1009

Biogas plant with their hands: the Internet-myths and reality of rural

Suppose, for example, natural gas in your village was and never will be. And even if there is, it costs money. Although much cheaper than the wasteful heating electricity and liquid fuels. The nearest workshop for the production of pellets is located a few hundred kilometers, to carry expensive. Wood to buy each year more and more difficult, and flushing them troublesome. Against this background, looks very tempting idea to get gratuitous biogas in their yards of weeds, chicken manure, manure from his pigs or the content of the master's outhouse. Just enough to make the bioreactor! On TV talk, as a Thrifty German farmers warm themselves "dung" resources and no "Gazprom" it is now not needed. This is where just saying "with the feces, the film will be removed". The Internet is full of articles and videos on the topic of "biogas from biomass" and "biogas plant with your hands." But on the practical application of technology we know little about the production of biogas at home telling all and Sundry, but the specific examples in the village, as well as the legendary E-Mobility on the road, few seen alive. Try to understand why this is so and what are the prospects for a progressive bio-energy technologies in rural areas.

What is biogas + a bit of history

Biogas is formed by the sequential three-stage decomposition (hydrolysis, acid and smetanoobraznye) of biomass of different species of bacteria. Useful combustible component, methane, can also be hydrogen.

The process of bacterial decomposition, resulting in the formation of combustible methane

To a greater or lesser extent flammable gases are formed during decomposition of any remains of animal and vegetable origin.

The approximate composition of the biogas, the specific proportions of the components used depend on the raw material and technology

People always try to use this kind of fossil fuel, in medieval Chronicles contain mention of the fact that the inhabitants of the lowland areas of present-day Germany even millennia ago received biogas from rotting vegetation, immersing in swamp muck leather bellows. In the dark middle ages and even the enlightened of the century the most talented meteorite, thanks to a specially selected diet knowing how to put and time to burn the abundant methane flatus, causing constant delight of the audience on a fun and fair view. Industrial biogas plants with varying degrees of success began to build in the mid XIX century. In the USSR in 80-e years of the last century was adopted, but not implemented state program on development of the industry, although about a dozen plants still ran. Abroad biogas is improved regarding progressing actively, the total number of working units in the tens of thousands. In developed countries (EEC, USA, Canada, Australia) is a highly automated large complexes in developing (China, India) — artisanal biogas plants for the home and small farms.

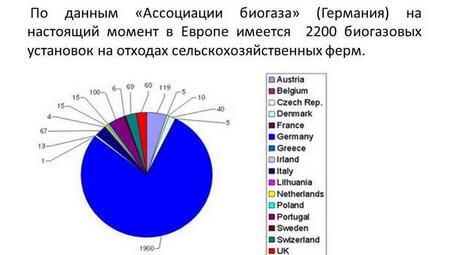

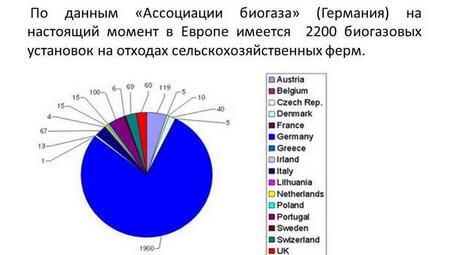

The percentage of the number of biogas plants in EU countries. It is clearly visible that technology is actively developed in Germany, cause — substantial government subsidies and tax incentives

What use is biogas

It is clear that as fuel, since it burns. Heating of industrial and residential buildings, electricity generation, cooking. However, not all so is simple, as shown in the videos scattered around YouTube. Biogas must stably burn in heat generating installations. To do this, its atmospheric parameters it is necessary to lead to rather rigid standards. The methane content should not be below 65% (optimum 90-95%), the hydrogen is missing, water vapor withdrawn, carbon dioxide is removed, the remaining components are inert to high temperatures.

Biogas to be used "manure-animal" origin, are not exempt from the fetid impurity, in residential homes can not.

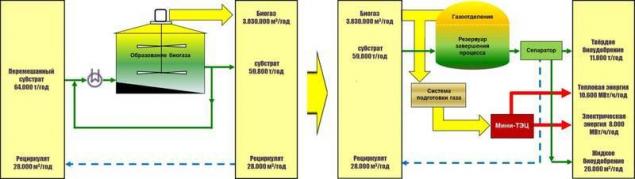

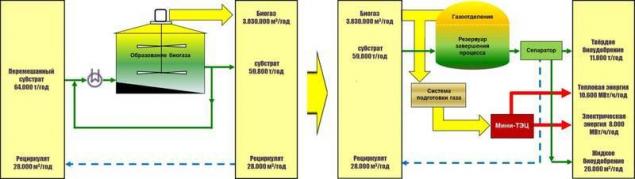

Regulated pressure of 12.5 bar, if the value is less than 8 to 10 bar automation in modern models of heating equipment and kitchen equipment stops the flow of gas. It is very important that the characteristics of the incoming heat source gas was stable. In the case of the pressure surge beyond the norm will work the valve to turn it back on have to manually. Bad, if you are using old gas appliances not equipped with gas control. In the best case can be damaged the burner is heating the boiler. Worst case — the gas will go out but the flow will not stop. And this is fraught with tragedy. To summarize this: characteristics of the biogas must lead to the necessary parameters, and safety precautions to be observed at all times. Simplified process chain for the production of biogas. Important phase — separation and gas

What materials are used for the production of biogas

Plant and animal raw materials

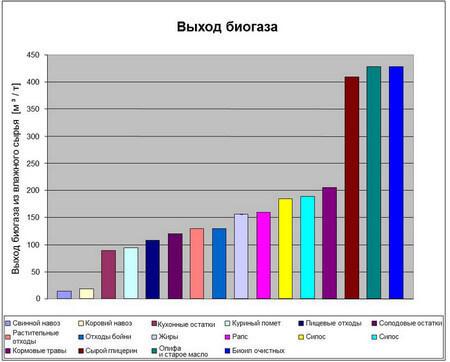

A serious problem faced by households who have installed modern equipment for the production of biogas — raw material must not contain solids, accidentally caught in a mass of stone, a nut, a piece of wire or Board clog the pipeline will damage expensive fecal pump or stirrer. I must say that given data on the maximum exit gas from the raw material correspond to ideal laboratory conditions. To zoom in the actual production to these figures, it is necessary to observe some conditions: to maintain the required temperature, stir occasionally finely crushed raw material, to make supplements that activates fermentation, etc. On artisanal installing collected on the recommendation of articles about "production of biogas with their hands", barely can reach 20% of the maximum level of high-tech plants allow to achieve values of 60-95%.

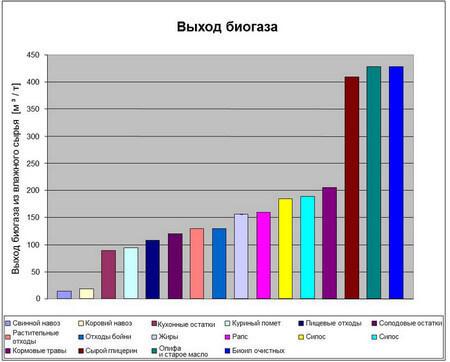

Enough objective data on the maximum biogas yield for different substrate types.

The device of a biogas plant

We have already mentioned that in developed countries, building large industrial plants, and in developing mainly small to small farms. Explain why this:

Is it profitable to produce biofuels at home in small quantities in his household? If you have a few metal barrels and other iron trash, as well as the abyss of free time and you don't know how to dispose of them — Yes. But the savings, alas, is negligible. And to invest in high-tech equipment for small volumes of raw materials and production of methane does not make sense for any scenario.

Another movie domestic Kulibin

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Without mixing the raw material and activation of the fermentation the yield of methane will not exceed 20% of the possible. So, in the best case, 100 kg (loading hopper) select herbs can get 5 m3 uncompressed. And it will be good if the methane content exceeds 50%, and not the fact that it will burn in heat. According to the author, the material is fed on a daily basis, that is, the production cycle from him — one day. In fact, the time required is 60 days. The number obtained by the inventor of the biogas contained in a 50-liter bottle, which he was able to fill in cold weather for boiler capacity 15 kW (residential house approx 150 m2) will last for 2 minutes.

Those whom the possibility of biogas production were interested in, we recommend that you carefully study the problem, especially from a financial point of view, from technical issues to address to the experts having experience of similar works. Would be very valuable practical information received in those households where bioenergy technologies are already in use for some time. published

Source: stroyaqua.com/vodosnab_otopl/kotel/biogazovaya-ustanovka-svoimi-rukami.html

What is biogas + a bit of history

Biogas is formed by the sequential three-stage decomposition (hydrolysis, acid and smetanoobraznye) of biomass of different species of bacteria. Useful combustible component, methane, can also be hydrogen.

The process of bacterial decomposition, resulting in the formation of combustible methane

To a greater or lesser extent flammable gases are formed during decomposition of any remains of animal and vegetable origin.

The approximate composition of the biogas, the specific proportions of the components used depend on the raw material and technology

People always try to use this kind of fossil fuel, in medieval Chronicles contain mention of the fact that the inhabitants of the lowland areas of present-day Germany even millennia ago received biogas from rotting vegetation, immersing in swamp muck leather bellows. In the dark middle ages and even the enlightened of the century the most talented meteorite, thanks to a specially selected diet knowing how to put and time to burn the abundant methane flatus, causing constant delight of the audience on a fun and fair view. Industrial biogas plants with varying degrees of success began to build in the mid XIX century. In the USSR in 80-e years of the last century was adopted, but not implemented state program on development of the industry, although about a dozen plants still ran. Abroad biogas is improved regarding progressing actively, the total number of working units in the tens of thousands. In developed countries (EEC, USA, Canada, Australia) is a highly automated large complexes in developing (China, India) — artisanal biogas plants for the home and small farms.

The percentage of the number of biogas plants in EU countries. It is clearly visible that technology is actively developed in Germany, cause — substantial government subsidies and tax incentives

What use is biogas

It is clear that as fuel, since it burns. Heating of industrial and residential buildings, electricity generation, cooking. However, not all so is simple, as shown in the videos scattered around YouTube. Biogas must stably burn in heat generating installations. To do this, its atmospheric parameters it is necessary to lead to rather rigid standards. The methane content should not be below 65% (optimum 90-95%), the hydrogen is missing, water vapor withdrawn, carbon dioxide is removed, the remaining components are inert to high temperatures.

Biogas to be used "manure-animal" origin, are not exempt from the fetid impurity, in residential homes can not.

Regulated pressure of 12.5 bar, if the value is less than 8 to 10 bar automation in modern models of heating equipment and kitchen equipment stops the flow of gas. It is very important that the characteristics of the incoming heat source gas was stable. In the case of the pressure surge beyond the norm will work the valve to turn it back on have to manually. Bad, if you are using old gas appliances not equipped with gas control. In the best case can be damaged the burner is heating the boiler. Worst case — the gas will go out but the flow will not stop. And this is fraught with tragedy. To summarize this: characteristics of the biogas must lead to the necessary parameters, and safety precautions to be observed at all times. Simplified process chain for the production of biogas. Important phase — separation and gas

What materials are used for the production of biogas

Plant and animal raw materials

- Plant material perfectly suited for the production of biogas: from grass to obtain maximum fuel yield — up to 250 m3 per tonne of feedstock, the methane content of 70%. Slightly less up to 220 m3 can be obtained from corn silage, up to 180 m3 of beet tops. Suitable any green plants, good algae, hay (100 m3 of tons), but to put valuable feed for fuel makes sense only when their apparent abundance. A small methane yield from bagasse, produced during the manufacture of juices, oils and biodiesel, but the material is gratuitous. The disadvantage of vegetable raw materials, long production cycle, 1.5-2 months. It is possible to obtain biogas and cellulose, and other slowly decomposing plant waste, but the efficiency is very low, little methane is produced, the production cycle is very long. In conclusion we can say that the vegetable raw materials must be finely ground.

- Raw materials of animal origin: the traditional barnyard, waste from dairies, abattoirs and processing plants are also suitable, and also in powdered form. The richest "ore" — animal fats, the yield of high-quality biogas with concentration of methane up to 87% 1500 m3 per tonne. However, animal raw materials in short supply and, as a rule, it find another use.

- Manure is cheap and many farms have in abundance, however, the yield and quality of biogas is significantly lower than other types. Cow pies and horse apples can be used in pure form, the fermentation begins immediately, the biogas yield of 60 m2 per tonne of feedstock with low content of methane (60%). The production cycle is short, 10-15 days. Pig manure and chicken manure toxic to the beneficial bacteria can grow, it is mixed with vegetable waste, silage. The big problem present cleaning compositions, surfactants, which are used when cleaning livestock buildings. Coupled with antibiotics, which in large quantities get into the manure, they inhibit the bacterial milieu and inhibit the formation of methane. Do not apply disinfectants not impossible and agribusinesses have invested in gas production from manure, forced to seek a compromise between hygiene and disease control of animals on the one hand and maintaining the productivity of bioreactors on the other.

- Human feces-absolutely free, fit. But the use of conventional sewage unprofitable, too small, the concentration of faeces and high disinfectants, surfactants. Technologists argue that they could be used only in the case that the drain will come "products" just from the toilet, provided that the flushing of the bowl is just one liter of water (standard 4/8 l). And without detergent, of course.

A serious problem faced by households who have installed modern equipment for the production of biogas — raw material must not contain solids, accidentally caught in a mass of stone, a nut, a piece of wire or Board clog the pipeline will damage expensive fecal pump or stirrer. I must say that given data on the maximum exit gas from the raw material correspond to ideal laboratory conditions. To zoom in the actual production to these figures, it is necessary to observe some conditions: to maintain the required temperature, stir occasionally finely crushed raw material, to make supplements that activates fermentation, etc. On artisanal installing collected on the recommendation of articles about "production of biogas with their hands", barely can reach 20% of the maximum level of high-tech plants allow to achieve values of 60-95%.

Enough objective data on the maximum biogas yield for different substrate types.

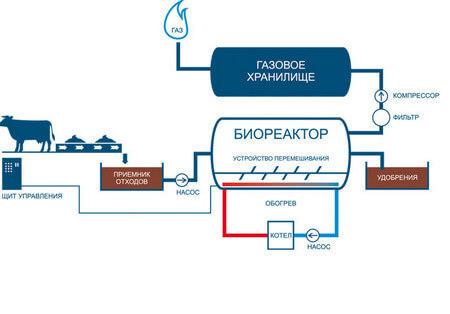

The device of a biogas plant

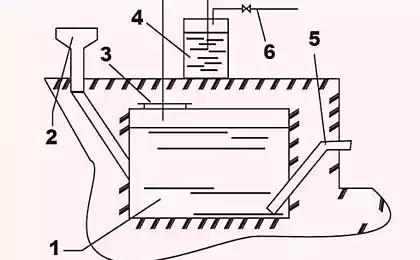

- "Home" biogas plant. As a minimum, you must have two sealed vessel, bioreactor, and storage, in which the tube is given gas. It is desirable to have a third vessel where the biogas will be pumped under pressure, then in the second partially deposited moisture. The design is slightly different from moonshine. The raw material would be good to stir constantly, it needs the agitator and the motor healthy or hardy man. Count on high performance and good quality biogas is not worth.

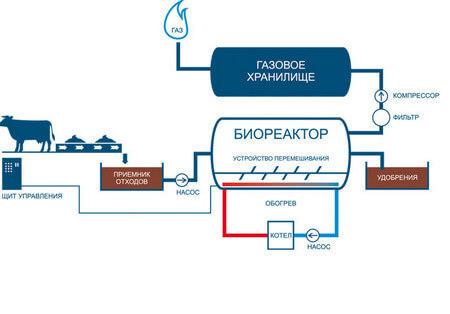

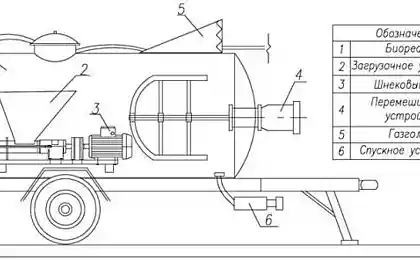

- Industrial installation for production of biogas. We will not go into details, it is better to present the concept:

Equipment includes, as a minimum, the reactor and the gas tank, separator, agitator, pumps, compressor station, system of keeping constant temperature, safety devices, control. For intensification of the processes applied also cavitators, and device for analysis of the environment and of any activators, etc - The composition of produced biogas is necessary to normalize, after he entered the store and dividing the sorption column, then the tank is brought to the required pressure and only then enters the highway leading to the appliance.

Bioenergy production in the modern livestock complex.The inclusion of the greenhouses and plant for the production of fertilizers increases profitability.

We have already mentioned that in developed countries, building large industrial plants, and in developing mainly small to small farms. Explain why this:

- Poor countries. In the primitive setting with its monstrous inefficiency of the entire work can be done manually. For countries where the peasants for their hard work to pay mere pennies, there is a catch. Especially in warm areas and can be harvested several times a year and cheap vegetable raw materials in abundance. Investing in a simple system with relatively small, low quality biogas people are willing to tolerate. The owner is cheaper to put to antediluvian boiler or stove "looking" than the purchase of equipment for the normalization of biogas.

Chinese farmers harvest the raw materials for biogas production - Rich countries. In Germany, the world leader in biogas production, almost half of the poultry farms and large cattle farms produces its own methane. Processes are automated, the quality of biogas is high, production capacity is large. Waste materials undergo additional processing, is mineralized, as a result of the economy get decontaminated non-aggressive complex fertilizer. Despite the high yield of methane from raw materials and considerable energy prices, experts say that for farmers biogas energy production is justified only because the government subsidizes 50% of the cost of the equipment. Additional benefits can be obtained by producing gas from electricity. First, the government buys it at inflated prices; second, this way you can minimize the effects of uneven seasonal production of biogas. For improving the ecological condition of land resulting from the application of manure is not aggressive, and "mild" fertilizer, the state also pays.

Biogas production in Germany: eco-friendly, aesthetically pleasing, thanks to financial aid from the Federal government - Russia. Somehow the biogas energy is developing and we have. From time to time the media report about the start of the next production, in an interview with joyous, a scientist, designer or the Director of agriculture reports that the payback period for installation is one year. But life makes its own adjustments. Over time, it turns out that in the preparation of the business plan did not take into account operating costs, in practice, the exit gas is much lower than planned, and the time of fermentation is much higher. Those who have worked with half a year, has called on the payback period of 5 years. But after this time people generally try not to give an interview. Unfortunately, bioenergy, we are engaged in disparate groups and credible data on profitability in the conditions of Russia. In General, we can assume that, given the lower than in the West, energy prices and the availability of local fuels, biogas production in our country is on the verge of profitability, which is not conducive to its development without state support.

Is it profitable to produce biofuels at home in small quantities in his household? If you have a few metal barrels and other iron trash, as well as the abyss of free time and you don't know how to dispose of them — Yes. But the savings, alas, is negligible. And to invest in high-tech equipment for small volumes of raw materials and production of methane does not make sense for any scenario.

Another movie domestic Kulibin

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Without mixing the raw material and activation of the fermentation the yield of methane will not exceed 20% of the possible. So, in the best case, 100 kg (loading hopper) select herbs can get 5 m3 uncompressed. And it will be good if the methane content exceeds 50%, and not the fact that it will burn in heat. According to the author, the material is fed on a daily basis, that is, the production cycle from him — one day. In fact, the time required is 60 days. The number obtained by the inventor of the biogas contained in a 50-liter bottle, which he was able to fill in cold weather for boiler capacity 15 kW (residential house approx 150 m2) will last for 2 minutes.

Those whom the possibility of biogas production were interested in, we recommend that you carefully study the problem, especially from a financial point of view, from technical issues to address to the experts having experience of similar works. Would be very valuable practical information received in those households where bioenergy technologies are already in use for some time. published

Source: stroyaqua.com/vodosnab_otopl/kotel/biogazovaya-ustanovka-svoimi-rukami.html