468

Home reactor for biofuel production

Love French fries? What to do with used vegetable oil? Poured into the sewer? There is a better way! The British company Biobot has developed a small chemical reactor in which vegetable oil is converted to biodiesel suitable for diesel engines.

Diesel fuel is widely used for multiple purposes, chief among them – transportation. It is denser than gasoline, is less dangerous in the fire relation, and the potential to allocate energy 11% more than gasoline. Every year, the world burned about a trillion liters of diesel fuel, are responsible for 10% of greenhouse gas emissions.

Biofuel, or biodiesel – the green alternative to fossil hydrocarbons. It is obtained from organic raw materials in different ways. Among methods of production of biodiesel the most preferable from the point of view of ecology – prerabotka waste.

Usually the production of biofuels are associated with industrial enterprises. Worldwide biodiesel produces about 20 billion litres per year. The British propose to be engaged in this process to anyone that will not only save money, but also to feel a personal involvement in improving the environment.

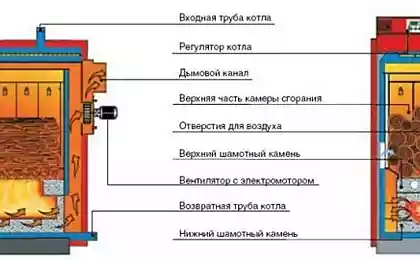

Portable chemical reactor BioBot 20 is advertised as a simple and reliable method of processing waste vegetable oil into biodiesel fuel, suitable for travel by private car. And not just suitable, but more friendly to the engine and clean, practically free of sulfur.

Everything is relative. The process of working with the reactor is really easy to understand and implement virtually anyone. However, there are no miracles, homemade biodiesel requires not only desire, but also certain effort and attention. As for skills, the accompanying instructions, all described in detail.

To obtain about 15 liters of biodiesel (this is the performance of the reactor for one cycle) need unnecessary vegetable oil and a set of chemicals, including methanol and sodium hydroxide or potassium hydroxide.

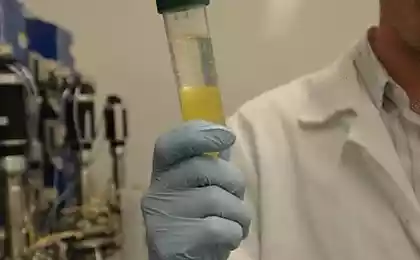

Briefly, the process of home "dizolvarea" as follows. Used oil is poured into the reactor and heated to the desired temperature while stirring. After heating, you will need to make an Express analysis of the quality of raw materials to determine the required amount of reagents that should be added.

Then the mixture of reagents is pumped into the BioBot 20 and starts the reaction converting the oil into biofuel lasting up to a day. At the end of the reaction from the camera are merged by-products, and the resultant oil is washed with water.

The value of the biofuels taking into account the purchase of reagents and a zero cost for raw materials is about € 0,25 per liter. The reactor itself BioBot 20 is sold at a price of 500 euros. Details of the production process, see the video.

Source: /users/104

Diesel fuel is widely used for multiple purposes, chief among them – transportation. It is denser than gasoline, is less dangerous in the fire relation, and the potential to allocate energy 11% more than gasoline. Every year, the world burned about a trillion liters of diesel fuel, are responsible for 10% of greenhouse gas emissions.

Biofuel, or biodiesel – the green alternative to fossil hydrocarbons. It is obtained from organic raw materials in different ways. Among methods of production of biodiesel the most preferable from the point of view of ecology – prerabotka waste.

Usually the production of biofuels are associated with industrial enterprises. Worldwide biodiesel produces about 20 billion litres per year. The British propose to be engaged in this process to anyone that will not only save money, but also to feel a personal involvement in improving the environment.

Portable chemical reactor BioBot 20 is advertised as a simple and reliable method of processing waste vegetable oil into biodiesel fuel, suitable for travel by private car. And not just suitable, but more friendly to the engine and clean, practically free of sulfur.

Everything is relative. The process of working with the reactor is really easy to understand and implement virtually anyone. However, there are no miracles, homemade biodiesel requires not only desire, but also certain effort and attention. As for skills, the accompanying instructions, all described in detail.

To obtain about 15 liters of biodiesel (this is the performance of the reactor for one cycle) need unnecessary vegetable oil and a set of chemicals, including methanol and sodium hydroxide or potassium hydroxide.

Briefly, the process of home "dizolvarea" as follows. Used oil is poured into the reactor and heated to the desired temperature while stirring. After heating, you will need to make an Express analysis of the quality of raw materials to determine the required amount of reagents that should be added.

Then the mixture of reagents is pumped into the BioBot 20 and starts the reaction converting the oil into biofuel lasting up to a day. At the end of the reaction from the camera are merged by-products, and the resultant oil is washed with water.

The value of the biofuels taking into account the purchase of reagents and a zero cost for raw materials is about € 0,25 per liter. The reactor itself BioBot 20 is sold at a price of 500 euros. Details of the production process, see the video.

Source: /users/104