584

A simple biogas plant at home

In the courtyard of any economy can be used not only wind, solar, and biogas.

Biogas — gaseous fuel, the product of anaerobic microbial decomposition of organic matter. Biogas technology is the most radical, environmentally friendly, waste-free method of recycling, disposal and decontamination of a variety of organic wastes of vegetable and animal origin.

The conditions for obtaining the energy value of biogas

Those who want to build in the courtyard of small-sized biogas plant, you must know the details of what raw materials and any technology is possible to obtain biogas.

The biogas is produced in anaerobic (without air) fermentation (decomposition) of organic matter (biomass) of different origin: bird droppings, leaves, leaves, straw, stalks of plants and other organic wastes from individual households. Thus, biogas can be produced from all domestic waste, which have the ability to ferment and decompose in liquid or wet state without oxygen. Anaerobic installation (fermenters) make it possible to process any organic mass during this process in two phases: the decomposition of the organic mass (hydration) and its gasification.

Application of organic mass that passed microbiological degradation in biogas plants, increases soil fertility, productivity of various crops by 10-50 %.

Biogas, which is released in a complex process of fermentation of organic wastes, consists of a mixture of gases: methane (marsh gas) — 55-75 %, carbon dioxide — 23-33 %, hydrogen sulphide — 7 %. Methane fermentation is a bacterial process. The main condition of its flow and biogas production — heat biomass without access of air, which can be created in simple biogas plants. Installation easy to build in individual households in the form of special fermenters for fermentation of biomass.

In the household plots, the main raw material for the organic load in the digester is manure.

In the first stage of loading into the capacity of the fermenter of cattle manure, the duration of the fermentation process should be 20 days, the pig manure — 30 days. The greater the amount of gas you get when you download various organic components compared with loading only one component. For example, in the processing of cattle manure and poultry manure in the biogas may contain up to 70 % methane, which significantly increases the efficiency of biogas as fuel. After the process of digestion stabiliziruemost, to load raw materials into the fermenter every day, but not more than 10 % of the number processed in this mass. The recommended humidity of raw materials in the summer of 92-95 %, in winter — 88-90 %.

In the fermenter, along with the production of gas is carried out disinfection of organic waste from pathogenic microorganisms, deodorization emitted unpleasant odors. The resulting brown sludge is periodically discharged from the digester and used as fertilizer.

For heating the processed mass using the heat which is released during its decomposition in biofermentator. When the temperature in the fermenter reduces the intensity of outgassing, as the microbial processes in organic matter slow down. Therefore, reliable thermal insulation of biogas plants (biofermentator) one of the most important conditions for its normal operation.

To ensure the desired mode of fermentation, it is recommended to mix put in the fermenter manure with hot water (preferably 35-40 °C). Heat loss should be minimized also during periodic loading and cleaning of the fermenter. For better heating of the fermenter, you can use the "greenhouse effect". To this end, over the dome install a wooden or light metal frame and covered with plastic wrap. The best results are achieved when the temperature of the raw material, which is fermented, 30-32 °C and humidity 90-95 %. In the South of Ukraine the biogas plant can work effectively without additional heating of organic matter in the fermenter. In the regions of Central and Northern strip of the part of gas produced has to be spent in the cold periods of the year for extra heating the fermented mass, which complicates the design of biogas plants. It is possible that after the first filling of the fermenter and the beginning of the last selection of the gas does not burn. This is because initially the produced gas contains more than 60% carbon dioxide. In this case, it must be released into the atmosphere and after 1-3 days of work biogas plant will occur in a stable manner.

During fermentation of feces from one animal can get per day: cattle (live weight of 500-600 kg) 1,5 cubic metres of biogas, pig (live weight 80-100 kg) of 0.2 cubic meters, chicken or rabbit — 0,015 CBM

One day the fermentation of the cattle manure is formed 36% of the biogas, and pig — 57 %. The amount of energy of 1 cubic meter of biogas is equivalent to 1.5 kg of coal, 0.6 kg of kerosene, 2 kW/h of electricity, 3.5 kg of wood, 12 kg of manure briquettes.

The wide development of biogas technology was in China, they are actively implemented in some countries of Europe, America, Asia and Africa. In Western Europe, such as Romania, Italy, more than 10 years ago has begun to use small-sized biogas plants with the volume of processed raw materials cu. m. of 6-12

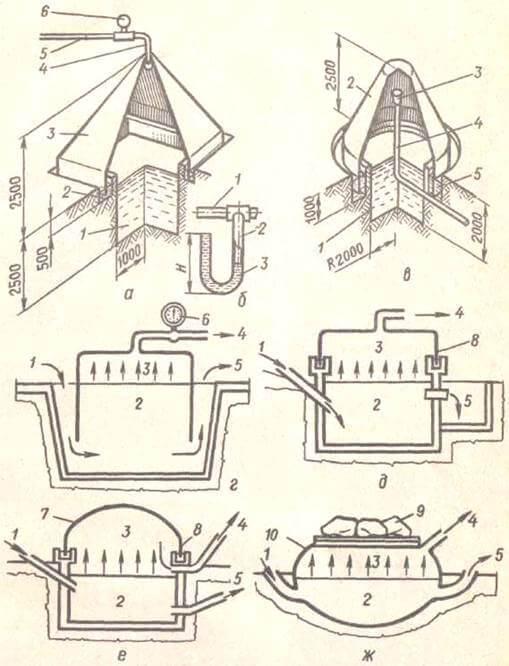

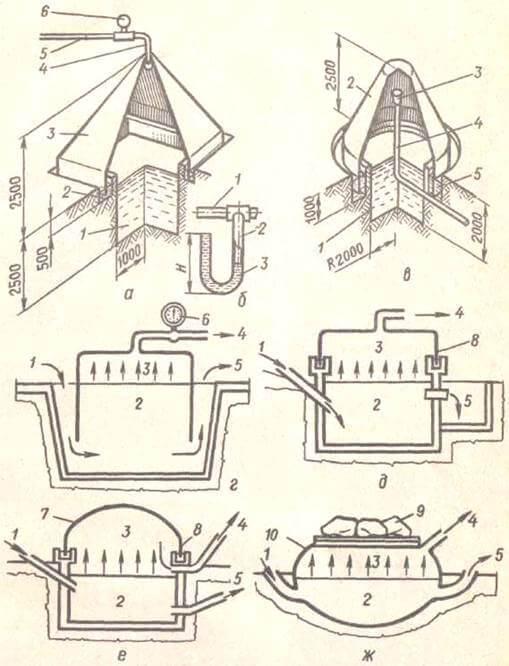

The owners of home gardens and farms in Ukraine also began to show interest in such installations. In the territory of any of the estate can be equipped with one of the most simple biogas plants, which for instance are used in individual farms in Romania. As shown in Fig. 1-a, the size of the equip hole 1 and the dome 3. Pit stone concrete slabs with a thickness of 10 cm, plastered with cement mortar and to seal covered with the resin. Of roofing iron welded bell a height of 3 m, the top of which will be biogas. For corrosion protection the bell periodically paint two coats of oil paint. Even better to pre-coat the inside of the bell with lead minium.

At the top of the bell set, the pipe 4 for discharging the biogas and the pressure gauge 5 for measuring its pressure. The exhaust pipe 6 can be made of rubber hose, a plastic or metal pipe.

Around the hole the fermenter arrange concrete groove-2 water lock filled with water in which is immersed the lower rim of the bell to 0.5 m.

To supply gas to the kitchen stove can be metal, plastic or rubber tubes. To the winter due to freezing of condensed water tube is not broken, apply a simple device (Fig. 1-b): a U-shaped pipe 2 joins pipe 1 at the lowest point. The height of the free part must be larger than the biogas pressure (in mm of water. calendar). 3 the condensate is discharged through the free end of the tube, with no gas leaks.

In the second setup (Fig. 1) a hole 1 with a diameter of 4 mm and depth of 2 m overlaid inside the roofing iron, the leaves of which are densely welded. The inner surface of the welded tank is covered with the resin for corrosion protection. On the outer side of the upper edge of the tank from a concrete throwing ring groove 5 to a depth of 1 m, which is filled with water. It can freely determine the vertical part of the dome 2, closing the reservoir. Thus the groove is filled with water it serves as a water seal. Biogas is collected at the top of the dome, where through the outlet 3 and further through the pipeline 4 (or hose) is supplied to the place of use.

In a round tank 1 is about 12 cubic metres of organic matter (preferably fresh manure), which is filled with liquid fraction of the manure (urine) without adding water. A week after filling the fermenter starts to work. In this installation, the capacity of the fermenter is 12 cubic meters, which gives you the opportunity to build it for 2-3 families whose houses are located nearby. This adjustment can be build in the backyard if the family grows on the contract contains several steers or cows.

Constructive-technological scheme of simple small plants is shown in Fig. 1-g, d, e, f. Arrows indicate the technological displacement of the source of organic matter, gas, ILA. Structurally, the dome can be rigid or made of plastic film. Hard dome can be performed with a long cylindrical part for deep immersion in the processed mass "floating" (Fig. 1-g), or inserted into the hydraulic valve (Fig. 1-d). The dome of the film can be inserted into the water seal (Fig. 1-e) or produce in the form of integrally laminated big bag (Fig. 1-W). In the latest performance in the bag from the film stack cargo 9 so that the bag is not very bloated, and for the formation of a film of sufficient pressure.

Gas, which meets under the dome or plastic, flows through the pipeline to the place of use. To avoid the explosion of gas in the exhaust pipe can be installed is adjusted to a certain pressure valve. However, the danger of a gas explosion is unlikely because when a significant increase of gas pressure under the dome of the latter will be raised through the water seal at the critical height, and will tip over, releasing the gas.

Production of biogas can be reduced due to the fact that on the surface of organic materials in the fermenter when fermentation crust is formed. In order to not let the gas escape, break it, mixing the mass in the fermenter. It is possible to mix manually and not by joining a bottom to the dome of the metal fork. The dome rises in the hydraulic shutter to a certain height by accumulation of gas and falls to the extent of its use.

Through the systematic movement of the dome from the top down, connected with the dome plug will destroy the crust.

High humidity and the presence of hydrogen sulfide (up to 0.5 %) contributes to increased corrosion of metal parts of biogas plants. Therefore, the condition of all the metal elements of the fermenter regularly control and localization in protected carefully, preferably with lead minium in one or two layers, and then paint two coats of any oil paint.

Fig. 1. Circuits of simple biogas plants:

a). with a pyramidal dome: 1 — pit manure; 2 — the groove-hydraulic gate; 3 — bell for collecting gas; 4, 5 — nozzle for discharging gas; 6 — pressure gauge;

b). a device for removing the condensate: 1 — conduit for discharging the gas; 2 — U-shaped pipe for condensate; 3 — condensate;

in). with its conical dome: 1 — pit manure; 2 — the dome (bell); 3 — expanded portion of the pipe; 4 — pipe for the gas outlet; 5 — groove, the water seal;

g, d, e, f — diagram of the simplest settings: 1 — supply of organic waste; 2 — container for organic waste; 3 — the place of gas collection under the dome; 4 — outlet for discharging gas; 5 — sludge; 6 — manometer; 7 — dome of plastic film; 8 — water paddle; 9 — weight; 10 — Casinocity polybag.

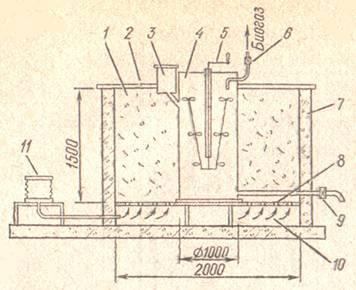

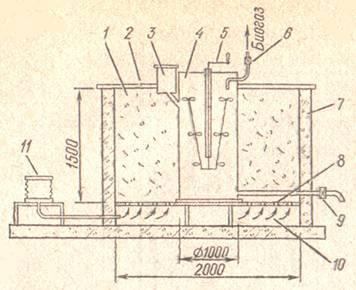

Biogas plant with heating the fermented mass heat released during the decomposition of manure under aerobic digester, shown in Fig. 2, includes a methane tank, a cylindrical metal container with a filling hole 3, the drain valve 9, a mechanical agitator 5 and the pipe 6 biogas extraction.

Fermenter 1 can be made rectangular wooden materials. To unload the processed manure side walls are removable. The floor of the fermenter — lattice, through the technological channel 10 air is blown from the blower 11. On top of the fermenter and cover with wooden boards 2. To reduce heat loss, wall and bottom is made with insulating layer 7.

Works installation. In the methane tank 4 through Golovin 3 pour the previously prepared liquid manure humidity of 88-92 %, the liquid level determined by the bottom of the filler neck. Aerobic fermenter 1 through the top opening of filled litter manure or mixture of manure with loose dry organic litter (straw, sawdust) and humidity of 65-69 %. When the air flow through the process channel in the fermenter begins to decompose organic matter and generate heat. It is sufficient for heating the contents of a methane tank. The result is the release of biogas. It accumulates in the upper part of the methane tank. Through the pipe 6 it is used for household needs. In the process of digestion of the manure in the digester is mixed by the stirrer 5.

This setup will pay for itself in a year only due to the recycling of waste in private households.

Fig. 2. Diagram of a biogas plant with heating:

1 — digester; 2 — wooden shield; 3 — filler; 4 — methane tank; 5 — stirrer; 6 — pipe for biogas extraction; 7 — insulating layer; 8 — grid; 9 — drain valve for processed weight; 10 — channel for air supply; 11 — blower.

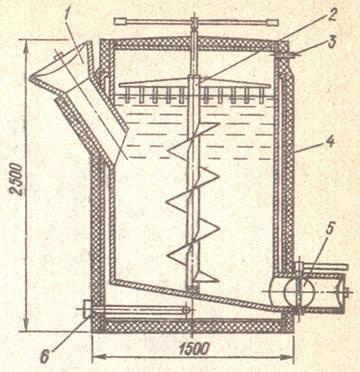

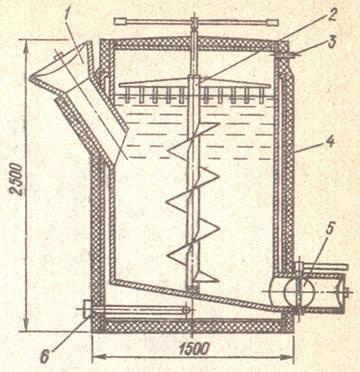

Individual biogas plant (IBGE-1) to a peasant family, having from 2 to 6 cows or pigs 20-60, or 100-300 birds (Fig. 3). Setting daily can process from 100 to 300 kg of manure and produces 100-300 kg of organic fertilizers and 3-12 cubic metres of biogas.

Cooking for a family of 3-4 people, you will need to burn 3-4 cubic meters of biogas per day, for the house heating area 50-60 sq. m — 10-11 cubic meters. the plant can operate in any climatic zone. Their mass production began in the Tula Zavod strojjtekhnika and repair-mechanical plant "Orel" (eagle).

Fig. 3. The circuit of the individual biogas plant ibhu-1:

1 — filler neck; 2 — mixer; 3 — a branch pipe for gas; 4 — insulating layer; 5 — a tube with a tap for discharging processed supply; 6 — thermometer.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: bazila.net/energetika-i-radioelektronika/prostaya-biogazovaya-ustanovka-doma.html

Biogas — gaseous fuel, the product of anaerobic microbial decomposition of organic matter. Biogas technology is the most radical, environmentally friendly, waste-free method of recycling, disposal and decontamination of a variety of organic wastes of vegetable and animal origin.

The conditions for obtaining the energy value of biogas

Those who want to build in the courtyard of small-sized biogas plant, you must know the details of what raw materials and any technology is possible to obtain biogas.

The biogas is produced in anaerobic (without air) fermentation (decomposition) of organic matter (biomass) of different origin: bird droppings, leaves, leaves, straw, stalks of plants and other organic wastes from individual households. Thus, biogas can be produced from all domestic waste, which have the ability to ferment and decompose in liquid or wet state without oxygen. Anaerobic installation (fermenters) make it possible to process any organic mass during this process in two phases: the decomposition of the organic mass (hydration) and its gasification.

Application of organic mass that passed microbiological degradation in biogas plants, increases soil fertility, productivity of various crops by 10-50 %.

Biogas, which is released in a complex process of fermentation of organic wastes, consists of a mixture of gases: methane (marsh gas) — 55-75 %, carbon dioxide — 23-33 %, hydrogen sulphide — 7 %. Methane fermentation is a bacterial process. The main condition of its flow and biogas production — heat biomass without access of air, which can be created in simple biogas plants. Installation easy to build in individual households in the form of special fermenters for fermentation of biomass.

In the household plots, the main raw material for the organic load in the digester is manure.

In the first stage of loading into the capacity of the fermenter of cattle manure, the duration of the fermentation process should be 20 days, the pig manure — 30 days. The greater the amount of gas you get when you download various organic components compared with loading only one component. For example, in the processing of cattle manure and poultry manure in the biogas may contain up to 70 % methane, which significantly increases the efficiency of biogas as fuel. After the process of digestion stabiliziruemost, to load raw materials into the fermenter every day, but not more than 10 % of the number processed in this mass. The recommended humidity of raw materials in the summer of 92-95 %, in winter — 88-90 %.

In the fermenter, along with the production of gas is carried out disinfection of organic waste from pathogenic microorganisms, deodorization emitted unpleasant odors. The resulting brown sludge is periodically discharged from the digester and used as fertilizer.

For heating the processed mass using the heat which is released during its decomposition in biofermentator. When the temperature in the fermenter reduces the intensity of outgassing, as the microbial processes in organic matter slow down. Therefore, reliable thermal insulation of biogas plants (biofermentator) one of the most important conditions for its normal operation.

To ensure the desired mode of fermentation, it is recommended to mix put in the fermenter manure with hot water (preferably 35-40 °C). Heat loss should be minimized also during periodic loading and cleaning of the fermenter. For better heating of the fermenter, you can use the "greenhouse effect". To this end, over the dome install a wooden or light metal frame and covered with plastic wrap. The best results are achieved when the temperature of the raw material, which is fermented, 30-32 °C and humidity 90-95 %. In the South of Ukraine the biogas plant can work effectively without additional heating of organic matter in the fermenter. In the regions of Central and Northern strip of the part of gas produced has to be spent in the cold periods of the year for extra heating the fermented mass, which complicates the design of biogas plants. It is possible that after the first filling of the fermenter and the beginning of the last selection of the gas does not burn. This is because initially the produced gas contains more than 60% carbon dioxide. In this case, it must be released into the atmosphere and after 1-3 days of work biogas plant will occur in a stable manner.

During fermentation of feces from one animal can get per day: cattle (live weight of 500-600 kg) 1,5 cubic metres of biogas, pig (live weight 80-100 kg) of 0.2 cubic meters, chicken or rabbit — 0,015 CBM

One day the fermentation of the cattle manure is formed 36% of the biogas, and pig — 57 %. The amount of energy of 1 cubic meter of biogas is equivalent to 1.5 kg of coal, 0.6 kg of kerosene, 2 kW/h of electricity, 3.5 kg of wood, 12 kg of manure briquettes.

The wide development of biogas technology was in China, they are actively implemented in some countries of Europe, America, Asia and Africa. In Western Europe, such as Romania, Italy, more than 10 years ago has begun to use small-sized biogas plants with the volume of processed raw materials cu. m. of 6-12

The owners of home gardens and farms in Ukraine also began to show interest in such installations. In the territory of any of the estate can be equipped with one of the most simple biogas plants, which for instance are used in individual farms in Romania. As shown in Fig. 1-a, the size of the equip hole 1 and the dome 3. Pit stone concrete slabs with a thickness of 10 cm, plastered with cement mortar and to seal covered with the resin. Of roofing iron welded bell a height of 3 m, the top of which will be biogas. For corrosion protection the bell periodically paint two coats of oil paint. Even better to pre-coat the inside of the bell with lead minium.

At the top of the bell set, the pipe 4 for discharging the biogas and the pressure gauge 5 for measuring its pressure. The exhaust pipe 6 can be made of rubber hose, a plastic or metal pipe.

Around the hole the fermenter arrange concrete groove-2 water lock filled with water in which is immersed the lower rim of the bell to 0.5 m.

To supply gas to the kitchen stove can be metal, plastic or rubber tubes. To the winter due to freezing of condensed water tube is not broken, apply a simple device (Fig. 1-b): a U-shaped pipe 2 joins pipe 1 at the lowest point. The height of the free part must be larger than the biogas pressure (in mm of water. calendar). 3 the condensate is discharged through the free end of the tube, with no gas leaks.

In the second setup (Fig. 1) a hole 1 with a diameter of 4 mm and depth of 2 m overlaid inside the roofing iron, the leaves of which are densely welded. The inner surface of the welded tank is covered with the resin for corrosion protection. On the outer side of the upper edge of the tank from a concrete throwing ring groove 5 to a depth of 1 m, which is filled with water. It can freely determine the vertical part of the dome 2, closing the reservoir. Thus the groove is filled with water it serves as a water seal. Biogas is collected at the top of the dome, where through the outlet 3 and further through the pipeline 4 (or hose) is supplied to the place of use.

In a round tank 1 is about 12 cubic metres of organic matter (preferably fresh manure), which is filled with liquid fraction of the manure (urine) without adding water. A week after filling the fermenter starts to work. In this installation, the capacity of the fermenter is 12 cubic meters, which gives you the opportunity to build it for 2-3 families whose houses are located nearby. This adjustment can be build in the backyard if the family grows on the contract contains several steers or cows.

Constructive-technological scheme of simple small plants is shown in Fig. 1-g, d, e, f. Arrows indicate the technological displacement of the source of organic matter, gas, ILA. Structurally, the dome can be rigid or made of plastic film. Hard dome can be performed with a long cylindrical part for deep immersion in the processed mass "floating" (Fig. 1-g), or inserted into the hydraulic valve (Fig. 1-d). The dome of the film can be inserted into the water seal (Fig. 1-e) or produce in the form of integrally laminated big bag (Fig. 1-W). In the latest performance in the bag from the film stack cargo 9 so that the bag is not very bloated, and for the formation of a film of sufficient pressure.

Gas, which meets under the dome or plastic, flows through the pipeline to the place of use. To avoid the explosion of gas in the exhaust pipe can be installed is adjusted to a certain pressure valve. However, the danger of a gas explosion is unlikely because when a significant increase of gas pressure under the dome of the latter will be raised through the water seal at the critical height, and will tip over, releasing the gas.

Production of biogas can be reduced due to the fact that on the surface of organic materials in the fermenter when fermentation crust is formed. In order to not let the gas escape, break it, mixing the mass in the fermenter. It is possible to mix manually and not by joining a bottom to the dome of the metal fork. The dome rises in the hydraulic shutter to a certain height by accumulation of gas and falls to the extent of its use.

Through the systematic movement of the dome from the top down, connected with the dome plug will destroy the crust.

High humidity and the presence of hydrogen sulfide (up to 0.5 %) contributes to increased corrosion of metal parts of biogas plants. Therefore, the condition of all the metal elements of the fermenter regularly control and localization in protected carefully, preferably with lead minium in one or two layers, and then paint two coats of any oil paint.

Fig. 1. Circuits of simple biogas plants:

a). with a pyramidal dome: 1 — pit manure; 2 — the groove-hydraulic gate; 3 — bell for collecting gas; 4, 5 — nozzle for discharging gas; 6 — pressure gauge;

b). a device for removing the condensate: 1 — conduit for discharging the gas; 2 — U-shaped pipe for condensate; 3 — condensate;

in). with its conical dome: 1 — pit manure; 2 — the dome (bell); 3 — expanded portion of the pipe; 4 — pipe for the gas outlet; 5 — groove, the water seal;

g, d, e, f — diagram of the simplest settings: 1 — supply of organic waste; 2 — container for organic waste; 3 — the place of gas collection under the dome; 4 — outlet for discharging gas; 5 — sludge; 6 — manometer; 7 — dome of plastic film; 8 — water paddle; 9 — weight; 10 — Casinocity polybag.

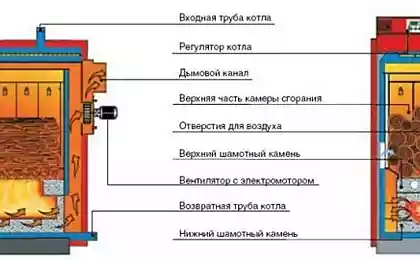

Biogas plant with heating the fermented mass heat released during the decomposition of manure under aerobic digester, shown in Fig. 2, includes a methane tank, a cylindrical metal container with a filling hole 3, the drain valve 9, a mechanical agitator 5 and the pipe 6 biogas extraction.

Fermenter 1 can be made rectangular wooden materials. To unload the processed manure side walls are removable. The floor of the fermenter — lattice, through the technological channel 10 air is blown from the blower 11. On top of the fermenter and cover with wooden boards 2. To reduce heat loss, wall and bottom is made with insulating layer 7.

Works installation. In the methane tank 4 through Golovin 3 pour the previously prepared liquid manure humidity of 88-92 %, the liquid level determined by the bottom of the filler neck. Aerobic fermenter 1 through the top opening of filled litter manure or mixture of manure with loose dry organic litter (straw, sawdust) and humidity of 65-69 %. When the air flow through the process channel in the fermenter begins to decompose organic matter and generate heat. It is sufficient for heating the contents of a methane tank. The result is the release of biogas. It accumulates in the upper part of the methane tank. Through the pipe 6 it is used for household needs. In the process of digestion of the manure in the digester is mixed by the stirrer 5.

This setup will pay for itself in a year only due to the recycling of waste in private households.

Fig. 2. Diagram of a biogas plant with heating:

1 — digester; 2 — wooden shield; 3 — filler; 4 — methane tank; 5 — stirrer; 6 — pipe for biogas extraction; 7 — insulating layer; 8 — grid; 9 — drain valve for processed weight; 10 — channel for air supply; 11 — blower.

Individual biogas plant (IBGE-1) to a peasant family, having from 2 to 6 cows or pigs 20-60, or 100-300 birds (Fig. 3). Setting daily can process from 100 to 300 kg of manure and produces 100-300 kg of organic fertilizers and 3-12 cubic metres of biogas.

Cooking for a family of 3-4 people, you will need to burn 3-4 cubic meters of biogas per day, for the house heating area 50-60 sq. m — 10-11 cubic meters. the plant can operate in any climatic zone. Their mass production began in the Tula Zavod strojjtekhnika and repair-mechanical plant "Orel" (eagle).

Fig. 3. The circuit of the individual biogas plant ibhu-1:

1 — filler neck; 2 — mixer; 3 — a branch pipe for gas; 4 — insulating layer; 5 — a tube with a tap for discharging processed supply; 6 — thermometer.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: bazila.net/energetika-i-radioelektronika/prostaya-biogazovaya-ustanovka-doma.html