961

As seasoned aircraft:

In order to promptly serve hundreds of boards, departing daily from the airport, you need to solve the thousands of questions. One of the most important tasks - to ensure all aircraft fuel. Refueling complex - a huge mechanism that operates smoothly and without interruption.

Let's see what happens with the fuel from the moment when it gets into the territory of the airport to fill the fuel tank of the aircraft.

At the airport the fuel falls in two ways: by rail or pipeline.

By rail fuel comes from different plants located throughout the country. Selection of suppliers depends on the price and the current market conditions. Currently, most of the fuel supplied by rail.

At the same time in Domodedovo may merge 22 tanks.

An interesting detail: the safety rope for the employees who are taking fuel.

All fuel passes mandatory foster control.

The possibility of flight is provided on the ground.

From railway tanks fuel pumped here in such reservoirs. The volume of this huge drums - 5000 m³.

Correct barrel is called "vertical steel tanks." Few technical details:

Here is the reservoir from the roof of a nearby reservoir.

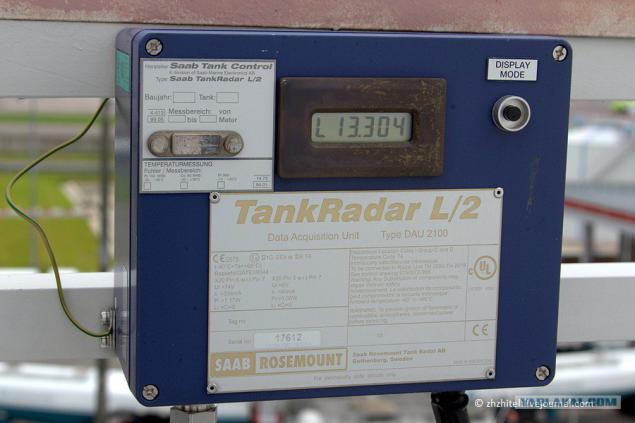

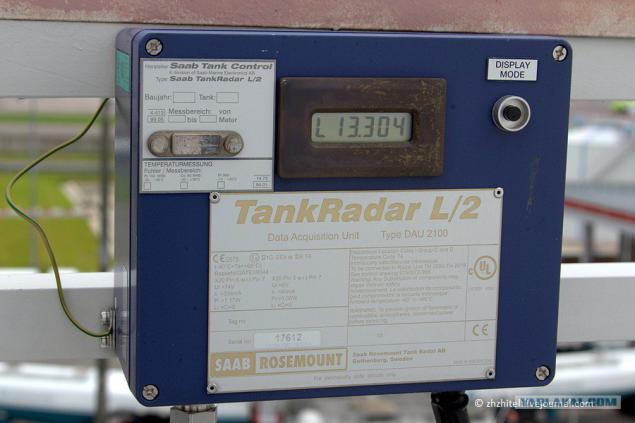

TankRadar - a device for controlling the parameters of the fuel in the tank.

You can estimate the fuel level, temperature and other parameters.

Not far from the fuel tanks are water tanks. Tanks type Casemates are located underground. About them they say: "May they never be used for other purposes».

In order to drive the fuel between the capacitances need powerful pumps.

This is the second way in which fuel gets to the airport - a pipeline running from Volodarskaya tank farm. This tank farm products pipelines associated with all the airports of the Moscow aviation hub. Under this canopy are metering devices, based on their testimony, the settlements between the companies.

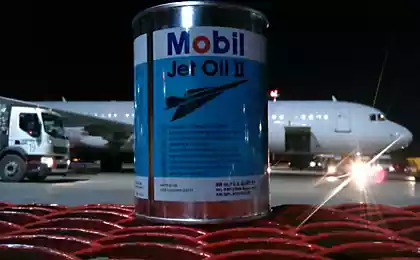

In civil aviation there are two types of fuel: TS-1 and RT. TC-1 - Fuel Jets, RT - jet fuel. The difference between them is small, in fact it is aviation kerosene.

At every stage of the fuel quality and the parameters are carefully controlled. There are several stages of control is carried out in the most rigorous laboratory. Here are aware of all the fuels.

Fuel passes a full analysis of 12 indicators. In addition, monitored and other liquids. For example, "I-M" - protivovodokristallizatsionnaya fuel additive and NGZH-5U - a hydraulic oil used, e.g., in the chassis ВС.

Each set has its own test equipment. Some devices externally do not look very impressive, but their task is, of course, not the case.

An employee of the lab work.

The results of each analysis are recorded in journals, in addition to this, some of the sample shall be sealed and kept a certain period. It demands security.

Prior to that, the last time I saw so many tubes only in the institute at the Department Physchemistry.

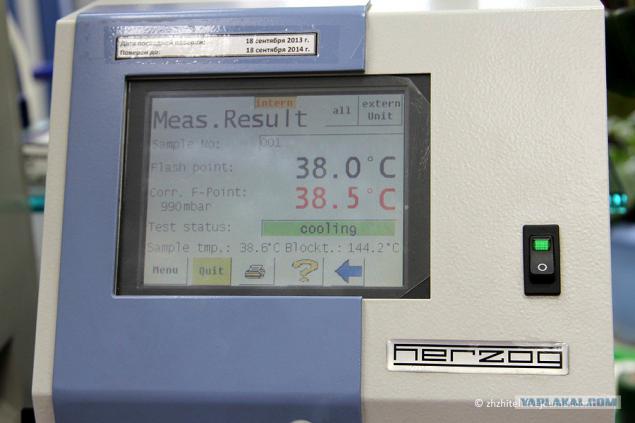

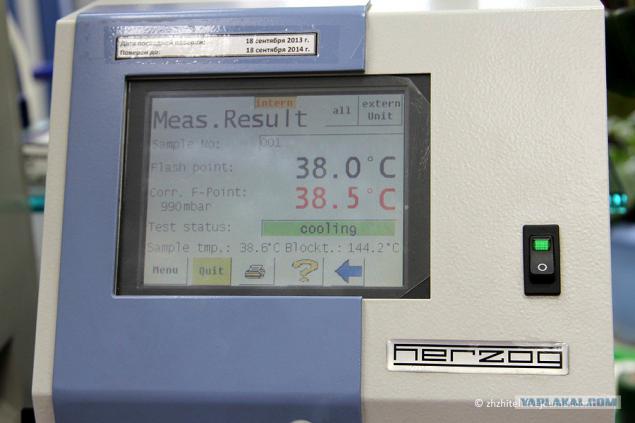

When we did some research. Who investigates flashpoint fuels in closed crucible.

The results are displayed.

Here we investigate the density and composition of the fuel fractions.

Sealing samples.

Once the fuel has passed a comprehensive analysis, the quality has been confirmed in a laboratory, it can be pumped to the central gas station located at the airport. This is where the fuel is supplied to aircrafts.

At the entrance of a plurality of filters that trap mechanical impurities and water.

Carry out additional controls for this fuel is drained from the bottom of tanks.

All the physical and chemical parameters tested in the laboratory, the presence of water and impurities can be detected by visual inspection. Fuel is absolutely clean.

Used filters coarse and fine. The filter system is able to retain particles of 1 micron impurities, it is almost 100 times smaller than the thickness of a human hair.

Engine room. The pumps operate automatically.

General view of the hub.

At the hub are six reservoirs with capacity of 5000 m³ and several smaller tanks.

The aircraft fuel tanks could get from tankers or from here such hydrant speakers located around the airfield. Total of columns 61, we are just in the control, with the number 61.

At Domodedovo has tankers with a different capacity, the maximum capacity used by tankers - 60 m³, in railway tank.

In order to completely fill the fuel tank tanker should be about 40 minutes. Hurry - you can not, there are standards limiting the maximum speed of the fuel supply.

On average, single-aisle jets take about 20 tons of fuel, Boeing-747 can carry 200 tons, and the giant Airbus A-380 - almost 300.

With the roof open reservoirs interesting species airport.

The whole point of reporting in a single photo.

Do not refuel - will not fly.

A little bit about how the fueling. First, second and third: safety. Everything must be grounded, all the instructions and regulations are painted much detail.

The hub is similar to the regular filling station, only cars are much more.

Column. She released fuel.

After fueling the next control.

Kerosene is transparent as a tear, impurities and water are not available.

Now tanker can go to the aircraft.

At Domodedovo are three operators, airlines can choose those who will offer the best conditions and prices.

In turn, operators can store the fuel in a common reservoir tanks or rent separately for themselves.

Refueling aircraft through hatches located in the wing.

For refueling of aircraft hydrant columns used here are mobile refueling units.

Filling occurs because the hatches located on the parking places of planes, so a huge tanker is not required to maneuver among the planes, all the fuel is fed through the pipes.

Let's see what happens with the fuel from the moment when it gets into the territory of the airport to fill the fuel tank of the aircraft.

At the airport the fuel falls in two ways: by rail or pipeline.

By rail fuel comes from different plants located throughout the country. Selection of suppliers depends on the price and the current market conditions. Currently, most of the fuel supplied by rail.

At the same time in Domodedovo may merge 22 tanks.

An interesting detail: the safety rope for the employees who are taking fuel.

All fuel passes mandatory foster control.

The possibility of flight is provided on the ground.

From railway tanks fuel pumped here in such reservoirs. The volume of this huge drums - 5000 m³.

Correct barrel is called "vertical steel tanks." Few technical details:

Here is the reservoir from the roof of a nearby reservoir.

TankRadar - a device for controlling the parameters of the fuel in the tank.

You can estimate the fuel level, temperature and other parameters.

Not far from the fuel tanks are water tanks. Tanks type Casemates are located underground. About them they say: "May they never be used for other purposes».

In order to drive the fuel between the capacitances need powerful pumps.

This is the second way in which fuel gets to the airport - a pipeline running from Volodarskaya tank farm. This tank farm products pipelines associated with all the airports of the Moscow aviation hub. Under this canopy are metering devices, based on their testimony, the settlements between the companies.

In civil aviation there are two types of fuel: TS-1 and RT. TC-1 - Fuel Jets, RT - jet fuel. The difference between them is small, in fact it is aviation kerosene.

At every stage of the fuel quality and the parameters are carefully controlled. There are several stages of control is carried out in the most rigorous laboratory. Here are aware of all the fuels.

Fuel passes a full analysis of 12 indicators. In addition, monitored and other liquids. For example, "I-M" - protivovodokristallizatsionnaya fuel additive and NGZH-5U - a hydraulic oil used, e.g., in the chassis ВС.

Each set has its own test equipment. Some devices externally do not look very impressive, but their task is, of course, not the case.

An employee of the lab work.

The results of each analysis are recorded in journals, in addition to this, some of the sample shall be sealed and kept a certain period. It demands security.

Prior to that, the last time I saw so many tubes only in the institute at the Department Physchemistry.

When we did some research. Who investigates flashpoint fuels in closed crucible.

The results are displayed.

Here we investigate the density and composition of the fuel fractions.

Sealing samples.

Once the fuel has passed a comprehensive analysis, the quality has been confirmed in a laboratory, it can be pumped to the central gas station located at the airport. This is where the fuel is supplied to aircrafts.

At the entrance of a plurality of filters that trap mechanical impurities and water.

Carry out additional controls for this fuel is drained from the bottom of tanks.

All the physical and chemical parameters tested in the laboratory, the presence of water and impurities can be detected by visual inspection. Fuel is absolutely clean.

Used filters coarse and fine. The filter system is able to retain particles of 1 micron impurities, it is almost 100 times smaller than the thickness of a human hair.

Engine room. The pumps operate automatically.

General view of the hub.

At the hub are six reservoirs with capacity of 5000 m³ and several smaller tanks.

The aircraft fuel tanks could get from tankers or from here such hydrant speakers located around the airfield. Total of columns 61, we are just in the control, with the number 61.

At Domodedovo has tankers with a different capacity, the maximum capacity used by tankers - 60 m³, in railway tank.

In order to completely fill the fuel tank tanker should be about 40 minutes. Hurry - you can not, there are standards limiting the maximum speed of the fuel supply.

On average, single-aisle jets take about 20 tons of fuel, Boeing-747 can carry 200 tons, and the giant Airbus A-380 - almost 300.

With the roof open reservoirs interesting species airport.

The whole point of reporting in a single photo.

Do not refuel - will not fly.

A little bit about how the fueling. First, second and third: safety. Everything must be grounded, all the instructions and regulations are painted much detail.

The hub is similar to the regular filling station, only cars are much more.

Column. She released fuel.

After fueling the next control.

Kerosene is transparent as a tear, impurities and water are not available.

Now tanker can go to the aircraft.

At Domodedovo are three operators, airlines can choose those who will offer the best conditions and prices.

In turn, operators can store the fuel in a common reservoir tanks or rent separately for themselves.

Refueling aircraft through hatches located in the wing.

For refueling of aircraft hydrant columns used here are mobile refueling units.

Filling occurs because the hatches located on the parking places of planes, so a huge tanker is not required to maneuver among the planes, all the fuel is fed through the pipes.