872

Fuels for solid fuel boilers, and the comparative table of their calorific value

Characteristics of fuel for heating boilers vary quite considerably. Choosing the right fuel helps you save money and keep the equipment operational.

Principal fuel for solid fuel boilers:

— Firewood

- Pellets (fuel granules)

Fuel briquettes

Coal

Wood

Wood sawn or chipped pieces of wood intended for burning in furnaces, fireplaces, etc to produce heat, heat and light.

The moisture content should be as small as possible.

Fireplace wood have a length of about 25 — 33 cm

Priority characteristics of firewood for fireplaces and stoves — their calorific value, combustion duration and comfort in use (the picture of the flame, smell).

For heating purposes it is important that the dissipation was slower but for a longer time.

For heating purposes, it is best to fit all the wood of deciduous trees in techdub, ash, birch, hazel, yew, hawthorn.

Features of burning firewood different wood species:

— firewood of beech, birch, ash, hazel, it is difficult to melt, but they can burn raw, because they have little humidity, and the wood of all these trees, besides beech, are easily split;

alder and aspen burns without soot and even burned her from the chimney;

— birch wood is good for heat, but the lack of air in the furnace, burns smoky and form tar (birch tar), which is deposited on the walls of the pipe;

— pine wood burn hotter than the spruce because of the higher resin content, sparking with a sharp increase in temperature;

— oak and hornbeam have better heat dissipation during the combustion, but bad split;

— the wood of pear and Apple trees are easily split and burn well;

— firewood from rocks with medium hardness, easy to inject;

cedar gives long embers;

— wood, cherry and elm in combustion smoke;

— the wood of sycamore is easily melted, but it's hard to shoot up;

— the wood of coniferous breeds have a low calorific value, smoke and sparks, contributing to the formation of tarry deposits in the chimney, but easily pricked and melted;

— poplar and basswood burn well, much spark and burn out very quickly.

Heating value of wood of different wood species varies greatly, which leads to fluctuations in wood density and fluctuations in the scalar coefficients of a cubic meter => skladometr.

Table with the average values of the calorific value of 1 skladometr of firewood.

Wood

(natural drying)

Calorific value,

kWh/kg

Calorific value,

mega Joule/kg

Calorific value,

MW*h/skladometr

Bulk density,

kg/dm3

Density,

kg/skladometr

Hornbeam firewood

4,2

15

2,1

0,72

495

Beech wood

4,2

15

2,0

0,69

480

Ash firewood

4,2

15

2,0

0,69

480

Oak firewood

4,2

15

2,0

0,67

470

Birch firewood

4,2

15

1,9

0.65

450

The wood of larch

4,3

15,5

1,8

0,59

420

Pine wood

4,3

15,5

1,6

0,52

360

Spruce firewood

4,3

15,5

1,4

0,47

330

1 skladometr dry wood of deciduous trees replace 200 — 210 l of fuel oil or 200 — 210 m3 of natural gas.

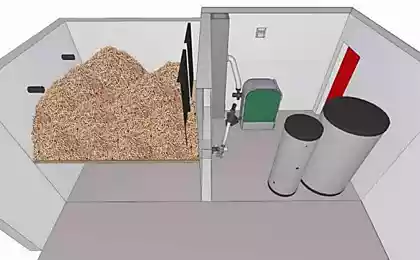

Pellets

Pellets (fuel pellets) is extruded under high pressure from natural raw materials of plant origin in the form of cylindrical granules of standard size.

The raw material for their production is bark, sawdust, wood chips and other logging wastes, and agricultural residues (sunflower husk, straw, flax, non-conforming, etc.), and organic packaging materials, cardboard packaging and so on.

The process of pellet production consists of stages: crushing, drying and granulation.

Raw material is ground into flour, then carefully dried and compressed into pellets of standard size with the help of special equipment — granulator.

During granulation, accompanied by a rise in temperature of the material contained in this polymer lignin contained in the cells of plant material, tightly adheres the crushed particles. Chemical binding of the impurities is not used.

The output is light, inexpensive, easy to store and safe fuel alternative to traditional fuels (coal, peat, firewood, natural gas).

Pellet mill press gives pellets form.

Pellets — a modern universal type of biofuel, on the effectiveness of equivalent coal.

The types of pellets:

— obtained by recycling of timber hard and softwood trees.

— obtained by recycling straw;

received processing by the sunflower husk;

— obtained by processing corn cobs and corn stalks;

— peat.

The advantage of pellets:

— environmentally friendly, appropriate technology, green fuel produced from harmless to human and environment materials subject to disposal in 10-50 times lower emission of carbon dioxide (CO2) into the environment, 15-20 times less generation of ash than burning coal;

— unlimited production in PM from wood of low quality

— lower cost compared to the price of coal, liquid fuel or wood,

— easy transportation, Packed in bags or bulk, and discharge through the sleeve with the possibility of automation of the process;

not require much warehouse space and can be stored outdoors, not swelled, without decay,

— when storage not ignite,

— does not require additional processing before use, no worse than gas or coal.

a large calorific value than sawdust and wood chips, 1.5 times more than firewood

— incineration of 1.9 MT of pellets is approximately the same amount of heat that the combustion of 1 ton of fuel oil with the cost of pellets in domestic market 3 times cheaper, that is heated with pellets 40% cheaper than fuel oil;

— almost complete combustion with a minimum amount of slag, which reduces the frequency of cleaning of the boiler can produce is much less

— possible automatic loading of pellets into the furnace in an industrial environment,

adjustment of residential heating devices, pellet boilers, are regulated in automatic mode,

— low volatility in prices, maybe the price of domestic

— pellet boilers last longer, need less maintenance and are more economical

Use of pellets:

— for heating homes by burning in furnaces, fireplaces and boilers

— to provide heat and electricity to industrial sites and small towns (large pellets with a high content of tree bark.

The demand for this alternative fuel and equipment for its production and combustion is constantly increasing.

Comparative characteristics of fuels

Fuel

The heat of combustion

MJ/kg

% sulfur

% ash

Carbon dioxide

kg/GJ

Coal

15 — 25

1-3

10 — 35

60

Motor fuel

42,5

0,2

1

78

Oil

42

1,2

1,5

78

Wood chips

10

0

2

0

Pellets wood

17,5

0,1

1

0

Pellets peat

10

0

20

70

Pellets made of straw

14,5

0,2

4

0

Natural gas

35 — 38 MJ/m3

0

0

57

Note:

"0" means that the combustion product CO2, the amount released does not exceed the amount that is formed during the natural decomposition, and the number of other harmful emissions is negligible.

Measurement of calorific value in Kcal/kg. 1 calorie is amount of heat required to heat 1 g of water at 1o. 4,500 Cal/kg ( 4,500 Cal/kg) heat of combustion of 1 kg of fuel in the Feces. Measurement of heat of combustion in MJ/kg heat international System units. 1 Calorie = 4,19 joules, 4,500 Kcal/kg * 4.19 j = 18,855 MJ/kg — calorific value of 1 kg of fuel in Joules. Measurement of calorific value in KWh. 5,238 KWh/ kg — calorific value of 1 kg of fuel, measured in "electrical units". The amount of energy vydelenie to Secunda (i.e. thermal capacity) = 18.855.000 j (see paragraph 2 ) /3600 sec = 5238 j/sec = 5,238 KWh.

Table 1. Heat pellets and alternative energy sources

Fuel

The thermal capacity,

kcal/kg

The peletty

4500

Wood

2500

Charcoal

7500

Coal

7400

Oil

9800

Diesel fuel

10200

Natural gas

8300

Standards for the production of pellets:

— to USA: Standard Regulations & Standards for Pellets in the US: The PFI (pellet), which allowed the production of pellets of grades of Premium and Standard. Premium, which is about 95% of US pellets are 1 % ash, and Standard - no more than 3 %. Premium can be used for heating any building. Grade Standard includes a greater amount of bark or agricultural waste. The standards also determine the density, size of pellets, humidity, dust content and other substances.

— in Germany: DIN 51731, in Austria: the Austrian standard önorm M 7135, UK: The British BioGen Code of Practice for biofuel (pellets) in Switzerland: SN 166000, Sweden :SS 187120.

The main European standards of quality pellets

Option

DIN 51 731

O-Norm M-7135

DINplus

SS187120

Germany

Austria

Germany

Sweden

Diameter (mm)

4-10

4-10

Length (mm)

< 50

< 5*d

< 5*d

< 5*d

Density (kg/dm3)

> 1,0-1,4

> 1,12

> 1,12

No

Humidity (%)

< 12

< 10

< 10

< 10

Bulk density (kg/m3)

650

650

650

650

Briquette dust (%)

No

< 2,3

< 2,3

No

Ash content (%)

< 1,5

< 0,5

< 0,5

< 1,5

The heat of combustion (MJ/kg)

17,5-19,5

> 18

> 18

> 18

Sulphur content (%)

< 0,08

< 0,04

< 0,04

< 0,08

Nitrogen content (%)

< 0,3

< 0,3

< 0,3

no

Chlorine content (%)

< 0,03

< 0,02

< 0,02

< 0,03

Arsenic (mg/kg)

< 0,8

No

< 0,8

No

Lead (mg/kg)

< 10

No

< 10

No

Cadmium (mg/kg)

< 0,5

No

< 0,5

No

Chromium (mg/kg)

< 8

No

< 8

No

Copper(mg/kg)

< 5

No

< 5

No

Mercury(mg/kg)

< 1,5

No

< 1,5

No

Zinc(mg/kg)

< 100

No

< 100

No

Binder, binding materials (%)

No

< 2

< 2

* "no" does not mean value, it may be, there is no information that is not defined, there is no exact size, etc.

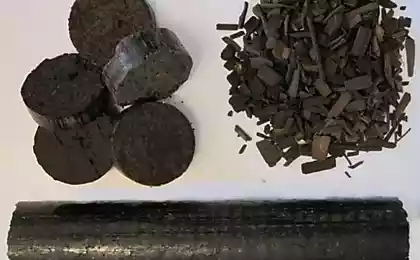

Fuel briquettes

Fuel briquettes is a compressed waste wood (shavings, chips), agricultural residues (straw, husks of sunflower seed, buckwheat), and also peat.

The binder is a natural polymer lignin. Chemical binding of the impurities is not used.

Fuel briquettes are widely used for heating private houses in different types of furnaces (kilns), wood burning boilers, fireplaces, preparing food on the grill.

Advantages of fuel briquettes:

— environmentally friendly product, the material of which in full is a natural raw material, and

— not susceptible to fungi,

— burn longer than firewood 2-4 times,

— easy to store and use.

high comparable with coal of the calorific value, on average, 2 times more compared to conventional wood,

— constant temperature at each stage of combustion due to the smooth flame

the ash content after combustion of about 1-3%. For comparison, the ash content after combustion of coal — 30-40%, wood - 8 -16%, wood chips - 11-18%,

modern solid fuel boilers briquettes can be cleaned with not more than 1 time per year,

— ash can be used as organic fertilizer,

— carbon monoxide is not allocated and other harmful substances are not formed,

— the cost of heating is lower than in the case of use of coal or wood.

Types of briquettes:

— RUF-briquettes in the form of nebolshogo brick of rectangular form,

— NESTRO-briquettes — briquettes cylindrical shape, sometimes with a radial hole inside,

— Pini&Kay briquettes — briquettes with 4, 6 or 8 faces with a longitudinal groove opening on the inside.

Coal

Coal is a combustible sedimentary rock of vegetable origin composed mainly of carbon and other chemical elements.

The composition of coal depends on the age and conditions of coalification:

— brown coal is the youngest,

— coal,

— anthracite — the oldest.

With aging there is a concentration of carbon and lower content of volatile constituents, particularly moisture.

Brown coal has a moisture content of 30-40%, more than 50% volatiles, anthracite these 2 indicator is 5-7%.

The moisture content of coal is 12 to 16%, the amount of volatile components is about 40%.

Coal also contains incombustible soleobrazutaya different supplements that "the rock".

Ash pollute the environment, and sintered in a slag on the grate that prevents the burning of coal.

The presence of the breed reduces the specific heat of combustion of coal.

Depending on the variety and conditions of production amount of minerals varies greatly, the ash content of coal of about 15% (10-20%).

Harmful component of coal also is sulfur in the combustion process, which produces oxides, which in the air turns into sulfuric acid.

Specific heat of combustion (coal concentrate)

Kind of coal

Calorific value of coal

kJ/kg

kcal/kg

Brown

14 700

3 500

Stone

29 300

7 000

Anthracite

31 000

7 400

The actual numbers may differ materially.

Kuzbass coal 5000-5500 kcal/kg .

The density of coal 1 and 1.7 (coal — to 1.3-1.4) g/cm3 depending on the type and content of mineral substances.

Uses the indicator of "bulk density", which is about 800-1, 000 kg/m3.

The types and varieties of coal

Coal is classified by many parameters (geography of production, chemical composition), but with "domestic" point of view it is enough to know the markings and possibilities of use.

Use the following notation coal: Grade = (mark) + (class size).

Brown

B

Stone

Flame types of coal

D

Gas

G

Fat

W

Coke

To

Otomano-caking

OS

Caking

SS

Skinny

T

Anthracite

And

In addition to the major brands, there are intermediate marks of coal: DG (long flame gas and gas), GZH (gas fat), KZH (coking fat), PA (paleointensity), brown coals are also divided into groups.

Coking coal brand (R, Cox, F, K, OS) in power are not used, as they are a scarce raw material for coking industry.

Class size (the size of the pieces, fraction) graded coal is divided into:

P

Slab

more than 100 mm

To

Large

50-100 mm

On

Walnut

Correspond 26-50 mm

M

Small

13-25 mm

With

Seed

6-13 mm

W

Dross

less than 6 mm

R

Private

not limited to sizes

In addition to high-quality coal sales there are a combined faction and screenings (PC, KO, OM, MC, SSH, MSSH, OMSS).

The size of the coal is determined on the basis of a smaller value for the smallest fraction and a larger value of the largest fraction specified in the name brand of coal.

For example, the fraction of OM (M — 13-25, 25-50) is 13-50 mm.

In addition to these varieties of coal in the market you can find coal briquettes, which is compressed from low-enriched coal slurry.

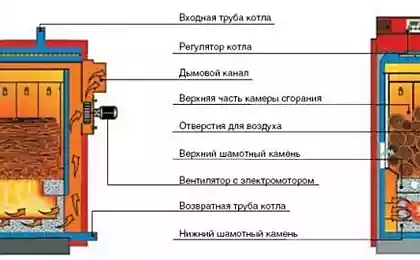

The process of coal combustion

Coal consists of combustible components 2: volatile substances and solid (coke) residue

On the 1st stage of combustion are allocated volatile components; with excess oxygen, they burn quickly, giving a long flame, but a small amount of heat.

On the 2nd stage burn of the coke residue; the intensity of its combustion and the ignition temperature depends on the degree of coalification, i.e., the type of coal (lignite, bituminous, anthracite).

The higher the degree of coalification (the highest she of anthracite), the higher the ignition temperature and calorific value, but lower the intensity.

Coal grades B, D, G

Due to the high content of volatile matter of such coal quickly flares up and burns out quickly.

The coal of these grades are available and are suitable for almost all types of boilers, however, for complete combustion of the coal should be fed in small portions, so that the released volatiles have time to fully connect with the oxygen in the air.

Complete combustion of coal is characterized by a yellow flame and clear the flue gases; incomplete combustion of volatiles gives a crimson flame and black smoke

For efficient combustion of the coal, the process must be continuously monitored.

Coal grades SS, T, And

It is more difficult to ignite, but it burns for a long time and emit a lot more heat.

Coal can be loaded in large batches, as they burn mostly coke residue, no mass emission of volatile substances.

A very important boost-mode, since the lack of combustion air is slow, it can its termination, or, conversely, excessive temperature rise, resulting in the entrainment of heat and burning of the boiler.

Comparative table of the calorific value of some fuels

The calorific value of a fuel describes the amount of heat released during the complete combustion of the fuel content of 1 kg or 1 m3 volume (1 l).

Most often, the calorific value is measured in j/kg (j/m3 j/l).

The higher calorific value of the fuel, the lower its consumption.

Calorific value of each fuel type depends on:

from its combustible components (carbon, hydrogen, volatile flammable sulfur, etc.);

from its moisture and ash content.

Fuel

Ed. izm.

Specific heat of combustion

Equivalent

kcal

kW

MJ

Natural gas, m3

Diz. fuel, l

Fuel oil, l

Electricity

1 kW/h

864

3,62 1,0 0,108 0,084 0,089 Diesel fuel (diesel) 1 l 10300 11,9 43,12 1,288 — 1,062 Oil 1 liter 9700 11,2 40,61 1,213 0,942 — Kerosene 1 l 10400 12,0 of 43.50 1,300 1,010 1,072 Oil 1 l 10500 12,2 44,00 1,313 1,019 1,082 Gasoline 1 l 10500 12,2 44,00 1,313 1,019 1,082 natural Gas 1 m3 8000 9,3 33,50 — 0,777 0,825 Liquefied gas 1 kg 10800 12,5 45,20 1,350 1,049 1,113 Methane 1 m3 13,8 11950 from 50.03 1,494 1,160 1,232 Propane 1 10885 12,6 m3 of 45.57 1,361 1,057 1,122 Ethylene 1 m3 11470 13,3 48,02 1,434 1,114 1,182 Hydrogen 28700 33.2 per 1 m3 of 120.00 2,786 2,959 3,588 Coal (W=10%) 1 kg 27,00 AZN 0.806 6450 7,5 0,665 0,626 brown Coal (W=30...40%) 1 kg 3100 3,6 12,98 0,388 had 0.301 0,320 anthracite 1 kg 6700 7,8 28,05 0,838 0,650 0,691 Charcoal 1 kg 7,5 6510 27,26 0,814 0,632 0,671 Peat (W=40%) 1 kg 2900 3,6 12,10 of 0.363 0,282 0,299 Peat briquettes (W=15%) 1 kg 4200 4,9 17,58 0,525 0,433 0,408 Peat crumb 1 kg 3,0 2590 10,84 0,251 0,267 0,324 wood Pellets 1 kg 4100 to 4.7 17,17 0,513 0,423 0,398 Pellets from straw 1 kg 3465 4,0 14,51 0,433 0,357 0,336 Pellets from sunflower husks 1 kg 4320 5,0 0,540 18,09 0,419 0,445 the Green wood (W=50...60%) 1 kg is 2.2 1940 8,12 0,188 0,243 0,200 Dried wood (W=20%) 1 kg 3400 3,9 14,24 0,425 0,330 0,351 Chips 1 kg 2610 3,0 10,93 0,253 0,326 0,269 Sawdust 1 kg 2000 2,3 of 8.37 0,250 0,194 0,206 Paper 1 kg 3970 4,6 16,62 0,496 0,385 0,409 sunflower Husks, soya 1 kg 4060 4,7 17,00 0,508 0,419 0,394 rice Hulls 1 kg 3180 3.7 V for 13, 31 0,398 0,328 0,309 Fire linseed 1 kg 3805 4,4 15,93 0,477 0,369 0,392 Corn on the cob (W>10%) 1 kg 3500 4,0 14,65 0,438 0,340 0,361 Straw 1 kg 3750 4,3 15,70 0,469 0,364 0,387 Cotton-stalks 1 kg 3470 4,0 0,434 14,53 0,337 0,358 vine (W=20%) 1 kg 3345 3,9 14,00 0,418 0,345 0,325 published

Source: neftegaz.ru/science/view/1268-Vidy-topliva-dlya-tverdotoplivnyh-kotlov-i-sravnitelnaya-tablitsa-ih-teplotvornoy-sposobnosti

Principal fuel for solid fuel boilers:

— Firewood

- Pellets (fuel granules)

Fuel briquettes

Coal

Wood

Wood sawn or chipped pieces of wood intended for burning in furnaces, fireplaces, etc to produce heat, heat and light.

The moisture content should be as small as possible.

Fireplace wood have a length of about 25 — 33 cm

Priority characteristics of firewood for fireplaces and stoves — their calorific value, combustion duration and comfort in use (the picture of the flame, smell).

For heating purposes it is important that the dissipation was slower but for a longer time.

For heating purposes, it is best to fit all the wood of deciduous trees in techdub, ash, birch, hazel, yew, hawthorn.

Features of burning firewood different wood species:

— firewood of beech, birch, ash, hazel, it is difficult to melt, but they can burn raw, because they have little humidity, and the wood of all these trees, besides beech, are easily split;

alder and aspen burns without soot and even burned her from the chimney;

— birch wood is good for heat, but the lack of air in the furnace, burns smoky and form tar (birch tar), which is deposited on the walls of the pipe;

— pine wood burn hotter than the spruce because of the higher resin content, sparking with a sharp increase in temperature;

— oak and hornbeam have better heat dissipation during the combustion, but bad split;

— the wood of pear and Apple trees are easily split and burn well;

— firewood from rocks with medium hardness, easy to inject;

cedar gives long embers;

— wood, cherry and elm in combustion smoke;

— the wood of sycamore is easily melted, but it's hard to shoot up;

— the wood of coniferous breeds have a low calorific value, smoke and sparks, contributing to the formation of tarry deposits in the chimney, but easily pricked and melted;

— poplar and basswood burn well, much spark and burn out very quickly.

Heating value of wood of different wood species varies greatly, which leads to fluctuations in wood density and fluctuations in the scalar coefficients of a cubic meter => skladometr.

Table with the average values of the calorific value of 1 skladometr of firewood.

Wood

(natural drying)

Calorific value,

kWh/kg

Calorific value,

mega Joule/kg

Calorific value,

MW*h/skladometr

Bulk density,

kg/dm3

Density,

kg/skladometr

Hornbeam firewood

4,2

15

2,1

0,72

495

Beech wood

4,2

15

2,0

0,69

480

Ash firewood

4,2

15

2,0

0,69

480

Oak firewood

4,2

15

2,0

0,67

470

Birch firewood

4,2

15

1,9

0.65

450

The wood of larch

4,3

15,5

1,8

0,59

420

Pine wood

4,3

15,5

1,6

0,52

360

Spruce firewood

4,3

15,5

1,4

0,47

330

1 skladometr dry wood of deciduous trees replace 200 — 210 l of fuel oil or 200 — 210 m3 of natural gas.

Pellets

Pellets (fuel pellets) is extruded under high pressure from natural raw materials of plant origin in the form of cylindrical granules of standard size.

The raw material for their production is bark, sawdust, wood chips and other logging wastes, and agricultural residues (sunflower husk, straw, flax, non-conforming, etc.), and organic packaging materials, cardboard packaging and so on.

The process of pellet production consists of stages: crushing, drying and granulation.

Raw material is ground into flour, then carefully dried and compressed into pellets of standard size with the help of special equipment — granulator.

During granulation, accompanied by a rise in temperature of the material contained in this polymer lignin contained in the cells of plant material, tightly adheres the crushed particles. Chemical binding of the impurities is not used.

The output is light, inexpensive, easy to store and safe fuel alternative to traditional fuels (coal, peat, firewood, natural gas).

Pellet mill press gives pellets form.

Pellets — a modern universal type of biofuel, on the effectiveness of equivalent coal.

The types of pellets:

— obtained by recycling of timber hard and softwood trees.

— obtained by recycling straw;

received processing by the sunflower husk;

— obtained by processing corn cobs and corn stalks;

— peat.

The advantage of pellets:

— environmentally friendly, appropriate technology, green fuel produced from harmless to human and environment materials subject to disposal in 10-50 times lower emission of carbon dioxide (CO2) into the environment, 15-20 times less generation of ash than burning coal;

— unlimited production in PM from wood of low quality

— lower cost compared to the price of coal, liquid fuel or wood,

— easy transportation, Packed in bags or bulk, and discharge through the sleeve with the possibility of automation of the process;

not require much warehouse space and can be stored outdoors, not swelled, without decay,

— when storage not ignite,

— does not require additional processing before use, no worse than gas or coal.

a large calorific value than sawdust and wood chips, 1.5 times more than firewood

— incineration of 1.9 MT of pellets is approximately the same amount of heat that the combustion of 1 ton of fuel oil with the cost of pellets in domestic market 3 times cheaper, that is heated with pellets 40% cheaper than fuel oil;

— almost complete combustion with a minimum amount of slag, which reduces the frequency of cleaning of the boiler can produce is much less

— possible automatic loading of pellets into the furnace in an industrial environment,

adjustment of residential heating devices, pellet boilers, are regulated in automatic mode,

— low volatility in prices, maybe the price of domestic

— pellet boilers last longer, need less maintenance and are more economical

Use of pellets:

— for heating homes by burning in furnaces, fireplaces and boilers

— to provide heat and electricity to industrial sites and small towns (large pellets with a high content of tree bark.

The demand for this alternative fuel and equipment for its production and combustion is constantly increasing.

Comparative characteristics of fuels

Fuel

The heat of combustion

MJ/kg

% sulfur

% ash

Carbon dioxide

kg/GJ

Coal

15 — 25

1-3

10 — 35

60

Motor fuel

42,5

0,2

1

78

Oil

42

1,2

1,5

78

Wood chips

10

0

2

0

Pellets wood

17,5

0,1

1

0

Pellets peat

10

0

20

70

Pellets made of straw

14,5

0,2

4

0

Natural gas

35 — 38 MJ/m3

0

0

57

Note:

"0" means that the combustion product CO2, the amount released does not exceed the amount that is formed during the natural decomposition, and the number of other harmful emissions is negligible.

Measurement of calorific value in Kcal/kg. 1 calorie is amount of heat required to heat 1 g of water at 1o. 4,500 Cal/kg ( 4,500 Cal/kg) heat of combustion of 1 kg of fuel in the Feces. Measurement of heat of combustion in MJ/kg heat international System units. 1 Calorie = 4,19 joules, 4,500 Kcal/kg * 4.19 j = 18,855 MJ/kg — calorific value of 1 kg of fuel in Joules. Measurement of calorific value in KWh. 5,238 KWh/ kg — calorific value of 1 kg of fuel, measured in "electrical units". The amount of energy vydelenie to Secunda (i.e. thermal capacity) = 18.855.000 j (see paragraph 2 ) /3600 sec = 5238 j/sec = 5,238 KWh.

Table 1. Heat pellets and alternative energy sources

Fuel

The thermal capacity,

kcal/kg

The peletty

4500

Wood

2500

Charcoal

7500

Coal

7400

Oil

9800

Diesel fuel

10200

Natural gas

8300

Standards for the production of pellets:

— to USA: Standard Regulations & Standards for Pellets in the US: The PFI (pellet), which allowed the production of pellets of grades of Premium and Standard. Premium, which is about 95% of US pellets are 1 % ash, and Standard - no more than 3 %. Premium can be used for heating any building. Grade Standard includes a greater amount of bark or agricultural waste. The standards also determine the density, size of pellets, humidity, dust content and other substances.

— in Germany: DIN 51731, in Austria: the Austrian standard önorm M 7135, UK: The British BioGen Code of Practice for biofuel (pellets) in Switzerland: SN 166000, Sweden :SS 187120.

The main European standards of quality pellets

Option

DIN 51 731

O-Norm M-7135

DINplus

SS187120

Germany

Austria

Germany

Sweden

Diameter (mm)

4-10

4-10

Length (mm)

< 50

< 5*d

< 5*d

< 5*d

Density (kg/dm3)

> 1,0-1,4

> 1,12

> 1,12

No

Humidity (%)

< 12

< 10

< 10

< 10

Bulk density (kg/m3)

650

650

650

650

Briquette dust (%)

No

< 2,3

< 2,3

No

Ash content (%)

< 1,5

< 0,5

< 0,5

< 1,5

The heat of combustion (MJ/kg)

17,5-19,5

> 18

> 18

> 18

Sulphur content (%)

< 0,08

< 0,04

< 0,04

< 0,08

Nitrogen content (%)

< 0,3

< 0,3

< 0,3

no

Chlorine content (%)

< 0,03

< 0,02

< 0,02

< 0,03

Arsenic (mg/kg)

< 0,8

No

< 0,8

No

Lead (mg/kg)

< 10

No

< 10

No

Cadmium (mg/kg)

< 0,5

No

< 0,5

No

Chromium (mg/kg)

< 8

No

< 8

No

Copper(mg/kg)

< 5

No

< 5

No

Mercury(mg/kg)

< 1,5

No

< 1,5

No

Zinc(mg/kg)

< 100

No

< 100

No

Binder, binding materials (%)

No

< 2

< 2

* "no" does not mean value, it may be, there is no information that is not defined, there is no exact size, etc.

Fuel briquettes

Fuel briquettes is a compressed waste wood (shavings, chips), agricultural residues (straw, husks of sunflower seed, buckwheat), and also peat.

The binder is a natural polymer lignin. Chemical binding of the impurities is not used.

Fuel briquettes are widely used for heating private houses in different types of furnaces (kilns), wood burning boilers, fireplaces, preparing food on the grill.

Advantages of fuel briquettes:

— environmentally friendly product, the material of which in full is a natural raw material, and

— not susceptible to fungi,

— burn longer than firewood 2-4 times,

— easy to store and use.

high comparable with coal of the calorific value, on average, 2 times more compared to conventional wood,

— constant temperature at each stage of combustion due to the smooth flame

the ash content after combustion of about 1-3%. For comparison, the ash content after combustion of coal — 30-40%, wood - 8 -16%, wood chips - 11-18%,

modern solid fuel boilers briquettes can be cleaned with not more than 1 time per year,

— ash can be used as organic fertilizer,

— carbon monoxide is not allocated and other harmful substances are not formed,

— the cost of heating is lower than in the case of use of coal or wood.

Types of briquettes:

— RUF-briquettes in the form of nebolshogo brick of rectangular form,

— NESTRO-briquettes — briquettes cylindrical shape, sometimes with a radial hole inside,

— Pini&Kay briquettes — briquettes with 4, 6 or 8 faces with a longitudinal groove opening on the inside.

Coal

Coal is a combustible sedimentary rock of vegetable origin composed mainly of carbon and other chemical elements.

The composition of coal depends on the age and conditions of coalification:

— brown coal is the youngest,

— coal,

— anthracite — the oldest.

With aging there is a concentration of carbon and lower content of volatile constituents, particularly moisture.

Brown coal has a moisture content of 30-40%, more than 50% volatiles, anthracite these 2 indicator is 5-7%.

The moisture content of coal is 12 to 16%, the amount of volatile components is about 40%.

Coal also contains incombustible soleobrazutaya different supplements that "the rock".

Ash pollute the environment, and sintered in a slag on the grate that prevents the burning of coal.

The presence of the breed reduces the specific heat of combustion of coal.

Depending on the variety and conditions of production amount of minerals varies greatly, the ash content of coal of about 15% (10-20%).

Harmful component of coal also is sulfur in the combustion process, which produces oxides, which in the air turns into sulfuric acid.

Specific heat of combustion (coal concentrate)

Kind of coal

Calorific value of coal

kJ/kg

kcal/kg

Brown

14 700

3 500

Stone

29 300

7 000

Anthracite

31 000

7 400

The actual numbers may differ materially.

Kuzbass coal 5000-5500 kcal/kg .

The density of coal 1 and 1.7 (coal — to 1.3-1.4) g/cm3 depending on the type and content of mineral substances.

Uses the indicator of "bulk density", which is about 800-1, 000 kg/m3.

The types and varieties of coal

Coal is classified by many parameters (geography of production, chemical composition), but with "domestic" point of view it is enough to know the markings and possibilities of use.

Use the following notation coal: Grade = (mark) + (class size).

Brown

B

Stone

Flame types of coal

D

Gas

G

Fat

W

Coke

To

Otomano-caking

OS

Caking

SS

Skinny

T

Anthracite

And

In addition to the major brands, there are intermediate marks of coal: DG (long flame gas and gas), GZH (gas fat), KZH (coking fat), PA (paleointensity), brown coals are also divided into groups.

Coking coal brand (R, Cox, F, K, OS) in power are not used, as they are a scarce raw material for coking industry.

Class size (the size of the pieces, fraction) graded coal is divided into:

P

Slab

more than 100 mm

To

Large

50-100 mm

On

Walnut

Correspond 26-50 mm

M

Small

13-25 mm

With

Seed

6-13 mm

W

Dross

less than 6 mm

R

Private

not limited to sizes

In addition to high-quality coal sales there are a combined faction and screenings (PC, KO, OM, MC, SSH, MSSH, OMSS).

The size of the coal is determined on the basis of a smaller value for the smallest fraction and a larger value of the largest fraction specified in the name brand of coal.

For example, the fraction of OM (M — 13-25, 25-50) is 13-50 mm.

In addition to these varieties of coal in the market you can find coal briquettes, which is compressed from low-enriched coal slurry.

The process of coal combustion

Coal consists of combustible components 2: volatile substances and solid (coke) residue

On the 1st stage of combustion are allocated volatile components; with excess oxygen, they burn quickly, giving a long flame, but a small amount of heat.

On the 2nd stage burn of the coke residue; the intensity of its combustion and the ignition temperature depends on the degree of coalification, i.e., the type of coal (lignite, bituminous, anthracite).

The higher the degree of coalification (the highest she of anthracite), the higher the ignition temperature and calorific value, but lower the intensity.

Coal grades B, D, G

Due to the high content of volatile matter of such coal quickly flares up and burns out quickly.

The coal of these grades are available and are suitable for almost all types of boilers, however, for complete combustion of the coal should be fed in small portions, so that the released volatiles have time to fully connect with the oxygen in the air.

Complete combustion of coal is characterized by a yellow flame and clear the flue gases; incomplete combustion of volatiles gives a crimson flame and black smoke

For efficient combustion of the coal, the process must be continuously monitored.

Coal grades SS, T, And

It is more difficult to ignite, but it burns for a long time and emit a lot more heat.

Coal can be loaded in large batches, as they burn mostly coke residue, no mass emission of volatile substances.

A very important boost-mode, since the lack of combustion air is slow, it can its termination, or, conversely, excessive temperature rise, resulting in the entrainment of heat and burning of the boiler.

Comparative table of the calorific value of some fuels

The calorific value of a fuel describes the amount of heat released during the complete combustion of the fuel content of 1 kg or 1 m3 volume (1 l).

Most often, the calorific value is measured in j/kg (j/m3 j/l).

The higher calorific value of the fuel, the lower its consumption.

Calorific value of each fuel type depends on:

from its combustible components (carbon, hydrogen, volatile flammable sulfur, etc.);

from its moisture and ash content.

Fuel

Ed. izm.

Specific heat of combustion

Equivalent

kcal

kW

MJ

Natural gas, m3

Diz. fuel, l

Fuel oil, l

Electricity

1 kW/h

864

3,62 1,0 0,108 0,084 0,089 Diesel fuel (diesel) 1 l 10300 11,9 43,12 1,288 — 1,062 Oil 1 liter 9700 11,2 40,61 1,213 0,942 — Kerosene 1 l 10400 12,0 of 43.50 1,300 1,010 1,072 Oil 1 l 10500 12,2 44,00 1,313 1,019 1,082 Gasoline 1 l 10500 12,2 44,00 1,313 1,019 1,082 natural Gas 1 m3 8000 9,3 33,50 — 0,777 0,825 Liquefied gas 1 kg 10800 12,5 45,20 1,350 1,049 1,113 Methane 1 m3 13,8 11950 from 50.03 1,494 1,160 1,232 Propane 1 10885 12,6 m3 of 45.57 1,361 1,057 1,122 Ethylene 1 m3 11470 13,3 48,02 1,434 1,114 1,182 Hydrogen 28700 33.2 per 1 m3 of 120.00 2,786 2,959 3,588 Coal (W=10%) 1 kg 27,00 AZN 0.806 6450 7,5 0,665 0,626 brown Coal (W=30...40%) 1 kg 3100 3,6 12,98 0,388 had 0.301 0,320 anthracite 1 kg 6700 7,8 28,05 0,838 0,650 0,691 Charcoal 1 kg 7,5 6510 27,26 0,814 0,632 0,671 Peat (W=40%) 1 kg 2900 3,6 12,10 of 0.363 0,282 0,299 Peat briquettes (W=15%) 1 kg 4200 4,9 17,58 0,525 0,433 0,408 Peat crumb 1 kg 3,0 2590 10,84 0,251 0,267 0,324 wood Pellets 1 kg 4100 to 4.7 17,17 0,513 0,423 0,398 Pellets from straw 1 kg 3465 4,0 14,51 0,433 0,357 0,336 Pellets from sunflower husks 1 kg 4320 5,0 0,540 18,09 0,419 0,445 the Green wood (W=50...60%) 1 kg is 2.2 1940 8,12 0,188 0,243 0,200 Dried wood (W=20%) 1 kg 3400 3,9 14,24 0,425 0,330 0,351 Chips 1 kg 2610 3,0 10,93 0,253 0,326 0,269 Sawdust 1 kg 2000 2,3 of 8.37 0,250 0,194 0,206 Paper 1 kg 3970 4,6 16,62 0,496 0,385 0,409 sunflower Husks, soya 1 kg 4060 4,7 17,00 0,508 0,419 0,394 rice Hulls 1 kg 3180 3.7 V for 13, 31 0,398 0,328 0,309 Fire linseed 1 kg 3805 4,4 15,93 0,477 0,369 0,392 Corn on the cob (W>10%) 1 kg 3500 4,0 14,65 0,438 0,340 0,361 Straw 1 kg 3750 4,3 15,70 0,469 0,364 0,387 Cotton-stalks 1 kg 3470 4,0 0,434 14,53 0,337 0,358 vine (W=20%) 1 kg 3345 3,9 14,00 0,418 0,345 0,325 published

Source: neftegaz.ru/science/view/1268-Vidy-topliva-dlya-tverdotoplivnyh-kotlov-i-sravnitelnaya-tablitsa-ih-teplotvornoy-sposobnosti

Tesla will introduce a solar-panel roof at the end of October

5 homemade sauces to complement any dish