1402

How to build a plant for biogas production: the bioreactor are doing with their hands

The constant increase of the cost of traditional energy sources is pushing domestic artists to create improvised equipment, allowing to obtain biogas from the waste with their hands. This approach to farming could not only to get cheap energy for home heating and other needs, but to make the process of recycling of organic waste and get free fertilizer for subsequent inclusion into the soil.

Surplus production of biogas and fertilizers, can be realized at market value to interested consumers, making the money that just "lying underfoot". Large farmers can afford to buy a ready-made station for the generation of biogas collected in the factory. The cost of such equipment is quite high. However, the impact of its operation corresponds to the investments made. Less powerful machines working on the same principle, you can assemble their own from available materials and parts.

This video shows a small unit, which allows to obtain biogas from manure. In the bioreactor load the waste products of livestock (100 kg/day).

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

What is biogas and how is it formed?

Biogas is considered to be a clean fuel. Its characteristics Beulah largely converges with the natural gas produced in industrial scale. To introduce the technology of biogas production in the following way:

How to build a bioreactor on their own?

To start I would like to indicate which design can build:

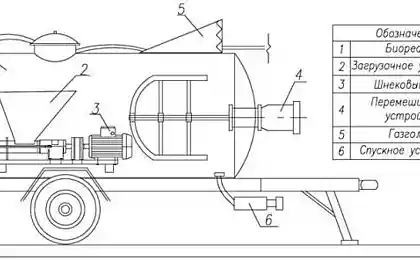

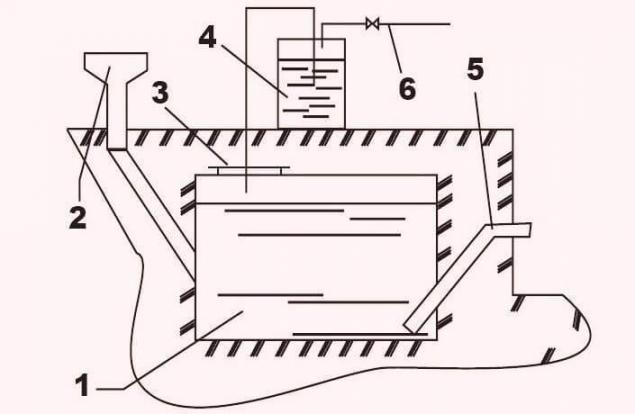

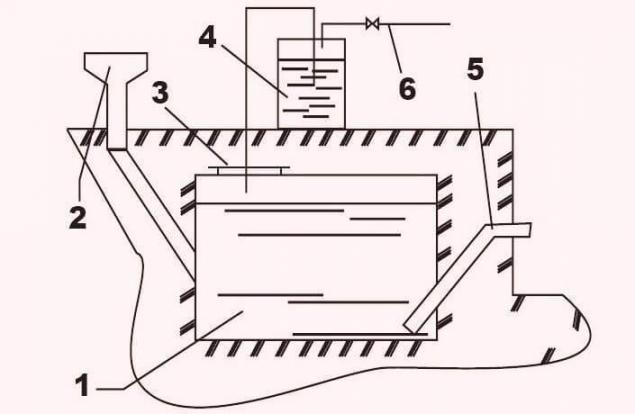

Diagram of a simple biogas plants, collect their forces. Its design cannot accommodate the presence of the heated mixing device. Legend: 1 — reactor (digester) for the processing of manure; 2 — hopper for loading raw material; 3 — hatch; 4 — hydraulic gate; 5 — pipe for the discharge of mining; 6 — pipe for discharging the biogas

To get free biofuels it would be necessary to choose a place for construction of reinforced concrete tank, which will serve as a bioreactor. In this capacity include the presence of holes, through which will be disposed of waste materials. This hole should be closed tightly, because the system works effectively only in airtight conditions.

The size of the concrete tank is determined from the amount of organic waste is created every day in a private farmstead or farm. Full bioreactor operation is possible in the case of filling two-thirds of the available capacity.

In the hermetic vessel of the bioreactor, buried in the ground, serves organic waste, which in the fermentation process promotes the release of biogas

When a small amount of waste concrete tank can be replaced by metal container, for example keg. P

ri the choice of container made of metal please note the presence of welds and their strength. Remember that to get a large number of biogas in small containers will not work. The output depends on the mass of the treated in the reactor organic waste. So to get 100 cubic metres of biogas, it is necessary to process a ton of organic waste.

How to ensure the active biomass?

To speed up the fermentation process of biomass with help of its heating. As a rule, in the southern regions don't have this problem. Ambient air temperature enough to activate the natural processes of fermentation. In regions with harsh climatic conditions in winter without heating is generally impossible the operation of the installation for production of biogas. After the fermentation process starts at a temperature exceeding the mark of 38 degrees Celsius.

Arrange heating of the reservoir with biomass in several ways:

Such temperature control system installed in the boilers, so they can be purchased in stores specializing in the sale of gas equipment.

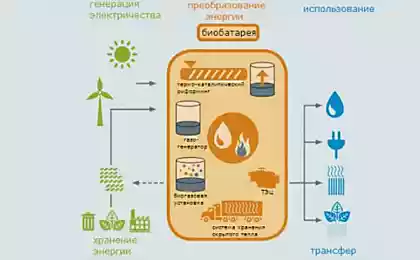

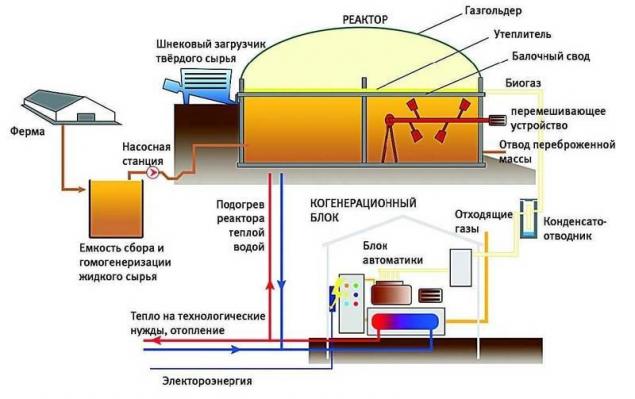

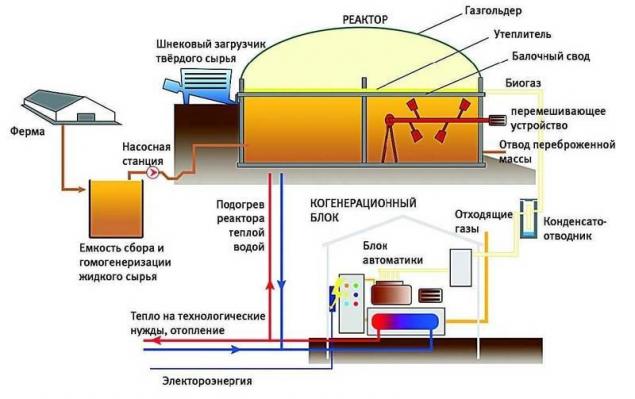

Organization of production of biogas at home. The diagram shows the entire cycle, from the loading of solid and liquid raw materials and ending with diversion of biogas to the consumers

It is important to note that to activate the production of biogas at home, you can use mixing biomass in the reactor. This made the device structurally similar to a household mixer. Allow device movement shaft, which is output through the hole located in the lid or the tank walls.

Correct gas outlet of the bioreactor

Produced in the fermentation process of organic gas is removed through a special hole provided in the design of the top of the lid which tightly closes the reservoir. To eliminate the possibility of mixing of biogas with air, it is necessary to ensure its removal through a water trap (water trap).

To control the pressure of the gas mixture inside the bioreactor by using the cover that is the excess gas to rise, that is, to play the role of a release valve. As opposed to use a normal weight. If the pressure is normal, then the generated gas will flow in the discharge pipe in the gas tank, on the way being subjected to cleaning in water.

Pipe installation for the production of biogas can allow to save on the payment of energy occupying a large share in determining the cost of agricultural products. Reduction in costs of production affect the profitability of the farm or backyard. Now that you know how to get from existing waste biogas, can only realize the idea in practice. Many farmers have long learned from manure to make money.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: aqua-rmnt.com/otoplenie/alt_otoplenie/kak-poluchit-biogaz.html

Surplus production of biogas and fertilizers, can be realized at market value to interested consumers, making the money that just "lying underfoot". Large farmers can afford to buy a ready-made station for the generation of biogas collected in the factory. The cost of such equipment is quite high. However, the impact of its operation corresponds to the investments made. Less powerful machines working on the same principle, you can assemble their own from available materials and parts.

This video shows a small unit, which allows to obtain biogas from manure. In the bioreactor load the waste products of livestock (100 kg/day).

SUBSCRIBE to OUR youtube channel that allows you to watch online, download from YouTube free video about the recovery, the rejuvenation of man. Love for others and ourselves, as the feeling of high vibrations — an important factor for improvement .

Put LIKES and share with your FRIENDS!

www.youtube.com/channel/UCXd71u0w04qcwk32c8kY2BA/videos

Subscribe -https://www.facebook.com//

What is biogas and how is it formed?

Biogas is considered to be a clean fuel. Its characteristics Beulah largely converges with the natural gas produced in industrial scale. To introduce the technology of biogas production in the following way:

- in a special container called a bioreactor, the process of biomass processing, with the participation of anaerobic bacteria in the airless conditions of fermentation for a certain period, the duration of which depends on the amount of loaded material;

- in the result, the isolation of a mixture of gases comprising 60% methane, 35% carbon dioxide, 5% from other gaseous substances, among which are the sulfide in a small amount; the produced gas is continuously removed from the bioreactor and after purification is sent to intended use;

- recycled waste became high-quality fertilizers, are periodically removed from the bioreactor and transported to the fields.

How to build a bioreactor on their own?

To start I would like to indicate which design can build:

Diagram of a simple biogas plants, collect their forces. Its design cannot accommodate the presence of the heated mixing device. Legend: 1 — reactor (digester) for the processing of manure; 2 — hopper for loading raw material; 3 — hatch; 4 — hydraulic gate; 5 — pipe for the discharge of mining; 6 — pipe for discharging the biogas

To get free biofuels it would be necessary to choose a place for construction of reinforced concrete tank, which will serve as a bioreactor. In this capacity include the presence of holes, through which will be disposed of waste materials. This hole should be closed tightly, because the system works effectively only in airtight conditions.

The size of the concrete tank is determined from the amount of organic waste is created every day in a private farmstead or farm. Full bioreactor operation is possible in the case of filling two-thirds of the available capacity.

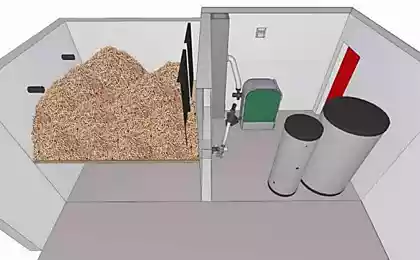

In the hermetic vessel of the bioreactor, buried in the ground, serves organic waste, which in the fermentation process promotes the release of biogas

When a small amount of waste concrete tank can be replaced by metal container, for example keg. P

ri the choice of container made of metal please note the presence of welds and their strength. Remember that to get a large number of biogas in small containers will not work. The output depends on the mass of the treated in the reactor organic waste. So to get 100 cubic metres of biogas, it is necessary to process a ton of organic waste.

How to ensure the active biomass?

To speed up the fermentation process of biomass with help of its heating. As a rule, in the southern regions don't have this problem. Ambient air temperature enough to activate the natural processes of fermentation. In regions with harsh climatic conditions in winter without heating is generally impossible the operation of the installation for production of biogas. After the fermentation process starts at a temperature exceeding the mark of 38 degrees Celsius.

Arrange heating of the reservoir with biomass in several ways:

- to connect to a heating coil located beneath the reactor;

- set basis capacity electric heating elements;

- to provide direct heating of the tank by using electric heaters.

Such temperature control system installed in the boilers, so they can be purchased in stores specializing in the sale of gas equipment.

Organization of production of biogas at home. The diagram shows the entire cycle, from the loading of solid and liquid raw materials and ending with diversion of biogas to the consumers

It is important to note that to activate the production of biogas at home, you can use mixing biomass in the reactor. This made the device structurally similar to a household mixer. Allow device movement shaft, which is output through the hole located in the lid or the tank walls.

Correct gas outlet of the bioreactor

Produced in the fermentation process of organic gas is removed through a special hole provided in the design of the top of the lid which tightly closes the reservoir. To eliminate the possibility of mixing of biogas with air, it is necessary to ensure its removal through a water trap (water trap).

To control the pressure of the gas mixture inside the bioreactor by using the cover that is the excess gas to rise, that is, to play the role of a release valve. As opposed to use a normal weight. If the pressure is normal, then the generated gas will flow in the discharge pipe in the gas tank, on the way being subjected to cleaning in water.

Pipe installation for the production of biogas can allow to save on the payment of energy occupying a large share in determining the cost of agricultural products. Reduction in costs of production affect the profitability of the farm or backyard. Now that you know how to get from existing waste biogas, can only realize the idea in practice. Many farmers have long learned from manure to make money.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: aqua-rmnt.com/otoplenie/alt_otoplenie/kak-poluchit-biogaz.html

The electric version of the BMW 3-Series sedans can be a rival Tesla Model 3

Manufacturers of LED lights solve the problem of a too long life