492

Water pyrolysis boiler babatana with the accelerator at the sawdust with their hands

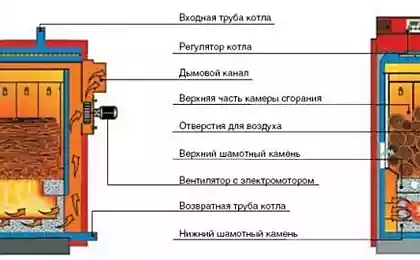

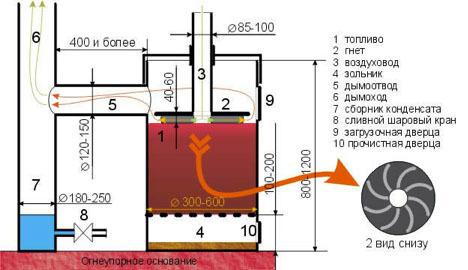

Materials for makingHomemade pyrolysis boiler "rubatone" it's unique to our time as the iPhone, and easy-to-follow invention of craftsmen. To create a furnace, you will need a gas tank capacity of 50 liters propane-butane, steel sheet, designed to cut 2 circles corresponding to the diameter of the cylinder.

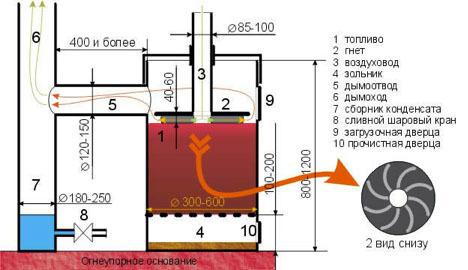

You will also need strips of metal with thickness up to 4 mm and a width of 40 mm for the blades and reinforcing bars of 14 mm for the grating should be placed over the combustion chamber.

Principle of operationthe Principle of operation of the boiler, call it so — "bub iPhone" is ingeniously simple. Blades, located on the bottom of the "pancake" pipe, are the generators of the vortex flow flowing along the air pipe. Obstacle on the route of air masses prevents the appearance of fire under the pipe.

Fuel (in most cases this dry sawdust) only smolders under the resistance of the piston, receiving the inflow of air masses from the pipe. Water and gas pairs, evaporated in the process of decay, congenerous welded to a vertical tube boiler.

The equipmentthe equipment consists of the steps of:

• making the furnace

• making the cover and clamping range

• fabrication of the chimney and doors.

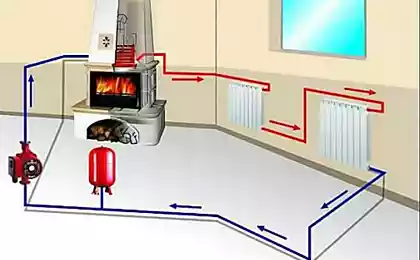

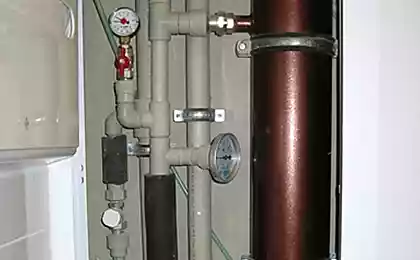

Gas cylinder to be cut using a grinder on top from the beginning of the round. Further, the upper part can be used as cover. This cut is polished to create an air tight seal. Reconciliation cut a hole to install the chimney pipe (piston). The gap should be 2-3 mm. Cover ovarium diameter steel strip. If you intend to make a furnace with cooling (water jacket), to build a gasification boiler with the water system require an extra outer cylinder.

For this purpose you can use the pipe of impressive diameter with thick walls.

It must be remembered that the difference of the diameters of the pipes generates two-step thrust, and angle of the flue pipe reduces the rate of excretion of the gas mixture. Therefore, the output side of the pipe can reach 0.15 m and the vertical – 0.20 m. the pressure Decrease of the mixture supports the process of pyrolysis for 10 hours.

Then using a welding machine of the armature produce a grid, which will provide the decomposition of decaying fuel in the bottom of the combustion chamber. To clean ash chamber in the bottom of the container, it is necessary to provide the door with a tight vestibule.

How to make the pyrolized boiler himself, is presented here.

published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: svouimirukami.ru/companies/materialyi/piroliznye-kotly-piroliznye-kotly-dlitelnogo-goreniya-pravilnaya-ustanovka.html

You will also need strips of metal with thickness up to 4 mm and a width of 40 mm for the blades and reinforcing bars of 14 mm for the grating should be placed over the combustion chamber.

Principle of operationthe Principle of operation of the boiler, call it so — "bub iPhone" is ingeniously simple. Blades, located on the bottom of the "pancake" pipe, are the generators of the vortex flow flowing along the air pipe. Obstacle on the route of air masses prevents the appearance of fire under the pipe.

Fuel (in most cases this dry sawdust) only smolders under the resistance of the piston, receiving the inflow of air masses from the pipe. Water and gas pairs, evaporated in the process of decay, congenerous welded to a vertical tube boiler.

The equipmentthe equipment consists of the steps of:

• making the furnace

• making the cover and clamping range

• fabrication of the chimney and doors.

Gas cylinder to be cut using a grinder on top from the beginning of the round. Further, the upper part can be used as cover. This cut is polished to create an air tight seal. Reconciliation cut a hole to install the chimney pipe (piston). The gap should be 2-3 mm. Cover ovarium diameter steel strip. If you intend to make a furnace with cooling (water jacket), to build a gasification boiler with the water system require an extra outer cylinder.

For this purpose you can use the pipe of impressive diameter with thick walls.

It must be remembered that the difference of the diameters of the pipes generates two-step thrust, and angle of the flue pipe reduces the rate of excretion of the gas mixture. Therefore, the output side of the pipe can reach 0.15 m and the vertical – 0.20 m. the pressure Decrease of the mixture supports the process of pyrolysis for 10 hours.

Then using a welding machine of the armature produce a grid, which will provide the decomposition of decaying fuel in the bottom of the combustion chamber. To clean ash chamber in the bottom of the container, it is necessary to provide the door with a tight vestibule.

How to make the pyrolized boiler himself, is presented here.

published

P. S. And remember, only by changing their consumption — together we change the world! ©

Join us in Facebook , Vkontakte, Odnoklassniki

Source: svouimirukami.ru/companies/materialyi/piroliznye-kotly-piroliznye-kotly-dlitelnogo-goreniya-pravilnaya-ustanovka.html