577

Pyrolytic boiler with their hands

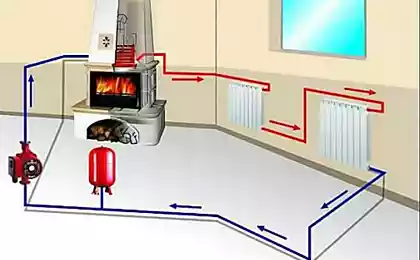

The solution to the problem of heating a country house or villas may be different. Not always this will help the traditional sources – gas and electricity: they simply may not be near or stability of supply is poor. The purchase of solid fuel boiler requires a lot of money. So many people wonder about how to build pyrolysis boiler with their hands. As fuel you can use wood or waste wood industry, as well as solid pallets are made from wood bark, shavings, pine needles, hay and agricultural waste. But before you begin, you should learn all about the pyrolysis.

What is pyrolysis

In fact, this process is destructive distillation. Dry wood at a temperature in the range of 200 – 800 °C and in conditions of oxygen deficiency becomes woody Cox with the release of pyrolysis gas which is in mixture with oxygen is the catalyst for the combustion process. During pyrolysis the gas produced reacts with the carbon, allowing gaseous emissions to the atmosphere are purified from harmful compounds. Solid components of the wood burn, giving off heat.

The pyrolysis process is exothermic, which means heat, which can be spent on space heating and wood drying.

Seventy three million six hundred thirty seven thousand nine hundred seventy five

Typically, as fuel in the boiler is used wood is fairly inexpensive and usual fuel

The advantages and disadvantages of pyrolysis equipment

The advantages include the following:

Procedure pyrolysis combustion is the formation of minor amounts of ash and soot, which is why this equipment rarely needs cleaning

The device gasification boiler

In its composition two of the combustion chamber, which provides higher efficiency equipment. The first camera intended for loading of fuel is pyrolysis: it is a division of the wood into a gaseous product and a dry charcoal. Gas is transferred into the next chamber, where, mixing with air, increasing the burning process. Divided camera of the grate, over which are stacked briquettes.

Used during pyrolysis of the overdraft technological feature, which has a pyrolysis boiler: working principle based on creating a forced draft through the combustion blower motor or the induced draft fan. They overcome the high flow resistance in the furnace.

Ninety seven million one hundred eighty seven thousand six hundred fifty three

Diagram of the device simple pyrolysis boiler

Scheme of pyrolysis boiler

Before starting Assembly work, be prepared: make a detailed diagram of the fuel equipment. Yourself to perform only an experienced engineer-heating equipment, therefore, to simplify this task, you can use the predefined scheme, which can slightly change.

Below is a diagram of the unit with a capacity of 40 kW. Changes to the scheme should not affect the size of the inner chamber. When the test run is necessary to determine the efficiency: it's easy to do if you pay attention to the character coming from the pipe smoke. If the smell of carbon monoxide is absent – then everything is in order. This check must be performed when the download of the pyrolysis chamber.

Forty eight million one hundred seventy four thousand one hundred thirty

An example of a drawing of pyrolysis boiler

Convention:

A controller circuit of the boiler; B is a door for loading fuel; C – cover ash pan; D — blast fan; E – coupler sensor of the temperature fuse with a radius of one-half inch; F is the inlet for the emergency line, G is the feed line circuit of the boiler; H – supply of cold water to the safety heat exchanger, K is the supply of hot water to the safety heat exchanger; L – return line of the boiler circuit; M – the surge tank and the connection for discharge.

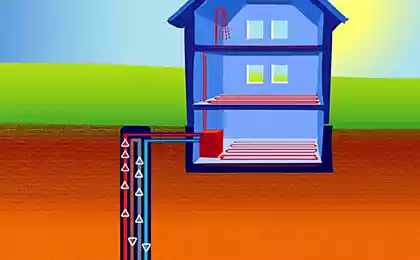

Not always as the coolant is water: often this function is performed by air. It is served in a heated condition through the pipes and back to the floor by gravity. It is convenient as there is no risk of the defrost system. In addition, there is no need to control the tightness of the pipes.

Determined costs

To get the desired result, you will have to spend a lot of energy and resources: will need to purchase a missing tool, and the material ain't cheap. But it is more important to assess the economic effect: if you do, you can save about $ 2000. This is precisely the difference between the cost of purchase of the boiler and materials intended for the manufacture of it himself. The complexity of the mapping Assembly can be overcome: today there are many companies that provide such services.

Ninety million five hundred forty four thousand one hundred eleven

Pyrolytic boiler with post-combustion chamber

What are the necessary tools and materials

To connect the parts, made mostly of sheet metal, it is necessary only with the help of electric welding machine. You will also need an electric drill with set of drill bits of different diameter and angle grinders machine (grinder) with a circle of metal with a diameter of 230. In some places it is more convenient to operate grinder with a circle with a diameter of 125, but not necessarily.

With regard to materials: the list is quite wide.

Steel sheet with thickness from 4.0 to 7.5 mm. allowed the use of sheets with a thickness of 4 mm for the manufacture of internal components and 3 mm for the case. Pipe of carbon steel with a wall thickness of 3.5 mm (with a diameter of 57) about 8 m. Pipe with a wall 4.5 mm (diameter 159) – half a meter. Tube wall 3.2 mm diameter 32 – 1 m. fire brick in the amount of half a dozen. Profiled pipe section 60×30 mm with sides of 2.0 – 1.5 m Profiled steel section 80 x 40 mm with walls 2.0 to 1 m Steel strip of 4 mm thickness and 20 width – 7.5 m. the Steel strip 4 mm thick and 30 wide, 1.5 m Steel strip of 5 mm in thickness 80 and width – 1 m. the welding Electrodes is about 5 packs. Cutting wheels with a diameter of 230 grinders – about 10 PCs Grinding wheels with diameter 125 – 5 PCs Blower electric fan. Temperature sensor. Eighty three million two hundred fifty three thousand fifteen

The view from the inside of the boiler with explanations

Basically, it contains everything. In the process still may need some stuff, but it will not have a major impact on the final cost.

Installation rules of equipment in accordance with the fire safety

After the boiler is assembled, you must install it. It is important to observe the rules of fire safety. Otherwise, might threaten the health and even the lives of people.

To place such equipment is allowed only in nonresidential areas. The Foundation for installation of the unit is made of concrete or brick. In front of the burners should be placed a metal sheet with a minimum thickness of 1.5 mm. Minimum acceptable distance from housing to furniture or other objects that can support combustion shall not be less than 200 mm. In the premises it is necessary to arrange natural ventilation, capable of maintaining sufficient air for normal combustion, there must be fresh air saturated with oxygen. It is important that the flue pipe was well insulated, otherwise the walls would be condensation and precipitate the resin, which would reduce the efficiency of the equipment and its service life.

Something about pyrolysis furnaces

Large and powerful units are needed only to residents of large homes. For owners of country houses, there is another solution – pyrolysis oven. It looks very similar to the boiler, and its operating principle is no different. But the size and capacity of its much less – up to 25 kW.

The pyrolysis oven is a good alternative to pot

In order to build enough 400 pieces of ceramic bricks, 100 pieces refractory bricks, sheet steel thickness 4 mm (1.5×6.0 m), 3 PCs., cast iron grate, fan pressurization, door blower and the furnace, the thermostat lever. This stove is enough to warm the house in winter. published

Source: teploguru.ru/kotel/tverd/piroliznyj-kotel-svoimi-rukami.html

What is pyrolysis

In fact, this process is destructive distillation. Dry wood at a temperature in the range of 200 – 800 °C and in conditions of oxygen deficiency becomes woody Cox with the release of pyrolysis gas which is in mixture with oxygen is the catalyst for the combustion process. During pyrolysis the gas produced reacts with the carbon, allowing gaseous emissions to the atmosphere are purified from harmful compounds. Solid components of the wood burn, giving off heat.

The pyrolysis process is exothermic, which means heat, which can be spent on space heating and wood drying.

Seventy three million six hundred thirty seven thousand nine hundred seventy five

Typically, as fuel in the boiler is used wood is fairly inexpensive and usual fuel

The advantages and disadvantages of pyrolysis equipment

The advantages include the following:

- due to the increased loading of pyrolysis boilers are able to maintain the desired temperature for a long time;

- combustion products practically do not contain carcinogenic substances;

- using this equipment can recycle some plastics, rubber, fiberboard and particleboard, but their part in the mass of the main fuel should not be more than 30%.

- the high cost of equipment: to solve this problem, producing pyrolysis boilers with their hands;

- large size;

- as fuel you can use only dry wood: if there is moisture in it, the process stops, and the boiler efficiency decreases drastically, lost a large amount of heat that goes along with steam;

- operation of this equipment depends on the power supply fan needed to maintain traction.

Procedure pyrolysis combustion is the formation of minor amounts of ash and soot, which is why this equipment rarely needs cleaning

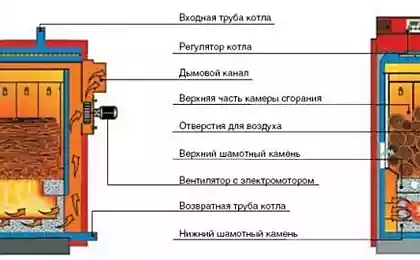

The device gasification boiler

In its composition two of the combustion chamber, which provides higher efficiency equipment. The first camera intended for loading of fuel is pyrolysis: it is a division of the wood into a gaseous product and a dry charcoal. Gas is transferred into the next chamber, where, mixing with air, increasing the burning process. Divided camera of the grate, over which are stacked briquettes.

Used during pyrolysis of the overdraft technological feature, which has a pyrolysis boiler: working principle based on creating a forced draft through the combustion blower motor or the induced draft fan. They overcome the high flow resistance in the furnace.

Ninety seven million one hundred eighty seven thousand six hundred fifty three

Diagram of the device simple pyrolysis boiler

Scheme of pyrolysis boiler

Before starting Assembly work, be prepared: make a detailed diagram of the fuel equipment. Yourself to perform only an experienced engineer-heating equipment, therefore, to simplify this task, you can use the predefined scheme, which can slightly change.

Below is a diagram of the unit with a capacity of 40 kW. Changes to the scheme should not affect the size of the inner chamber. When the test run is necessary to determine the efficiency: it's easy to do if you pay attention to the character coming from the pipe smoke. If the smell of carbon monoxide is absent – then everything is in order. This check must be performed when the download of the pyrolysis chamber.

Forty eight million one hundred seventy four thousand one hundred thirty

An example of a drawing of pyrolysis boiler

Convention:

A controller circuit of the boiler; B is a door for loading fuel; C – cover ash pan; D — blast fan; E – coupler sensor of the temperature fuse with a radius of one-half inch; F is the inlet for the emergency line, G is the feed line circuit of the boiler; H – supply of cold water to the safety heat exchanger, K is the supply of hot water to the safety heat exchanger; L – return line of the boiler circuit; M – the surge tank and the connection for discharge.

Not always as the coolant is water: often this function is performed by air. It is served in a heated condition through the pipes and back to the floor by gravity. It is convenient as there is no risk of the defrost system. In addition, there is no need to control the tightness of the pipes.

Determined costs

To get the desired result, you will have to spend a lot of energy and resources: will need to purchase a missing tool, and the material ain't cheap. But it is more important to assess the economic effect: if you do, you can save about $ 2000. This is precisely the difference between the cost of purchase of the boiler and materials intended for the manufacture of it himself. The complexity of the mapping Assembly can be overcome: today there are many companies that provide such services.

Ninety million five hundred forty four thousand one hundred eleven

Pyrolytic boiler with post-combustion chamber

What are the necessary tools and materials

To connect the parts, made mostly of sheet metal, it is necessary only with the help of electric welding machine. You will also need an electric drill with set of drill bits of different diameter and angle grinders machine (grinder) with a circle of metal with a diameter of 230. In some places it is more convenient to operate grinder with a circle with a diameter of 125, but not necessarily.

With regard to materials: the list is quite wide.

Steel sheet with thickness from 4.0 to 7.5 mm. allowed the use of sheets with a thickness of 4 mm for the manufacture of internal components and 3 mm for the case. Pipe of carbon steel with a wall thickness of 3.5 mm (with a diameter of 57) about 8 m. Pipe with a wall 4.5 mm (diameter 159) – half a meter. Tube wall 3.2 mm diameter 32 – 1 m. fire brick in the amount of half a dozen. Profiled pipe section 60×30 mm with sides of 2.0 – 1.5 m Profiled steel section 80 x 40 mm with walls 2.0 to 1 m Steel strip of 4 mm thickness and 20 width – 7.5 m. the Steel strip 4 mm thick and 30 wide, 1.5 m Steel strip of 5 mm in thickness 80 and width – 1 m. the welding Electrodes is about 5 packs. Cutting wheels with a diameter of 230 grinders – about 10 PCs Grinding wheels with diameter 125 – 5 PCs Blower electric fan. Temperature sensor. Eighty three million two hundred fifty three thousand fifteen

The view from the inside of the boiler with explanations

Basically, it contains everything. In the process still may need some stuff, but it will not have a major impact on the final cost.

Installation rules of equipment in accordance with the fire safety

After the boiler is assembled, you must install it. It is important to observe the rules of fire safety. Otherwise, might threaten the health and even the lives of people.

To place such equipment is allowed only in nonresidential areas. The Foundation for installation of the unit is made of concrete or brick. In front of the burners should be placed a metal sheet with a minimum thickness of 1.5 mm. Minimum acceptable distance from housing to furniture or other objects that can support combustion shall not be less than 200 mm. In the premises it is necessary to arrange natural ventilation, capable of maintaining sufficient air for normal combustion, there must be fresh air saturated with oxygen. It is important that the flue pipe was well insulated, otherwise the walls would be condensation and precipitate the resin, which would reduce the efficiency of the equipment and its service life.

Something about pyrolysis furnaces

Large and powerful units are needed only to residents of large homes. For owners of country houses, there is another solution – pyrolysis oven. It looks very similar to the boiler, and its operating principle is no different. But the size and capacity of its much less – up to 25 kW.

The pyrolysis oven is a good alternative to pot

In order to build enough 400 pieces of ceramic bricks, 100 pieces refractory bricks, sheet steel thickness 4 mm (1.5×6.0 m), 3 PCs., cast iron grate, fan pressurization, door blower and the furnace, the thermostat lever. This stove is enough to warm the house in winter. published

Source: teploguru.ru/kotel/tverd/piroliznyj-kotel-svoimi-rukami.html