803

As to biofuels with their hands

What kinds of biofuels are the most popular

Actually you can get any variant of biofuels ranging from charcoal, and ending with biodiesel. However, the production of liquid biofuels is associated with certain problems. First, to obtain the required vegetable oil (rapeseed, linseed and so on). Most of the farms do not have their own sources of raw materials. In addition, biodiesel production is connected with work with toxic substances (for example, methanol) that makes him dangerous to others. And a small error in the process can lead to a fatal loss of quality of the resulting biofuel.

Currently, the greatest interest for those who are interested in energy autonomy and wishes to produce biofuels on their own, is biogas. A device for producing biogas are fairly easy to construct with his own hands, and the resulting product is more than enough for their own needs and the needs in heat and electricity, especially if we are talking about livestock or crop agriculture.

Following demand for biogas is the solid fuel briquettes from organic materials, pellets and so on. At the moment briquettes are more popular as the use of pellets requires special equipment to burn fuel that has not yet come into use everywhere, as, for example, a standard solid fuel boilers or furnaces.

What the biofuel is made with their own handsFor the manufacture of liquid biofuels used different organic oils combined with alcohol additives. Also to obtain high-quality biodiesel used alkali. Given the specificity of substances used in the manufacture of biodiesel is necessary to use special precautions. Also, certain precautions are required when storing these substances.

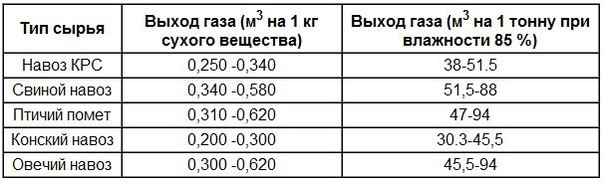

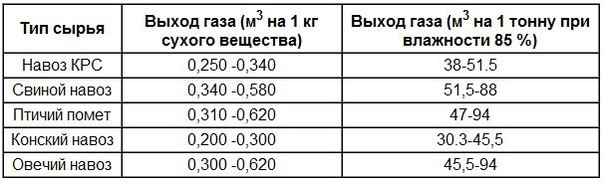

For biogas production using various organic wastes. In the first place are liquid organic waste, a byproduct of livestock (manure, etc.). In the presence of livestock farms of raw materials for full load of a biogas plant is sufficient. If you own livestock or crop farming is not, should consider options for the purchase of materials for installation. True if raw material suppliers are nearby, and if the raw materials have to be transported from afar, the biogas plant becomes unprofitable.

For producing briquettes or pellets are often used various wood waste (sawdust, bark, chips, and so on), peat, paper and so on. Briquettes are usually obtained by using special presses. Domestic press can be purchased in specialized shops or on the Internet. There are options to make the press with their hands. The user can take from the Internet.

Another option of biofuel is charcoal. It is used for grills, stoves, barbecue, and also to filter water and so on. Charcoal is produced by burning wood in pits or barrels.

Biogas – full of fuel from wastewe All know that new is well forgotten old. So, biogas is not a discovery of our time, and gaseous biofuels, which were able to extract in Ancient China. So what is biogas and how it can be obtained by your efforts?

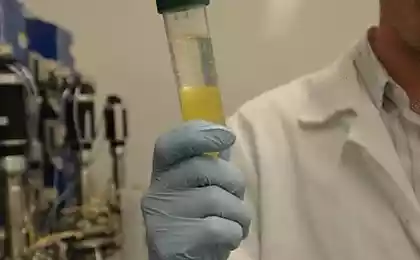

Biogas is a mixture of gases produced by perepravnaya of organic matter without access to air. As source material you can use manure, the tops of cultivated plants, grass or any waste. Typically, the manure is used as fertilizer, and few people know that it can be useful to produce biofuel, using which it is possible to heat residential premises, greenhouses, and also to cook food.

Approximate composition of biogas: methane CH4, carbon dioxide CO2, impurities of other gases, e.g., hydrogen sulfide H2S, and the proportion of methane can reach up to 70%. 1 kg of organic matter can produce about 0.5 kg of biogas.

What factors affect production?First, is the environment. The warmer it is, the more reaction occurs decomposition of organic matter and the release of gas. No wonder the first installation for the production of biofuels such as biogas, has been involved in regions with a warm climate. Despite this, when a sufficient insulation of biogas plants and the use of heated water, it is possible to build them in more harsh climatic conditions and has been successfully implemented at present.

Secondly, raw materials. It should be easy to decompose and contain in their composition a large quantity of water, without impurities detergents, antibiotics and other substances that can slow the fermentation process.

Bostanovna from Yuri Davydov

The inventor of the Lipetsk region have built their skilful hands a device that allows you to get the "blue biofuel" in home possessions. Shortage of raw materials was not, as he himself and the neighbors had plenty of cattle, and, of course, manure.

What he came up with? His own hands dug a huge hole, laid in it the concrete rings, and covered it with iron construction in the form of a dome and weighing about one ton. From this vessel, brought the pipes and then filled the hole with organic matter. After a few days he was able to received the biogas to cook the beast and heat the bath. Later held the gas to the house for domestic use.

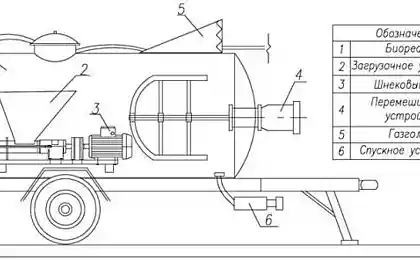

Recommended composition of raw materials for processing

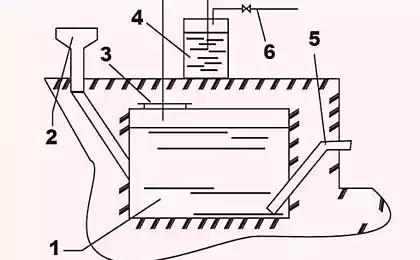

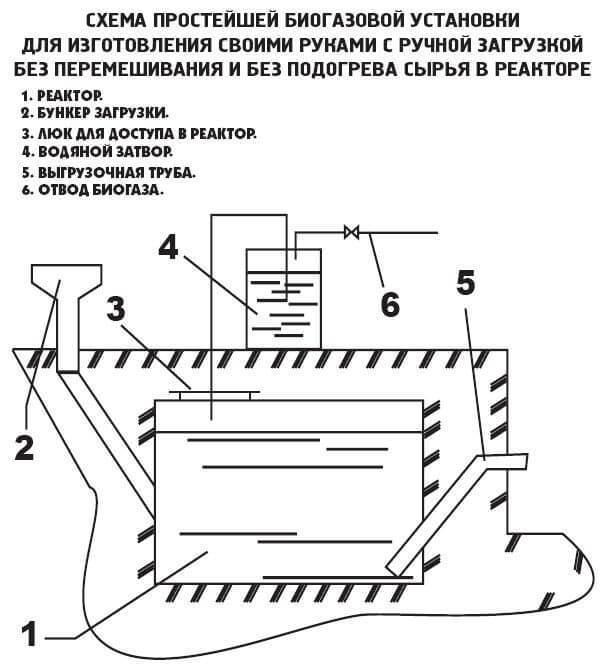

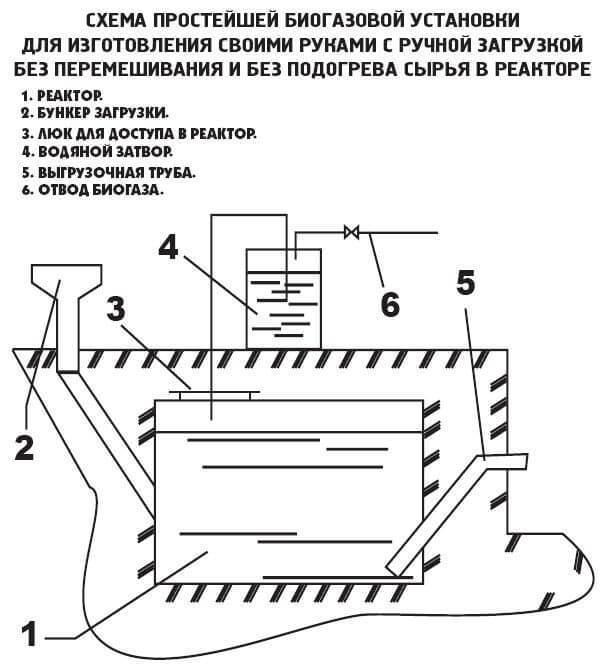

For this purpose the 1.5 – 2 tons of manure and 3 to 4 tons of plant waste is poured in water to achieve 60-70% moisture mixture. The resulting mixture was placed in a reservoir and is heated by the coil to 35 degrees Celsius. In such circumstances, the mixture begins to wander without access of air heated to a higher temperature, which contributes to the reaction gases. Gas special tubes removed from the pit and is intended. The unit design is performed by the hands of a master, is clearly visible in the diagram.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Pipe installation for the production of biogas :

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Burning of charcoal is hard?

When talking – charcoal, just imagine the camping, barbecue, barbecue. Pleasant smoke, the twinkling lights on the barbecue! However, the use of charcoal is not limited only to cooking meat, it is needed in blacksmithing, foundry work, medicine, drinking water filtration and even for making gunpowder and for household needs.

Who had to deal with charcoal, you know that his purchase is worth a lot of money, they often think about how it is possible to obtain independently at home or in the field, personally – with their very skillful hands. Indeed, it is possible! There are two commonly used methods – the production of this biofuel in the pit or metal barrel.

A method of manufacturing coal in the pitis Usually the burning of coal is carried out in a forest that is more convenient than at home, but due to widespread forest fires, the place and time of the works need to think.

Select a place near a large supply of dead wood or fallen tree, and such, so as not to damage the surrounding vegetation. To get two bags of coal, enough to dig a pit depth of 50 cm and a diameter of 75-80 cm with slightly sloping walls. It is also easy to carry with their hands.

Packed on the bottom of the pit hands bred a small fire of dry bark and twigs and when the fire breaks out good, it fit felled wood of small size, about 30 cm in length. If you select branches with a diameter of about 7 cm, with cut it is possible to cope on their own, without an assistant. Firewood stacked tightly and gradually, as the firing of each layer. Well charred wood can be corrected with a long stick.

For full burning out in such conditions quite 3 hours. Then the coals are hiding with moss, dry leaves or grass and covered with earth, which is tamped tightly. Below the coal is sufficiently cool, it will take another two days, after which the solid biofuel is ready. After this time, with the pits removed a layer of earth, coal shovel, screened and Packed in sacks.

If a new piece of wood is not done, the pit is backfilled so that the topsoil of the earth was on the surface, all well covered by foliage. Of course the production of coal requires certain expenditures, but it is much cheaper than the cost of buying it, but still there is the moral aspect – all achieved through my own efforts and made with his own hands.

A method of manufacturing charcoal in the barrel on its own territoryin order to obtain solid biofuel at home, namely charcoal, use a thick-walled metal barrel with a capacity of 200 liters. At the bottom to make fitting to force the air injection household vacuum cleaner.

Similarly, as in the pit, at the bottom of the barrel bred a small fire and then gradually added in small lumps. For more dense packing of the wood barrel, you can periodically shake. After the supply of air the wood will be less smoke and erupt into flames. The flow of air from bottom should begin only after filling the barrel with firewood by about half. Periodically need to adjust the coals and the sixth not to forget about safety while working in hot conditions.

To continue the process of burning coal without access of air should cover the barrel lid and cover up all the cracks with mortar of land with water. If there is no "native" cap, it should be done from a piece of iron.

We must note that with this method, work at home, often in unsuitable conditions, produces a certain number of marriage and ash, but within reasonable limits. After the final cooling of the barrel tilt it, and the finished coal is sifted and packaged. Here is a trade that you can master with their hands.

The first time can not get high quality coal, but patience and labor – little effort! Importantly, with no neighbors to quarrel from-for strong smoke.

How to manufacture equipment for the production of biofuelsMost of the fixtures and equipment for the production of any type of biofuels with their hands made of scrap materials. For the manufacture of devices of the selected type, it is recommended to turn to the Internet – the Internet enough diagrams, drawings and step-by-step examples of making such installations, ranging from simple to complex devices that are able to provide heat and electricity to the whole economy. Optimally not just to study technical documentation, but also to contact the author to clarify how the device works, how long it runs, whether there were problems in operation, breakage, and so on.

It is best to start with making the simplest – in fact, a trial device to determine whether you need it. Or, perhaps, the best option for you is to purchase setup factory production. published

Source: altenergiya.ru/bio/kak-poluchit-biotoplivo-svoimi-rukami.html

Actually you can get any variant of biofuels ranging from charcoal, and ending with biodiesel. However, the production of liquid biofuels is associated with certain problems. First, to obtain the required vegetable oil (rapeseed, linseed and so on). Most of the farms do not have their own sources of raw materials. In addition, biodiesel production is connected with work with toxic substances (for example, methanol) that makes him dangerous to others. And a small error in the process can lead to a fatal loss of quality of the resulting biofuel.

Currently, the greatest interest for those who are interested in energy autonomy and wishes to produce biofuels on their own, is biogas. A device for producing biogas are fairly easy to construct with his own hands, and the resulting product is more than enough for their own needs and the needs in heat and electricity, especially if we are talking about livestock or crop agriculture.

Following demand for biogas is the solid fuel briquettes from organic materials, pellets and so on. At the moment briquettes are more popular as the use of pellets requires special equipment to burn fuel that has not yet come into use everywhere, as, for example, a standard solid fuel boilers or furnaces.

What the biofuel is made with their own handsFor the manufacture of liquid biofuels used different organic oils combined with alcohol additives. Also to obtain high-quality biodiesel used alkali. Given the specificity of substances used in the manufacture of biodiesel is necessary to use special precautions. Also, certain precautions are required when storing these substances.

For biogas production using various organic wastes. In the first place are liquid organic waste, a byproduct of livestock (manure, etc.). In the presence of livestock farms of raw materials for full load of a biogas plant is sufficient. If you own livestock or crop farming is not, should consider options for the purchase of materials for installation. True if raw material suppliers are nearby, and if the raw materials have to be transported from afar, the biogas plant becomes unprofitable.

For producing briquettes or pellets are often used various wood waste (sawdust, bark, chips, and so on), peat, paper and so on. Briquettes are usually obtained by using special presses. Domestic press can be purchased in specialized shops or on the Internet. There are options to make the press with their hands. The user can take from the Internet.

Another option of biofuel is charcoal. It is used for grills, stoves, barbecue, and also to filter water and so on. Charcoal is produced by burning wood in pits or barrels.

Biogas – full of fuel from wastewe All know that new is well forgotten old. So, biogas is not a discovery of our time, and gaseous biofuels, which were able to extract in Ancient China. So what is biogas and how it can be obtained by your efforts?

Biogas is a mixture of gases produced by perepravnaya of organic matter without access to air. As source material you can use manure, the tops of cultivated plants, grass or any waste. Typically, the manure is used as fertilizer, and few people know that it can be useful to produce biofuel, using which it is possible to heat residential premises, greenhouses, and also to cook food.

Approximate composition of biogas: methane CH4, carbon dioxide CO2, impurities of other gases, e.g., hydrogen sulfide H2S, and the proportion of methane can reach up to 70%. 1 kg of organic matter can produce about 0.5 kg of biogas.

What factors affect production?First, is the environment. The warmer it is, the more reaction occurs decomposition of organic matter and the release of gas. No wonder the first installation for the production of biofuels such as biogas, has been involved in regions with a warm climate. Despite this, when a sufficient insulation of biogas plants and the use of heated water, it is possible to build them in more harsh climatic conditions and has been successfully implemented at present.

Secondly, raw materials. It should be easy to decompose and contain in their composition a large quantity of water, without impurities detergents, antibiotics and other substances that can slow the fermentation process.

Bostanovna from Yuri Davydov

The inventor of the Lipetsk region have built their skilful hands a device that allows you to get the "blue biofuel" in home possessions. Shortage of raw materials was not, as he himself and the neighbors had plenty of cattle, and, of course, manure.

What he came up with? His own hands dug a huge hole, laid in it the concrete rings, and covered it with iron construction in the form of a dome and weighing about one ton. From this vessel, brought the pipes and then filled the hole with organic matter. After a few days he was able to received the biogas to cook the beast and heat the bath. Later held the gas to the house for domestic use.

Recommended composition of raw materials for processing

For this purpose the 1.5 – 2 tons of manure and 3 to 4 tons of plant waste is poured in water to achieve 60-70% moisture mixture. The resulting mixture was placed in a reservoir and is heated by the coil to 35 degrees Celsius. In such circumstances, the mixture begins to wander without access of air heated to a higher temperature, which contributes to the reaction gases. Gas special tubes removed from the pit and is intended. The unit design is performed by the hands of a master, is clearly visible in the diagram.

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Pipe installation for the production of biogas :

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Burning of charcoal is hard?

When talking – charcoal, just imagine the camping, barbecue, barbecue. Pleasant smoke, the twinkling lights on the barbecue! However, the use of charcoal is not limited only to cooking meat, it is needed in blacksmithing, foundry work, medicine, drinking water filtration and even for making gunpowder and for household needs.

Who had to deal with charcoal, you know that his purchase is worth a lot of money, they often think about how it is possible to obtain independently at home or in the field, personally – with their very skillful hands. Indeed, it is possible! There are two commonly used methods – the production of this biofuel in the pit or metal barrel.

A method of manufacturing coal in the pitis Usually the burning of coal is carried out in a forest that is more convenient than at home, but due to widespread forest fires, the place and time of the works need to think.

Select a place near a large supply of dead wood or fallen tree, and such, so as not to damage the surrounding vegetation. To get two bags of coal, enough to dig a pit depth of 50 cm and a diameter of 75-80 cm with slightly sloping walls. It is also easy to carry with their hands.

Packed on the bottom of the pit hands bred a small fire of dry bark and twigs and when the fire breaks out good, it fit felled wood of small size, about 30 cm in length. If you select branches with a diameter of about 7 cm, with cut it is possible to cope on their own, without an assistant. Firewood stacked tightly and gradually, as the firing of each layer. Well charred wood can be corrected with a long stick.

For full burning out in such conditions quite 3 hours. Then the coals are hiding with moss, dry leaves or grass and covered with earth, which is tamped tightly. Below the coal is sufficiently cool, it will take another two days, after which the solid biofuel is ready. After this time, with the pits removed a layer of earth, coal shovel, screened and Packed in sacks.

If a new piece of wood is not done, the pit is backfilled so that the topsoil of the earth was on the surface, all well covered by foliage. Of course the production of coal requires certain expenditures, but it is much cheaper than the cost of buying it, but still there is the moral aspect – all achieved through my own efforts and made with his own hands.

A method of manufacturing charcoal in the barrel on its own territoryin order to obtain solid biofuel at home, namely charcoal, use a thick-walled metal barrel with a capacity of 200 liters. At the bottom to make fitting to force the air injection household vacuum cleaner.

Similarly, as in the pit, at the bottom of the barrel bred a small fire and then gradually added in small lumps. For more dense packing of the wood barrel, you can periodically shake. After the supply of air the wood will be less smoke and erupt into flames. The flow of air from bottom should begin only after filling the barrel with firewood by about half. Periodically need to adjust the coals and the sixth not to forget about safety while working in hot conditions.

To continue the process of burning coal without access of air should cover the barrel lid and cover up all the cracks with mortar of land with water. If there is no "native" cap, it should be done from a piece of iron.

We must note that with this method, work at home, often in unsuitable conditions, produces a certain number of marriage and ash, but within reasonable limits. After the final cooling of the barrel tilt it, and the finished coal is sifted and packaged. Here is a trade that you can master with their hands.

The first time can not get high quality coal, but patience and labor – little effort! Importantly, with no neighbors to quarrel from-for strong smoke.

How to manufacture equipment for the production of biofuelsMost of the fixtures and equipment for the production of any type of biofuels with their hands made of scrap materials. For the manufacture of devices of the selected type, it is recommended to turn to the Internet – the Internet enough diagrams, drawings and step-by-step examples of making such installations, ranging from simple to complex devices that are able to provide heat and electricity to the whole economy. Optimally not just to study technical documentation, but also to contact the author to clarify how the device works, how long it runs, whether there were problems in operation, breakage, and so on.

It is best to start with making the simplest – in fact, a trial device to determine whether you need it. Or, perhaps, the best option for you is to purchase setup factory production. published

Source: altenergiya.ru/bio/kak-poluchit-biotoplivo-svoimi-rukami.html

Each of us has a "control point" of happiness

Mobile Factory turns ruins in modular building materials