1095

Facilities in Moscow

Most people by pressing the toilet do not think that comes with the fact that they wash. Flowed and flowed, the business then. In such a big city like Moscow a day leaking into the sewage system is not as many as four million cubic meters of wastewater. This is about as much water flows into the Moskva River from the Kremlin for the day. All this huge volume of waste water to be cleaned and the task is very difficult.

In Moscow, there are the two largest treatment plant. It Kuryanovskoy Lyubertsy treatment facilities and wastewater treatment plants, located in the department Mosvodokanal (also in the department of the organization all the water and all drainage). They are among the largest in Europe and take about 2 million cubic meters of wastewater per day. Kuryanovskaya station serves the south-western half of the city Lyubertsy - northeast. There are a number of sewage treatment plants, but they are relatively small.

ech go about Kuryanovskoy treatment plant (WWTP), which are located within the city, and not on the margins, and between residential areas Marino, Nagatino, Saburovo and others.

Kuryanovskoy treatment plant - the oldest. They began to build in 1939, but because of the war work was suspended as a result of the construction have been started only in 1950. At the time, buildings were located far outside of town among the fields and industries.

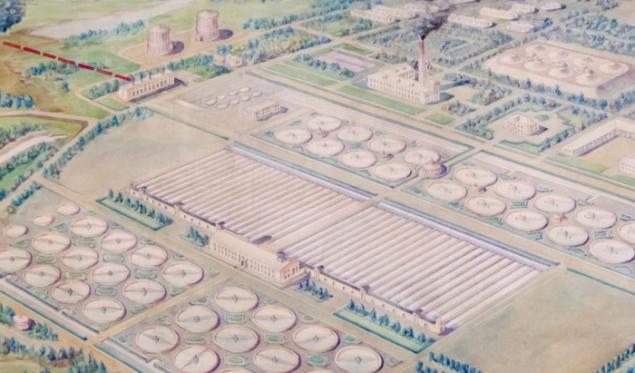

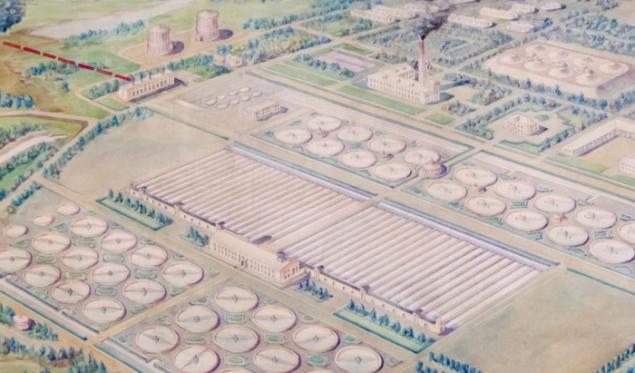

So treatment facilities looked after launch:

The red dotted line shows where flowed sewage. It is also easy to see the narrow winding channel through which in the Moscow River was discharged purified water. Separately pleases the beautiful architecture of the time

Over time, the city grew, and two things happened. First it was the CBS is not outside of the city, and within it, and surrounded by residential areas. Second volume of wastewater has increased and the station had to be expanded. In the 70 years next door to the old treatment were built New Kuryanovskoy treatment plant consisting of two units (NACA-1, 2-NACA).

During the construction of the new units it was also built a new outlet channel. The outlines of the old, you can still see on satellite images. At present, NACA unit-1 (east) is stopped and held reconstruction unit NACA-2 (west) works, but to be reconstructed after the first. Next will be discussed mainly on the block NACA-2. It completely mirrors the block NACA-1.

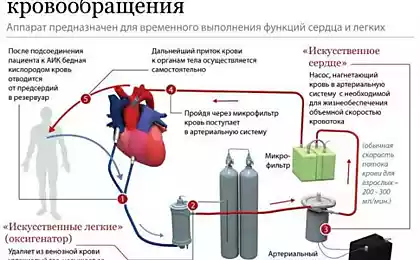

Water purification is carried out in several stages. In order to better understand how and what is happening on the ground, I drew a diagram showing the path of conditional water during cleaning.

It begins with the receiving chamber. A total of three stations receiving chamber. They waste water from urban sewage collectors come to the treatment plant. The objective of the camera is to repay the excessive speed of the flow and distribute the flow into many small channels with laminar flow. It looks like from space, and the first receiving chamber vtrogo blocks NACA:

Waste water flow on the left and right bottom, turn 90 degrees, and distributed in small channels.

Let's go down to the ground :)

In this photo from left to waste water flow, as part of the wastewater flows through a curved pipe and falls straight down (probably to pay off the horizontal flow velocity). This is one of the most foul-smelling places on CBS, for obvious reasons. The truth is actually quite straight Nothing terrible in my opinion no, if not deliberately sniff couples :)

Then the flow is divided into two parts, each of which is then divided by 8 parts. In the photo is the real river of sewage. This is 1/6 of that "produces" Moscow and 1/3 that goes to CBS.

The second channel is closed from mid-2012, as NACA unit-1 is under construction, about which I will tell a bit more detail below. During this time, on the fertile soil had time to grow a whole field. Note the white building on the background - more about him will be discussed.

Each of the smaller channels can overlap their own slide valve if necessary. All valves in the station (and then them in the photo is not enough) and have automated electric.

But the white building, it is called the building grids. To him, underground, through small channels flow fecal water.

Inside the building are installed so-called lattice. This special mechanisms designed to remove solid contaminants present in wastewater. Here is perhaps the most interesting begins.

Grille itself is a kind of conveyor mounted in the flow of water. The conveyor belt consisting of metal plates with holes slowly rotates so horrible garbage does not accumulate, and constantly rises (otherwise grating very quickly be hammered). At the top of the garbage automatic scraper scraped and falls on the moving rubber belt, which passes all lattices. Fascinating spectacle

Long thought to write about this moment or not, but for the sake of objectivity decided to still write. The only thing left a bad impression on the whole station. At the end of the conveyor is aunt, the meaning of work which I do not fully understand. She rakes debris from the edge of the conveyor to the middle. Perhaps this operation is necessary because of a structural flaw. Why it can not be automated is not clear, but I think the reason the fact is. And maybe the problem from the other aunties.

Not a good picture, but well captures the essence:

But the essence is that - do not throw the inorganic waste into the toilet. If you think that you go down the toilet plastic wrap / pad / package / solid piece of food / ... and that's that - you're wrong. All of that goes into the sewer does not disappear to nowhere. All of this falls on the conveyor belt and, moreover, all this sees a living person.

A separate item worth cotton swabs. It turns out they bring a lot of problems. The fact that the rods are in the flow along the flow and become easily overcome lattice as the cross-section is very small, and make a lattice with very small cells can not. As a result of sticks through the stage of mechanical cleaning and clog structures in subsequent stages.

Also employees of the station complained about irresponsibility of people dumping trash into the wells. A particularly acute problem Subbotniks when a large number of wells cleared of leaves and branches, and at the same time throughout the city. People think they are doing good work, but do not think that all this rubbish then arrives at the station and it will have to extract and export.

The building grids divided into two halves, each serving its own block NACA. In the center is equipped descent, apparently to serve grids or some other equipment. The photo also see one lying on the floor grating.

After building gratings water enters the sand trap, which are not difficult to guess, the sand is removed from it. By the way, "mined" sand washed, cleaned and then used for various purposes, including for the construction and for the manufacture of tiles.

Following the sand traps water flows into primary sedimentation tanks in which gravity settle the suspended particles in the water. In total, each block NACA eight primary otsoynikov.

After the water has defended it flows into the aeration tanks. And then it starts the whole essence of biological treatment. In the aeration basin contains a special activated sludge. Roughly speaking, the activated sludge - a mixture of various bacteria and protozoa that process biological waste. In fact, the same processes occur naturally in lakes, where such sludge is at the bottom. However, the difference in the size and speed. The nature of the processes taking place quite slowly, while at their treatment stations must be carried as quickly as possible. For this process dispersed using a huge amount of air flow. Hence the name of the building. In fact it is a large swimming pool, which contains activated sludge, which receives primary treated wastewater and, through a special tube, a huge amount of air. Also a beneficial effect on the process is the fact that the waste water is warm throughout the year.

For air to build a machine room, which are blowers, huge power, pump air into the pipes leading to the aeration tank.

Blowers consume huge amounts of electricity and continuous operation is extremely important. The fact is that, without air supply, activated sludge begins to die within a few hours. During the day he dies completely. If this happens, the restoration of the activated sludge take many months, during which all the wastewater will have to be drained directly into the Moscow River, which will lead to environmental disaster of enormous proportions.

On CBS very well remember the accident in 2005, when half of Moscow has been de-energized. Including electricity for several hours and did not arrive at the station. Since then, much has been done to prevent similar accidents in the future, as will be discussed below.

Air intake for aeration is done through four intake impressive size, standing near the main engine room.

Aeration tank a little bit bigger, pay attention to the large blue tube to the right - it is served on the air:

I can not comment on this process only as "seething Gauvin» :)

Now a little about the reconstruction. NACA first unit was commissioned in the early 70s. In those days, we loved to build with precast concrete. Not difficult to guess that for the forty years of construction have begun to break down and leak, especially in such an aggressive environment. Further facilities just technologically obsolete. Therefore, drafted new facilities in the last year has begun reconstruction.

New facilities are built of reinforced concrete and are designed for 50 years. In addition there will be some change treatment technology that will purify water even better.

Returning to the process of purification. After aeration, the biologically purified water with a mixture of activated sludge flows to secondary settling tanks. The aim of these settlers - to separate activated sludge.

Separately, it should be noted that all of the water flows by gravity on the station. To make this possible - each following structure built below the previous one, so that the water flows under its own weight.

To understand how the settler - let's look at the partially dismantled sump reconstructed block. Water enters from a hole in the center of the sump and enters the total volume. In the settler mud gradually settles on the bottom, in which constantly moving ilosgrebatel attached to the farm, rotating in a circle. Rakes sludge scraper ring special tray, which is visible in the photograph, and from there, in turn, he gets in a round pit, from where is pumped through a pipe with special pumps. Excess water leaked into the channel laid in a circle, and from there into the sump tube.

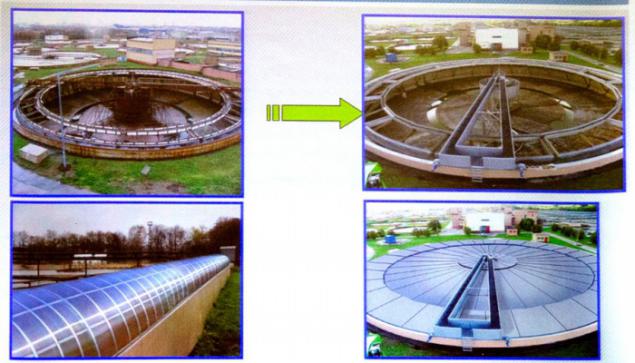

Returning again to the reconstruction :)

One problem is the odor station. As I wrote above - CBS is actually surrounded by residential areas, and to many residential buildings not far. Under certain weather conditions, the smell of the station heard before these houses and received numerous complaints from residents. To get rid of the smell, it was decided to cover the floors of the buildings in the process of reconstruction. The biggest challenge turned out to cover the lagoons. The fact that the diameter is 54 meters (!), With no additional struts could not be considered because of the constantly rotating farm. As a result of the special design was invented floating floors, consisting of two parts. The inner part is rotated together with the farm, outside fixed. As an experiment, similar overlap was set at one settler Lyubertsy treatment facilities and successfully worked for more than three months. Measurements showed that the emissions of odorous gases to the atmosphere were reduced to 33 times.

Let's go back to the sludge. In the process of recycling, sludge actively propagated. Part of the sludge sent to "rest" and then repeatedly allowed to work in the aeration tanks, the excess is sent to the fermentation in the digesters - special floor underground tanks. There sludge is heated to 53-54 degrees, and starts to produce methane. The obtained methane is used for preheating the sludge and for the mini-TES which is constructed after the aforementioned emergency. Mini-thermal power plants generate 10 MW of electricity and 8 MW of heat, providing up to 50% of the technological processes of treatment facilities.

The remaining sludge is a waste product in a certain way to prepare ilouplotnitelyah:

Il partially dewatered and sent special iloprovodu a distance of about 60 kilometers, in the Moscow region to special landfills, where it is further dewatered and either landfilled or used as a raw material. Thus, there is no need to take out the waste from the station by road, which would create a lot of problems.

After secondary settling tanks, virtually pure water flows into the exhaust channel going to the Moscow River. Before cleaning this completed, however, recently it built a new block for additional water disinfection.

So begins the discharge channel length of 700 meters:

The new unit was built directly over the exhaust channel:

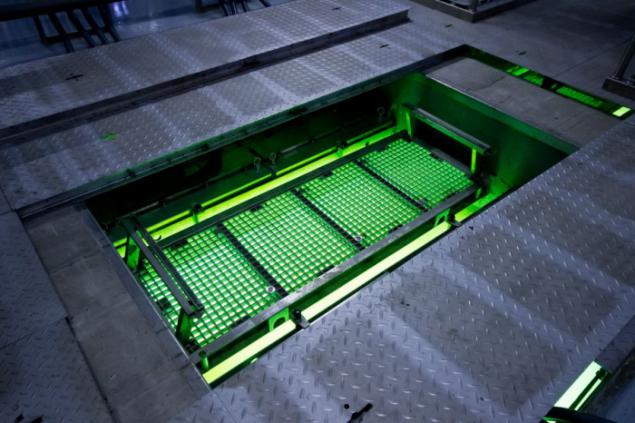

Within a block, the water is divided into 17 parallel channels, each of which can be opened or closed.

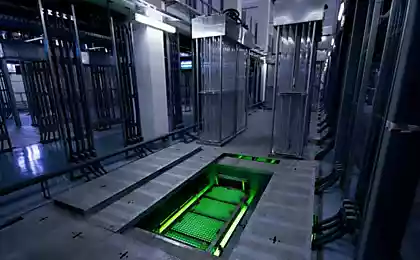

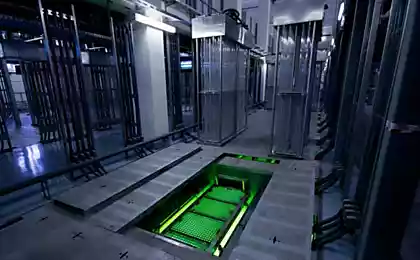

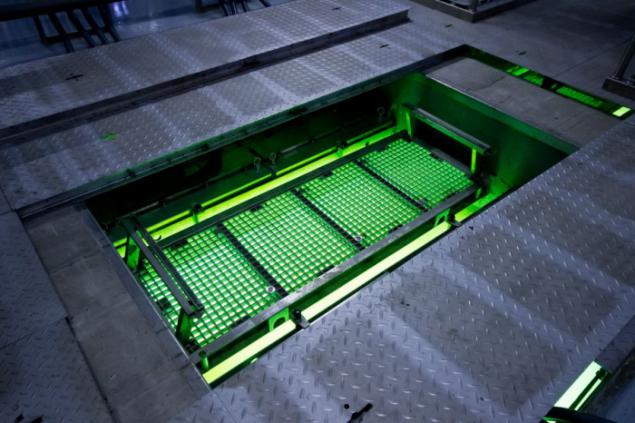

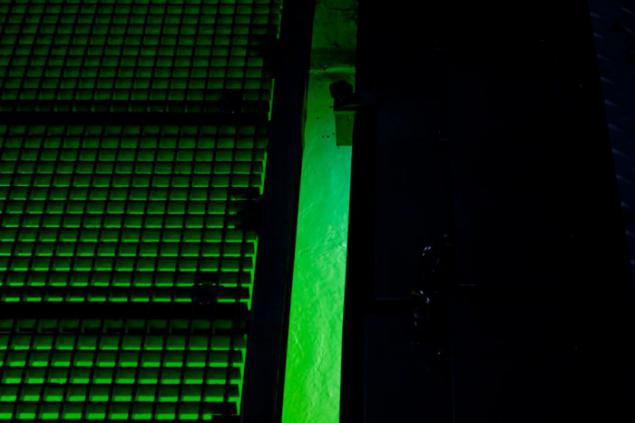

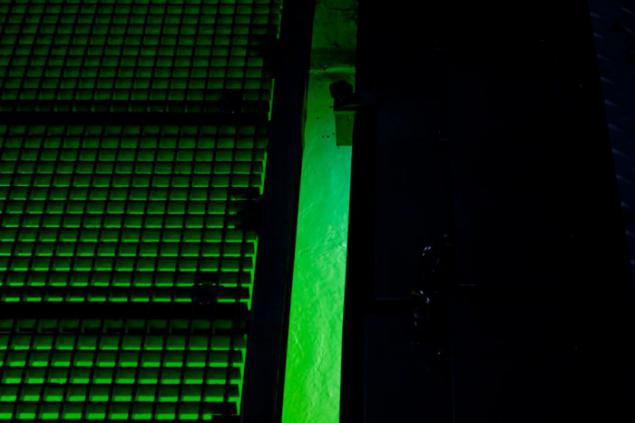

We go inside and get into the HALF-LIFE :)

Additional disinfection is done by hard ultraviolet.

The water fall special blocks comprising a plurality of light-emitting tubes in the UV range of 200-300 nm. It is hard ultraviolet, the most effective impact on microorganisms (resulting in the destruction of DNA, which does not allow them to multiply in the future).

The hall consists of two levels. On the upper level is the control apparatus and the power lamp on the lower level are the cables to the lamps are located hatches for access to running lamps.

Also at the lower level are not used at the moment the lamp. Some channels are currently unused and bulbs are removed. By the way, all made of stainless steel. The fact is that although the water with sewage enters the net, it is highly saturated with air after aeration, and greatly contributes to corrosion.

When the lights under the water, there is a green light. As I understand it the fluorescence of water in the extreme ultraviolet.

The spectacle must say enchanting. The photo can not see the movement of water, but it is there. Looks like in science fiction films or games :)

The output from the block is also installed vane locks on each channel.

Also in the box there is a special room where the water is pumped through a pipe from the exhaust channel. This tube passes through a plurality of sensors that measure a variety of parameters, and displays them in real time and transmitted to the control room. thus constantly monitor the quality of water purification.

Finally cleaned and disinfected water flows from under the UV disinfection unit.

And the long channel is directed straight into the Moscow River. In the channel of the nutrient medium and warm water is found a huge amount of fish. At the station fishing is prohibited, as a special plaque reads, but outside, near the canal can often be found fishermen.

I would like to say a few words about what you do not pass the photo - are employees of CBS. I do not vouch for all-all-all, but the many workers (from superiors to ordinary workers) who have seen - have made the best impression. Kind and sympathetic people enthusiastic about their work. However, perhaps this is not surprising, it seems to me in such places can only enthusiastic people

©

In Moscow, there are the two largest treatment plant. It Kuryanovskoy Lyubertsy treatment facilities and wastewater treatment plants, located in the department Mosvodokanal (also in the department of the organization all the water and all drainage). They are among the largest in Europe and take about 2 million cubic meters of wastewater per day. Kuryanovskaya station serves the south-western half of the city Lyubertsy - northeast. There are a number of sewage treatment plants, but they are relatively small.

ech go about Kuryanovskoy treatment plant (WWTP), which are located within the city, and not on the margins, and between residential areas Marino, Nagatino, Saburovo and others.

Kuryanovskoy treatment plant - the oldest. They began to build in 1939, but because of the war work was suspended as a result of the construction have been started only in 1950. At the time, buildings were located far outside of town among the fields and industries.

So treatment facilities looked after launch:

The red dotted line shows where flowed sewage. It is also easy to see the narrow winding channel through which in the Moscow River was discharged purified water. Separately pleases the beautiful architecture of the time

Over time, the city grew, and two things happened. First it was the CBS is not outside of the city, and within it, and surrounded by residential areas. Second volume of wastewater has increased and the station had to be expanded. In the 70 years next door to the old treatment were built New Kuryanovskoy treatment plant consisting of two units (NACA-1, 2-NACA).

During the construction of the new units it was also built a new outlet channel. The outlines of the old, you can still see on satellite images. At present, NACA unit-1 (east) is stopped and held reconstruction unit NACA-2 (west) works, but to be reconstructed after the first. Next will be discussed mainly on the block NACA-2. It completely mirrors the block NACA-1.

Water purification is carried out in several stages. In order to better understand how and what is happening on the ground, I drew a diagram showing the path of conditional water during cleaning.

It begins with the receiving chamber. A total of three stations receiving chamber. They waste water from urban sewage collectors come to the treatment plant. The objective of the camera is to repay the excessive speed of the flow and distribute the flow into many small channels with laminar flow. It looks like from space, and the first receiving chamber vtrogo blocks NACA:

Waste water flow on the left and right bottom, turn 90 degrees, and distributed in small channels.

Let's go down to the ground :)

In this photo from left to waste water flow, as part of the wastewater flows through a curved pipe and falls straight down (probably to pay off the horizontal flow velocity). This is one of the most foul-smelling places on CBS, for obvious reasons. The truth is actually quite straight Nothing terrible in my opinion no, if not deliberately sniff couples :)

Then the flow is divided into two parts, each of which is then divided by 8 parts. In the photo is the real river of sewage. This is 1/6 of that "produces" Moscow and 1/3 that goes to CBS.

The second channel is closed from mid-2012, as NACA unit-1 is under construction, about which I will tell a bit more detail below. During this time, on the fertile soil had time to grow a whole field. Note the white building on the background - more about him will be discussed.

Each of the smaller channels can overlap their own slide valve if necessary. All valves in the station (and then them in the photo is not enough) and have automated electric.

But the white building, it is called the building grids. To him, underground, through small channels flow fecal water.

Inside the building are installed so-called lattice. This special mechanisms designed to remove solid contaminants present in wastewater. Here is perhaps the most interesting begins.

Grille itself is a kind of conveyor mounted in the flow of water. The conveyor belt consisting of metal plates with holes slowly rotates so horrible garbage does not accumulate, and constantly rises (otherwise grating very quickly be hammered). At the top of the garbage automatic scraper scraped and falls on the moving rubber belt, which passes all lattices. Fascinating spectacle

Long thought to write about this moment or not, but for the sake of objectivity decided to still write. The only thing left a bad impression on the whole station. At the end of the conveyor is aunt, the meaning of work which I do not fully understand. She rakes debris from the edge of the conveyor to the middle. Perhaps this operation is necessary because of a structural flaw. Why it can not be automated is not clear, but I think the reason the fact is. And maybe the problem from the other aunties.

Not a good picture, but well captures the essence:

But the essence is that - do not throw the inorganic waste into the toilet. If you think that you go down the toilet plastic wrap / pad / package / solid piece of food / ... and that's that - you're wrong. All of that goes into the sewer does not disappear to nowhere. All of this falls on the conveyor belt and, moreover, all this sees a living person.

A separate item worth cotton swabs. It turns out they bring a lot of problems. The fact that the rods are in the flow along the flow and become easily overcome lattice as the cross-section is very small, and make a lattice with very small cells can not. As a result of sticks through the stage of mechanical cleaning and clog structures in subsequent stages.

Also employees of the station complained about irresponsibility of people dumping trash into the wells. A particularly acute problem Subbotniks when a large number of wells cleared of leaves and branches, and at the same time throughout the city. People think they are doing good work, but do not think that all this rubbish then arrives at the station and it will have to extract and export.

The building grids divided into two halves, each serving its own block NACA. In the center is equipped descent, apparently to serve grids or some other equipment. The photo also see one lying on the floor grating.

After building gratings water enters the sand trap, which are not difficult to guess, the sand is removed from it. By the way, "mined" sand washed, cleaned and then used for various purposes, including for the construction and for the manufacture of tiles.

Following the sand traps water flows into primary sedimentation tanks in which gravity settle the suspended particles in the water. In total, each block NACA eight primary otsoynikov.

After the water has defended it flows into the aeration tanks. And then it starts the whole essence of biological treatment. In the aeration basin contains a special activated sludge. Roughly speaking, the activated sludge - a mixture of various bacteria and protozoa that process biological waste. In fact, the same processes occur naturally in lakes, where such sludge is at the bottom. However, the difference in the size and speed. The nature of the processes taking place quite slowly, while at their treatment stations must be carried as quickly as possible. For this process dispersed using a huge amount of air flow. Hence the name of the building. In fact it is a large swimming pool, which contains activated sludge, which receives primary treated wastewater and, through a special tube, a huge amount of air. Also a beneficial effect on the process is the fact that the waste water is warm throughout the year.

For air to build a machine room, which are blowers, huge power, pump air into the pipes leading to the aeration tank.

Blowers consume huge amounts of electricity and continuous operation is extremely important. The fact is that, without air supply, activated sludge begins to die within a few hours. During the day he dies completely. If this happens, the restoration of the activated sludge take many months, during which all the wastewater will have to be drained directly into the Moscow River, which will lead to environmental disaster of enormous proportions.

On CBS very well remember the accident in 2005, when half of Moscow has been de-energized. Including electricity for several hours and did not arrive at the station. Since then, much has been done to prevent similar accidents in the future, as will be discussed below.

Air intake for aeration is done through four intake impressive size, standing near the main engine room.

Aeration tank a little bit bigger, pay attention to the large blue tube to the right - it is served on the air:

I can not comment on this process only as "seething Gauvin» :)

Now a little about the reconstruction. NACA first unit was commissioned in the early 70s. In those days, we loved to build with precast concrete. Not difficult to guess that for the forty years of construction have begun to break down and leak, especially in such an aggressive environment. Further facilities just technologically obsolete. Therefore, drafted new facilities in the last year has begun reconstruction.

New facilities are built of reinforced concrete and are designed for 50 years. In addition there will be some change treatment technology that will purify water even better.

Returning to the process of purification. After aeration, the biologically purified water with a mixture of activated sludge flows to secondary settling tanks. The aim of these settlers - to separate activated sludge.

Separately, it should be noted that all of the water flows by gravity on the station. To make this possible - each following structure built below the previous one, so that the water flows under its own weight.

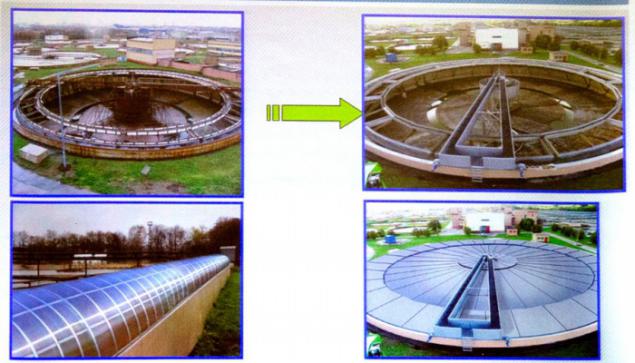

To understand how the settler - let's look at the partially dismantled sump reconstructed block. Water enters from a hole in the center of the sump and enters the total volume. In the settler mud gradually settles on the bottom, in which constantly moving ilosgrebatel attached to the farm, rotating in a circle. Rakes sludge scraper ring special tray, which is visible in the photograph, and from there, in turn, he gets in a round pit, from where is pumped through a pipe with special pumps. Excess water leaked into the channel laid in a circle, and from there into the sump tube.

Returning again to the reconstruction :)

One problem is the odor station. As I wrote above - CBS is actually surrounded by residential areas, and to many residential buildings not far. Under certain weather conditions, the smell of the station heard before these houses and received numerous complaints from residents. To get rid of the smell, it was decided to cover the floors of the buildings in the process of reconstruction. The biggest challenge turned out to cover the lagoons. The fact that the diameter is 54 meters (!), With no additional struts could not be considered because of the constantly rotating farm. As a result of the special design was invented floating floors, consisting of two parts. The inner part is rotated together with the farm, outside fixed. As an experiment, similar overlap was set at one settler Lyubertsy treatment facilities and successfully worked for more than three months. Measurements showed that the emissions of odorous gases to the atmosphere were reduced to 33 times.

Let's go back to the sludge. In the process of recycling, sludge actively propagated. Part of the sludge sent to "rest" and then repeatedly allowed to work in the aeration tanks, the excess is sent to the fermentation in the digesters - special floor underground tanks. There sludge is heated to 53-54 degrees, and starts to produce methane. The obtained methane is used for preheating the sludge and for the mini-TES which is constructed after the aforementioned emergency. Mini-thermal power plants generate 10 MW of electricity and 8 MW of heat, providing up to 50% of the technological processes of treatment facilities.

The remaining sludge is a waste product in a certain way to prepare ilouplotnitelyah:

Il partially dewatered and sent special iloprovodu a distance of about 60 kilometers, in the Moscow region to special landfills, where it is further dewatered and either landfilled or used as a raw material. Thus, there is no need to take out the waste from the station by road, which would create a lot of problems.

After secondary settling tanks, virtually pure water flows into the exhaust channel going to the Moscow River. Before cleaning this completed, however, recently it built a new block for additional water disinfection.

So begins the discharge channel length of 700 meters:

The new unit was built directly over the exhaust channel:

Within a block, the water is divided into 17 parallel channels, each of which can be opened or closed.

We go inside and get into the HALF-LIFE :)

Additional disinfection is done by hard ultraviolet.

The water fall special blocks comprising a plurality of light-emitting tubes in the UV range of 200-300 nm. It is hard ultraviolet, the most effective impact on microorganisms (resulting in the destruction of DNA, which does not allow them to multiply in the future).

The hall consists of two levels. On the upper level is the control apparatus and the power lamp on the lower level are the cables to the lamps are located hatches for access to running lamps.

Also at the lower level are not used at the moment the lamp. Some channels are currently unused and bulbs are removed. By the way, all made of stainless steel. The fact is that although the water with sewage enters the net, it is highly saturated with air after aeration, and greatly contributes to corrosion.

When the lights under the water, there is a green light. As I understand it the fluorescence of water in the extreme ultraviolet.

The spectacle must say enchanting. The photo can not see the movement of water, but it is there. Looks like in science fiction films or games :)

The output from the block is also installed vane locks on each channel.

Also in the box there is a special room where the water is pumped through a pipe from the exhaust channel. This tube passes through a plurality of sensors that measure a variety of parameters, and displays them in real time and transmitted to the control room. thus constantly monitor the quality of water purification.

Finally cleaned and disinfected water flows from under the UV disinfection unit.

And the long channel is directed straight into the Moscow River. In the channel of the nutrient medium and warm water is found a huge amount of fish. At the station fishing is prohibited, as a special plaque reads, but outside, near the canal can often be found fishermen.

I would like to say a few words about what you do not pass the photo - are employees of CBS. I do not vouch for all-all-all, but the many workers (from superiors to ordinary workers) who have seen - have made the best impression. Kind and sympathetic people enthusiastic about their work. However, perhaps this is not surprising, it seems to me in such places can only enthusiastic people

©