1310

How to make pellets with your hands

Pellets with their hands can do. Enough to get acquainted with the technology and have the right equipment, and a home master can not only provide your home with cheap fuel efficient, but also create a promising business selling pellets.

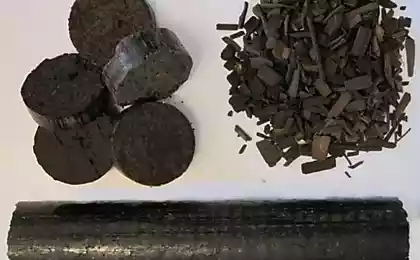

The pros and cons of pellet fuelpellets Today under understand not only the finished product of fine sawdust, but in the form of pellets and waste wood and agricultural industries in General. For the production of pellets is all that can burn and in most cases simply thrown away or inefficiently disposed of.

Granular fuel is divided into three classes:

The disadvantages of pellets is that they require special conditions of storage, dryness and secure protection from fire. The pros have much more. This is a low price relative to other fuels (primarily natural gas) and high heat output, and ease of production and ease of storage and transportation.

But the main plus is that the house master will be able to produce pellets with your hands without any cost and special skills.

Equipment and materialsSUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

In order to establish the production of pellet fuel at home need not so many equipments. And the material can serve as waste from carpentry shops and small branches and twigs that you can collect. The owners of large farms even use chicken manure for production of pellets, but the heat of combustion of such pellets are lower than wood.

So, in the mandatory set of equipment for production of pellet desired, the following mechanisms and tools:

Chopper will need to obtain the small masses for the extrusion of granules. He, like crusher, you can do with your hands, but most business executives prefer to use ready-made installations. But a granulating press can do with their hands based on the volume that you want to. His drawings are simple and clear.

The granulator consists of an electric drive, reducer, drum masses, forming the matrix and rollers. Them (except the motor) can make any master with experience on lathe and milling machines.

In the production of fuels use two types of matrices — flat or drum (cylinder). In the first type pellet mill raw material poured on top, rollers, rolled it, squeezing the mass. The second type is relevant for large productions, rollers located inside the drum in which there is a supply of chopped wood and other raw materials.

Some of the owners for greater efficiency provide the pellet machine with belt-conveyor, which provides automatic feeding of the starting material and the same conveyor for removal of the finished pellets, so they are not bombarded with the press and did not prevent it to work properly.

Note that homemade setup has a small capacity compared to the factory models. Now pay attention to the manufacturing of pellet fuel and will consider the entire process from beginning to end.Do granules

Pellet fuel has a lot of advantages, the main thing is ease of fabrication. The first phase is the procurement of raw materials. It can be used, as mentioned above, waste wood, branches and small twigs that remain in the plantations in the felling of trees, husks of sunflower seeds and grain, peat.

The raw materials are ground in a crusher, resulting in a smaller fraction with a diameter of about 2-4 mm.

Given that the material previously passed heat treatment, the moisture content may be higher than desired. The standard rate is 12% moisture of the total weight of raw materials. This is accomplished by the second stage drying of raw materials to the required condition. To do this, use industrial type equipment drying drums or pneumission.

Then move to the third stage, secondary grinding of the prepared raw materials. Passing it through a chopper, get the so-called wood flour. At this stage you should check the humidity of the mass. Why is it so important? Too dry and the flour won't be compressed, resulting fuel pellets would crumble into dust immediately after leaving the press.

Therefore, it is recommended to check the condition of the masses, and if its moisture content is less than 8% by weight, it is necessary to increase this figure by means of steam or water.

Finally, the last thing you need to make pellets with your hands, is to fill the prepared mass in a granulating press, and start the process. The gearbox transmits rotational movement of the rollers, which squeeze the raw material through the forming die.

Under pressure engages the pellet fuel released from wood lignin, the substances contained in lignified plant cells. It plays the role of natural glue, fixing the form of granules and not allowing them to crumble.A few words on storage

At the exit from the press the pellets are heated to 90°C. Therefore they should be cool and dry "until done". Drying is carried out naturally, i.e. without using additional heating.

Stored as fuel pellets is recommended in areas protected from potential fire hazard. Though they themselves are quite inert and do not apply to flammable substances that ignited the pellets are not easy to repay.

For this zealous owners obtained pellets Packed in bags weighing 10 to 20 kg each. It is convenient to store, and if granulated fuel produced for sale, also convenient to let buyers.published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: sdelaypechi.ru/toplivo/pellety-svoimi-rukami.html

The pros and cons of pellet fuelpellets Today under understand not only the finished product of fine sawdust, but in the form of pellets and waste wood and agricultural industries in General. For the production of pellets is all that can burn and in most cases simply thrown away or inefficiently disposed of.

Granular fuel is divided into three classes:

- premium — made from purified from impurities and small waste sawdust of soft wood species;

- industrial — made from sawdust and other small waste wood;

- industrial — the manufacture is almost all that remains in the waste of agriculture, wood harvesting, wood processing and even poultry.

The disadvantages of pellets is that they require special conditions of storage, dryness and secure protection from fire. The pros have much more. This is a low price relative to other fuels (primarily natural gas) and high heat output, and ease of production and ease of storage and transportation.

But the main plus is that the house master will be able to produce pellets with your hands without any cost and special skills.

Equipment and materialsSUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

In order to establish the production of pellet fuel at home need not so many equipments. And the material can serve as waste from carpentry shops and small branches and twigs that you can collect. The owners of large farms even use chicken manure for production of pellets, but the heat of combustion of such pellets are lower than wood.

So, in the mandatory set of equipment for production of pellet desired, the following mechanisms and tools:

- crusher;

- dryer;

- chopper;

- a granulating press.

Chopper will need to obtain the small masses for the extrusion of granules. He, like crusher, you can do with your hands, but most business executives prefer to use ready-made installations. But a granulating press can do with their hands based on the volume that you want to. His drawings are simple and clear.

The granulator consists of an electric drive, reducer, drum masses, forming the matrix and rollers. Them (except the motor) can make any master with experience on lathe and milling machines.

In the production of fuels use two types of matrices — flat or drum (cylinder). In the first type pellet mill raw material poured on top, rollers, rolled it, squeezing the mass. The second type is relevant for large productions, rollers located inside the drum in which there is a supply of chopped wood and other raw materials.

Some of the owners for greater efficiency provide the pellet machine with belt-conveyor, which provides automatic feeding of the starting material and the same conveyor for removal of the finished pellets, so they are not bombarded with the press and did not prevent it to work properly.

Note that homemade setup has a small capacity compared to the factory models. Now pay attention to the manufacturing of pellet fuel and will consider the entire process from beginning to end.Do granules

Pellet fuel has a lot of advantages, the main thing is ease of fabrication. The first phase is the procurement of raw materials. It can be used, as mentioned above, waste wood, branches and small twigs that remain in the plantations in the felling of trees, husks of sunflower seeds and grain, peat.

The raw materials are ground in a crusher, resulting in a smaller fraction with a diameter of about 2-4 mm.

Given that the material previously passed heat treatment, the moisture content may be higher than desired. The standard rate is 12% moisture of the total weight of raw materials. This is accomplished by the second stage drying of raw materials to the required condition. To do this, use industrial type equipment drying drums or pneumission.

Then move to the third stage, secondary grinding of the prepared raw materials. Passing it through a chopper, get the so-called wood flour. At this stage you should check the humidity of the mass. Why is it so important? Too dry and the flour won't be compressed, resulting fuel pellets would crumble into dust immediately after leaving the press.

Therefore, it is recommended to check the condition of the masses, and if its moisture content is less than 8% by weight, it is necessary to increase this figure by means of steam or water.

Finally, the last thing you need to make pellets with your hands, is to fill the prepared mass in a granulating press, and start the process. The gearbox transmits rotational movement of the rollers, which squeeze the raw material through the forming die.

Under pressure engages the pellet fuel released from wood lignin, the substances contained in lignified plant cells. It plays the role of natural glue, fixing the form of granules and not allowing them to crumble.A few words on storage

At the exit from the press the pellets are heated to 90°C. Therefore they should be cool and dry "until done". Drying is carried out naturally, i.e. without using additional heating.

Stored as fuel pellets is recommended in areas protected from potential fire hazard. Though they themselves are quite inert and do not apply to flammable substances that ignited the pellets are not easy to repay.

For this zealous owners obtained pellets Packed in bags weighing 10 to 20 kg each. It is convenient to store, and if granulated fuel produced for sale, also convenient to let buyers.published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: sdelaypechi.ru/toplivo/pellety-svoimi-rukami.html