480

Server farm for clean energy

Server farms use a lot of energy. How, you ask? According to CNN, more than the entire automotive industry in the production of cars and trucks. If the Internet were a country, it would rank fifth in use of energy and production of greenhouse gases.

To date, a number of large users, servers trying to turn this tide. Google claim that the emissions planned to bring it down to zero. This is a real feat, when you consider that in 2010 the company produced 1.5 million tons of carbon dioxide (the most recent available data year). 30 thousand employees, Google has provided the total carbon footprint, which equals the emissions of a city with 200 thousand inhabitants.

We have already seen that Google has been taking environmental measures by installing 395 of chargers for electric vehicles in its corporate fleet. The company is working on Autonomous transport and ensures the transport of employees on 73 was built by the own ordering buses (with free Wi-Fi!), so they are not driving to work alone.

But servers are a big problem. They heat up, and bills for cooling is enormous. Google invested in the company "BrightSource Energy", which creates a large solar thermal plant in the Mojave desert, as well as in geothermal projects of the company "AltaRock". Without a doubt, the global server farm would have all together to send to Iceland, where electricity is actually too cheap to measure due to: a) tiny population, b) the enormous potential of geothermal plants and hydropower plants. One problem – the volcanoes.

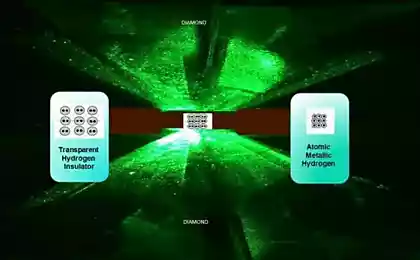

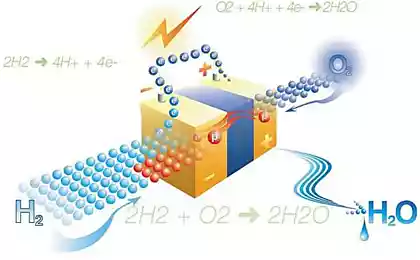

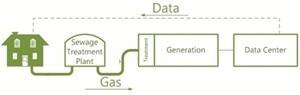

Energy investment Google is not so great, considering the size of the company. But she made a commitment to buy 12 percent of its energy from "green" sources (wind and solar farms). What she did not build their own servers powered by clean energy. That's because the latest news from Microsoft". The company launched a pilot program given the scheme, which involves the collection of biogas station for treatment of waste water (common today). From it emit hydrogen, which is used for electricity-generating fuel cells, which in turn is connected to the data center.

The basis of this technology is the anaerobic bioreactor, which is also used in dairy farms for the production of electricity from methane gas cows. Stations wastewater treatment bioreactors provide the decomposition of the organic material with the aid of special microorganisms, resulting in a hydrogen-rich biogas methane.

The company "Fuel Cell Energy" produces a liquid carbonate fuel cell giant size, which suck the methane and generate electricity on an industrial scale. In addition, they generate heat that is directed back into the bioreactor, providing in hot conditions high performance.

There is someone else. As stated in Microsoft, at the end of the process still remains a certain amount of CO2 as a by-product of electrolysis in fuel cells. The CO2 high enough quality for reuse in industrial purposes. In other words, the installation turns the pollutant into a valuable product and sends it for commercial purposes.

"Information farms usually use enormous amounts of energy. There is a question about providing environmentally responsible electricity. We use biogas as a primary energy source, and the grid acts as a back-up option, i.e., we actually changed the usual pattern. Our intention is to run the install around the middle of next year. Fuel cells are right beside the information centre and the station for processing waste water."

In the words of Botton, at the moment, fuel cells produce electricity at a price of 15 cents per kilowatt. It is quite expensive but you can avoid buying expensive generators. In addition, the energy source is very reliable, and information centers lose a lot of money for every minute of downtime. Yes, it is connected to the network but can work without it.

How far is Microsoft willing to go? Research Manager company Sin, James says that at this time conducted a detailed study of the possibilities of biogas. "Our pilot project designed to find stable, clean, customized, and cost-effective source of energy information centres," he says. – I hope that this practice will be the best for our equipment and other industries in the future."

right beside information center and the station for processing waste water."

Source: /users/104

To date, a number of large users, servers trying to turn this tide. Google claim that the emissions planned to bring it down to zero. This is a real feat, when you consider that in 2010 the company produced 1.5 million tons of carbon dioxide (the most recent available data year). 30 thousand employees, Google has provided the total carbon footprint, which equals the emissions of a city with 200 thousand inhabitants.

We have already seen that Google has been taking environmental measures by installing 395 of chargers for electric vehicles in its corporate fleet. The company is working on Autonomous transport and ensures the transport of employees on 73 was built by the own ordering buses (with free Wi-Fi!), so they are not driving to work alone.

But servers are a big problem. They heat up, and bills for cooling is enormous. Google invested in the company "BrightSource Energy", which creates a large solar thermal plant in the Mojave desert, as well as in geothermal projects of the company "AltaRock". Without a doubt, the global server farm would have all together to send to Iceland, where electricity is actually too cheap to measure due to: a) tiny population, b) the enormous potential of geothermal plants and hydropower plants. One problem – the volcanoes.

Energy investment Google is not so great, considering the size of the company. But she made a commitment to buy 12 percent of its energy from "green" sources (wind and solar farms). What she did not build their own servers powered by clean energy. That's because the latest news from Microsoft". The company launched a pilot program given the scheme, which involves the collection of biogas station for treatment of waste water (common today). From it emit hydrogen, which is used for electricity-generating fuel cells, which in turn is connected to the data center.

The basis of this technology is the anaerobic bioreactor, which is also used in dairy farms for the production of electricity from methane gas cows. Stations wastewater treatment bioreactors provide the decomposition of the organic material with the aid of special microorganisms, resulting in a hydrogen-rich biogas methane.

The company "Fuel Cell Energy" produces a liquid carbonate fuel cell giant size, which suck the methane and generate electricity on an industrial scale. In addition, they generate heat that is directed back into the bioreactor, providing in hot conditions high performance.

There is someone else. As stated in Microsoft, at the end of the process still remains a certain amount of CO2 as a by-product of electrolysis in fuel cells. The CO2 high enough quality for reuse in industrial purposes. In other words, the installation turns the pollutant into a valuable product and sends it for commercial purposes.

"Information farms usually use enormous amounts of energy. There is a question about providing environmentally responsible electricity. We use biogas as a primary energy source, and the grid acts as a back-up option, i.e., we actually changed the usual pattern. Our intention is to run the install around the middle of next year. Fuel cells are right beside the information centre and the station for processing waste water."

In the words of Botton, at the moment, fuel cells produce electricity at a price of 15 cents per kilowatt. It is quite expensive but you can avoid buying expensive generators. In addition, the energy source is very reliable, and information centers lose a lot of money for every minute of downtime. Yes, it is connected to the network but can work without it.

How far is Microsoft willing to go? Research Manager company Sin, James says that at this time conducted a detailed study of the possibilities of biogas. "Our pilot project designed to find stable, clean, customized, and cost-effective source of energy information centres," he says. – I hope that this practice will be the best for our equipment and other industries in the future."

right beside information center and the station for processing waste water."

Source: /users/104