecting boilers for solid fuelBoilers, designed for burning various types of solid fuels are divided into the following varieties:

For the water jacket, use a thin metal (2mm or less).

There is a separate category of units long burning without heat exchanger and represents one large firebox of steel surrounded by coolant. The process of burning it comes from the top down. The principle of operation of a classic boilerFor comparison, how does the classic solid fuel boiler:

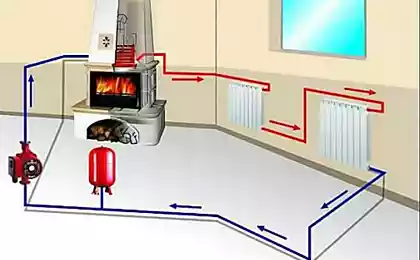

Fuel (wood or coal) laid on the grate and ignited. The combustion flames heat the walls of the firebox and the heat beneath them. Hot gases and smoke before exiting to the chimney pipe run through a heat exchanger, where it give the most part of thermal energy of the same water. The air for combustion is supplied through the ash pan door due to the chimney draught. The second method is the injection of air by fan, controlled electronic control unit depending on the sensor readings. The cooled heat carrier from the heating system enters in a shirt of a boiler from the bottom and heated from the walls of the furnace, out of the nozzle at the top. The principle of operation of the boiler pyrolysispyrolysis boilers of the algorithm works slightly different and takes place in 2 stages.

The first Studenicani solid fuel occurs in the regime of corruption, in which stands a combustible pyrolysis gas. From the fan that pulls air into the main furnace, the gas rushes down and goes with the ashpit through the grate and baffle with a ceramic insert. Second stadial ceramic insert holes (nozzle), where the gas comes out. It burns down inside the ash pan, creating a torch flame directed downwards. It is heated from the bottom chamber, followed by water. Then the process is the same as in classic heat source. Unlike traditional and pyrolysis units, the walls of the firebox pellet boiler heated by the burner flame built into the boot door. It is able to burn and turn off automatically under the control of the control unit. Coal or pellets served in the required amount to the burner by a screw conveyor.

Classic boiler direct combustion

Traditional solid fuel boiler runs more efficient than any furnace, evidenced — efficiency 70%, high – 75%.

These advantages of the heating Assembly are not limited to:

Blame the negative part of the classic units:

Pyrolysis boilers, Pyrolysis boilers will be your best choice provided a competent and balanced attitude toward them.

The sellers give this type of boiler is often exaggerated advantages – burning without smoke and ash, the duration is 12 hours 1 bookmark and efficiency 83-89%. Such statements – it is a competent marketing course. These factors are actually present and working, but only if the qualified approach according to the boiler from the owner.

The material and design of the heat exchanger, there are no differences, as in the features of operation. The same inertness, which requires the installation of battery heat, plus need protection against condensation and thermal shock.

Interesting point: using well dried firewood and high quality charcoal, the same excellent result can be obtained in a conventional solid-fuel boiler, which is 1.5—2 times cheaper. Pellet boilerConsidering the heating system on wood pellets, you should start with the disadvantages because there are only two:

If you have a constant source of cheap supply of wood, we recommend to buy classic wood-fired boiler, despite all its shortcomings.

If you pick up the right heating unit for power, run the harness and put the tank for the accumulation of heat, the boiler direct combustion will reliably serve you for many years.

When choosing you need to consider these points:

Also does not always make sense to buy the solid fuel boiler with cast iron heat exchanger, which is much more expensive. In normal operating conditions the steel calm will last at least 10 years.

Why you should buy a boiler operating on wood pelletsWhere to invest, so it is in solid fuel boiler for pellets.

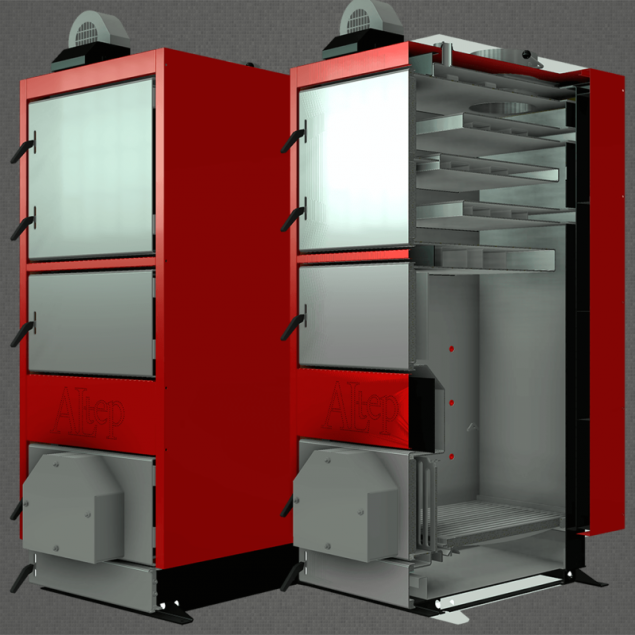

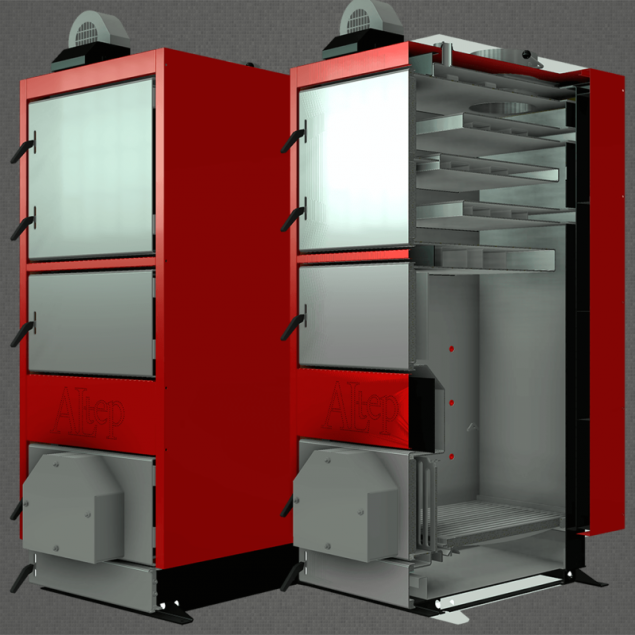

It consists of 3 main parts:

the unit; burner automatic; hopper for pellets. Often the first 2 parts are manufactured in different places — at the factory weld iron box with a water jacket, and then inserted into a burner, brought out of nowhere. Ideally, when all the elements are made in one place.

If the design team still, then this is not a disaster. To choose the boiler by the recommendations given above. But burner is better to take the European or Baltic production. But keep in mind that these devices are produced in 3 versions, each of which has its pros and cons:

Torch burner more reliable, but due to the horizontal flame it has to be embedded in the elongated body of the boiler to not burn the rear wall of the furnace. This form of housing does not suit everyone due to lack of space.

Cheap burner type "Pelletron" — equipment for everybody. Definitely recommend it we can't, although the idea is good. Important condition: you need excellent traction of the chimney, as his fan from the burner, and no air flows naturally. The intensity of burning is regulated by the gratings with a different orifice.

Brands deserve your trust

Conventionally, all the brands under which sold by heating equipment on solid fuel, can be divided into 3 groups:

To average price category can be attributed very much honored brands, including some manufacturers from Russia and Ukraine.

Here is an incomplete list of them:

To make a successful choice, we suggest to apply at least to the average price category. If you are severely limited in the funds, before choosing a budget solid-fuel boiler it is necessary to consult with friends who have this unit operates. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Source: energylogia.com/home/otoplenie/vybor-tverdotoplivnogo-kotla-s-nami.html

Because the boilers are different, with different objectives and characteristics, we will help to choose the right model for your home. To solve this problem, start with studying information on all species, in order to understand what to choose.

Guidance on selecting boilers for solid fuelBoilers, designed for burning various types of solid fuels are divided into the following varieties:

- Classic (traditional), direct combustion. Operate on the principle of a conventional oven, only instead of air heat water for the heating system.

- Pyrolysis. They, of wood and coal during combustion is allocated a combustible gas, which after is burned in the secondary chamber, heating the heat carrier.

- Pellet and coal. Warm water using burners where the fuel pellets are fed automatically.

- All of these boilers are sold in outdoor performance and can be equipped with a water circuit to ensure hot water.

- Attempts to make and sell wall-hung boilers have been made, but was not successful due to high prices of finished products and lack of demand for them.

- combustion chamber (firebox), which laid the wood are burning;

- the grate, which plays the role of a platform for fuel;

- ash chamber (ash pan), which poured through the grate ash and fly ash;

- the heat exchanger, where the heat of combustion is transferred to the water;

- the water jacket surrounding the firebox on all sides.

- system of air supply to a boiler furnace;

- control devices (manometer, thermometer).

For the water jacket, use a thin metal (2mm or less).

There is a separate category of units long burning without heat exchanger and represents one large firebox of steel surrounded by coolant. The process of burning it comes from the top down. The principle of operation of a classic boilerFor comparison, how does the classic solid fuel boiler:

Fuel (wood or coal) laid on the grate and ignited. The combustion flames heat the walls of the firebox and the heat beneath them. Hot gases and smoke before exiting to the chimney pipe run through a heat exchanger, where it give the most part of thermal energy of the same water. The air for combustion is supplied through the ash pan door due to the chimney draught. The second method is the injection of air by fan, controlled electronic control unit depending on the sensor readings. The cooled heat carrier from the heating system enters in a shirt of a boiler from the bottom and heated from the walls of the furnace, out of the nozzle at the top. The principle of operation of the boiler pyrolysispyrolysis boilers of the algorithm works slightly different and takes place in 2 stages.

The first Studenicani solid fuel occurs in the regime of corruption, in which stands a combustible pyrolysis gas. From the fan that pulls air into the main furnace, the gas rushes down and goes with the ashpit through the grate and baffle with a ceramic insert. Second stadial ceramic insert holes (nozzle), where the gas comes out. It burns down inside the ash pan, creating a torch flame directed downwards. It is heated from the bottom chamber, followed by water. Then the process is the same as in classic heat source. Unlike traditional and pyrolysis units, the walls of the firebox pellet boiler heated by the burner flame built into the boot door. It is able to burn and turn off automatically under the control of the control unit. Coal or pellets served in the required amount to the burner by a screw conveyor.

Classic boiler direct combustion

Traditional solid fuel boiler runs more efficient than any furnace, evidenced — efficiency 70%, high – 75%.

These advantages of the heating Assembly are not limited to:

- the heater takes wood at any moisture content, coal and wood waste, briquettes;

- it is the most affordable among all solid fuel boilers;

- simple in design and maintenance;

- takes up relatively little space.

Blame the negative part of the classic units:

- The firebox often need to replenish firewood (1 every 4-6 hours) and cleaned 1 time a day. Exception – the long burning boilers, working from 1 download 8-12 hours.

- Inertia. Burning wood or coal in the furnace cannot be stopped instantly, when the water gets hot. The boiler must be somewhere to dump the heat, while it is not necessary the heating system, which uses additional water tank (buffer tank).

When used wet firewood efficiency of the unit is drastically reduced. Example: dry wood can produce about 4 kW of heat from 1 kg and green — only 2 kW. - If the slow combustion of the overlap of air, the efficiency of the heat source decreases by 10-20%.

Steel heat exchangers need to be protected from condensate, and cast iron from temperature shock. Will have to put extra piping of the boiler — mixing unit with three-way valve.

Pyrolysis boilers, Pyrolysis boilers will be your best choice provided a competent and balanced attitude toward them.

The sellers give this type of boiler is often exaggerated advantages – burning without smoke and ash, the duration is 12 hours 1 bookmark and efficiency 83-89%. Such statements – it is a competent marketing course. These factors are actually present and working, but only if the qualified approach according to the boiler from the owner.

- The efficiency of the pyrolysis heat source is 75-80%, if you follow the advice and "feed" it with dry wood.

- Smokeless burning also give the wood a moisture content of 20%, are only allowed to use in the boiler.

- Since the air is blown by fan, from dried wood remains a light ash discharged to the flue pipe.

- Duration of work with 1 loading is achieved by increasing the volume of the firebox.

The material and design of the heat exchanger, there are no differences, as in the features of operation. The same inertness, which requires the installation of battery heat, plus need protection against condensation and thermal shock.

Interesting point: using well dried firewood and high quality charcoal, the same excellent result can be obtained in a conventional solid-fuel boiler, which is 1.5—2 times cheaper. Pellet boilerConsidering the heating system on wood pellets, you should start with the disadvantages because there are only two:

- the high cost of equipment;

- the complexity of the setup and repairs requiring specialists.

- Use high-calorie burner and the fuel increases the efficiency of the heat source to 80-85%.

- Inertia are almost there, because in the combustion chamber is always a small part of the fuel. After disconnecting the air supply to fester there remains a small handful of pellets or coal.

- There is no need to install the buffer tank, although protection from condensation is required.

- The boilers are fully automated and require human intervention 1 time per 4-7 days to clean and add fuel in the hopper.

- The ability to program the operation of the equipment and operate it at a distance via the Internet or mobile communications.

- The absence of dirt and sawdust in the boiler room.

- For the fuel bunker designed for 5-10 days continuous operation, the pellet boiler takes up more space than the traditional one. But the level of comfort during use is comparable to gas and electric heaters.

If you have a constant source of cheap supply of wood, we recommend to buy classic wood-fired boiler, despite all its shortcomings.

If you pick up the right heating unit for power, run the harness and put the tank for the accumulation of heat, the boiler direct combustion will reliably serve you for many years.

When choosing you need to consider these points:

- Power TT-boiler, take the needs of a private house in the heat, only by a safety factor of 1.2. If you need to heat water for domestic hot water, then take the unit with power reserve of 1.5.

- The more powerful the boiler, the greater the firebox and the combustion duration. The less you will have to visit the boiler room.

- Don't rely on a Combi boiler if is in constant need of hot water in large quantities. It will not provide the required flow rate should be set to solid fuel boiler with a boiler of indirect heating.

- Choose a model with a maximum operating pressure of 3 Bar. Cheap heaters from a thin metal stand only 1-2 Bar.

- Try to choose a boiler with a large volume of the furnace. Standard size firebox for up to 6 hours of operation at a power of 20 kW is equal to 60-65 l, in units of continuous burning, the figure will be 80 or more liters for the same 20 kW.

- The heat source fitted with a fan, works better than simple, with the flow of air through the open door. This unit is worth buying only with frequent power outages. Make sure that the ash pan door was controlled by a mechanical throttle.

- The fan will last longer at the solid fuel boiler when it's standing up. On models where the supercharger is built into the door, the impeller is drawing the dust and dirt from the floor.

- Pay attention to the origin of the electronic control unit. Avoid Chinese controllers, the choice of budget models you can find an inexpensive heater with a more reliable Polish unit.

- Don't get boilers with upper combustion of fuel, they have several drawbacks. Low pressure, hanging wood waste on the walls of the firebox and the inability to throw fire wood on the go — included in this list.

- If you plan to heat the house with coal, pay special attention to the thickness of the walls of the firebox you. Because the temperature of the burning coal reaches 1000-1100 °C, to long for her to withstand, the necessary thickness of steel not less than 3 mm, better 5 mm. Otherwise your new boiler will last a long time.

Also does not always make sense to buy the solid fuel boiler with cast iron heat exchanger, which is much more expensive. In normal operating conditions the steel calm will last at least 10 years.

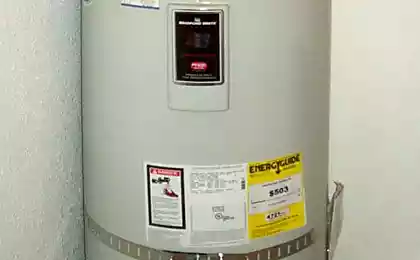

Why you should buy a boiler operating on wood pelletsWhere to invest, so it is in solid fuel boiler for pellets.

It consists of 3 main parts:

the unit; burner automatic; hopper for pellets. Often the first 2 parts are manufactured in different places — at the factory weld iron box with a water jacket, and then inserted into a burner, brought out of nowhere. Ideally, when all the elements are made in one place.

If the design team still, then this is not a disaster. To choose the boiler by the recommendations given above. But burner is better to take the European or Baltic production. But keep in mind that these devices are produced in 3 versions, each of which has its pros and cons:

- retort-type air supply fan;

- the same flare type;

- Russian burner with natural air supply and manual regulation of the "Pelletron".

Torch burner more reliable, but due to the horizontal flame it has to be embedded in the elongated body of the boiler to not burn the rear wall of the furnace. This form of housing does not suit everyone due to lack of space.

Cheap burner type "Pelletron" — equipment for everybody. Definitely recommend it we can't, although the idea is good. Important condition: you need excellent traction of the chimney, as his fan from the burner, and no air flows naturally. The intensity of burning is regulated by the gratings with a different orifice.

Brands deserve your trust

Conventionally, all the brands under which sold by heating equipment on solid fuel, can be divided into 3 groups:

- higher price category (elite);

- average price;

- budget.

To average price category can be attributed very much honored brands, including some manufacturers from Russia and Ukraine.

Here is an incomplete list of them:

- Atmos (Czech Republic);

- Virbel (Austria);

- Protherm (Slovakia);

- Zota (Russian Federation);

- Altep (Ukraine).

To make a successful choice, we suggest to apply at least to the average price category. If you are severely limited in the funds, before choosing a budget solid-fuel boiler it is necessary to consult with friends who have this unit operates. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Source: energylogia.com/home/otoplenie/vybor-tverdotoplivnogo-kotla-s-nami.html