507

How to save on heating: gas condensing boilers

Gas condensing boilers can provide the most efficient, economical and safe heating of the room. This is a relatively new type of heating equipment, but more than 75% of the European market of gas boilers accounted for by the solution condensation type. The main advantage is unattainable for other types the value of the conditional efficiency, which can exceed 100%.

Gas condensing boilers allow you to heat the room as efficiently, reduce natural gas consumption and reduce emissions of harmful substances. "Carbon footprint" from the operation is minimal. And thanks to the most efficient use of the energy of combustion gas capacity of such boilers is significantly higher. Condensing boilers don't just dominate on the European market and in some countries permitted the operation of only the heating equipment of this type.

The operating principle and the advantages of condensing boilers

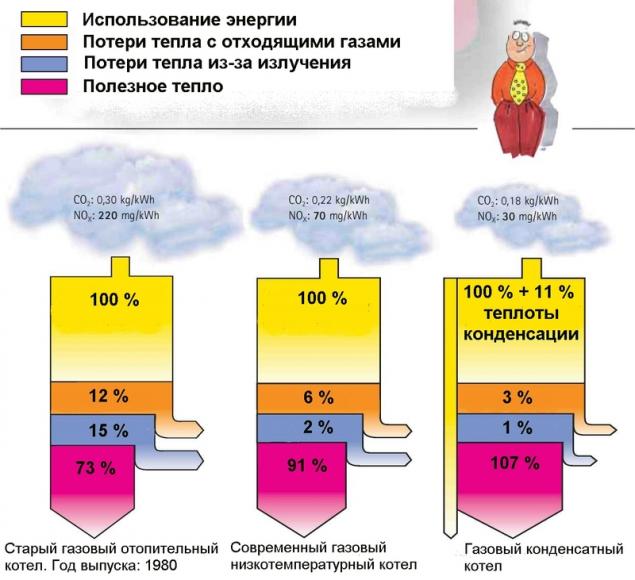

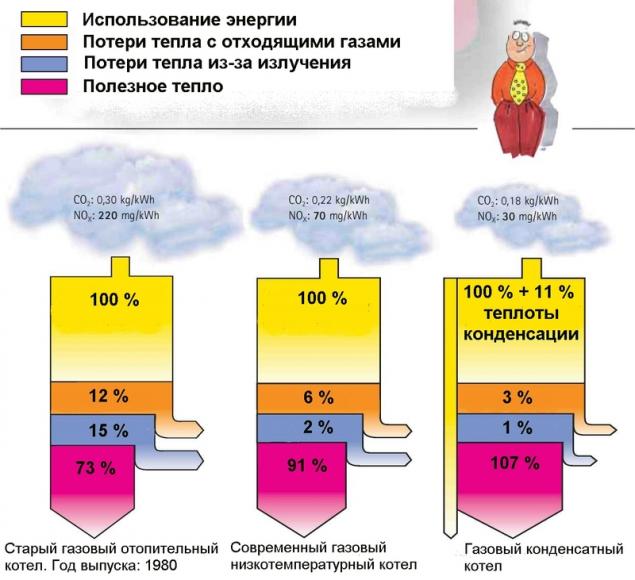

To begin with we note that in traditional heating kotloagregaty of combustion give up heat to the coolant, and some are simply thrown away into the atmosphere. The combustion temperature is markedly above 100 °C. it is obvious that in this case, together with the hot gases released into the atmosphere large amounts of thermal energy.

In condensing boilers the heat likewise produced by natural gas, and generated during this pair of hot smoke discharged to the reservoir, through which comes already passed through the system water. Such leads to instantaneous condensation of the steam. And this is one of the main advantages, because, as you know, in the condensation of steam provided a significant amount of energy. And instead throw it all into the atmosphere, it is also used for heating.

Thanks to the more efficient extraction of energy from the products of combustion and energy recovery of steam condensation and results in further efficiency gains. So, if traditional gas boilers, the temperature of the combustion products before emission into the atmosphere can be as high as 170 °C, condensing the figure does not exceed 70 °C, and the best models — 40 °C. the Use of condensing boilers significantly reduces unproductive losses of thermal energy increases the efficiency of the heating system and reduce natural gas consumption by 10-15%.

As the efficiency can be above 100%?

One of the main characteristics of efficiency of heating equipment is the performance coefficient or efficiency is the ratio of the useful heat energy to the total amount of energy expended. Any conversion is lossy, therefore, the efficiency never exceeds 100% is known from school.

But the producers of condensing heating equipment claim an efficiency level of 105 to 109%. This value is more correctly called a conditional efficiency. Conditional efficiency condensing boilers is based on the heat of combustion plus the heat of condensation of water vapor, which we discussed above. That is why it can exceed 100%.

As a rule, almost all modern models are fitted with a set of mandatory protection systems, which provide the necessary safety of operation. So, if the gas pressure is insufficient or the flow is stopped, the gas pipeline is automatically shut off. The same thing happens when flame failure. After restore the device manually.

In the event of termination of electricity supply, the boiler stops as these models. When a violation of the circulation of the coolant or the fluid from freezing in the heating circuit is switched off the pump and stops the supply of gas to the burner. But the availability control thrust is relevant only for models with open combustion chamber because it prevents the accumulation of combustion products in the room.

Similar scenarios of response to emergency situations ensure a high level of safety of operation and prevent damage to gas condensing boiler and heating system.

Condensing boiler in real life, Consider the use of such boiler on a real example. Heating gas Combi condensing boiler with capacity up to 25 kW, can heat the room with a total area of 150-180 m2, as well as produce hot water in the hot water system. Hot water temperature can reach 60°C and 12 liters heated at 25°C for only one minute. Maximum natural gas consumption does not exceed 2.7 m3 per hour. The manufacturer specifies the conditional efficiency of the device at 108%.

A boiler is a wall-mounted, its weight does not exceed 40 kg and a size comparable to the wall-mounted kitchen cabinets. To ensure the operation of the electronic control systems necessary to ensure the supply. As for the diameters of the connected pipelines, as a rule, the gas pipe and pipe of hot water system have a diameter of 1/2”, and pipe on the inlet and return of heating system can have a diameter of 1/2” or 3/4”.

The average cost of the model — from 1000 to 2000 $, but on the market are as affordable and expensive models with additional features. Among the major manufacturers of gas condensing boilers is possible to name of the company: BAXI, Bosch, Buderus, Buderus, Vaillant. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: ek.ua/post/231/287_kak_vybrat_gazovyy_kondensatsionnyy_kotel/

Gas condensing boilers allow you to heat the room as efficiently, reduce natural gas consumption and reduce emissions of harmful substances. "Carbon footprint" from the operation is minimal. And thanks to the most efficient use of the energy of combustion gas capacity of such boilers is significantly higher. Condensing boilers don't just dominate on the European market and in some countries permitted the operation of only the heating equipment of this type.

The operating principle and the advantages of condensing boilers

To begin with we note that in traditional heating kotloagregaty of combustion give up heat to the coolant, and some are simply thrown away into the atmosphere. The combustion temperature is markedly above 100 °C. it is obvious that in this case, together with the hot gases released into the atmosphere large amounts of thermal energy.

In condensing boilers the heat likewise produced by natural gas, and generated during this pair of hot smoke discharged to the reservoir, through which comes already passed through the system water. Such leads to instantaneous condensation of the steam. And this is one of the main advantages, because, as you know, in the condensation of steam provided a significant amount of energy. And instead throw it all into the atmosphere, it is also used for heating.

Thanks to the more efficient extraction of energy from the products of combustion and energy recovery of steam condensation and results in further efficiency gains. So, if traditional gas boilers, the temperature of the combustion products before emission into the atmosphere can be as high as 170 °C, condensing the figure does not exceed 70 °C, and the best models — 40 °C. the Use of condensing boilers significantly reduces unproductive losses of thermal energy increases the efficiency of the heating system and reduce natural gas consumption by 10-15%.

As the efficiency can be above 100%?

One of the main characteristics of efficiency of heating equipment is the performance coefficient or efficiency is the ratio of the useful heat energy to the total amount of energy expended. Any conversion is lossy, therefore, the efficiency never exceeds 100% is known from school.

But the producers of condensing heating equipment claim an efficiency level of 105 to 109%. This value is more correctly called a conditional efficiency. Conditional efficiency condensing boilers is based on the heat of combustion plus the heat of condensation of water vapor, which we discussed above. That is why it can exceed 100%.

As a rule, almost all modern models are fitted with a set of mandatory protection systems, which provide the necessary safety of operation. So, if the gas pressure is insufficient or the flow is stopped, the gas pipeline is automatically shut off. The same thing happens when flame failure. After restore the device manually.

In the event of termination of electricity supply, the boiler stops as these models. When a violation of the circulation of the coolant or the fluid from freezing in the heating circuit is switched off the pump and stops the supply of gas to the burner. But the availability control thrust is relevant only for models with open combustion chamber because it prevents the accumulation of combustion products in the room.

Similar scenarios of response to emergency situations ensure a high level of safety of operation and prevent damage to gas condensing boiler and heating system.

Condensing boiler in real life, Consider the use of such boiler on a real example. Heating gas Combi condensing boiler with capacity up to 25 kW, can heat the room with a total area of 150-180 m2, as well as produce hot water in the hot water system. Hot water temperature can reach 60°C and 12 liters heated at 25°C for only one minute. Maximum natural gas consumption does not exceed 2.7 m3 per hour. The manufacturer specifies the conditional efficiency of the device at 108%.

A boiler is a wall-mounted, its weight does not exceed 40 kg and a size comparable to the wall-mounted kitchen cabinets. To ensure the operation of the electronic control systems necessary to ensure the supply. As for the diameters of the connected pipelines, as a rule, the gas pipe and pipe of hot water system have a diameter of 1/2”, and pipe on the inlet and return of heating system can have a diameter of 1/2” or 3/4”.

The average cost of the model — from 1000 to 2000 $, but on the market are as affordable and expensive models with additional features. Among the major manufacturers of gas condensing boilers is possible to name of the company: BAXI, Bosch, Buderus, Buderus, Vaillant. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: ek.ua/post/231/287_kak_vybrat_gazovyy_kondensatsionnyy_kotel/