902

How to organize an induction heating

In the context of the energy crisis and the constant increase in energy prices, it is necessary to look for new opportunities for space heating at the lowest cost. Developed back in the mid-19th century and has not found wide application while in the home of induction heating technology is becoming popular because of their efficiency and availability.

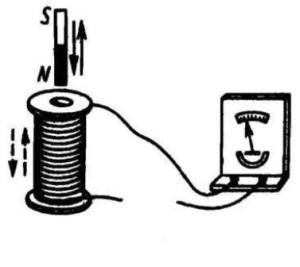

The principle of heating

Occurrence of electromagnetic induction phenomenon is to create an induced current under the action of an alternating magnetic field coils. The thermal effect of the resulting stream is used to heat the coolant.

If a closed circuit (inductor), consisting of several turns, to place the object of electrically conductive material and pass through the high frequency currents in the coils is formed an electromagnetic field creating eddy currents heating the object located therein. On the heating intensity is influenced by several parameters:

by increasing the power of the magnetic field strength increases heating;

dependence on the magnetic properties of the core;

distance from the inductor to the subject.

Equally important is to choose the correct operating frequency of the inverter, which affects the depth of penetration of heat into the core, that is the point where the current density drops to 37%. This rate increases with increasing frequency.

To use this phenomenon in practice, must be installed, consisting of a coil, which creates an electromagnetic field, and heat exchange element is heated under its influence.

Further heat is consumed to increase the temperature of the coolant.

Equipment that uses the principle of electromagnetic induction, is widely used in the metallurgical industry in the crucible furnaces, and is becoming more popular in home appliances - induction cooking stoves and heating boilers

. The advantages and disadvantages of such equipment

Determine the type of heating devices, you first need to find their strengths and weaknesses. For obvious advantages of induction boilers can include the following qualities:

Induction Cooker

High efficiency, reaching 98%;

Reducing heating costs up to 30%;

The reliability of the equipment due to the lack of heating elements therein;

The increased degree of electrical and fire safety;

Ability to use any type of coolant;

Wide range of obtained parameters;

Lack of scale;

Reliable and trouble-free operation for a long time.

The main disadvantages of such devices limit their use, it has always been very high price, large size and weight, and complexity of adjustment. Recently, induction devices become more compact, and can make them available to build with their own hands.

Which is better to use the heater?

The principle of induction heating is applied for many years in the industry. Such devices are popular in the steel industry, in the manufacture of electrofusion pipe for thermal processing and improved tempering metals, welding machines. In recent years, various models are produced for domestic heating.

Water heating

Due to intense heat coolant can be installed in fluid equipment for hot water supply using the calorific value of the induction forces.

It consists of a unit converter which generates a magnetic field, and the pipe with water, performing the role of the core.

The heat in the heating system

Any electric boiler is the most eco-friendly and convenient means for heating private houses.

But habitual use of heaters leads to high operating costs, making the search for alternative ways to generate heat. The situation will correct induction boiler, having a minimum energy consumption.

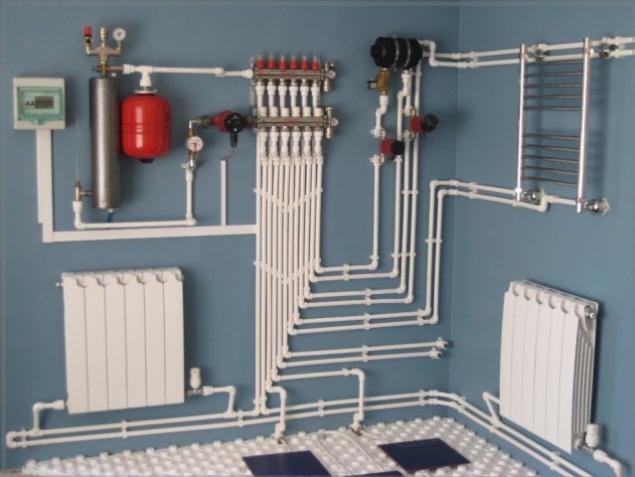

By setting a fairly simple device, a vortex induction heater for hot water heating pipe, you can get the best option, which combines small payments for fuel-efficient heating.

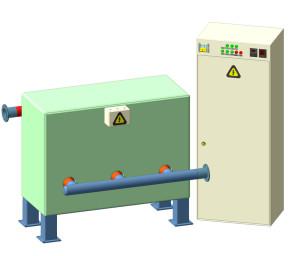

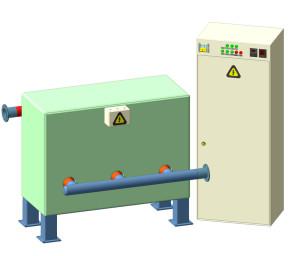

Essentially identical to the design of the water heater, just as the core pipe is used, a part of the heating boiler heating kontur.Induktsionny

The rate of heating the coolant in the VIN is much higher than in other electrical devices, and the entire area is heated in contact with the device, which allows for significant resource savings.

Like all modern boilers, induction is complete pump, sensor system and control panel that allows you to select the desired mode.

Heated rooms

Another simple and reliable method involves the use of two heating devices, induction plate and the inductor connected to the battery. This design can be used instead of the traditional operating system of the boiler. The inverter creates a magnetic field which acts on the plate with installed on it a casing of a magnetic material. It passed through the pipe.

It is important to outline was made of non-magnetic material, or eddy currents will be spread throughout the system, which has a negative impact on efficiency. For a small home will be provided with sufficient heating induction cooker 2000 W.

Improvised heating

One of the latest developments - the use of inverter heat from the welding machine. On the tube is wound several turns of wire, placed inside a copper shavings. The whole structure is connected to a small inverter.

What determines the economy of the system

The costs of induction boilers up to 30% less than the heating of heaters. This is primarily achieved through the simplicity of the design and proper installation. An important factor is also the fact, that for heating the warm water is not required of other elements in the loop, and the apparatus is used as a heater.

By judicious choice of automation you can adjust the boiler output according to changes in external factors. The machine should start with a low power, which will increase as heating.

For the economical operation of the equipment it is necessary that part of the system elements conform to certain requirements:

We use any radiators, in addition to iron;

equipment was modern and provided precision adjustment;

Installation was carried out in accordance with the instructions.

Mounting apparatus

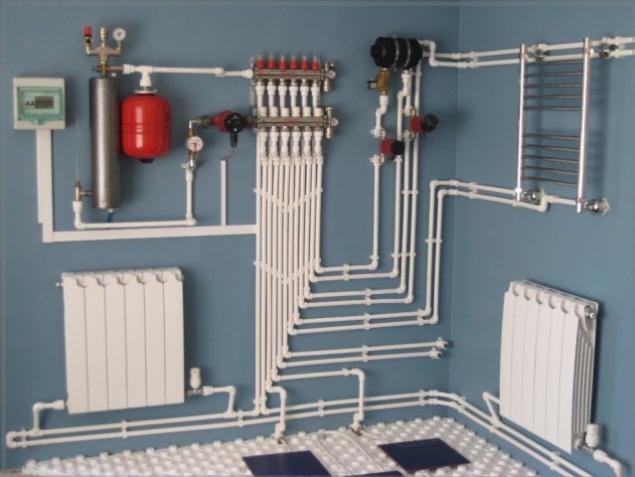

For efficient operation of induction boiler must be installed in a closed heating system, and it should be placed vertically. By connecting the outputs and inputs to the circuit, and switching the coolant flow through the device installed, you can get a reliable and affordable heating. Moreover, any substance can be used as the working fluid:

ordinary water;

antifreeze;

special antifreeze for heating systems.

Of particular note is the place of the boiler location. Do not mount the unit closer than 30 cm to the wall and at a distance of less than 80 cm from the horizontal overlaps.

In addition, given a decent weight of the unit, the wall must be strong enough, and fasteners to choose reliable.

The process operation

The big advantage of this equipment is easy to use. over time, the device settings are not changed and the power does not drop. No need for special maintenance, lubrication or replacement of failed components. almost no equipment is broken!

It has no moving parts, it does not overheat. Once spent the money to buy the machine and its installation, you can be sure that will not need other expenses, except for the electricity payment. But these payments will be significantly less than a conventional electric boiler for heating.

The main disadvantage of the electric equipment, dependence on unstable energy supply networks, can be corrected by setting a voltage stabilizer and UPS. With a small power consumption, it is often sufficient to connect a powerful battery that can ensure constant operation of the boiler in all energy problems.

Due to the high reliability and service life of such devices is at least 25 years. The weakest point in the design can be quality weld in the tube core.

The principle of heating

Occurrence of electromagnetic induction phenomenon is to create an induced current under the action of an alternating magnetic field coils. The thermal effect of the resulting stream is used to heat the coolant.

If a closed circuit (inductor), consisting of several turns, to place the object of electrically conductive material and pass through the high frequency currents in the coils is formed an electromagnetic field creating eddy currents heating the object located therein. On the heating intensity is influenced by several parameters:

by increasing the power of the magnetic field strength increases heating;

dependence on the magnetic properties of the core;

distance from the inductor to the subject.

Equally important is to choose the correct operating frequency of the inverter, which affects the depth of penetration of heat into the core, that is the point where the current density drops to 37%. This rate increases with increasing frequency.

To use this phenomenon in practice, must be installed, consisting of a coil, which creates an electromagnetic field, and heat exchange element is heated under its influence.

Further heat is consumed to increase the temperature of the coolant.

Equipment that uses the principle of electromagnetic induction, is widely used in the metallurgical industry in the crucible furnaces, and is becoming more popular in home appliances - induction cooking stoves and heating boilers

. The advantages and disadvantages of such equipment

Determine the type of heating devices, you first need to find their strengths and weaknesses. For obvious advantages of induction boilers can include the following qualities:

Induction Cooker

High efficiency, reaching 98%;

Reducing heating costs up to 30%;

The reliability of the equipment due to the lack of heating elements therein;

The increased degree of electrical and fire safety;

Ability to use any type of coolant;

Wide range of obtained parameters;

Lack of scale;

Reliable and trouble-free operation for a long time.

The main disadvantages of such devices limit their use, it has always been very high price, large size and weight, and complexity of adjustment. Recently, induction devices become more compact, and can make them available to build with their own hands.

Which is better to use the heater?

The principle of induction heating is applied for many years in the industry. Such devices are popular in the steel industry, in the manufacture of electrofusion pipe for thermal processing and improved tempering metals, welding machines. In recent years, various models are produced for domestic heating.

Water heating

Due to intense heat coolant can be installed in fluid equipment for hot water supply using the calorific value of the induction forces.

It consists of a unit converter which generates a magnetic field, and the pipe with water, performing the role of the core.

The heat in the heating system

Any electric boiler is the most eco-friendly and convenient means for heating private houses.

But habitual use of heaters leads to high operating costs, making the search for alternative ways to generate heat. The situation will correct induction boiler, having a minimum energy consumption.

By setting a fairly simple device, a vortex induction heater for hot water heating pipe, you can get the best option, which combines small payments for fuel-efficient heating.

Essentially identical to the design of the water heater, just as the core pipe is used, a part of the heating boiler heating kontur.Induktsionny

The rate of heating the coolant in the VIN is much higher than in other electrical devices, and the entire area is heated in contact with the device, which allows for significant resource savings.

Like all modern boilers, induction is complete pump, sensor system and control panel that allows you to select the desired mode.

Heated rooms

Another simple and reliable method involves the use of two heating devices, induction plate and the inductor connected to the battery. This design can be used instead of the traditional operating system of the boiler. The inverter creates a magnetic field which acts on the plate with installed on it a casing of a magnetic material. It passed through the pipe.

It is important to outline was made of non-magnetic material, or eddy currents will be spread throughout the system, which has a negative impact on efficiency. For a small home will be provided with sufficient heating induction cooker 2000 W.

Improvised heating

One of the latest developments - the use of inverter heat from the welding machine. On the tube is wound several turns of wire, placed inside a copper shavings. The whole structure is connected to a small inverter.

What determines the economy of the system

The costs of induction boilers up to 30% less than the heating of heaters. This is primarily achieved through the simplicity of the design and proper installation. An important factor is also the fact, that for heating the warm water is not required of other elements in the loop, and the apparatus is used as a heater.

By judicious choice of automation you can adjust the boiler output according to changes in external factors. The machine should start with a low power, which will increase as heating.

For the economical operation of the equipment it is necessary that part of the system elements conform to certain requirements:

We use any radiators, in addition to iron;

equipment was modern and provided precision adjustment;

Installation was carried out in accordance with the instructions.

Mounting apparatus

For efficient operation of induction boiler must be installed in a closed heating system, and it should be placed vertically. By connecting the outputs and inputs to the circuit, and switching the coolant flow through the device installed, you can get a reliable and affordable heating. Moreover, any substance can be used as the working fluid:

ordinary water;

antifreeze;

special antifreeze for heating systems.

Of particular note is the place of the boiler location. Do not mount the unit closer than 30 cm to the wall and at a distance of less than 80 cm from the horizontal overlaps.

In addition, given a decent weight of the unit, the wall must be strong enough, and fasteners to choose reliable.

The process operation

The big advantage of this equipment is easy to use. over time, the device settings are not changed and the power does not drop. No need for special maintenance, lubrication or replacement of failed components. almost no equipment is broken!

It has no moving parts, it does not overheat. Once spent the money to buy the machine and its installation, you can be sure that will not need other expenses, except for the electricity payment. But these payments will be significantly less than a conventional electric boiler for heating.

The main disadvantage of the electric equipment, dependence on unstable energy supply networks, can be corrected by setting a voltage stabilizer and UPS. With a small power consumption, it is often sufficient to connect a powerful battery that can ensure constant operation of the boiler in all energy problems.

Due to the high reliability and service life of such devices is at least 25 years. The weakest point in the design can be quality weld in the tube core.

The double cropping raspberry Sobolev - a guarantee of a great harvest!

Air heating private house: saving and high efficiency