856

How to make a tandoor with your hands

How to build a tandoor with your hands? A practical guide

Go to practice, show the process of building stationary tandoor. Before its construction, we have conducted preparatory work – completed drawings and it determined the quantity of necessary building materials.

Used such basic materials: fire brick and clay, facing brick, cement and other Materials were purchased near the construction hypermarket and taken to a suburban area.

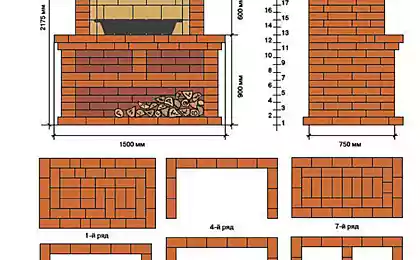

To purchase the above materials for the week we laid a concrete Foundation. The depth of the concrete Foundation under the stove was adopted 40...50 cm (about 10 cm below Pocono vegetation layer).

On top of the Foundation arranged a bottom of refractory bricks. A firebox bottom, the bottom has a recess – ash drawer that also provides combustion air to fuel burning in the tandoor.

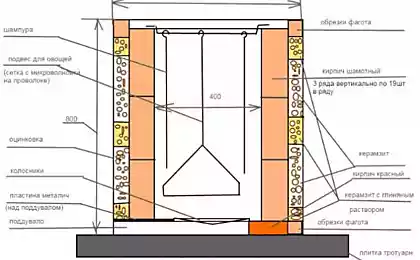

The tandoor is a kind of stone "bag". To during firing and then, during cooking, do not go long the heat from the "bag" we decided to make it multilayered.

The insulation of the walls of the tandoor with glass wool

The interior of the tandoor furnace, was built of refractory brick fire resistant clay-cement mortar. The thickness of the inner part of the tandoor to 65 mm (1/4 brick). The lower part of the combustion chamber has a cylindrical shape, and the upper part with wide opening for loading was performed arched shape.

Stone fireplace outside for containment temperature deformations was reinforced with steel wire mesh.

To simplify the construction of the tandoor, it is the outer part we have performed cylindrical, made of bricks, the thickness of the 1/4 brick.

Between the inner and outer walls of the tandoor constructively provided a gap width of 30...40 mm, which was filled with fiberglass insulation for heating furnace.

For the construction of the arched side of the tandoor is used generally to cut fire brick.

The furnace of the tandoor

For normal operation of the furnace, we have produced a round metal cover. It is made of steel sheet steel with a thickness of 3 mm.

Metal fabrication cover for the tandoor

At the center of the metal lid mounted metal handle for removal (installation) of the cover. For convenience, the handle should be of sufficient height and width.

The first test of a furnace, we carried out 3 weeks after its construction. During this time, oven dried, and the mortar has gained primary strength.

After the construction of the tandoor we have fully experienced all of the advantages of this wonderful furnace. Our experience has been, and what You want. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: gidproekt.com/kak-sdelat-stacionarnyj-tandyr-svoimi-rukami-prakticheskaya-instrukciya.html

Go to practice, show the process of building stationary tandoor. Before its construction, we have conducted preparatory work – completed drawings and it determined the quantity of necessary building materials.

Used such basic materials: fire brick and clay, facing brick, cement and other Materials were purchased near the construction hypermarket and taken to a suburban area.

To purchase the above materials for the week we laid a concrete Foundation. The depth of the concrete Foundation under the stove was adopted 40...50 cm (about 10 cm below Pocono vegetation layer).

On top of the Foundation arranged a bottom of refractory bricks. A firebox bottom, the bottom has a recess – ash drawer that also provides combustion air to fuel burning in the tandoor.

The tandoor is a kind of stone "bag". To during firing and then, during cooking, do not go long the heat from the "bag" we decided to make it multilayered.

The insulation of the walls of the tandoor with glass wool

The interior of the tandoor furnace, was built of refractory brick fire resistant clay-cement mortar. The thickness of the inner part of the tandoor to 65 mm (1/4 brick). The lower part of the combustion chamber has a cylindrical shape, and the upper part with wide opening for loading was performed arched shape.

Stone fireplace outside for containment temperature deformations was reinforced with steel wire mesh.

To simplify the construction of the tandoor, it is the outer part we have performed cylindrical, made of bricks, the thickness of the 1/4 brick.

Between the inner and outer walls of the tandoor constructively provided a gap width of 30...40 mm, which was filled with fiberglass insulation for heating furnace.

For the construction of the arched side of the tandoor is used generally to cut fire brick.

The furnace of the tandoor

For normal operation of the furnace, we have produced a round metal cover. It is made of steel sheet steel with a thickness of 3 mm.

Metal fabrication cover for the tandoor

At the center of the metal lid mounted metal handle for removal (installation) of the cover. For convenience, the handle should be of sufficient height and width.

The first test of a furnace, we carried out 3 weeks after its construction. During this time, oven dried, and the mortar has gained primary strength.

After the construction of the tandoor we have fully experienced all of the advantages of this wonderful furnace. Our experience has been, and what You want. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: gidproekt.com/kak-sdelat-stacionarnyj-tandyr-svoimi-rukami-prakticheskaya-instrukciya.html