546

Pyrolysis boiler in a private house: a worthy alternative to gas heating

Hot summer, unfortunately, fleeting. Most of the time of year, the house needs heating. To heat their homes in different ways, but I want to choose the least troublesome and most economical option. Many believe that the most practical and inexpensive method of heating using a gas boiler. However, this is debatable. Recently introduced technologies allow to create a good alternative to gas heating. The use of pyrolysis process gives you the opportunity to turn an ordinary solid fuel boiler in an economical and efficient device of continuous burning.

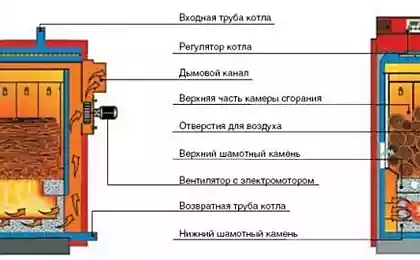

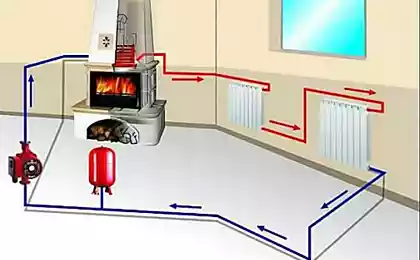

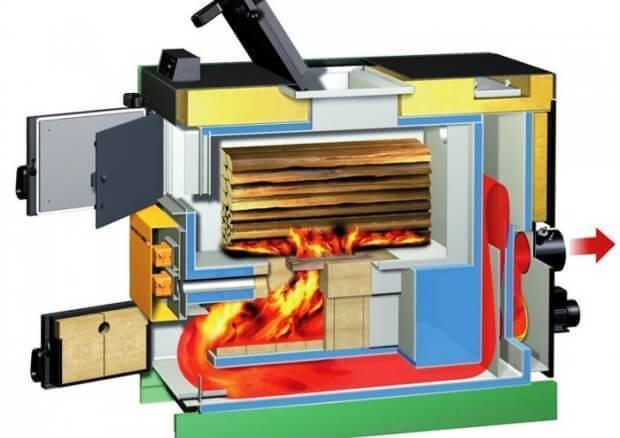

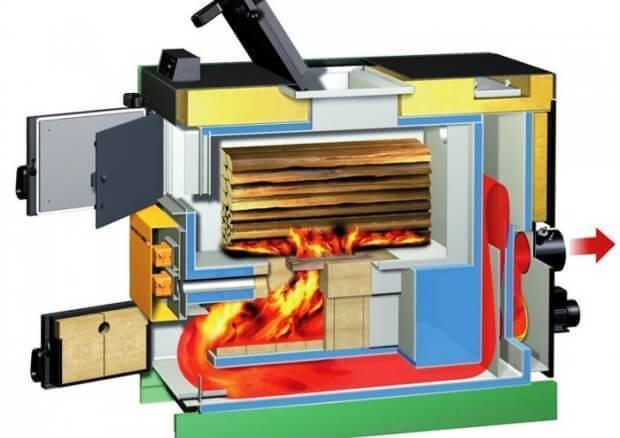

Pyrolysis boiler is considered to be a variation on the traditional solid device. It warms the coolant, which is then fed into the heating system. The main difference in principle. The basis for the operation of the equipment on pyrolysis or dry distillation of solid organic fuels, which is most often used wood. Under the influence of very high temperatures, lack of oxygen breaks down into solid organic matter dry residue or coke and gas mixture. The reaction is accompanied by release of large amounts of heat.

The presence of carcinogenic substances and CO₂ in the exhaust of waste gases is minimal, as wood gas reacts with the active carbon. When compared to conventional solid fuel boilers, these figures are on average three times lower. Pyrolysis equipment is another feature. It divides the process of teplotvornaja in two stages. At first the combustion of fossil fuels in the lack of oxygen. In such circumstances, the combustion process takes place very slowly, smoldering organic matter and emit the gas.

The evolved pyrolysis gas enters the second chamber, where it burns, creating additional heat. Both processes are controlled by automation, by opening and closing the air supply to the cells. The thermostat, which is equipped with pyrolysis boilers, adjust the combustion process, controls the flow of air and thereby maintains the desired temperature. Heaters capable of long time to work on a single fuel tab. The average term of the operation — about 12 hours. If you want, you can find the device with high performance.

Manufacturers produce two types of pyrolysis boilers. The main difference between them lies in the placement of the camera afterburners. The so-called chamber, where the burning gas mixture. Most sales you can find the modification with the lower compartment afterburner. These devices are most convenient to use. The fuel is placed in the upper chamber, exhaust gases are in a natural way, without using any additional devices. The system is completely non-volatile. Among the disadvantages of the device include the lack of natural traction that require enhanced air circulation due to the installation of tall chimneys.

Another drawback: instruments with chamber for afterburning, located downstairs, has much more clean, as the ash from the top of the camera always gets in the lower compartment. This deficiency deprived of boilers, in which the afterburning compartment is located on top. To clean them you will have much less. A combustion chamber located at the bottom that allows you to withdraw the pyrolysis gas in the upper compartment. Here it burns and the combustion products are directed into the chimney and removed. In General, this system is very practical, but it is more complicated and requires more materials and, consequently, more cost of equipping the chimney, which is longer than the analogues with a lower afterburning chamber.

The performance of the boiler substantially affected by the presence of the discharge device. Forced whipping up thrust provides an opportunity to increase its efficiency, to accelerate heating of the room and the flue products. In addition, the increased period of operation of the device on a single fuel tab. A significant flaw boilers with forced draught – dependence. That, however, can be compensated by connecting the device to the generator or the UPS system. Equipment with natural draft are easy to install and non-volatile, but often maintain, it is less convenient to use.

As fuel for pyrolysis boiler, you can use any solid organic matter: peat, coal, or wood. Using the latest most economically advantageous, so often in the pyrolysis system lay wood or wood briquettes. The equipment is very demanding on the humidity level of the fuel. Optimally, it does not exceed 45%, but the best option is 20%. Proven that a kilogram of firewood humidity 20% burning, produces heat, equivalent to 4 kW/h Wood is 50% moisture under the same conditions, will give half the heat, so when choosing the fuel, special attention should be paid to its humidity.

Pyrolysis boilers is a worthy alternative to gas heating. The fuel burns as efficiently as possible, efficiency of the device is an average of 90%. The amount of waste is minimal, so clean equipment is not often. The boiler is capable of a long time offline to work on one load of fuel. The combustion process is automated, which allows the system to operate without human intervention. The main disadvantage of pyrolysis boilers is their high cost, which pays off quite quickly due to the low fuel consumption, high efficiency and cost-effectiveness of the system.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.stroitelstvo365.ru/Mobile/otoplenie/piroliznij-kotel

Pyrolysis boiler is considered to be a variation on the traditional solid device. It warms the coolant, which is then fed into the heating system. The main difference in principle. The basis for the operation of the equipment on pyrolysis or dry distillation of solid organic fuels, which is most often used wood. Under the influence of very high temperatures, lack of oxygen breaks down into solid organic matter dry residue or coke and gas mixture. The reaction is accompanied by release of large amounts of heat.

The presence of carcinogenic substances and CO₂ in the exhaust of waste gases is minimal, as wood gas reacts with the active carbon. When compared to conventional solid fuel boilers, these figures are on average three times lower. Pyrolysis equipment is another feature. It divides the process of teplotvornaja in two stages. At first the combustion of fossil fuels in the lack of oxygen. In such circumstances, the combustion process takes place very slowly, smoldering organic matter and emit the gas.

The evolved pyrolysis gas enters the second chamber, where it burns, creating additional heat. Both processes are controlled by automation, by opening and closing the air supply to the cells. The thermostat, which is equipped with pyrolysis boilers, adjust the combustion process, controls the flow of air and thereby maintains the desired temperature. Heaters capable of long time to work on a single fuel tab. The average term of the operation — about 12 hours. If you want, you can find the device with high performance.

Manufacturers produce two types of pyrolysis boilers. The main difference between them lies in the placement of the camera afterburners. The so-called chamber, where the burning gas mixture. Most sales you can find the modification with the lower compartment afterburner. These devices are most convenient to use. The fuel is placed in the upper chamber, exhaust gases are in a natural way, without using any additional devices. The system is completely non-volatile. Among the disadvantages of the device include the lack of natural traction that require enhanced air circulation due to the installation of tall chimneys.

Another drawback: instruments with chamber for afterburning, located downstairs, has much more clean, as the ash from the top of the camera always gets in the lower compartment. This deficiency deprived of boilers, in which the afterburning compartment is located on top. To clean them you will have much less. A combustion chamber located at the bottom that allows you to withdraw the pyrolysis gas in the upper compartment. Here it burns and the combustion products are directed into the chimney and removed. In General, this system is very practical, but it is more complicated and requires more materials and, consequently, more cost of equipping the chimney, which is longer than the analogues with a lower afterburning chamber.

The performance of the boiler substantially affected by the presence of the discharge device. Forced whipping up thrust provides an opportunity to increase its efficiency, to accelerate heating of the room and the flue products. In addition, the increased period of operation of the device on a single fuel tab. A significant flaw boilers with forced draught – dependence. That, however, can be compensated by connecting the device to the generator or the UPS system. Equipment with natural draft are easy to install and non-volatile, but often maintain, it is less convenient to use.

As fuel for pyrolysis boiler, you can use any solid organic matter: peat, coal, or wood. Using the latest most economically advantageous, so often in the pyrolysis system lay wood or wood briquettes. The equipment is very demanding on the humidity level of the fuel. Optimally, it does not exceed 45%, but the best option is 20%. Proven that a kilogram of firewood humidity 20% burning, produces heat, equivalent to 4 kW/h Wood is 50% moisture under the same conditions, will give half the heat, so when choosing the fuel, special attention should be paid to its humidity.

Pyrolysis boilers is a worthy alternative to gas heating. The fuel burns as efficiently as possible, efficiency of the device is an average of 90%. The amount of waste is minimal, so clean equipment is not often. The boiler is capable of a long time offline to work on one load of fuel. The combustion process is automated, which allows the system to operate without human intervention. The main disadvantage of pyrolysis boilers is their high cost, which pays off quite quickly due to the low fuel consumption, high efficiency and cost-effectiveness of the system.published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: www.stroitelstvo365.ru/Mobile/otoplenie/piroliznij-kotel

Help with depression: how and how not to. 7 simple recipes

40 simple techniques of self-massage to promote health