561

First flight on pure biofuel

Recently, the national research Council of Canada (National Research Council of Canada, NRC) conducted the world's first flight of a civilian aircraft, engines which run on 100 per cent biofuel without any mineral additives.

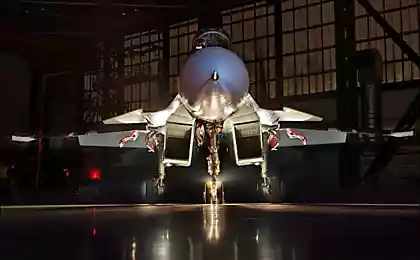

The first flight lasted one hour in the sky of Ottawa. It carried out 29 Oct 2012 specially equipped for this purpose twin-engine business jet Dassault Falcon 20. Tanks of the aircraft was fueled with biofuels from oilseeds. Falcon 20 in flight was accompanied by the air laboratory of the U.S. air force Lockheed T-33, whose task was to collect data on emissions of engines running on biofuels.

Before posting business jet in the sky, the engines were tested on the test bench and then on the ground.

"I was flying on 100 percent biofuel," says the pilot of the Falcon 20 Tim Leslie (Tim Leslie). "We have worked hard with our partners for several months, and I'm glad to see them all gathered together. It's really exciting to make a step towards an environmentally sustainable future".

The biofuel, ReadiJet for the historic flight made by the company Agrisoma Biosciences Inc. Raw material for it served as the plant Brassica carinata, also known as Ethiopian or Abyssinian mustard.

According to the representative of the Association for applied research (Applied Research Associates, ARA) developed a fuel together with Chevron Lummus Global: "Herb is unpleasant to taste and may not be used in food, but it can be grown on marginal land in hot and dry climate".

Among the advantages of Ethiopian mustard high yield and oil content. The plant is undemanding to the conditions, and is ideal for semi-arid areas, which are many in the prairies of Canada and the United States. Agrisoma has signed contracts for its production with more than 40 farmers. This year's planting amounted to more than 2,400 hectares.

Biofuels from Brassica carinata get using rapid and inexpensive technology catalytic hydrothermolysis. Under the influence of water, high temperature and pressure of vegetable oil becomes a transitional neftebazovskiy product. The intermediate under the action of catalysts, enriched with hydrogen, and further converted into alternative fuels, according to the manufacturer "virtually indistinguishable from their petroleum counterparts".

The advantages of the process of hydrothermolysis that it does not require large production areas, and capital and operating costs significantly lower than when manufacturing biofuels in other ways. In addition, the process requires a smaller amount of hydrogen.

Association of applied research ARA hopes to obtain permission for commercial use of their ReadiJet biofuel by the end of 2013.

Source: /users/104

The first flight lasted one hour in the sky of Ottawa. It carried out 29 Oct 2012 specially equipped for this purpose twin-engine business jet Dassault Falcon 20. Tanks of the aircraft was fueled with biofuels from oilseeds. Falcon 20 in flight was accompanied by the air laboratory of the U.S. air force Lockheed T-33, whose task was to collect data on emissions of engines running on biofuels.

Before posting business jet in the sky, the engines were tested on the test bench and then on the ground.

"I was flying on 100 percent biofuel," says the pilot of the Falcon 20 Tim Leslie (Tim Leslie). "We have worked hard with our partners for several months, and I'm glad to see them all gathered together. It's really exciting to make a step towards an environmentally sustainable future".

The biofuel, ReadiJet for the historic flight made by the company Agrisoma Biosciences Inc. Raw material for it served as the plant Brassica carinata, also known as Ethiopian or Abyssinian mustard.

According to the representative of the Association for applied research (Applied Research Associates, ARA) developed a fuel together with Chevron Lummus Global: "Herb is unpleasant to taste and may not be used in food, but it can be grown on marginal land in hot and dry climate".

Among the advantages of Ethiopian mustard high yield and oil content. The plant is undemanding to the conditions, and is ideal for semi-arid areas, which are many in the prairies of Canada and the United States. Agrisoma has signed contracts for its production with more than 40 farmers. This year's planting amounted to more than 2,400 hectares.

Biofuels from Brassica carinata get using rapid and inexpensive technology catalytic hydrothermolysis. Under the influence of water, high temperature and pressure of vegetable oil becomes a transitional neftebazovskiy product. The intermediate under the action of catalysts, enriched with hydrogen, and further converted into alternative fuels, according to the manufacturer "virtually indistinguishable from their petroleum counterparts".

The advantages of the process of hydrothermolysis that it does not require large production areas, and capital and operating costs significantly lower than when manufacturing biofuels in other ways. In addition, the process requires a smaller amount of hydrogen.

Association of applied research ARA hopes to obtain permission for commercial use of their ReadiJet biofuel by the end of 2013.

Source: /users/104