578

Fuel pellets from waste energy source of the future

The most progressive form of solid fuel used to heat buildings, are pellets.

Pellets — what is it?

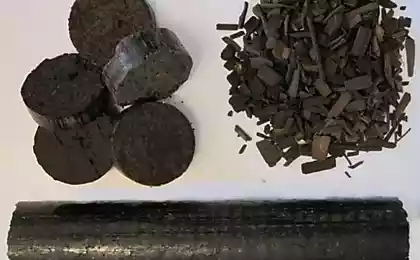

This solid cylindrical pellets of 6-10 mm in diameter, obtained by extrusion (granulation) of waste in various industries, wood processing and agriculture. Their use in the heating sector is very different from burning other types of biomass — wood, coal, sawdust, and straw in its purest form.

What good pellets

Advantages of fuel pellets made them one of the widely used energy sources in the countries of Western Europe:

Heating equipment that burns pellets, stops to clean off soot on average 1 time a week. Fuel excellent transfers transportation and bulk storage, not destroyed and not turning into dust. This allows you to arrange the supply of fuel in industrial boilers of large capacity of special storage — silos, and places a one-month supply of pellets.

Pellet fuel is convenient and environmentally friendly energy source not formed when heating a private house dirt and dust, so he gradually conquers the market of Ukraine and Russia.

Types of waste for pellet productionthe Raw material for pellet production are such types of wastes in various industries:

About granulation technology isthe Goal of each production process for the production of fuel pellets — raw materials obtained from dense and durable cylinders with low moisture content. Pelleting of wood waste this is achieved in several stages:

First is sorting wood waste into small and large fractions. The first is sawdust and small chips, whose dimensions do not exceed 25 mm at a thickness of 2-4 mm. Chips, branches, slabs and other timber of large dimensions otsortirovyvaya and sent to primary crushing. Primary crushing large waste produced by crushers of various types. Objective – to obtain wood particles of these sizes. The ground raw material moves to the next stage pneumatically or by screw conveyor. Secondary crushing takes place all raw materials, turning into a fine fraction. The maximum particle size output – 4 mm with a thickness of 1.5 mm. Drying. To obtain high quality fuel with high heat emission, it is necessary to remove from the tree all the excess moisture that freshly cut branches of up to 50%. The process goes in a special drying chamber, a drum or other type. At the output of the raw material moisture should not exceed 12%. Adjustment of the humidity. Since initially job fall waste with different moisture content, at the previous stage of the raw material is too dry, i.e. its moisture content is less than 8%. For the formation of strong granules that is not enough. Therefore, in the bunker with the raw mass is fed some amount of steam. The grain of the wood comes with a humidity from 8% to 18%. Granulation. Here are pelleting presses with cylindrical or flat die (thick metal with a grooved hole). Raw materials coming from the hopper of the dispenser is pressed into the holes with steel rollers which move at a high speed inside the matrix. During this process, the already heated and Peratallada weight of the raw material is heated to even higher temperature above 100 degrees Celsius. This is due to high-pressure pelleting. From the raw materials allocated bonding material – lignin. This contributes to the humidity level, which is achieved by the adjustment. In addition, the pressure of 30-40 MPa, the mass is spontaneously heated to temperatures above 100 degrees Celsius.For removing the excess mass on the surface of the rollers cut grooves. Raw pellets by pneumatic conveyor or auger is directed into the chamber of the secondary drying and cooling, where blown by powerful fans, and finally harden. The last stage is packing in plastic bags or big bags. Major customers products can be dispensed bulk method. The principle of granulation does not involve the use of external binders or extra heating of the raw material. The pressing of pellets from straw is somewhat simpler because the process excluded sorting and primary crushing. Pelleting of hulls from sunflower seeds is also possible the drying step. The reason is that the waste of processing of sunflower seeds initially have a moisture content close to the desired, and immediately sent to the adjustment and pressing.

Comparison with other solid fuelsStrong point pellets — their progressiveness compared with wood, coal and briquettes even. Imagine a solid fuel boiler in the same way as a gas. Only safer, because pellets do not explode like natural gas.

The difference between gas and pellet heating is expressed in several points:

The results of the comparison according to other criteria also speak in favor of heating with pellets:

Fuel Heat impact 1 kg kW kW efficiency of thermal plants, % Real heat of 1 kg kWh Price for 1 kg in Russia, rubles Price of 1 kg in Ukraine, UAH the Cost of 1 kW of heat in Russia, rubles Cost of 1 kW of heat in Ukraine, UAH the Ash content of fuel, % Wood green 2 75 2,25 1,50 0,75 1,50 0,50 3 to 10 Firewood dry with a moisture content of 4.10 to 3.08 75 3,00 1,00 0,98 0,33 to 2 Briquettes 75 3,75 5,00 5,50 2,00 1,47 0,53 to 3 Agrability 5,00 80 4,00 7,00 2,00 1,75 0,50 to 3 anthracite Coal 75 5,74 7,65 10,00 3,80 0,66 1,74 15 to 25 Real heat energy, may differ from the theoretical and depends on the efficiency of your heating equipment and humidity of the raw material that you purchased.

The difference between these parameters is shown in the table, and then for the price of 1 kg of each type of fuel in the Russian Federation and Ukraine determined the cost of 1 kW of heat to heat the building.

Comparing the cost per unit of heat pellet boilers, wood and coal, it is easy to conclude that pellet heating is not much more expensive wood or carbon.

Note that the comparison involves not the highest quality pellets — agropellets. Pellets from wood waste show even better.

Excellent performance on all the criteria have briquettes, but pelletan they lose in degree of automation otopitelnogo equipment.

Pellets, like firewood, should be used in the furnace of the home owner. The disadvantages of pellet fuel quite a bit:

The use of pellets for heating, there are several secondary benefits that also will not prevent to consider:

Now this waste is simply burned, polluting the atmosphere, or exported to landfills. The problem of disposal of husk from the seeds is facing many enterprises producing sunflower oil. The conclusion is that manufacturing and burning wood pellets is not just comfortable and safe, it helps to preserve the environment and "green lungs" of the planet — the forest.

Our advice is simple:

buy pellets first class from suppliers that are responsible for their safekeeping and compliance with certain humidity. In some cases, justified the purchase of pellets not in bags of 20-25 kg, and immediately one or several big runs, with this approach you can claim a substantial discount; to Determine the quality of pellets can be quite simple: a good solid pellets are dry and crumble to dust, even under extreme compression. When she raspadaetsya pellets fracture into two or more particles not pile and turn into dust. Appearance glossy and shiny; keep pellets in a dry place with low humidity to prevent any presence around them open fire; use pellets only in specially designed pellet boilers. Experience shows that combination boilers have a number of problems associated with poorly tuned combustion and increased formation of soot in the chimney and other unpleasant problems. Specialized boilers such problems as lack.

Pellets — one of the main energy carriers in the long run, when free of the wood will remain. With the further development of production the price of pellets will be reduced. If necessary, the providers will always bring a batch of pellets to your home, as is customary in Western Europe.

published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: energylogia.com/home/otoplenie/pellety-chto-eto-takoe.html

Pellets — what is it?

This solid cylindrical pellets of 6-10 mm in diameter, obtained by extrusion (granulation) of waste in various industries, wood processing and agriculture. Their use in the heating sector is very different from burning other types of biomass — wood, coal, sawdust, and straw in its purest form.

What good pellets

Advantages of fuel pellets made them one of the widely used energy sources in the countries of Western Europe:

- high bulk density of 550-600 kg/m3, allowing to save space for storing fuel;

- low relative humidity allowed maximum of 12%;

- due to the high degree of compaction and low moisture content pellets have a high calorific value — 5 to 5.4 kW/kg;

- low ash content — 0.5 to 3% depending on the raw materials.

Heating equipment that burns pellets, stops to clean off soot on average 1 time a week. Fuel excellent transfers transportation and bulk storage, not destroyed and not turning into dust. This allows you to arrange the supply of fuel in industrial boilers of large capacity of special storage — silos, and places a one-month supply of pellets.

Pellet fuel is convenient and environmentally friendly energy source not formed when heating a private house dirt and dust, so he gradually conquers the market of Ukraine and Russia.

Types of waste for pellet productionthe Raw material for pellet production are such types of wastes in various industries:

- wood chips, sawdust, slabs, chips and other non-conforming forest;

- the husk remaining from the processing of sunflower seeds or buckwheat;

- stems of different crops in the form of a straw;

- peat.

- From pure wood without additives bark pellets made of first grade (white). They are distinguished by their low ash content — 0,5% and better calorific value — up to 5.4 kW/kg. This is the best choice for heating your home!

- Fuel 2nd grade includes a variety of impurities, making color is darker than top-notch. This includes pellets made of straw cereal crops. Impurities have virtually no effect on the calorific value of the fuel, but its ash content is higher — 1-1,5%.

- All sorts of agricultural waste pellets are made in 3rd grade with ash content 2,5—3%. The heat of combustion of this fuel is also quite high — not less than 5 kW/kg.

- The low-grade fuel obtained from peat. Ash content and calorific value of peat pellets behind the rest and therefore not too popular.

About granulation technology isthe Goal of each production process for the production of fuel pellets — raw materials obtained from dense and durable cylinders with low moisture content. Pelleting of wood waste this is achieved in several stages:

First is sorting wood waste into small and large fractions. The first is sawdust and small chips, whose dimensions do not exceed 25 mm at a thickness of 2-4 mm. Chips, branches, slabs and other timber of large dimensions otsortirovyvaya and sent to primary crushing. Primary crushing large waste produced by crushers of various types. Objective – to obtain wood particles of these sizes. The ground raw material moves to the next stage pneumatically or by screw conveyor. Secondary crushing takes place all raw materials, turning into a fine fraction. The maximum particle size output – 4 mm with a thickness of 1.5 mm. Drying. To obtain high quality fuel with high heat emission, it is necessary to remove from the tree all the excess moisture that freshly cut branches of up to 50%. The process goes in a special drying chamber, a drum or other type. At the output of the raw material moisture should not exceed 12%. Adjustment of the humidity. Since initially job fall waste with different moisture content, at the previous stage of the raw material is too dry, i.e. its moisture content is less than 8%. For the formation of strong granules that is not enough. Therefore, in the bunker with the raw mass is fed some amount of steam. The grain of the wood comes with a humidity from 8% to 18%. Granulation. Here are pelleting presses with cylindrical or flat die (thick metal with a grooved hole). Raw materials coming from the hopper of the dispenser is pressed into the holes with steel rollers which move at a high speed inside the matrix. During this process, the already heated and Peratallada weight of the raw material is heated to even higher temperature above 100 degrees Celsius. This is due to high-pressure pelleting. From the raw materials allocated bonding material – lignin. This contributes to the humidity level, which is achieved by the adjustment. In addition, the pressure of 30-40 MPa, the mass is spontaneously heated to temperatures above 100 degrees Celsius.For removing the excess mass on the surface of the rollers cut grooves. Raw pellets by pneumatic conveyor or auger is directed into the chamber of the secondary drying and cooling, where blown by powerful fans, and finally harden. The last stage is packing in plastic bags or big bags. Major customers products can be dispensed bulk method. The principle of granulation does not involve the use of external binders or extra heating of the raw material. The pressing of pellets from straw is somewhat simpler because the process excluded sorting and primary crushing. Pelleting of hulls from sunflower seeds is also possible the drying step. The reason is that the waste of processing of sunflower seeds initially have a moisture content close to the desired, and immediately sent to the adjustment and pressing.

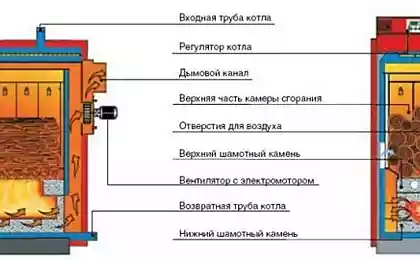

Comparison with other solid fuelsStrong point pellets — their progressiveness compared with wood, coal and briquettes even. Imagine a solid fuel boiler in the same way as a gas. Only safer, because pellets do not explode like natural gas.

The difference between gas and pellet heating is expressed in several points:

- supply of pellets must be replenished;

- once a week the boiler stops for cleaning;

- when working pellet heat generator noise is pouring from a plastic pipe, granules;

- the use of this fuel is not related to the work of public services and various inspections;

- heating equipment, burning pellets is not worse than the gas.

The results of the comparison according to other criteria also speak in favor of heating with pellets:

- Burning safer than wood pellets and coal. Boilers equipped with a pellet burner, does not suffer lag, as usual solid. Upon reaching the desired temperature the burner is switched off and the supply of fuel is terminated. Burns only a small handful of pellets.

- Indoor pellet boiler is clean, no smoke smell that is present when downloads firebox with coal and firewood.

Installation of buffer tank — at the request of the owner. Pellet heat can do without a battery for dumping excess heat.

Fuel Heat impact 1 kg kW kW efficiency of thermal plants, % Real heat of 1 kg kWh Price for 1 kg in Russia, rubles Price of 1 kg in Ukraine, UAH the Cost of 1 kW of heat in Russia, rubles Cost of 1 kW of heat in Ukraine, UAH the Ash content of fuel, % Wood green 2 75 2,25 1,50 0,75 1,50 0,50 3 to 10 Firewood dry with a moisture content of 4.10 to 3.08 75 3,00 1,00 0,98 0,33 to 2 Briquettes 75 3,75 5,00 5,50 2,00 1,47 0,53 to 3 Agrability 5,00 80 4,00 7,00 2,00 1,75 0,50 to 3 anthracite Coal 75 5,74 7,65 10,00 3,80 0,66 1,74 15 to 25 Real heat energy, may differ from the theoretical and depends on the efficiency of your heating equipment and humidity of the raw material that you purchased.

The difference between these parameters is shown in the table, and then for the price of 1 kg of each type of fuel in the Russian Federation and Ukraine determined the cost of 1 kW of heat to heat the building.

Comparing the cost per unit of heat pellet boilers, wood and coal, it is easy to conclude that pellet heating is not much more expensive wood or carbon.

Note that the comparison involves not the highest quality pellets — agropellets. Pellets from wood waste show even better.

Excellent performance on all the criteria have briquettes, but pelletan they lose in degree of automation otopitelnogo equipment.

Pellets, like firewood, should be used in the furnace of the home owner. The disadvantages of pellet fuel quite a bit:

- The high cost of boiler equipment and automation. Price for pellet burner average quality comparable to conventional solid-fuel boiler with capacity up to 15 kW.

- Pellets need to be stored in certain conditions, so they do not become impregnated with a moisture and from falling apart. A method of storing a bunch of under cover absolutely will not fit, you will need an enclosed space or container such as a silo.

The use of pellets for heating, there are several secondary benefits that also will not prevent to consider:

- burning pellets not only gives little ash, but leaves on the inner walls of the chimney is much less soot;

- the mode of combustion and the design of the burners allows you to use the energy more efficiently compared to wood, the efficiency of pellet boilers is 85%;

- automatic pellet heat source interacts well with devices of automatic control of water heating systems, including Underfloor heating.

Now this waste is simply burned, polluting the atmosphere, or exported to landfills. The problem of disposal of husk from the seeds is facing many enterprises producing sunflower oil. The conclusion is that manufacturing and burning wood pellets is not just comfortable and safe, it helps to preserve the environment and "green lungs" of the planet — the forest.

Our advice is simple:

buy pellets first class from suppliers that are responsible for their safekeeping and compliance with certain humidity. In some cases, justified the purchase of pellets not in bags of 20-25 kg, and immediately one or several big runs, with this approach you can claim a substantial discount; to Determine the quality of pellets can be quite simple: a good solid pellets are dry and crumble to dust, even under extreme compression. When she raspadaetsya pellets fracture into two or more particles not pile and turn into dust. Appearance glossy and shiny; keep pellets in a dry place with low humidity to prevent any presence around them open fire; use pellets only in specially designed pellet boilers. Experience shows that combination boilers have a number of problems associated with poorly tuned combustion and increased formation of soot in the chimney and other unpleasant problems. Specialized boilers such problems as lack.

Pellets — one of the main energy carriers in the long run, when free of the wood will remain. With the further development of production the price of pellets will be reduced. If necessary, the providers will always bring a batch of pellets to your home, as is customary in Western Europe.

published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: energylogia.com/home/otoplenie/pellety-chto-eto-takoe.html

Any solid fuel boiler to choose for a private house

The heat loss of the house - thermos, the dome house and the hut