701

Gasification furnace for an eco house – practical and modern

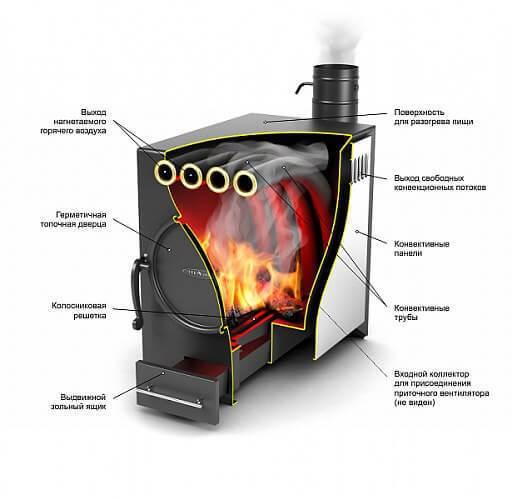

In this age of new technology the use of heating equipment is quite common. It is intended to provide any room with warmth, to create the conditions for comfort living of its residents. For this important mission are perfect gasification furnace. They operate at minimum cost of fuel which undergoes combustion using a small amount of oxygen. The temperature in this process may be low, resulting in high heat, the result is significantly increased efficiency of the equipment used.

Today, manufacturers offer the buyer various models of gas stoves for the cottages, each of which has its own characteristics, advantages and specifications.

Gas generating long burning shoulders, their characteristics and advantagesGas long burning ovens are great for heating a country cottage, the cottages in which, for whatever reason, there is no possibility to provide Central heating. The main advantage of such furnaces is considered to be the maximum value of heat and a long period between the placing of dry fuel (wood).

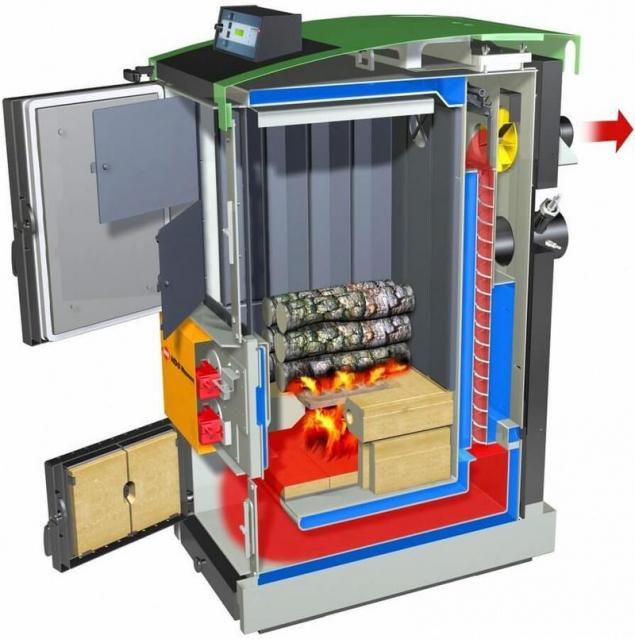

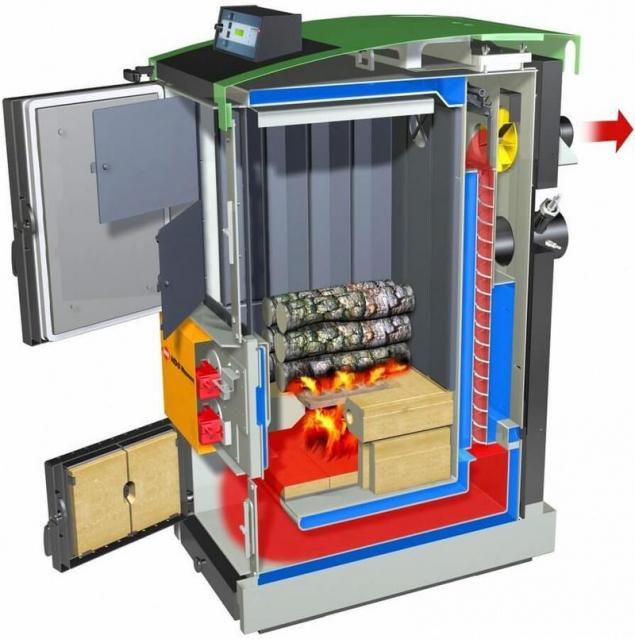

The main difference between furnaces of long burning from the normal heating is their working principle. Conventional ovens require a permanent lining of firewood as combustion of fuel takes place from the bottom to the top, with the result that the temperature at the time of combustion increases (there is output). When from the wood there are only coals, a lining of wood, or heating system will not produce heat. Long burning ovens are in the process of burning from the top to the bottom, retain heat in the room after the fuel is completely burned in for 20 hours. Thus, the home owner saves as solid fuel, and money, which are periodically spent to acquire it.

Advantages of furnaces of long burning:

1. the cost (before such equipment could afford mostly wealthy people, but now the manufacturer provides and most cost options that are affordable to almost anyone who wishes to provide themselves with high-efficiency heating equipment);

2. the duration of heat generation (due to the updated engine, the time of heating is reduced, and the period of heat transfer increases);

3. durable in use (designs are made from high strength metals such as cast iron, steel);

4. environmental safety (carbon monoxide poisoning generated by the equipment are excluded);

5. fuel economy (requires less wood for heating, as the increased burn duration).

Gas furnace long burning is the most appropriate option compared to conventional furnaces that confirm its advantages.

Gasification furnace with the water system, application and specific features of theGas furnace with a water circuit operates not worse than the furnace long burning differs only in the principle of operation and variety of fuels. Inside the furnace (flue or furnace) is a heat exchanger that is filled with water. When the operation of the oven is quick heating of water, after which it is transferred to the radiator. Their mechanism involves two reservoirs, the first water is heated, passing in the second, it is converted into steam. This method is a uniform heating over the entire area.

Gasification furnace with the water system have its own characteristics and benefits:

Depending on model, this design may be provided with a cooking surface on which to cook a delicious dinner.

Install gas furnaces with his own hands – practicality and economy.

It would seem that to buy a modern gas furnace easier to install it does not require additional effort. But the production of gasification furnace with his own hands quite economical activity. For the manufacture of this equipment required knowledge, abilities and skills of welding and basic knowledge of physics and materials:

Gasification furnace are famous not only for its technical characteristics and cost-effectiveness, but also because they perfectly fit any room design. Easy to install, and then in exploitation are among the important criteria of furnaces. Their activities are aimed at quality heating large spaces and areas, the duration of heat. If You are considering the acquisition of such gasification furnace, it is possible to consider a model that combines low price and good quality characteristics. In the case of disability, at a cost of furnace will not be difficult to make the equipment which will be long and efficiently to heat Your home! published

Source: stroy-king.ru/gazogeneratornye-pechi-praktichno-i-sovremenno.html

Today, manufacturers offer the buyer various models of gas stoves for the cottages, each of which has its own characteristics, advantages and specifications.

Gas generating long burning shoulders, their characteristics and advantagesGas long burning ovens are great for heating a country cottage, the cottages in which, for whatever reason, there is no possibility to provide Central heating. The main advantage of such furnaces is considered to be the maximum value of heat and a long period between the placing of dry fuel (wood).

The main difference between furnaces of long burning from the normal heating is their working principle. Conventional ovens require a permanent lining of firewood as combustion of fuel takes place from the bottom to the top, with the result that the temperature at the time of combustion increases (there is output). When from the wood there are only coals, a lining of wood, or heating system will not produce heat. Long burning ovens are in the process of burning from the top to the bottom, retain heat in the room after the fuel is completely burned in for 20 hours. Thus, the home owner saves as solid fuel, and money, which are periodically spent to acquire it.

Advantages of furnaces of long burning:

1. the cost (before such equipment could afford mostly wealthy people, but now the manufacturer provides and most cost options that are affordable to almost anyone who wishes to provide themselves with high-efficiency heating equipment);

2. the duration of heat generation (due to the updated engine, the time of heating is reduced, and the period of heat transfer increases);

3. durable in use (designs are made from high strength metals such as cast iron, steel);

4. environmental safety (carbon monoxide poisoning generated by the equipment are excluded);

5. fuel economy (requires less wood for heating, as the increased burn duration).

Gas furnace long burning is the most appropriate option compared to conventional furnaces that confirm its advantages.

Gasification furnace with the water system, application and specific features of theGas furnace with a water circuit operates not worse than the furnace long burning differs only in the principle of operation and variety of fuels. Inside the furnace (flue or furnace) is a heat exchanger that is filled with water. When the operation of the oven is quick heating of water, after which it is transferred to the radiator. Their mechanism involves two reservoirs, the first water is heated, passing in the second, it is converted into steam. This method is a uniform heating over the entire area.

Gasification furnace with the water system have its own characteristics and benefits:

- a small fuel cost, thereby achieving cost savings;

- uniform heating of relatively large areas and premises;

- energy saving technology (when using this kind of gas furnaces do not require a connection to electricity);

- the strength and reliability of the design (made by the manufacturer of high quality materials, allow to serve a long and virtually not subject to repair).

Depending on model, this design may be provided with a cooking surface on which to cook a delicious dinner.

Install gas furnaces with his own hands – practicality and economy.

It would seem that to buy a modern gas furnace easier to install it does not require additional effort. But the production of gasification furnace with his own hands quite economical activity. For the manufacture of this equipment required knowledge, abilities and skills of welding and basic knowledge of physics and materials:

- shaped tube;

- one steel tube;

- grate;

- 2 sheets of steel.

Gasification furnace are famous not only for its technical characteristics and cost-effectiveness, but also because they perfectly fit any room design. Easy to install, and then in exploitation are among the important criteria of furnaces. Their activities are aimed at quality heating large spaces and areas, the duration of heat. If You are considering the acquisition of such gasification furnace, it is possible to consider a model that combines low price and good quality characteristics. In the case of disability, at a cost of furnace will not be difficult to make the equipment which will be long and efficiently to heat Your home! published

Source: stroy-king.ru/gazogeneratornye-pechi-praktichno-i-sovremenno.html

As a statement of Nikola Tesla "All is light" reveals the secrets of his life

SUPER remedy for wrinkles from the nearest pharmacy