533

Fuel from sewage pipes are our future, and it is closer than we could imagine

Hard to imagine, but thanks to new research National laboratory Pacific Northwest Department of energy, plants on purification of sewage on the territory of the United States can transform organic waste into biodiesel or "green diesel".

To create a crude oil uses a technology called hydrothermal liquefaction, simulating the geological conditions of the Earth. With the use of high pressure and temperatures in a matter of minutes, you can achieve the effect for which mother nature takes millions of years. The resulting material is similar to conventional oil, with a small amount of water and oxygen in the mixture. In the future, the biodiesel is cleaned using conventional refining operations.

Station for the wastewater treatment throughout the U.S. daily to process about 34 billion gallons of sewage. Of this amount, it is possible to produce up to 30 million barrels of biofuel per year. According to the assessment of Pacific Northwest national laboratory (SSNL) one person can generate 2 to 3 litres of biofuel per year.

Wastewater, and more specifically wastewater sludge, has long not been considered as a suitable component for the production of biofuels, because they are too liquid. Approach, the study of which is engaged in SSNL, eliminates the need for drying, unlike the majority of modern thermal technology, which made the process of converting waste water into fuel is too energy intensive and costly. For the production of fuel from other types of wet organic materials such as agricultural waste, can also be used for hydrothermal liquefaction.

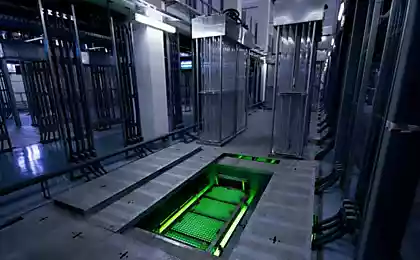

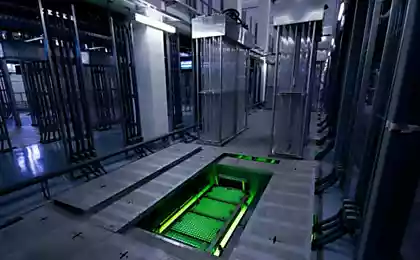

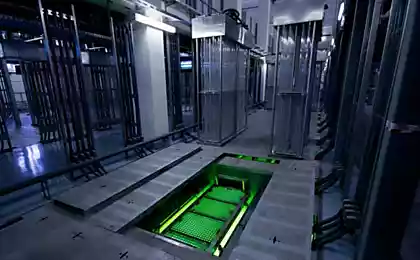

Using hydrothermal liquefaction, organic substances such as human waste, are broken down into simpler chemical compounds. The substance is pressurized to 3000 pounds per square inch, almost a hundred times more than a car tire. The compressed sludge passes into a reactor system, operated at 660 degrees Fahrenheit. Heat and pressure forces the waste to split into separate factions – the biofuels and the liquid component.

Corinne Drennan, responsible for research of bioenergy technologies in SSNL, argues that urban wastewater is a lot of carbon as well as fat. Apparently, the fats or lipids facilitate the decomposition of various materials such as toilet paper, in the wastewater. Thanks to them, the sediment passes through the reactor, and we get top quality fuel – gasoline, diesel fuel and jet fuel.

In addition to the production of fuel system hydrothermal liquefaction significantly reduced the expenses of local authorities on the treatment of industrial wastes, their transport and disposal.

Simple and effective technology.

Drennan believes that the most beautiful in the recycling process is its simplicity. For six years they have greatly accelerated hydrothermal conversion technology and created a continuous and variable process, involving the use of liquid wastes such as wastewater sludge.

According to the Fund of the aquatic environment and its re-use, system for hydrothermal liquefaction is a technology of the future. Soon it is planned the presentation of this method.

The system in operation.

DSNL received a patent for a system for hydrothermal liquefaction in Utah in the "Genifuel Corporation", which currently together with "Metro Vancouver" and in partnership with 23 local authorities of Gran Colombia, and Canada are going to build a demonstration plant.

Darrell Mussatto, Chairman of the utilities Committee, Metro Vancouver hopes that they will be the first company for the treatment of waste and carrying out hydrothermal sisenevad in North America. The cost of the pilot project will be from 8 to 9 million dollars. Canada and Metro Vancouver will take almost half the cost, as well as involve external funding.

After receiving funding, Metro Vancouver plans in 2017 to move to the design stage and manufacture of the equipment. In 2018 it is expected to start production.

Mussato also added that if new technology will be a success, this production base will be the beginning of the involvement of Metro Vancouver in the process of treatment of wastewater to produce clean energy.

Forward progress

Due to this, the liquid component, after catalyzation, it is possible to obtain not only biofuels but also other fuels and chemical products. And also produces a small amount of solids that contain important nutrients. The first attempt demonstrated the ability of phosphorus to recovery, it can replace phosphate ore used in the production of fertilizers.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: phys.org/news/2016-11-fuel-sewage-futureand-closer.html

To create a crude oil uses a technology called hydrothermal liquefaction, simulating the geological conditions of the Earth. With the use of high pressure and temperatures in a matter of minutes, you can achieve the effect for which mother nature takes millions of years. The resulting material is similar to conventional oil, with a small amount of water and oxygen in the mixture. In the future, the biodiesel is cleaned using conventional refining operations.

Station for the wastewater treatment throughout the U.S. daily to process about 34 billion gallons of sewage. Of this amount, it is possible to produce up to 30 million barrels of biofuel per year. According to the assessment of Pacific Northwest national laboratory (SSNL) one person can generate 2 to 3 litres of biofuel per year.

Wastewater, and more specifically wastewater sludge, has long not been considered as a suitable component for the production of biofuels, because they are too liquid. Approach, the study of which is engaged in SSNL, eliminates the need for drying, unlike the majority of modern thermal technology, which made the process of converting waste water into fuel is too energy intensive and costly. For the production of fuel from other types of wet organic materials such as agricultural waste, can also be used for hydrothermal liquefaction.

Using hydrothermal liquefaction, organic substances such as human waste, are broken down into simpler chemical compounds. The substance is pressurized to 3000 pounds per square inch, almost a hundred times more than a car tire. The compressed sludge passes into a reactor system, operated at 660 degrees Fahrenheit. Heat and pressure forces the waste to split into separate factions – the biofuels and the liquid component.

Corinne Drennan, responsible for research of bioenergy technologies in SSNL, argues that urban wastewater is a lot of carbon as well as fat. Apparently, the fats or lipids facilitate the decomposition of various materials such as toilet paper, in the wastewater. Thanks to them, the sediment passes through the reactor, and we get top quality fuel – gasoline, diesel fuel and jet fuel.

In addition to the production of fuel system hydrothermal liquefaction significantly reduced the expenses of local authorities on the treatment of industrial wastes, their transport and disposal.

Simple and effective technology.

Drennan believes that the most beautiful in the recycling process is its simplicity. For six years they have greatly accelerated hydrothermal conversion technology and created a continuous and variable process, involving the use of liquid wastes such as wastewater sludge.

According to the Fund of the aquatic environment and its re-use, system for hydrothermal liquefaction is a technology of the future. Soon it is planned the presentation of this method.

The system in operation.

DSNL received a patent for a system for hydrothermal liquefaction in Utah in the "Genifuel Corporation", which currently together with "Metro Vancouver" and in partnership with 23 local authorities of Gran Colombia, and Canada are going to build a demonstration plant.

Darrell Mussatto, Chairman of the utilities Committee, Metro Vancouver hopes that they will be the first company for the treatment of waste and carrying out hydrothermal sisenevad in North America. The cost of the pilot project will be from 8 to 9 million dollars. Canada and Metro Vancouver will take almost half the cost, as well as involve external funding.

After receiving funding, Metro Vancouver plans in 2017 to move to the design stage and manufacture of the equipment. In 2018 it is expected to start production.

Mussato also added that if new technology will be a success, this production base will be the beginning of the involvement of Metro Vancouver in the process of treatment of wastewater to produce clean energy.

Forward progress

Due to this, the liquid component, after catalyzation, it is possible to obtain not only biofuels but also other fuels and chemical products. And also produces a small amount of solids that contain important nutrients. The first attempt demonstrated the ability of phosphorus to recovery, it can replace phosphate ore used in the production of fertilizers.

P. S. And remember, only by changing their consumption — together we change the world! ©

Source: phys.org/news/2016-11-fuel-sewage-futureand-closer.html

What kind of oil to use for cooking is STRONGLY NOT recommended

On parental guilt: we give what we have