695

Furnace Kuznetsova: the structure and principles of functioning, advantages, variations, drawings

Nine million two hundred fourteen thousand seventy two

Furnace Kuznetsova is well known not only to the potters – they heat a lot of houses in Russia and abroad. I. V. Kuznetsov has been working for improvement of furnaces 1962 and gathered around him a strong team of like-minded people. The team – more than a hundred and fifty developments, covering almost the whole range of household heaters.

Some of the furnaces I. V. Kuznetsova

Many would like to lay down some of the furnaces Kuznetsova his own hands, and this article – to help them. But we're not going to reveal some deep, dark secrets "Kuznetsovo" – they simply do not. On the website of Igor Viktorovich stove.ru wish for free will find a huge array of kiln information: information on designing and building furnaces to detailed drawings and recommendations for the installation of the furnace in the house and the arrangement of blind area around the building with stove heating. We also do not intend anything in this home-furnace encyclopedia to criticize or correct: we are up to I. V. Kuznetsova on furnace case, to put it mildly, far away.

The purpose of this article is to give to the collection of information Kuznetsova, some sort of introduction, allowing you to freely navigate in the source material. Let me explain with an example why this is necessary. For example, I'm a mechanic-universal with a lot of experience and want to pass it on to other investigators. The car is a difficult thing. If I start the course of the presentation distracted, explaining in detail that the running-in and caster (say, readers are not quite so kettles, go-now all) affect the handling and directional stability machine and diagram valve timing on fuel consumption depending on road conditions, and so on in the same spirit, I end up confused to the point that he will cease to understand how the car in which I travel. Willy-nilly I have to present the material and let the "fingers", but professional fluently.

However, reading it will be hard even the same as I, professionals, and the Amateur generally the head around goes. So I need someone who can be called "polochanka". In fact, he does not the kettle itself and the suspension adjusted and tappets out. But in this case his task is to describe how all the stuffing machine is going into one governed by the principle: "the Wheel to steer, gas gas, brake brake".

In the automotive industry of the USSR a similar situation occurred in the late 50's-early 60's, when the industry began producing cars for General sale to the public. Then came out superbestseller the time – "How's the car running". Edited by not anyone other than himself the chief designer of the legendary "Victory" by A. A. Lipgart.

Information "from polochanka" still will not allow you to get to work: it does not give the deep knowledge that will allow at least intuitive to figure out in the process, the desired values of the numerical parameters. But it is essentially fundamental: owning the property, professional text already read with understanding and faster. And if somewhere something it is not clear yet, it is not causes confusion and rushing, but just a mark in mind: that's what you need to find out more.

About furnaces and furnace heating, the government is no epoch-making decisions are not taken. But their role in the domestic power system in times of energy shortages is certain: already the heating furnace with an efficiency of 70% with the mass you use will give fuel savings on the national scale, as the projects new district heating plants are heat losses in pipelines, 35%, and reduce their too. So with the popularization of furnace knowledge is necessary to extricate himself, being neither Lipgart, nor Kuznetsov. Well, let's try.

Why – kuznetsovka? But needless to dwell on the furnace that is Kuznetsova? Worth because they are worth it. Igor Viktorovich from the outset considered the furnace of Russian design is not as guarded relic of the past or an expensive luxury item but as an indispensable attribute of economical energy future, which is now – the present. The others woke up, that is, when roasted rooster pecked.

The result – kuznetsovka 4 kW heats the house 100 sq. m. as well as a brand "out there" furnace 12 kW. Which, incidentally, is not talking about the invention of perpetual motion, and that brand advertisers are doing their prospectuses, perhaps, winuha "path of happiness". In any case, the fact that Kuznetsov is constantly receiving orders from USA, Canada, Sweden, Finland, which ovens are not the tail spins. Specifically the advantages of Kuznetsovo are as follows:

- High efficiency of 80% for furnaces Kuznetsova not the miracle.

- High temperature combustion without the use of technologies and materials for industrial production.

- As a first consequence of the previous one – omnivorous. In kuznetsovka to the ash burns any fuel, and the soot deposition is minimal.

- The second consequence is the simple maintenance: because of burns and carbon black, furnace Kuznetsova can not clean.

- Less material consumption in combination with uniform heat transfer between the furnaces: in a city apartment with Central heating the temperature during the day varies more than in the house, heated kuznetsovka, with 2 furnaces per day.

- Wide possibilities of integration hot-water circuit without the deterioration of the technical parameters of the furnace.

- Good traction with a short chimney, which reduces the cost and simplifies the construction and installation work in its construction.

- Plasticity of design and appearance as a consequence of dvuhlampovoe scheme (see below): without compromising the furnace, it is possible to construct virtually any room and design requirements.

- Automatic redistribution of traction channels in the transition from firing to cooling, which ensures of intoxication: a view you almost never need to close, she provided more for non-standard modes of operation.

Imagine a furnace with a complex system of smoke passages: yermakovka, four to five the reverse Dutch. In this small maze are bound to encounter strong turbulence. Heard oven buzzing? It is only a minor manifestation raging in her vortex of energy. And to take it nowhere except from the tab fuel. If the channels are long and narrow, that at first glance there is nothing wrong there: eddies, until you get to the pipe, dissipate, cooling down, and still give their energy to the oven body, and it is in the room. But in fact appear nuances, which will be discussed later in the text. They channel efficiency furnace more than 60% is extremely rare.

In channel furnaces, until it burns, torn a huge flow of energy, and for heating or water heating is possible, without disturbing its operation, to take only a small part of it. This pizza oven is something like a nuclear reactor. Don't worry, only the synergetic, i.e. in the ways the circulation of energy in it. In a nuclear reactor it is necessary to lay the fuel is ten times more than necessary to ensure the design energovod. Otherwise, the neutrons will just fly out, before we are prepared to meet them make the atoms of uranium. In a channel furnace – hot eddies, not having had time to cool, take off the pipe, or Vice versa, will cool down immediately, giving the smoke and soot.

But the kuznetsovka (details below) on the synergy is closer to the fusion reactors of the future. "Fusion" sounds scary, but it is only by Association with a hydrogen bomb. Actually eromagine reactors are quite safe. Why? Because they produce energy as much, how much should go to the consumer, and technological reserve of power for rarefied plasma need miserable. If the chamber of the tokamak or stellarator suddenly completely gone, plasma is fully displayed (heavy-atoms in it) and has cooled down before you reach the walls of the room. Repairers swore – in the duty room with the talking – but after 5 mins will be able to blunt the elimination of the protective means.

So what is common in furnaces Kuznetsova with fusion reactors? Then, coenergy flue gas due to the principle of free passage does not scroll many times in the thread until you are pushed into the oven body, and impregnates it immediately. And to go to her there is now nowhere except in the room and/or hot water register.

First, the cap on the hood The principle of construction of the furnace, which allows to realize the advantages of the free motion of gases has long been known. It is dvuhkolonchataja oven, diagram of the device which is shown in Fig. We start the analysis with the left POS.

Sixty five million three hundred nine thousand one hundred ninety three

Scheme dvuhdollarovymi furnaces Ambient air is drawn through the ash pit 1 into the furnace 2. The furnace can be fitted with tapering nozzle with YAP – in odnostolpnoy furnace gas is formed, the view: light and heated gases under the hood its pressure is not allowed "blowing" of heavy external cold air, like water in an overturned glass. But dvuhdollarovymi gas furnaces view due to the thrust from the second cap is often unstable. So dvuhdollarovymi oven until Kuznetsova was built rarely.

Immediately after the fire, when the burning light and energetic fraction of the fuel, combustion occurs in a mode close to the most efficient pyrolysis. In furnaces Kuznetsova in the pyrolysis mode, they are specifically so designed. Pyrolysis gases burn out under the arch 4 of the first cap 3. Podvodnoe space of the first cap is similar to afterburner purely a pyrolysis furnace.

Pyrolysis, combustion under the hood it turns out self-regulating: if the fuel is very much inflamed, cushion burning gas expands down; gives up the arch of the hood. Because of this difficult outflow of flue gases, he's going down. Accordingly, the thrust is weakening and burning subside a little. If combustion weakens, the opposite is happening.

During the transition of combustion in inactive mode or catlevania coal cap both have been working just as the heat duct furnaces, dobera residual heat of the fuel. But the Dutch and the Swedes it is the most part "whistled" in a pipe: according to all known hydrodynamic Bernoulli principle, in a narrow channel the flow velocity will be greater. And under the hoods of residual gases will slowly toss and turn until their heat is not going to brick.

Note: duct furnaces at a strong wind outside often is removed from the furnace still some embers and close the view, otherwise all the heat "WinVista", until the fuel burns out to ash. In bell-type furnaces of this harmful effect is a dramatic extension off the chimney to the cap not allowing the wind to roam in the oven, and you can safely wait until the fuel will not give your energy to the last calorie. Perfect dvuhkolonchataja oven, round in plan. Then her body 5 is both the second cap. It also has an invisible area of thermochemical reactions 6 under the arch. It neytralizuya residues of carbon monoxide (carbon monoxide) and nitrogen oxides formed in the furnace due to the much higher than in a fiery furnace, the combustion temperature. In duct 7 leaving only carbon dioxide and water vapor.

Although a round brick oven of conventional type can be folded, but if it dvuhkolonchataja, make it a cleanout door hard, and cleaned it (once, Yes you have) difficult. Therefore, in practice dvuhdollarovymi furnace is performed if to draw an analogy with electronics, not parallel, and sequential cascade scheme: the second cap on the first hoist and connect the caps between chimneys (or one continuous wide slit) from the rear of the furnace, the right poses. for rice. Efficiency brick oven with falls of only 1-2 percentage points.

Note: to round dvuhlampovoe gas, the view was stable, except for the hurricane winds, the annular gap L2 between the first and second hoods must be wider than the same L1 between the firebox and the first cap. In either case, the second cap can without any fear to build hot water register of any type. Heat the main body furnace is passed under the first arch of the hood. This, incidentally, is also one of the reasons why early dvuhdollarovymi was not in use: when cheap fuel a small increase in efficiency did not cover the complexity of the work, and to bathe in the kitchen in the trough was then commonplace.

Now the fuel is more expensive, and requirements for higher quality of life. And then the second cap came just in time. How much heat beneath left fotograma, the combustion mode will not be violated: first, a cap from a poorly heat conductive brick insulate high temperature cascade from the parasitic heat loss.

And at the same time the gases under the second cap are suitable, on the one hand, sufficiently cooled and reacted to the heat exchanger can be run from conventional structural materials, without the worries of burn-out and deposition of soot on it. On the other – the temperature in the second cap for furnace efficiency of 80% will be in the range of 200-400 degrees which gives just enough temperature gradient for an effective heat transfer to the water.

About mnogogolovkovym

It is in principle possible round bell furnace to perform multi-stage; each stage – 2 of the cap, with a hole in the roof and deaf from above, as shown in Fig. In three stages (6 caps), a construct which can be called the furnace with free gas during the (left POS. for rice.) it is possible to do self-tuning for any fuel, from fuel oil to dung, with efficiency up to 97-98% in any mode of the furnace. However, exact analytical calculation it is not suitable, a computer simulation requires a fairly powerful hardware and software platform.

Forty seven million seven hundred fifty eight thousand three hundred forty nine

Scheme mnogogolovkovym furnaces

Oven even (with a hole in the roof) caps brought to her frame (right POS. for rice.), is capable, in principle, show an efficiency of 85-90%, depending on the combustion mode and fuel type. But the one and the other, first, it is very difficult to clean. Secondly, the first cap turns out to be very small, and the temperature under it will be quite pyrolysis, about 1500 degrees. No metal it will not stand, except that platinum. Tungsten and he will burn like a string of light bulb with a broken bulb. And whether to stay on weight lining for the pyrolysis furnace, while no one was identified.

Note: black dotted lines on the drawings – not metal. This form (parabolas and straight) of appropriate dimensions: diameter flue hole and the distance of the lower trim caps from the hearth.Video: sample project dvuhlampovoe heating and cooking stoves

Second, heat load On bare principles nothing works. To theoretically right the oven is well warmed, dried and boiled, it must also perform correctly in the material. In relation to Kolpakov ovens (and especially to dvuhdollarovymi) this means that the thermal load on the material should be high. To make a hooded oven is massive with thick walls – it's like that burn the fire in the cave. To feel the warmth, you need to sit near the fire, and the smoke will be…

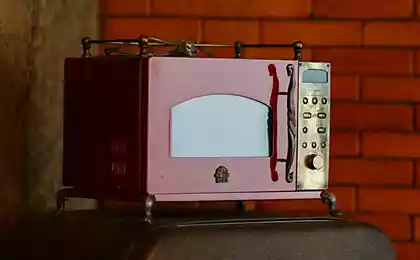

Take a look at Fig. On it – drawings and porjadovki some furnaces Kuznetsova: bathing, heating and cooking, Combi hot water boiler and advanced Russian with the couch. Not being an experienced Builder, it is seen that material per unit emitted power (500 W*sq m external surface) in a furnace Kuznetsova is a half to two times less than in traditional. In General, any hooded oven "emptier" inside of equal power channel.

Twenty four million five hundred ninety one thousand five hundred fifty five

Porjadovki some stoves Kuznetsova On the one hand, it's good, brick with mortar cost money. But on the other requires careful design and adherence to construction technologies (see below). Heat load which will not move a pile of rock, thin brick wall will shatter already at the upper stage of the furnace.

For furnaces Kuznetsova important and structural mechanics. The strength of the wall with clay mortar when reducing its thickness drops much faster than the cement-sand. So the Foundation for these ovens should be performed thoroughly in strict accordance with the recommendations of the author. They must be strictly followed during the construction.

Note: I. V. Kuznetsov allows you to freely copy their material for yourself, for the construction, but is against reprints. However, the pictures in Fig. small. The Amateur in him nothing will be invented, and the master knows where to take a full-fledged drawings. So I hope that Igor will forgive us for this small borrowing for business use.Third: step right, step left… High load on the material in the furnaces Kuznetsova require not only careful design but also of compliance with certain fundamental principles of design already. Chief among them – floating furnace of fireclay bricks brand SHB-8 or W-5. The body of the furnace is laid out with ceramic bricks grade not lower M150.

What do you mean floating firebox? First, around it completely, or accurately calculated by the author must be a dry joint. Make it not so easy: on the computation of the last row of chamotte (unless otherwise specified in the specifications on the oven), the clay mortar from joints between firebrick and regular brick vykovyrivat, but instead are inserted strips of cardboard mineral – basalt, kaolin, etc.

Eight million five hundred thousand eighty one

Unrelated and related construction modules Secondly, you need to strictly follow the principle of disconnection modules. What it is, shows Fig. No protrusions of the fireclay should not enter into the grooves of conventional brick and Vice versa, even with dampening joints. TKR and the heat capacity of fireclay differ significantly from the brick, and the furnace associated with the body of the oven, tear the walls during heating. Insert "kuznetsovka" must be a compact unit to be installed in the socket of a conventional brick. How to make her way in the smoke flue, the author explains in detail on the website.

Also need to strictly follow his recommendations about selection and preparation of materials. "Kuznetsovka", though brick, but high-tech, and sustain a replacement for ersatz and negligence is nothing more than a rocket or submarine – a replacement of titanium and tin composites. The consequences, however, will not be so catastrophic, but to see them have the house and not read in the news. And pay out of pocket.

In General, technology: oven Kuznetsova can build diligent, attentive and careful beginner. But a very experienced setter, with half-drunk, but mindlessly spread is really very good cooker or Dutch, oven Kuznetsova will secede.

About followers Seventy one million six hundred thirteen thousand six hundred sixty two

Drawing a homemade furnace Kuznetsova However, "kuznetsovka" is not some untold miracle. Already there were many fans and artists-Pro, not only repeating the original construction Igor Viktorovich, but creating their own. For rice. right – drawing, and Fig. under the lining of one of them.

She has two features. First – moves starting at the 21st row. They are quite similar to the idle air passages Kuznetsova, but included in the work during heating, accelerating and facilitating it. On the flame or the corruption of their capacity does not allow the release of gases and thingies these muffled by the gas tubes.

Second – sawn lengthways, but still on the corner bricks in the 17th, 28th and some other ranks. Actually potters and builders know that the bricks along the cutting. But this belief was formed in a time when the concept of "angle drill", aka the grinder, was not. About the diamond tool had just heard that, say, the use of such somewhere in the secret shops of military plants.

But to cut the brick along the grinder at the weight of all his strength will fall below an extremely low because of the beating tool in her hands. There are two options, the first is to install the tool in the base frame with walking in the vertical plane of the lever to get a cutting machine. This can be done yourself, there are ready-made on sale.

Three million nine hundred eighty eight thousand fifty one

The lining homemade stove Kuznetsova The other method is good if the farm has a circular saw at least 1500 obmin, but preferably at 2500-3000. Then the diamond grinding stone is charged instead of regular saw toothed. This option is preferable: basic Board with reflex stop ensure the cut is much more clean and accurate. And if necessary, finished on the other hand, not risking on the high end of the step.

Video: the process of a laying of the furnace 3 x 3.5 brick

More about tidy Round kiln theoretically generally have a lot of advantages, only in the house not very comfortable. However, a considerable demand for compact mobile furnace, and here very high efficiency round novokondakove can be a decisive factor, because when reducing the size of the furnace, its efficiency drops sharply due to the square-cube law..

Such furnaces, of course, would have to do of metal. This solves the problem of cleaning, the stove can be run portable. But the choice of metals suitable in terms of heat capacity and thermal conductivity, is extremely limited. Of the cheap – only cast iron but it's heavy and fragile.

However, there is a metal material lighter and stronger with similar properties. It is production of powder metallurgy. In relation to the knives-scissors "powder stuff" is justified, but for a furnace in which nothing works on the shift, powder parts can be a godsend.

The second problem, which has already been mentioned – heat-resistant lining on the vault of the first cap. If you manage to solve it, then maybe the work and effort of Igor Viktorovich Kuznetsov will give the fruit a more extensive and significant than it is now it seems. published

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: clubpechnikov.ru/pech-kuznecova/