246

Solid fuel furnace: fire protection rules

It seems that one thing in the world will remain unchanged, even when it changes at all: people will sink the ovens. Neither electricity nor gas can displace solid fuel stoves from our homes. Today we will talk about fire protection of premises in which a solid fuel furnace is used.

Wooden stoves and fireplaces are real symbols of home comfort: wood crackles in the furnace, soft heat spreads around the house ... But if you do not think about fire protection or frivolously save on it, the stove can become a source of danger to property and life. A fire can start because of one spark that fell from the furnace, or an overheated wall. When we install a stove or fireplace, fire protection should become an "extremely important expense" and it is impossible to save on it in any case.

Therefore, conscientious manufacturers of furnaces and fireplaces in the instructions always write that in the place of installation of heating devices necessary to protect the floor, walls and ceiling.

Screen

To reduce the thermal radiation of a metal heater, protective screens are made of cast iron or steel sheets. The screen lowers the temperature of the hot stove to +100 degrees. The finished screen is easily mounted at a distance of up to 50 mm to the stove wall.

Paul

The floor on which the TT oven is installed must be protected by a non-combustible and durable coating. Variants of the base on which the furnace is installed can be as follows:

How to determine the size of this flame retardant gasket on the floor? Usually it is made so that on each side it is 100 mm protruding beyond the perimeter of the furnace. Before the furnace must be mounted pre-flow sheet, which will protect against sparks and coals falling from the furnace. Depending on the size of the furnace, the size of the sheet can be small, 500×700 mm, or 400×640 mm, or 100 mm to stand for the furnace from that other moan.

Now rarely anyone makes sheets in the old-fashioned way, nailing a piece of tin to the floor. More often buy ready-made beautiful sheets of polished stainless steel, and for a fireplace - copper or brass, decorated with artistic etching and patina.

The stove should be at least 100 millimeters from the floor.

Ceiling

For fire protection of the ceiling, you can use the same materials as for the floor, only the distance to the heating device changes.

If we are talking about a stone stove (smoke pipe and the top of a heat-intensive furnace, covered with three rows of masonry), the ceiling should be at least 250 mm from the surface of the furnace. If you are talking about an uninsulated metal oven (as are most baths), the minimum distance is 1200 millimeters. If the ceiling is protected, and the furnace has thermal insulation, the distance is reduced to 800 mm.

Fire protection on the ceiling should be larger than the perimeter of the heating appliance - add 150 millimeters to the perimeter of the stove surface on each side.

Walls.

For optimal fire protection, the solid fuel furnace is placed at a safe distance from the wall, which should be protected from fire. The material and method of wall protection depends on the thickness of the walls of the furnace. Participants of our portal use fireproof impregnations, mastics, foaming compounds, etc. for wall treatment. Such fire protection needs frequent updates. But more in demand among FORUMHOUSE users are not compositions for surface treatment, but materials for their protection: basalt fiber mats, foil fire protection, etc.

Especially popular refractory plates: vermiculite, superforce (thin plates designed for use in the defense industry and withstanding temperatures above + 1000 degrees), fibrocement panel, glass magnesite sheet, gypsum fiber sheet (GVL), calcium silicate (superizole). Not all of these materials are equally good, but they withstand long-term heating to high temperatures, conduct heat poorly and serve long enough without losing strength.

And in the baths, some still use the old-fashioned method: finish the walls with two layers of felt soaked in a solution of clay.

Options and combinations

Most of these materials and methods can be used only under certain conditions, combining them with each other and meeting a number of requirements. For example, we finish the walls with slabs of flame retardant material, and of a certain thickness, and we install a protective shield on a metal furnace, etc.

Here are the options for protecting the walls that are used by the participants of our portal (in both cases, the furnaces are in the country, the walls are a tram):

The wall is treated with a flame retardant composition, a sheet of asbestos (or similar) is installed on top from the ceiling to the floor, and on the sides of the stove it protrudes 15 centimeters. On top of the sheet of drywall, and completes the "cake" - tile for beauty.

- On the tram in staggering order, with overlap, two layers of basalt cardboard are applied, it is closely mineralite, it has a roofing profile sheet with a round section. The subtlety is that the sheet from the floor for the convention should have a gap of 5 centimeters.

The combination of several methods of wall insulation makes protection reliable. And vice versa.

The distance between the oven and the wall depends primarily on the type of oven. It should be borne in mind that no matter how you protect the walls, for metal furnaces, the distance should always be laid with reserve. .

The distance between the wall and the outer surface of the furnace in the professional language of the furnace is called a retreat. It is a correctly made retreat that protects the wall from an accidental spark that can fall from the slot of the door, and from overheating, which leads to ignition.

The table presented at FORUMHOUSE by Alexei Telegin shows the minimum permissible distances between the furnace and the wall.

Wall thickness

furnace, mm retreat

Distance from the outer surface of the furnace or smoke duct(s) to the wall(s), mm

shelterless

protected

120

Open.

260

200.

120

Closed.

320

260

65

Open.

320

260

65

Closed.

500.

380

If the furnace is thin-walled and the wall surface is not protected, the distance shall be 500 mm. If the stove is thick-walled, and you have protected the wall to the maximum, a distance of even 200 mm is allowed.

With an open retreat on all sides of the furnace there is an open space.

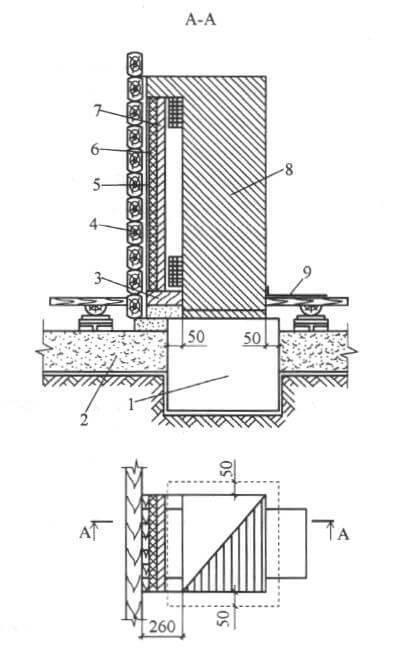

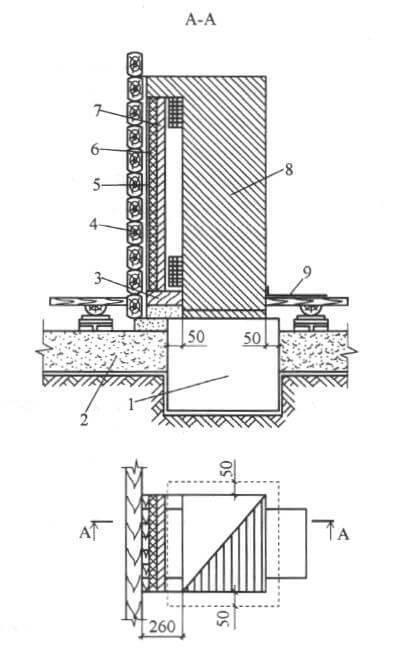

A closed retreat is a structure that is closed on all or several sides. How it works can be seen from the picture below.

1. The foundation of the stove. 2. The sealing layer. 3. Unburnable floor. 4. Wooden wall. 5. Board shield. 6. Heat insulation (asbestos or felt). 7. Brick on the edge. 8. Oven. 9. Pre-flow leaf.

If the furnace (or chimney) "cut" into some partitions - this, for example, often happens in the bath, when the furnace itself is in the steam room, and the furnace door - in another room, a retreat is also made between the furnace and partitions. The less protected the structures, the greater the distance should be.

In general, when installing a furnace or fireplace, it is recommended to carefully study the manufacturer's instructions, which usually indicate both the amount of concessions and the recommended modes of operation. If the distances in the instructions are not specified, you need to study the SNiP, the reference to which gives the certificate of conformity. Most often, the size of the concessions is given there, and even depending on the mode of operation that you choose.

Source: www.forumhouse.ru/articles/house/7178

Wooden stoves and fireplaces are real symbols of home comfort: wood crackles in the furnace, soft heat spreads around the house ... But if you do not think about fire protection or frivolously save on it, the stove can become a source of danger to property and life. A fire can start because of one spark that fell from the furnace, or an overheated wall. When we install a stove or fireplace, fire protection should become an "extremely important expense" and it is impossible to save on it in any case.

Therefore, conscientious manufacturers of furnaces and fireplaces in the instructions always write that in the place of installation of heating devices necessary to protect the floor, walls and ceiling.

Screen

To reduce the thermal radiation of a metal heater, protective screens are made of cast iron or steel sheets. The screen lowers the temperature of the hot stove to +100 degrees. The finished screen is easily mounted at a distance of up to 50 mm to the stove wall.

Paul

The floor on which the TT oven is installed must be protected by a non-combustible and durable coating. Variants of the base on which the furnace is installed can be as follows:

How to determine the size of this flame retardant gasket on the floor? Usually it is made so that on each side it is 100 mm protruding beyond the perimeter of the furnace. Before the furnace must be mounted pre-flow sheet, which will protect against sparks and coals falling from the furnace. Depending on the size of the furnace, the size of the sheet can be small, 500×700 mm, or 400×640 mm, or 100 mm to stand for the furnace from that other moan.

Now rarely anyone makes sheets in the old-fashioned way, nailing a piece of tin to the floor. More often buy ready-made beautiful sheets of polished stainless steel, and for a fireplace - copper or brass, decorated with artistic etching and patina.

The stove should be at least 100 millimeters from the floor.

Ceiling

For fire protection of the ceiling, you can use the same materials as for the floor, only the distance to the heating device changes.

If we are talking about a stone stove (smoke pipe and the top of a heat-intensive furnace, covered with three rows of masonry), the ceiling should be at least 250 mm from the surface of the furnace. If you are talking about an uninsulated metal oven (as are most baths), the minimum distance is 1200 millimeters. If the ceiling is protected, and the furnace has thermal insulation, the distance is reduced to 800 mm.

Fire protection on the ceiling should be larger than the perimeter of the heating appliance - add 150 millimeters to the perimeter of the stove surface on each side.

Walls.

For optimal fire protection, the solid fuel furnace is placed at a safe distance from the wall, which should be protected from fire. The material and method of wall protection depends on the thickness of the walls of the furnace. Participants of our portal use fireproof impregnations, mastics, foaming compounds, etc. for wall treatment. Such fire protection needs frequent updates. But more in demand among FORUMHOUSE users are not compositions for surface treatment, but materials for their protection: basalt fiber mats, foil fire protection, etc.

Especially popular refractory plates: vermiculite, superforce (thin plates designed for use in the defense industry and withstanding temperatures above + 1000 degrees), fibrocement panel, glass magnesite sheet, gypsum fiber sheet (GVL), calcium silicate (superizole). Not all of these materials are equally good, but they withstand long-term heating to high temperatures, conduct heat poorly and serve long enough without losing strength.

And in the baths, some still use the old-fashioned method: finish the walls with two layers of felt soaked in a solution of clay.

Options and combinations

Most of these materials and methods can be used only under certain conditions, combining them with each other and meeting a number of requirements. For example, we finish the walls with slabs of flame retardant material, and of a certain thickness, and we install a protective shield on a metal furnace, etc.

Here are the options for protecting the walls that are used by the participants of our portal (in both cases, the furnaces are in the country, the walls are a tram):

The wall is treated with a flame retardant composition, a sheet of asbestos (or similar) is installed on top from the ceiling to the floor, and on the sides of the stove it protrudes 15 centimeters. On top of the sheet of drywall, and completes the "cake" - tile for beauty.

- On the tram in staggering order, with overlap, two layers of basalt cardboard are applied, it is closely mineralite, it has a roofing profile sheet with a round section. The subtlety is that the sheet from the floor for the convention should have a gap of 5 centimeters.

The combination of several methods of wall insulation makes protection reliable. And vice versa.

The distance between the oven and the wall depends primarily on the type of oven. It should be borne in mind that no matter how you protect the walls, for metal furnaces, the distance should always be laid with reserve. .

The distance between the wall and the outer surface of the furnace in the professional language of the furnace is called a retreat. It is a correctly made retreat that protects the wall from an accidental spark that can fall from the slot of the door, and from overheating, which leads to ignition.

The table presented at FORUMHOUSE by Alexei Telegin shows the minimum permissible distances between the furnace and the wall.

Wall thickness

furnace, mm retreat

Distance from the outer surface of the furnace or smoke duct(s) to the wall(s), mm

shelterless

protected

120

Open.

260

200.

120

Closed.

320

260

65

Open.

320

260

65

Closed.

500.

380

If the furnace is thin-walled and the wall surface is not protected, the distance shall be 500 mm. If the stove is thick-walled, and you have protected the wall to the maximum, a distance of even 200 mm is allowed.

With an open retreat on all sides of the furnace there is an open space.

A closed retreat is a structure that is closed on all or several sides. How it works can be seen from the picture below.

1. The foundation of the stove. 2. The sealing layer. 3. Unburnable floor. 4. Wooden wall. 5. Board shield. 6. Heat insulation (asbestos or felt). 7. Brick on the edge. 8. Oven. 9. Pre-flow leaf.

If the furnace (or chimney) "cut" into some partitions - this, for example, often happens in the bath, when the furnace itself is in the steam room, and the furnace door - in another room, a retreat is also made between the furnace and partitions. The less protected the structures, the greater the distance should be.

In general, when installing a furnace or fireplace, it is recommended to carefully study the manufacturer's instructions, which usually indicate both the amount of concessions and the recommended modes of operation. If the distances in the instructions are not specified, you need to study the SNiP, the reference to which gives the certificate of conformity. Most often, the size of the concessions is given there, and even depending on the mode of operation that you choose.

Source: www.forumhouse.ru/articles/house/7178