852

Pellet boilers – what it is, what fuel work, the design and the nuances of choice

Despite the fact that our country is one of the largest exporters of natural gas, to talk about universal gasification is not necessary. For many consumers, the cheapest way of heating and is now unattainable, and not the fact that it will be available in the future. So you have to look for alternative sources of heat, fortunately, the choice in this area is impressive. In recent years, the range of the heating equipment has added an interesting unit – pellet boiler. Let us dwell on this type of equipment, for which consider the following aspects:

What is a pellet boilerIn fact, is a kind of solid fuel boiler, but is designed for a certain type of fuel (pellets) with possibility of full or partial automation of working process.

It is the ability to function in Autonomous mode with minimum interference of the owners of pellet boilers are fundamentally different from conventional, solid. In addition, they have a higher efficiency (efficiency) and due to the characteristics of pellets, and due to the design features. Pellet boilers can be highly specialized – available only under pellets, and combined (universal) – able to work on firewood or coal, some models work on almost any biomass (husk, fire wood waste and the like).

When a certain design of the boiler it can burn any biomass very low calorie is chips, bark, waste wood, selhozgodu, sunflower husks and more.

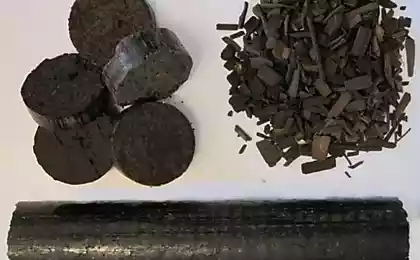

Pellets, or wood pellets – environmentally neutral fuels derived mainly from waste of woodworking industry (wood chips, shavings, bark), but they can be made from waste crops. Pellets appeared in the thirties of the last century, when Idaho was invented and tested the first installation by pressing into pellets of waste from the local sawmills. Under the strong pressure of the raw mass is heated, which causes the formation of lignin, which binds the smallest particles in a dense, smooth granules. This eliminates the use of chemicals – pellets all-natural, safe, in terms of ecology, fuel. The diameter of the granules varies in the range of 6-8 mm and a length of 50 mm. In European countries the pellets is standardized fuels and manufactured according to DIN plus.

In our country, their production is not as developed and regulated, the quality of the pellets, which will depend on the efficiency of the boiler, and its performance determine visual white better than gray. Unlike wood, pellets low moisture content and high density, in view of which upon combustion generates more heat and a minimal amount of carbon dioxide. If we translate this property in the figures, for comparison, we obtained the following relation – while burning tons of pellets is allocated the same amount of heat as the burning of 1.6 tons of firewood. The ash content is only 0.5% of the burned volume, and the released combustion gases are colorless.

Approximate calorific value of pellets is 5 kWh from one kilogram of, but as far as real efficiency would be close to the theoretical data depends on the quality of the pellets, and from the performance of the boiler where they are burned.

Device unitItself pellet boiler consists of three main components:

Depending on the capacity of the hopper and the selected mode is the one filling may last for a few days or a week or even more.

To make the heating process is fully automatic, the boiler can be connected directly with the storage – pneumothroax will apply the granules in the hopper to the extent of its devastation. Advantages and disadvantages of the pellet boilerOne of the main benefits of pellet boilers – efficiency, for this indicator, they are second only to gas main heating. This is due to the high efficiency equipment, and with high calorific value pellets, and their affordable cost. The second aspect that attracts the consumer – process automation. In contrast to other solid fuel boilers, pellet does not need constant control and regular manual supply of fuel. In units operating on diesel fuel, he wins and in terms of environmental friendliness – no smells and black smoke.

The main disadvantage of these units is solid, the price is the most expensive tverdotoplivnye, the cost of the automated station of the European production in the hundreds of thousands, the domestic is a little cheaper. Not every owner can afford such injections into the heating system of your home. However, given the durability of the equipment, which is now close to two decades, is a wise investment in the long term.

In addition to the high cost, the disadvantages include energy dependence – automatics need electricity, and if the trip is several hours (average of 10) is valid and not hit the settings, then a longer stop operation of the boiler. In this regard, the station should be equipped with an independent energy source that will increase the cost of the system.

What to look for when choosing a unitDespite the relative "youth" of this type of tverdotoplivnyh on the market large selection of the boilers of foreign and domestic production. To find the optimal conditions for their Assembly, should pay attention to several important parameters.

Power – each producer has a fairly wide model range, including both household and industrial units. As with any heating equipment, the power is measured in kilowatts (kW), capacity of the household model starts from 15 kW. As it is believed that for heating with an average heat loss should be about 1 kW per 10 m2, it turns out that the boiler is able to heat the house 150 m2. However, it is understood that the boiler needed with a small margin.

Efficiency – the higher the rate, the more economical the heating process. Palatnikov efficiency in the range of 85-95% and depends on pellet quality and design.

Pathology heat exchanger provides high efficiency of the boiler – it allows you to get maximum cooling during the passage of the gases through the convective zone to the chimney. Also pay attention to the material from which made the boiler, and the type of heat exchanger.

Boilers made of thick metal (6 mm and 8 mm, depending on capacity) – durable. The thickness of the metal affects the life of the boiler, it is also important – how many years will work on the unit. Plate heat exchanger has advantages over the tubular – it is more convenient in terms of cleaning. Pellet boilers modern, environmentally friendly and cost effective heating equipment. At the moment they are less popular than conventional solid fuel units, but in the future may conquer the market due to decent performance.published

Source: www.forumhouse.ru/articles/engineering-systems/6929

- What is a pellet boiler, and what fuel he is running.

- The device unit.

- Advantages and disadvantages of the pellet boiler.

- What to look for when choosing a unit.

What is a pellet boilerIn fact, is a kind of solid fuel boiler, but is designed for a certain type of fuel (pellets) with possibility of full or partial automation of working process.

It is the ability to function in Autonomous mode with minimum interference of the owners of pellet boilers are fundamentally different from conventional, solid. In addition, they have a higher efficiency (efficiency) and due to the characteristics of pellets, and due to the design features. Pellet boilers can be highly specialized – available only under pellets, and combined (universal) – able to work on firewood or coal, some models work on almost any biomass (husk, fire wood waste and the like).

When a certain design of the boiler it can burn any biomass very low calorie is chips, bark, waste wood, selhozgodu, sunflower husks and more.

Pellets, or wood pellets – environmentally neutral fuels derived mainly from waste of woodworking industry (wood chips, shavings, bark), but they can be made from waste crops. Pellets appeared in the thirties of the last century, when Idaho was invented and tested the first installation by pressing into pellets of waste from the local sawmills. Under the strong pressure of the raw mass is heated, which causes the formation of lignin, which binds the smallest particles in a dense, smooth granules. This eliminates the use of chemicals – pellets all-natural, safe, in terms of ecology, fuel. The diameter of the granules varies in the range of 6-8 mm and a length of 50 mm. In European countries the pellets is standardized fuels and manufactured according to DIN plus.

In our country, their production is not as developed and regulated, the quality of the pellets, which will depend on the efficiency of the boiler, and its performance determine visual white better than gray. Unlike wood, pellets low moisture content and high density, in view of which upon combustion generates more heat and a minimal amount of carbon dioxide. If we translate this property in the figures, for comparison, we obtained the following relation – while burning tons of pellets is allocated the same amount of heat as the burning of 1.6 tons of firewood. The ash content is only 0.5% of the burned volume, and the released combustion gases are colorless.

Approximate calorific value of pellets is 5 kWh from one kilogram of, but as far as real efficiency would be close to the theoretical data depends on the quality of the pellets, and from the performance of the boiler where they are burned.

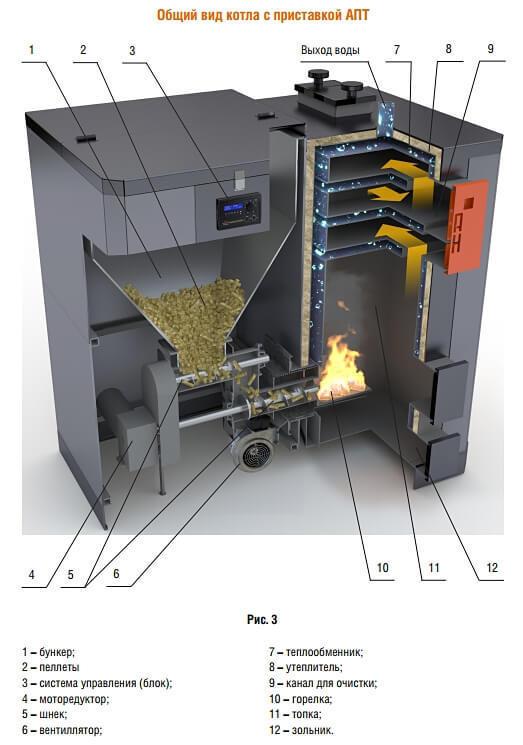

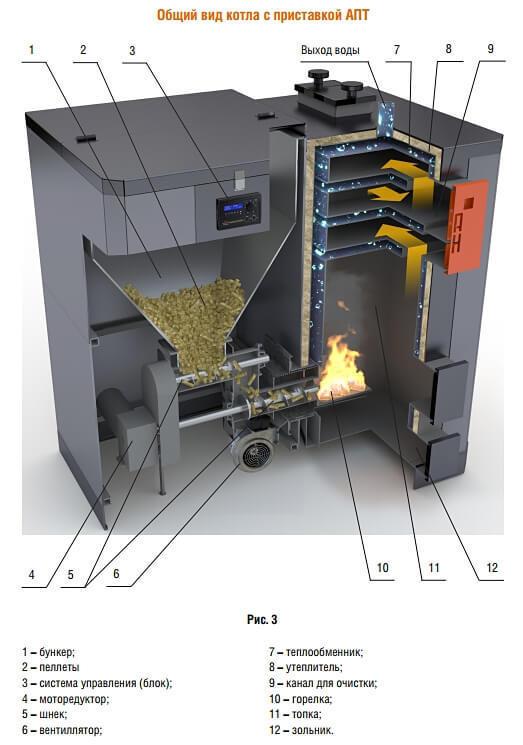

Device unitItself pellet boiler consists of three main components:

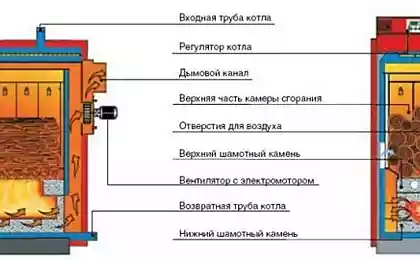

- The furnace is equipped with a special burner (retort or torch) and two doors (control, treatment).

- Convection zone – it is a heat exchanger: it can be vertical, horizontal or compound, tubular or plate type. In the convection zone there is a heating medium in the heat exchanger the gases emitted during combustion of pellets. Most units are only designed for heating and have a single loop, but in some models — two circuits: heating and water heating.

- The ash pan – it receives waste combustion (insignificant during normal afterburner), which are periodically removed through the treatment door.

- Hopper capacity for pellets of a certain amount, from which the granules are transferred to the furnace may be internal or external.

- Auger – a portion feeds the pellets into the burner as required, is driven by the reducer.

- The fan is needed to sustain the combustion process, as the equipment does not include a natural draft.

Depending on the capacity of the hopper and the selected mode is the one filling may last for a few days or a week or even more.

To make the heating process is fully automatic, the boiler can be connected directly with the storage – pneumothroax will apply the granules in the hopper to the extent of its devastation. Advantages and disadvantages of the pellet boilerOne of the main benefits of pellet boilers – efficiency, for this indicator, they are second only to gas main heating. This is due to the high efficiency equipment, and with high calorific value pellets, and their affordable cost. The second aspect that attracts the consumer – process automation. In contrast to other solid fuel boilers, pellet does not need constant control and regular manual supply of fuel. In units operating on diesel fuel, he wins and in terms of environmental friendliness – no smells and black smoke.

The main disadvantage of these units is solid, the price is the most expensive tverdotoplivnye, the cost of the automated station of the European production in the hundreds of thousands, the domestic is a little cheaper. Not every owner can afford such injections into the heating system of your home. However, given the durability of the equipment, which is now close to two decades, is a wise investment in the long term.

In addition to the high cost, the disadvantages include energy dependence – automatics need electricity, and if the trip is several hours (average of 10) is valid and not hit the settings, then a longer stop operation of the boiler. In this regard, the station should be equipped with an independent energy source that will increase the cost of the system.

What to look for when choosing a unitDespite the relative "youth" of this type of tverdotoplivnyh on the market large selection of the boilers of foreign and domestic production. To find the optimal conditions for their Assembly, should pay attention to several important parameters.

Power – each producer has a fairly wide model range, including both household and industrial units. As with any heating equipment, the power is measured in kilowatts (kW), capacity of the household model starts from 15 kW. As it is believed that for heating with an average heat loss should be about 1 kW per 10 m2, it turns out that the boiler is able to heat the house 150 m2. However, it is understood that the boiler needed with a small margin.

Efficiency – the higher the rate, the more economical the heating process. Palatnikov efficiency in the range of 85-95% and depends on pellet quality and design.

Pathology heat exchanger provides high efficiency of the boiler – it allows you to get maximum cooling during the passage of the gases through the convective zone to the chimney. Also pay attention to the material from which made the boiler, and the type of heat exchanger.

Boilers made of thick metal (6 mm and 8 mm, depending on capacity) – durable. The thickness of the metal affects the life of the boiler, it is also important – how many years will work on the unit. Plate heat exchanger has advantages over the tubular – it is more convenient in terms of cleaning. Pellet boilers modern, environmentally friendly and cost effective heating equipment. At the moment they are less popular than conventional solid fuel units, but in the future may conquer the market due to decent performance.published

Source: www.forumhouse.ru/articles/engineering-systems/6929

Saving disease it is VITAL to know about the flu and colds

Rocket stove for ECO-houses with his own hands: master class