581

Tiled stove: tradition, do not lose relevance!

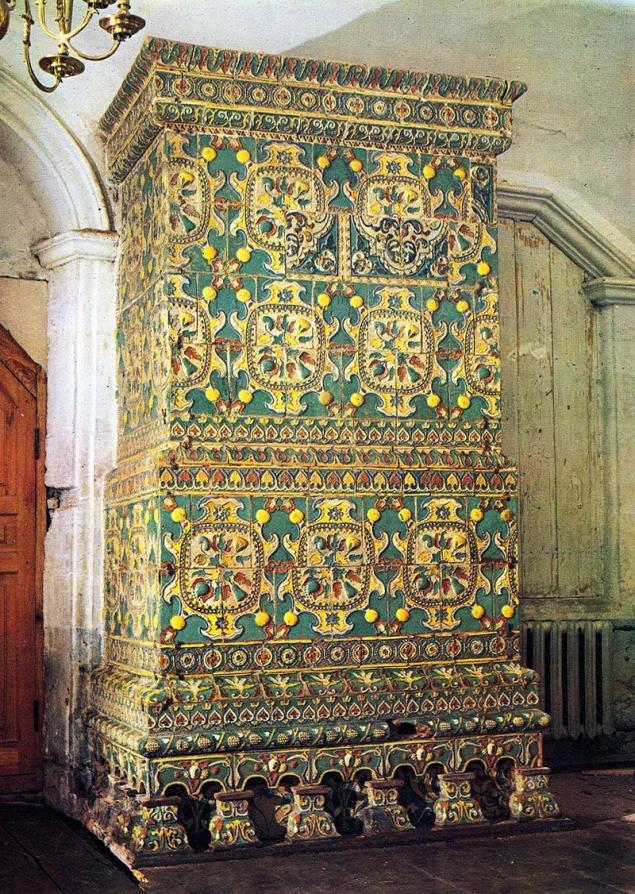

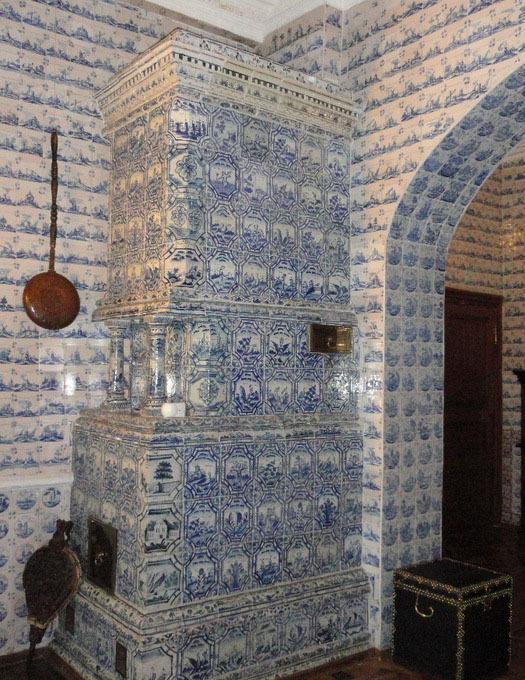

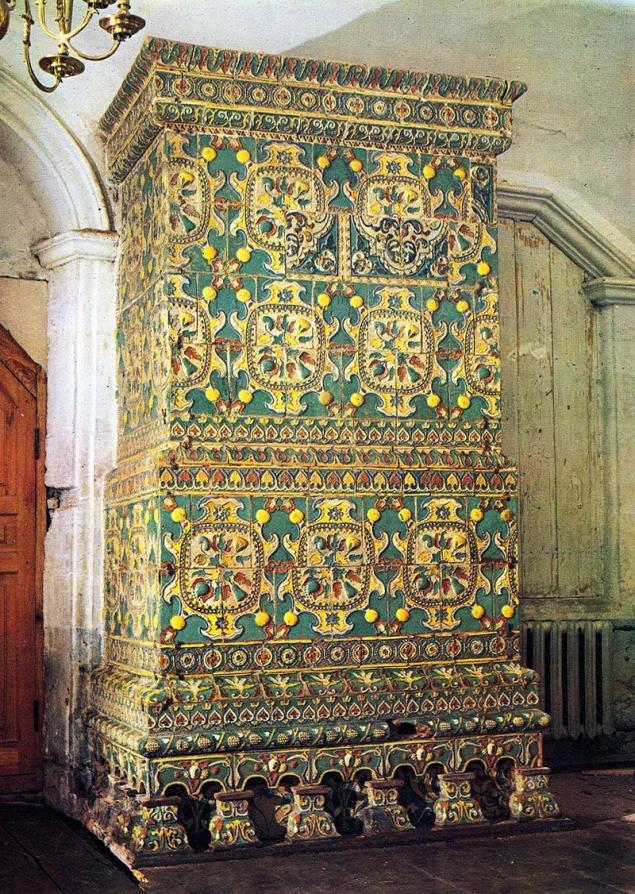

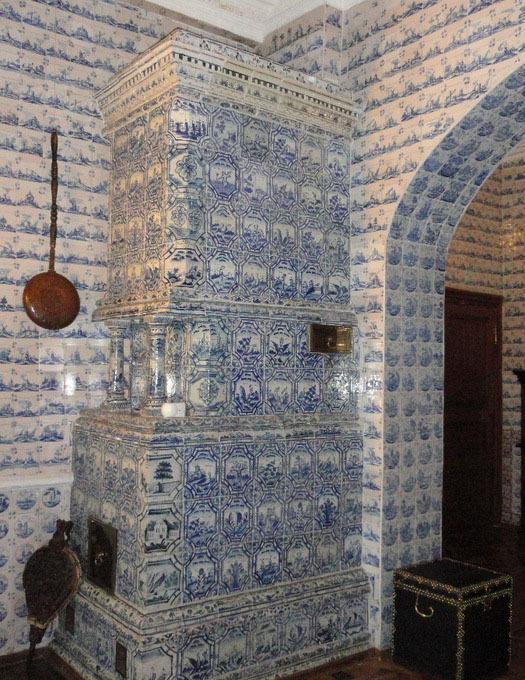

Tradition, do not lose relevance today, is a tiled or tiled stove in the house. 've all seen these stoves and fireplaces in old homes of their grandparents and remember how much warmth, comfort and serenity gives them the fire in the harsh winter evenings. Stoves often make a rectangular shape and decorated tiles with a refined pattern.

Stoves built using cast iron or steel furnaces, operating on solid fuel (firewood), although this type is relatively easy to convert to gas heating. Tiled stoves can also be a part of house Central heating. Modern stoves and fireplaces are distinguished by the fact that they are tiles covered with a frame made of metal .

What good stoves?Fireplaces, tiled, have a good coefficient of energy saving and do not require frequent furnace. The tile due to the structure involved in the process of heating, accumulating, slowly and evenly giving warmth. Refractory brick furnace collects the heat and transfers it to the tile, and he, in turn, heats the air in the room. The most important advantage possessed by the tiled stove, is the heat lasts all day. While each square meter gives heat to 0.25-0.3 kW more than any other type of heating devices. The weight of the furnace is small, so will not need facilities for individual Foundation.

Properly folded furnace tiled always serve many generations of tenants without requiring special care.

All care for tiled stoves consists in wiping of the dust.

Because the tiles from ancient times to the present day is a product exclusively handmade, tile stoves and fireplaces are the exclusive Central element of the interior of the house. A wide variety of styles, sizes, colors and patterns will allow to implement even the most intricate design ideas.

By the way, scientists experienced research Institute, located in Austria, proved that heat, which give a tile kiln, for a man is most comfortable in comparison with other types of heating. Pulse near their lower than near other heating appliances, making the man quickly recovers and moves away from everyday stress.Features of the fabrication and properties of tiles

Encaustic tile was originally created for lining furnaces and is a traditional finishing material in Kievan Rus. Ceramic tiles are made from special types of clay and fired. Other types of ceramic covering materials they are form. The hollow part of the tile for better heat savings is filled with brick, stone or granite and clay mortar. This technique significantly enhances its energy-saving features, and tiled fireplaces and stoves are environmentally friendly and useful for human health.

Thanks to the technology of laying tile is the most durable material of all, which stone stoves and fireplaces.

The back side of the tiles there is a special square ledge — rumpa, which made the hole for the wire. The connection between tiles and brickwork produce, bringing the wire into the joints. For greater reliability, use Googly — U-shaped staples, which pull together rumpy.

The coefficient of thermal expansion of the tile and brick are almost the same, because both materials are made from the same raw material — clay. In addition, in masonry as a connecting link used clay solution. When heated, all parts expand in the ovens almost simultaneously, and fastening of wire and clamps securely connects the tiles.

Today tiles is not only glossy tiles with floral or geometric patterns. Manufacturers offer a variety of tile shapes, sizes, styles, and types of coverage. Some even specially designed surface that simulates an aging effect, matte surface, etc. Tiles, which veneer fireplaces, you can also make to order. They fit perfectly into the interior of the house.

Each series of tiles is represented by an ordinary tile size 220×220 mm, halves 110×220 mm and angular elements. To produced elements of cornices — the ordinary and angular, and shelf corner tile — 90 mm and 135 mm, ordinary shelf (tables). Any other items can be made to order.The secrets of masonry tile stoves and furnaces

Unlike conventional ovens, a feature of the process of laying tile is to install in the first place themselves tiles, then mount it to the brick buildings.

Stoves erected in several stages, at the same time clad with their tiles. So this clutch is quite difficult and time consuming, to trust it can only be a good specialist.

Unlike other materials, trim and tile running parallel with the walls. It is quite complicated and time consuming. So trust this work only to the masters, holding all the secrets of this ancient art.

Tiles that stone stoves and fireplaces are custom boxed products. Therefore, the first stage of the work is always sorts them by color and culling of the tiles with defects in the glaze or cracks. Ideally, culling must be done before buying, but if you have already purchased the tiles, darker tiles lay out the lower ranks, and those on which there is a small defect, hardly noticeable.

The second step is adjusting the tiles by processing a grinder and sanding roll. First treated first sample, which is subsequently used as a benchmark, adjusting to the other. When fitting, first carefully cut the back edge, and then glazed the front, so when laying the frosting neighboring tiles do not touch. Before masonry for the best coupling with a solution they are soaked in water.

If the stove is placed simultaneously with the installation of tiles, use of chamotte-clay solution. If tiles is coated ready heater, it is better to use special adhesive Profix.

The construction of stoves and fireplaces with laying tiles. Then attach the first row of bricks. To check the placement of tiles vertically and horizontally, experts recommend beginning to lay the wall tile without mortar. After checking it apart and start laying on the mortar with the corners. The procedure of facing tiles simultaneously with the brickwork shown in the pictures: 1 — masonry brick; 2 — tile; 3 — rumpa; 4 — pin; 5 — bracket; 6 — binding of the wire rows; 7 — loop fasteners.

Rumpu half filled with stones, pebbles or granite and clay mortar. The solution is applied on a level with the sides and pressed to the brick tile. Tile fasten wire, when the brickwork reaches the top of its range. The wire is carried through the curved part of the crutches of attachment. Then wire the output to the clutch. In the vertical rows of tiles set flush and fastened with steel brackets. To the shrinkage of the brick foundations tiled settled with her, the thickness of the seams between the horizontal rows of tiles should not be less than 3 mm.

On completion of masonry joints on furnaces clean awl and wash tiles from the remaining solution. The joints fill with the plaster test. Dries tiled stove, after laying 2-3 weeks. Only after that it can start flushing.Summing uptoday tiled stoves and fireplaces have become synonymous with good taste of the owners. Tiled stove in the house — for those who have outgrown the mass-market goods and prefers the sophistication and practicality of the classics.

Due to the large heat retaining ceramic mass folded artfully tiled stove gives you the opportunity to enjoy a cozy soft, warm enough for a long time. With this stove you never have to go back to work in a cold house.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: sdelaypechi.ru/vidy/kafelnaya-kamin.html

Stoves built using cast iron or steel furnaces, operating on solid fuel (firewood), although this type is relatively easy to convert to gas heating. Tiled stoves can also be a part of house Central heating. Modern stoves and fireplaces are distinguished by the fact that they are tiles covered with a frame made of metal .

What good stoves?Fireplaces, tiled, have a good coefficient of energy saving and do not require frequent furnace. The tile due to the structure involved in the process of heating, accumulating, slowly and evenly giving warmth. Refractory brick furnace collects the heat and transfers it to the tile, and he, in turn, heats the air in the room. The most important advantage possessed by the tiled stove, is the heat lasts all day. While each square meter gives heat to 0.25-0.3 kW more than any other type of heating devices. The weight of the furnace is small, so will not need facilities for individual Foundation.

Properly folded furnace tiled always serve many generations of tenants without requiring special care.

All care for tiled stoves consists in wiping of the dust.

Because the tiles from ancient times to the present day is a product exclusively handmade, tile stoves and fireplaces are the exclusive Central element of the interior of the house. A wide variety of styles, sizes, colors and patterns will allow to implement even the most intricate design ideas.

By the way, scientists experienced research Institute, located in Austria, proved that heat, which give a tile kiln, for a man is most comfortable in comparison with other types of heating. Pulse near their lower than near other heating appliances, making the man quickly recovers and moves away from everyday stress.Features of the fabrication and properties of tiles

Encaustic tile was originally created for lining furnaces and is a traditional finishing material in Kievan Rus. Ceramic tiles are made from special types of clay and fired. Other types of ceramic covering materials they are form. The hollow part of the tile for better heat savings is filled with brick, stone or granite and clay mortar. This technique significantly enhances its energy-saving features, and tiled fireplaces and stoves are environmentally friendly and useful for human health.

Thanks to the technology of laying tile is the most durable material of all, which stone stoves and fireplaces.

The back side of the tiles there is a special square ledge — rumpa, which made the hole for the wire. The connection between tiles and brickwork produce, bringing the wire into the joints. For greater reliability, use Googly — U-shaped staples, which pull together rumpy.

The coefficient of thermal expansion of the tile and brick are almost the same, because both materials are made from the same raw material — clay. In addition, in masonry as a connecting link used clay solution. When heated, all parts expand in the ovens almost simultaneously, and fastening of wire and clamps securely connects the tiles.

Today tiles is not only glossy tiles with floral or geometric patterns. Manufacturers offer a variety of tile shapes, sizes, styles, and types of coverage. Some even specially designed surface that simulates an aging effect, matte surface, etc. Tiles, which veneer fireplaces, you can also make to order. They fit perfectly into the interior of the house.

Each series of tiles is represented by an ordinary tile size 220×220 mm, halves 110×220 mm and angular elements. To produced elements of cornices — the ordinary and angular, and shelf corner tile — 90 mm and 135 mm, ordinary shelf (tables). Any other items can be made to order.The secrets of masonry tile stoves and furnaces

Unlike conventional ovens, a feature of the process of laying tile is to install in the first place themselves tiles, then mount it to the brick buildings.

Stoves erected in several stages, at the same time clad with their tiles. So this clutch is quite difficult and time consuming, to trust it can only be a good specialist.

Unlike other materials, trim and tile running parallel with the walls. It is quite complicated and time consuming. So trust this work only to the masters, holding all the secrets of this ancient art.

Tiles that stone stoves and fireplaces are custom boxed products. Therefore, the first stage of the work is always sorts them by color and culling of the tiles with defects in the glaze or cracks. Ideally, culling must be done before buying, but if you have already purchased the tiles, darker tiles lay out the lower ranks, and those on which there is a small defect, hardly noticeable.

The second step is adjusting the tiles by processing a grinder and sanding roll. First treated first sample, which is subsequently used as a benchmark, adjusting to the other. When fitting, first carefully cut the back edge, and then glazed the front, so when laying the frosting neighboring tiles do not touch. Before masonry for the best coupling with a solution they are soaked in water.

If the stove is placed simultaneously with the installation of tiles, use of chamotte-clay solution. If tiles is coated ready heater, it is better to use special adhesive Profix.

The construction of stoves and fireplaces with laying tiles. Then attach the first row of bricks. To check the placement of tiles vertically and horizontally, experts recommend beginning to lay the wall tile without mortar. After checking it apart and start laying on the mortar with the corners. The procedure of facing tiles simultaneously with the brickwork shown in the pictures: 1 — masonry brick; 2 — tile; 3 — rumpa; 4 — pin; 5 — bracket; 6 — binding of the wire rows; 7 — loop fasteners.

Rumpu half filled with stones, pebbles or granite and clay mortar. The solution is applied on a level with the sides and pressed to the brick tile. Tile fasten wire, when the brickwork reaches the top of its range. The wire is carried through the curved part of the crutches of attachment. Then wire the output to the clutch. In the vertical rows of tiles set flush and fastened with steel brackets. To the shrinkage of the brick foundations tiled settled with her, the thickness of the seams between the horizontal rows of tiles should not be less than 3 mm.

On completion of masonry joints on furnaces clean awl and wash tiles from the remaining solution. The joints fill with the plaster test. Dries tiled stove, after laying 2-3 weeks. Only after that it can start flushing.Summing uptoday tiled stoves and fireplaces have become synonymous with good taste of the owners. Tiled stove in the house — for those who have outgrown the mass-market goods and prefers the sophistication and practicality of the classics.

Due to the large heat retaining ceramic mass folded artfully tiled stove gives you the opportunity to enjoy a cozy soft, warm enough for a long time. With this stove you never have to go back to work in a cold house.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: sdelaypechi.ru/vidy/kafelnaya-kamin.html

Everything in the head: the psychological component of infertility

Education as a way of liberation: lessons Babinskoe school