682

Installation of induction heating boiler with their hands

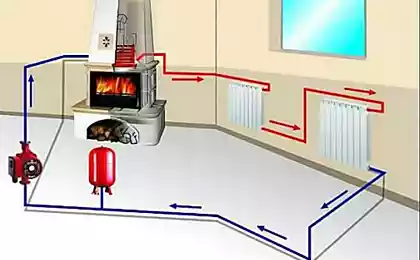

The rapid growth of energy prices used for thousands of years (solid fuel, gas), lead to a constant search for alternatives to heating systems, which could show efficient working and significant savings. Through this article, you will learn how to make induction heating boiler with their hands, without spending a lot of effort, time, and most importantly Finance.

Advantages of induction heatingFor the reason that not all people are willing to use in everyday life are not as familiar devices, giving preference to systems that are known for their productivity and quality a long time ago, they often reject the option of a homemade induction boiler, not even learning of his predominant characteristics:

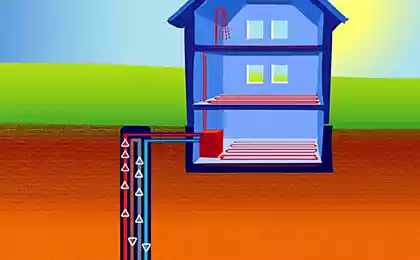

Cost. Despite the fact that purchase the system will need to spend considerably, not to mention the costs of maintenance, and the factory settings are expensive, assembling the heating unit on your own — a great option for good savings. This unit can be installed on already operating heating system, which will significantly lower your maintenance costs. In addition, homemade induction tunic, with the correct Assembly, will not require constant cleaning, replacement of components, as in the case with the factory models. Power. Given the fact that retailer systems are available with different capacity, self-made apparatus it is also possible to provide different power supply hot air. This figure mainly depends on the size of the coil and can vary from 3 kW to 70 kW. So if you require heating large industrial premises, several induction boilers, with their hands raised in the series, will complete the task with 100% efficiency. Security. The most exciting question that stops some homeowners prior to Assembly of the induction pot with their hands. It is important to understand that the machine made independently, subject to all rules, described below, will be absolutely safe. The reliability of your models and the factory will be significantly different, and in your favor. The principle of operation of induction heating, the Formation of thermal energy from electrical — the main problem is how the factory and homemade units. He insane speed increases the coolant temperature that sends the Heaters on the bench.

The base or heart of the system is the inductor winding in one of two ways:

Due to the simplicity of their construction made with your own hands induction pricks can never be broken for all time of its work. Also many consumers of these units don't want to try making them because of the potential for scale formation. But the vibration during operation of the system, prevent his education. These points are more than important, because the health of a homemade system lies entirely on your shoulders.

Instructions for the manufacture of induction heating with his own handsFor proper Assembly, reliable, safe, effective and durable unit you will need to get some things:

7-millimeter wire cut into small segments with a length of about 6 cm in such an amount that can fill the pipe. At the bottom of the pipe laid steel mesh. Previously prepared pieces of wire are filled into the pipe. The other side of the pipe is closed in the same way (grid).

Wire will play the role of the secondary winding, and the grid will not allow its segments to fall under the force of the water flow.

Filled the wire tube is wound enamelled copper wire (90 turns). It should be smooth, without defects. Each coil shall be at the same distance from previous. All that's left to do, ready to install the device in already existing heating system. This will require:

Rules of installation

At first glance, self-Assembly induction boiler can seem difficult or even impossible task. But first, this is not the case — everything is much easier and not need to learn the mechanics to implement your plans. Second, the benefits that you will receive from the heating system, will justify all your efforts and costs. A minimum of materials, good build quality, the safety of the family budget and durable work machine — it's all worth it to spend a few hours assembling the induction of the boiler with their hands. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Source: normdom.ru/otoplenie/indukcionnyi-kotel-otopleniya-svoimi-rukami.html

Advantages of induction heatingFor the reason that not all people are willing to use in everyday life are not as familiar devices, giving preference to systems that are known for their productivity and quality a long time ago, they often reject the option of a homemade induction boiler, not even learning of his predominant characteristics:

Cost. Despite the fact that purchase the system will need to spend considerably, not to mention the costs of maintenance, and the factory settings are expensive, assembling the heating unit on your own — a great option for good savings. This unit can be installed on already operating heating system, which will significantly lower your maintenance costs. In addition, homemade induction tunic, with the correct Assembly, will not require constant cleaning, replacement of components, as in the case with the factory models. Power. Given the fact that retailer systems are available with different capacity, self-made apparatus it is also possible to provide different power supply hot air. This figure mainly depends on the size of the coil and can vary from 3 kW to 70 kW. So if you require heating large industrial premises, several induction boilers, with their hands raised in the series, will complete the task with 100% efficiency. Security. The most exciting question that stops some homeowners prior to Assembly of the induction pot with their hands. It is important to understand that the machine made independently, subject to all rules, described below, will be absolutely safe. The reliability of your models and the factory will be significantly different, and in your favor. The principle of operation of induction heating, the Formation of thermal energy from electrical — the main problem is how the factory and homemade units. He insane speed increases the coolant temperature that sends the Heaters on the bench.

The base or heart of the system is the inductor winding in one of two ways:

- primary — converts electrical energy into eddy currents, directing them to the secondary;

- the secondary housing and the heating element gives up eddy currents in the coolant.

Due to the simplicity of their construction made with your own hands induction pricks can never be broken for all time of its work. Also many consumers of these units don't want to try making them because of the potential for scale formation. But the vibration during operation of the system, prevent his education. These points are more than important, because the health of a homemade system lies entirely on your shoulders.

Instructions for the manufacture of induction heating with his own handsFor proper Assembly, reliable, safe, effective and durable unit you will need to get some things:

- 7-milimetrov (in diameter) stainless steel wire;

- 50-milimetrov (in diameter) plastic pipe with walls from 5 mm, length about 50 cm;

- steel mesh diameter pipe (two piece);

- 1.2 mm (diameter) enamelled copper wire with a length of about 5 m;

- welding inverter.

7-millimeter wire cut into small segments with a length of about 6 cm in such an amount that can fill the pipe. At the bottom of the pipe laid steel mesh. Previously prepared pieces of wire are filled into the pipe. The other side of the pipe is closed in the same way (grid).

Wire will play the role of the secondary winding, and the grid will not allow its segments to fall under the force of the water flow.

Filled the wire tube is wound enamelled copper wire (90 turns). It should be smooth, without defects. Each coil shall be at the same distance from previous. All that's left to do, ready to install the device in already existing heating system. This will require:

- cut the necessary long;

- using the adapter, ready to install the pipe.

- to the ends of copper wire connected to the inverter;

- the boiler fills with water and starts the flow of energy.

- welding inverter;

- three phase transformer (it is advisable to be equipped with fasteners for secure attachment);

- two tubes welded to each other so that they resembled a bagel.

Rules of installation

- the system is installed at 30-cm distance from the walls and 80-cm distance from the floor and ceiling. A precaution to ensure safe use of the unit;

- such systems are used only in closed heating networks, which will be forced circulation of the coolant;

- the boiler with their hands can be used in systems with a distribution of polypropylene or plastic tubes;

- also, for lead pipe, it is recommended to install a pressure gauge, subversive valve, and a device for removing the air running on the machine.

At first glance, self-Assembly induction boiler can seem difficult or even impossible task. But first, this is not the case — everything is much easier and not need to learn the mechanics to implement your plans. Second, the benefits that you will receive from the heating system, will justify all your efforts and costs. A minimum of materials, good build quality, the safety of the family budget and durable work machine — it's all worth it to spend a few hours assembling the induction of the boiler with their hands. published

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Source: normdom.ru/otoplenie/indukcionnyi-kotel-otopleniya-svoimi-rukami.html