1076

As seasoned butter planes

One of the most frequent activities in servicing aircraft - is fueling the engine with oil. The oil is generally filled in here such as in the photo, a sealed tins.

Capacity to 1 quart (0, 946 l).

Oil system as a whole - is a matter of long and with many details.

So today we kratenko Walk only on the tops - on the oil tank and oil charge.

Let's start with the fact that the engines are different.

Some may swoop for dozens of hours, and spend only a liter or two.

Others consume excessively, and one flight somewhere in Sharm Sheikh back and have time to spend five liters.

Accordingly, the engine oil and fill a need not always. But usually it happens every Destination aircraft at the base (at a transit port is usually not filled in).

Oil for modern gas turbine engines made on the basis of esters.

It is efficient in a wide temperature range - from 40 to 200 degrees.

There are several types of such oils from different manufacturers approved for use by the engine manufacturer.

They are interchangeable and can generally be mixed without prejudice to the materiel.

The aircraft operator chooses which of the approved oils to maintain the engine.

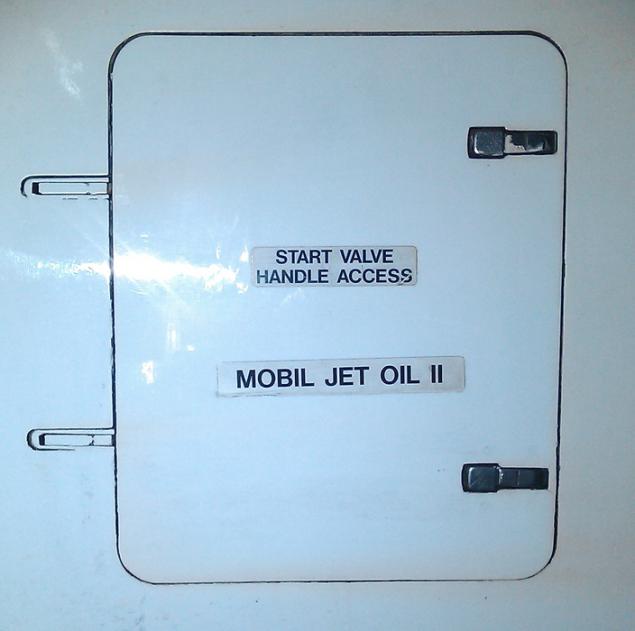

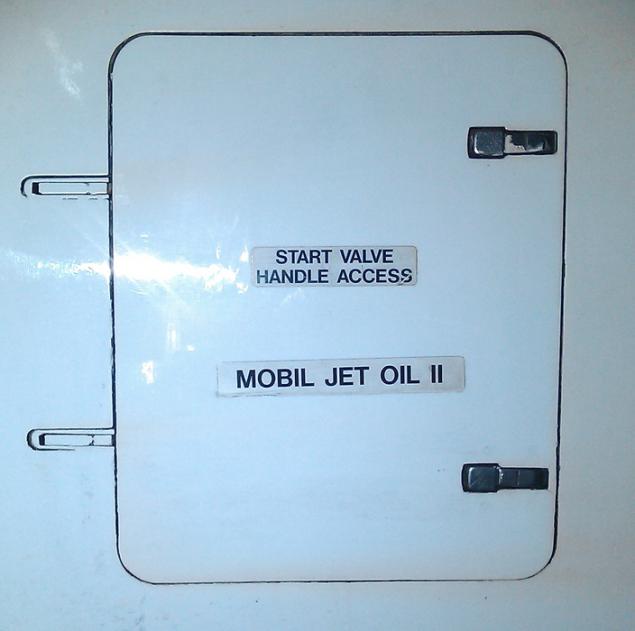

For example, the pictures can be seen oil Mobil Jet Oil 2.

Analogues are its oil TurboNicOil 600, BP 2380 and others.

In the bank also written specification, which meets this oil - MIL-PRF-23699 (US military standard) and NATOvsky Code O-156.

Hatch access to the oil tank is at the Eyrbasovskom (A320) CFM56-5 engines on the left (in flight).

Here he is on the hood fan, yellow circled column:

Closer it looks like.

Left - two hinges hinge door, right - two push-lock.

Lower inscription informs us about the brand of oil used.

The upper inscription - mistaken: in fact, said air valve is on the right engine starter (probably confused the label).

Check the oil level it is necessary in the range from 5 to 30 minutes after the engine stops.

At that time, oil has already managed to drain into the oil tank, but has not yet had time to cool down. And the pressure in the oil tank had to pit.

At cooling oil is reduced in volume, and if it is poured through a considerable amount of time, you can refill the engine cool. Then the excess oil is ejected through a venting system to the atmosphere.

Some engines may then hit the excess oil in the bleed air and further as a vapor in the air conditioning system number. Passengers may be unhappy.

Opening the hatch, you can see literally the following:

Oil tank is covered with a gray refractory coating.

In the lower right corner hangs filler cap, but usually it is, of course, closed.

On top of the tank is the oil level sensor:

Its signal is converted into the display in the cockpit:

(circled in yellow)

It looks like the cabin A320

The level is shown in quarts (QT).

Also, we see the following:

In the lower left corner of the flap pictures - sightglass.

According to it, one can only understand the full oil tank or not.

Between the second top steel clamping screws can be uglyadet glass horizontal mark on the glass, which indicates the level of the maximum filling of the tank - it is about 18 liters.

A full oil tank capacity - about 20 liters of oil.

The minimum for a flight of approximately 10 liters (of course, in such a quantity in normal conditions no flies).

It is clear that with such an expenditure and capacity tank engine oil do not need to change - it's just topped up, and it is completely replaced by fresh itself a dozen flights.

During the flight the oil evaporates through a venting system of the engine.

In the glass, it ceases to be visible already at a level of 16 liters.

So exactly how much it is necessary to fill in the land impossible. And oil is poured until it seems in the window and did not reach a level near the mark on the glass.

On the right we see the two fitting connection system filling pressure.

They have a quick coupling with a ball lock.

Lower fitting - filling. To this is connected with the oil tank is small, usually with a hand pump.

Upper fitting - to equalize the pressure in the tank to the atmosphere, and the overflow of excess oil.

To it is connected a hose descended into the canister.

Then swing the handle of the pump oil is not enough. Look at the sightglass.

However, this dressing is used infrequently.

Usually dressed with oil open way through the filler neck.

It has a spring-loaded lid with handle.

To open the need to raise the handle, slightly rotate it counter-clockwise and pull the cover up the slots.

The cover will hang on the chain side of the neck, while the oil is poured.

The oil comes in sealed jars.

Cultural techniques punches a hole in the pot on top of a special device, and the usual - a screwdriver.

The oil is then poured out of the jar, as long as the level of the sightglass is not near the mark «Full» («full»).

Around the neck is equipped lotochek, into which the oil when the technician pours it by the neck.

It gets the oil pan through the hose into the drain nozzles below the engine and from there pours onto the platform.

Since oil is poured on the CFM56-5 engines are not very comfortable, and at the end of the oil in the tank goes slowly, the overflow or small misses in the neck - is a common phenomenon.

And traces of oil on the concrete under the engine are not uncommon.

For cleanliness before filling can be put in the tray around the filler neck a little rag.

After pouring the oil must not forget to close the tank filler cap and check the same on the second engine.

Here, perhaps, and all that "first approximation" You can tell quite a normal process.

Thank you for your attention.

source

Source:

Capacity to 1 quart (0, 946 l).

Oil system as a whole - is a matter of long and with many details.

So today we kratenko Walk only on the tops - on the oil tank and oil charge.

Let's start with the fact that the engines are different.

Some may swoop for dozens of hours, and spend only a liter or two.

Others consume excessively, and one flight somewhere in Sharm Sheikh back and have time to spend five liters.

Accordingly, the engine oil and fill a need not always. But usually it happens every Destination aircraft at the base (at a transit port is usually not filled in).

Oil for modern gas turbine engines made on the basis of esters.

It is efficient in a wide temperature range - from 40 to 200 degrees.

There are several types of such oils from different manufacturers approved for use by the engine manufacturer.

They are interchangeable and can generally be mixed without prejudice to the materiel.

The aircraft operator chooses which of the approved oils to maintain the engine.

For example, the pictures can be seen oil Mobil Jet Oil 2.

Analogues are its oil TurboNicOil 600, BP 2380 and others.

In the bank also written specification, which meets this oil - MIL-PRF-23699 (US military standard) and NATOvsky Code O-156.

Hatch access to the oil tank is at the Eyrbasovskom (A320) CFM56-5 engines on the left (in flight).

Here he is on the hood fan, yellow circled column:

Closer it looks like.

Left - two hinges hinge door, right - two push-lock.

Lower inscription informs us about the brand of oil used.

The upper inscription - mistaken: in fact, said air valve is on the right engine starter (probably confused the label).

Check the oil level it is necessary in the range from 5 to 30 minutes after the engine stops.

At that time, oil has already managed to drain into the oil tank, but has not yet had time to cool down. And the pressure in the oil tank had to pit.

At cooling oil is reduced in volume, and if it is poured through a considerable amount of time, you can refill the engine cool. Then the excess oil is ejected through a venting system to the atmosphere.

Some engines may then hit the excess oil in the bleed air and further as a vapor in the air conditioning system number. Passengers may be unhappy.

Opening the hatch, you can see literally the following:

Oil tank is covered with a gray refractory coating.

In the lower right corner hangs filler cap, but usually it is, of course, closed.

On top of the tank is the oil level sensor:

Its signal is converted into the display in the cockpit:

(circled in yellow)

It looks like the cabin A320

The level is shown in quarts (QT).

Also, we see the following:

In the lower left corner of the flap pictures - sightglass.

According to it, one can only understand the full oil tank or not.

Between the second top steel clamping screws can be uglyadet glass horizontal mark on the glass, which indicates the level of the maximum filling of the tank - it is about 18 liters.

A full oil tank capacity - about 20 liters of oil.

The minimum for a flight of approximately 10 liters (of course, in such a quantity in normal conditions no flies).

It is clear that with such an expenditure and capacity tank engine oil do not need to change - it's just topped up, and it is completely replaced by fresh itself a dozen flights.

During the flight the oil evaporates through a venting system of the engine.

In the glass, it ceases to be visible already at a level of 16 liters.

So exactly how much it is necessary to fill in the land impossible. And oil is poured until it seems in the window and did not reach a level near the mark on the glass.

On the right we see the two fitting connection system filling pressure.

They have a quick coupling with a ball lock.

Lower fitting - filling. To this is connected with the oil tank is small, usually with a hand pump.

Upper fitting - to equalize the pressure in the tank to the atmosphere, and the overflow of excess oil.

To it is connected a hose descended into the canister.

Then swing the handle of the pump oil is not enough. Look at the sightglass.

However, this dressing is used infrequently.

Usually dressed with oil open way through the filler neck.

It has a spring-loaded lid with handle.

To open the need to raise the handle, slightly rotate it counter-clockwise and pull the cover up the slots.

The cover will hang on the chain side of the neck, while the oil is poured.

The oil comes in sealed jars.

Cultural techniques punches a hole in the pot on top of a special device, and the usual - a screwdriver.

The oil is then poured out of the jar, as long as the level of the sightglass is not near the mark «Full» («full»).

Around the neck is equipped lotochek, into which the oil when the technician pours it by the neck.

It gets the oil pan through the hose into the drain nozzles below the engine and from there pours onto the platform.

Since oil is poured on the CFM56-5 engines are not very comfortable, and at the end of the oil in the tank goes slowly, the overflow or small misses in the neck - is a common phenomenon.

And traces of oil on the concrete under the engine are not uncommon.

For cleanliness before filling can be put in the tray around the filler neck a little rag.

After pouring the oil must not forget to close the tank filler cap and check the same on the second engine.

Here, perhaps, and all that "first approximation" You can tell quite a normal process.

Thank you for your attention.

source

Source: