1358

Lyubertsy treatment facilities - as purified

Most people by pressing the toilet do not realize what's going on so that they wash. Flowed and flowed, the business is. In a big city like Moscow a day leaking into the sewage system is not as many as four million cubic meters of wastewater. This is about as much as the water flows into the Moskva River from the Kremlin for the day. All this huge amount of waste water to be cleaned and the task is very difficult.

In Moscow, the two largest wastewater treatment plant, about the same size. Each of them cleans half of what "makes" Moscow. About Kuryanovskoy station I already spoke in detail. Today I will talk about Lyuberetskaya station - we again go over the main stages of water treatment, but also touch on a very important subject - both treatment plants are struggling with unpleasant odors by using low-temperature plasma and waste the perfume industry and why this problem has become even more relevant than ever .

50 photos + letters via alex-avr2

First, a little history. For the first time sewerage "came" to the area of modern Lyuberets in the early twentieth century. Then were created Luberetskiy field irrigation, in which the wastewater is still on the old technology seeps through the ground and thus cleaned. Over time, this technology has become unacceptable to an increasing number of waste water and in 1963 built a new treatment plant - Lyuberetskaya. A little later built another station - Novolyuberetskaya actually bordering on the first and uses a part of its infrastructure. In fact now it is one large treatment plant, but made up of two parts - the old and the new.

Take a look at the map - the left, to the west - the old part of the station, on the right, in the east - new:

The area of the station - a huge, straight from corner to corner about two kilometers.

Not difficult to guess - the station is the smell. Previously, he was a little worried about someone, and now this problem has become urgent for two main reasons:

1) When the station was built in the '60s, around almost no one lived. Nearby was a small village, where they lived the workers themselves station. Then the area was far away from Moscow. Now there is a very active development. Station actually surrounded on all sides and new buildings will be more of them. New houses are built on the former even sludge plant site (field, which dumped the remaining sludge from waste water treatment). As a result, residents of nearby houses have to periodically sniff "sewer" smell, and of course they are always complaining.

2) Discharge of water become more concentrated than in the past, in Soviet times. This happened due to the fact that the volume of water used for the last time greatly reduced, while go to the toilet not diminished, but on the contrary - the population grew. The reasons that the "dilution" of water has become much less a lot:

a) the use of counters - the water became more economical to use;

b) the use of more modern plumbing - all rarely possible to meet the current tap or toilet;

c) the use of more economical household appliances - washing machines, dishwashers etc .;

g) the closure of a huge number of industrial enterprises, which consumed a lot of water - AZLK, ZIL, Hammer and Sickle (partly), etc.

As a result - if the station is under construction on the calculated volume of 800 liters of water per person per day, now this figure is not really more 200. Increase in concentration and reduction of flow led to a number of side effects - in sewer pipes are designed for high flow became deposited sediment, resulting in unpleasant odors. At the station became more smell.

To combat the smell of Waterworks, which administers the treatment plant reconstruction works carried out in stages, using a number of different ways of getting rid of odors, which are about the story and go below.

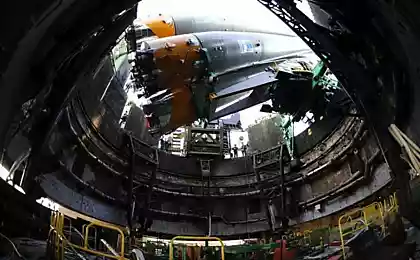

Let's go in order, but rather a current of water. Wastewater from Moscow arrives at the station at Lyubertsy sewer, which is a huge underground reservoir filled with wastewater. Channel gravity and almost all over is a very shallow depth, and sometimes actually do on the ground. Its scale can be estimated from the roof of the administrative building of sewage treatment plants:

Channel width - about 15 meters (divided into three parts), height - 3 meters.

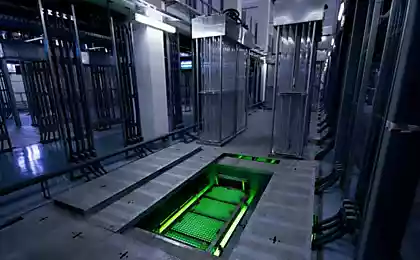

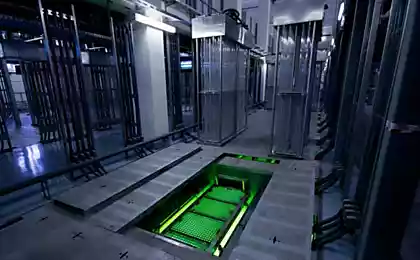

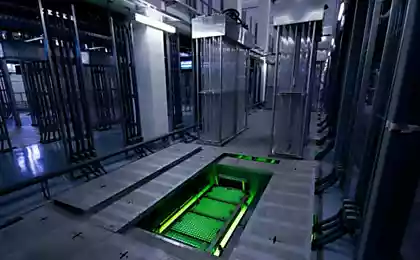

Channel arrives at the station in a so-called receiving chamber from which is split into two streams - the old part is part of the station, the new part. Receiving chamber looks like this:

Channel itself comes from right behind, and divided into two parts, the flow goes through the green channel in the background, each of which may overlap so-called slide gate - special gate (pictured - dark design). Here you can see the first innovation to combat odors. Receiving chamber is completely covered with metal sheets. Previously, she looked like a "pool" filled with fecal waters, and now can not see them, of course continuous metallic coating is almost completely covers the smell.

For technological purposes was left only a very small hatch, lifting that you can enjoy all the bouquet of smells. Greetings from walsk :)

These huge dampers allow overlapping channels coming from the receiving chamber if necessary.

From the receiving chamber is two channels. They, too, has recently been opened, and now they completely cover the metal ceiling.

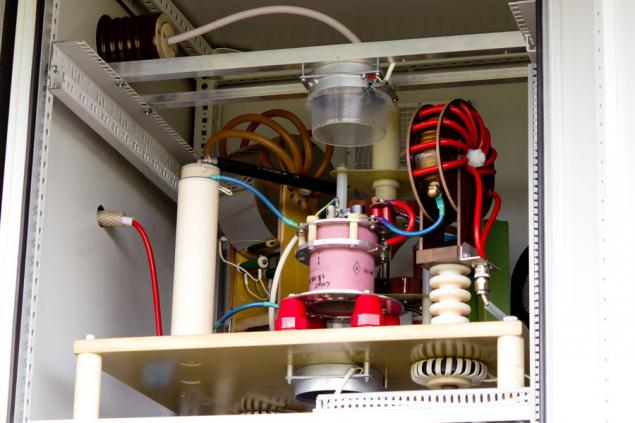

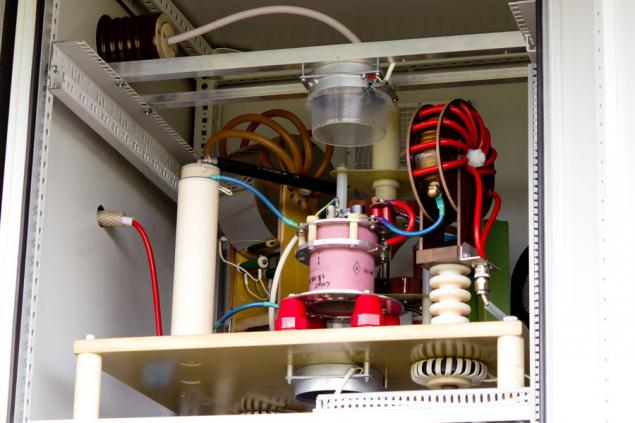

By overlapping accumulate gases released from the wastewater. This is mainly methane and hydrogen sulfide - both gases are explosive at high concentrations, so the space under the ceiling it is necessary to ventilate, but then the following problem arises - if you just put the fan, the whole point of overlap will just disappear - the smell gets out. Therefore, to solve the problem of ICD "Horizon" has developed and produced a special installation for air purification. Installation is in a separate booth and it is the vent pipe from the channel.

The setting - experimental, for development of the technology. In the near future such facilities will be put on mass treatment plants and sewage pumping stations, which in Moscow more than 150 pieces, of which the unpleasant smell too. Right in the photo - one of the developers and testers to install - Alexander Pozinovky.

...

The principle of the installation the following:

Four vertical stainless steel tube polluted air is fed from below. In these pipes are electrodes to which several hundred times per second, a high voltage (tens of thousands of volts), causing discharges occur and the low temperature plasma. When interacting with it most odorous gases to liquid and deposited on the tube walls. On the walls of pipes constantly dripping a thin layer of water with which these substances are mixed. The water is recirculated, water tank - blue container on the right in the photo below. The cleaned air exits the top of the stainless steel tubes and simply released into the atmosphere.

For those who are interested in the details - photo booth, where everything is explained.

For the Patriots - the installation is completely designed and built in Russia, except for the voltage regulator (in the cabinet below the photo). High part of the installation:

Since the installation of an experimental - it has an additional measuring equipment - gas analyzer and oscilloscope.

The oscilloscope shows the voltage on the capacitors. During each discharge the capacitors are discharged and the waveform is clearly visible process of their charge.

To the gas analyzer is two tubes - one takes air to the installation, the other after. In addition there is a tap that allows you to choose the tube, which is connected to the sensor analyzer. Alexander shows us the first "dirty" air. Hydrogen sulfide content - 10.3 mg / m3. After switching crane - content drops almost to zero: 0.0-0.1.

Further, the supply channel abuts the special distribution chamber (also covered with a metal), where the flow is divided into 12 parts, and goes further in the building of so-called lattice, that is seen in the background. There wastewater passes the very first stage of treatment - removal of large debris. Is not difficult to guess from the title - for this it is passed through a special grille with a mesh size of about 5-6 mm. More details about them can read and see in the post with Kuryanovskoy station.

Each channel also overlaps a separate slide valve. Generally speaking, at the station of a huge number - sticking out here and there :)

After purification of large debris in the water enters the sand trap, which is again not hard to guess from the title are designed to remove fine particulate matter. The principle of operation is quite simple sand traps - essentially long rectangular tank in which water flows at a certain rate, as a result of sand just manages to settle. Also, there is fed air that promotes the process. Sand is removed from the bottom by means of special mechanisms.

As often happens in technology - the idea is simple, but the execution - the complex. So here - this is the most visually "fancy" design in the way of water purification.

Sand traps chosen by seagulls. Generally seagulls on Lyuberetskaya station turned out very much, but it was on the sand trap them most.

Enlarge photo at home and laughed with their kind - funny birds. Called gull lake. No, dark head they do not because they are constantly dipped it where it is not necessary, just such a design feature :)

But soon they will have is not easy - many open water at the station will be covered.

Let us return to the technology. In the photo - the bottom of the sand trap (not working at the moment). That's where the sand settles and from there and removed.

After sand traps water again flows into the common channel.

...

Here you can see how all the channels look at the station, before they began to cover. This channel is now covered.

Frame made of stainless steel cook, like most metal structures in the sewers. The fact that very aggressive environment sanitation - any substance water total 100% humidity, gases contribute to corrosion. Average iron quickly turns to dust in such conditions.

Work is carried out directly over the existing channel - as it is one of the two main channels, it can not be disabled (Muscovites will not wait :)).

In the photo a small level difference, about 50 centimeters. The bottom at this point to make a special form, to quench the horizontal velocity of the water. As a result - a very active wildness.

After sand traps water enters the primary settling tank. The photo - foreground chamber that receives the water from it, it falls into the central portion of the settler in the background.

Classic settler looks like:

...

And without water - so:

Dirty water enters the hole in the center of the sump and enters the total volume. In the sump slurry contained in dirty water gradually settles to the bottom, through which constantly moves ilosgrebatel mounted on a farm, rotating in a circle. Scraper rakes deposit in a special circular tray, and from it, in turn, he falls into a round pit, from which is pumped through a pipe with special pumps. Excess water funneling channel laid in a circle, and thence into the sump tube.

Primary clarifiers - another source of odors at the station, because they are actually dirty (cleaned only on solids) sewage water. In order to get rid of the smell Moskvodokanal decided to cover the lagoons, but then got a big problem. The diameter of the sump is 54 meters (!). Photo with a man for scale:

Moreover, if the roof doing, it must withstand the first winter snow load, and secondly to have only one support in the center - of a sump support itself can not be done because there constantly rotates farm. As a result, it was decided an elegant solution - do overlap floating.

Overlapping blocks assembled from floating stainless steel. Moreover, the outer ring of the blocks are fixed, and the inner part rotates afloat, together with the farm.

This decision proved to be very successful, because Firstly there is no problem with snow load, and secondly, the amount of air is formed, which would have to be ventilated and further purified.

According to the Mosvodokanal this design smelling gas emissions reduced by 97%.

This was the first settler and experimental, which was perfected this technology. The experiment was considered a success and now Kuryanovskoy station already served in a similar way the other settlers. Over time, all of the primary settling tanks will be covered in this way.

However, the process of reconstruction of the long - turn off the whole station at once is impossible to reconstruct the settlers can only be one after another, cutting off one by one. Yes, and a lot of money is needed. Therefore, not all covered lagoons used the third way of dealing with odors - spray neutralizing agents.

Around the primary sedimentation tanks were equipped with special sprays that create a cloud of substances neutralizing odors. Substances themselves not to say that the smell is very pleasant or unpleasant, but quite specific, but their task is not to mask the smell and neutralize it. Unfortunately I do not remember the specific substances that are used, but said at the station - this waste of perfume industry in France.

For special uses spray nozzles which create a particle diameter of 5-10 microns. Pressure in the pipes if I am not mistaken 6-8 atmospheres.

After primary clarifiers water enters the aerotenki - long concrete tanks. They served a huge amount of air through the pipes, and also contains activated sludge - the basis of all biological method of water purification. Activated sludge processes "waste", while multiplies rapidly. The process is similar to what occurs naturally in ponds, but runs much faster because of the warm water, large amounts of air and sludge.

Air is supplied from the main turbine hall, which establishes the blowers. Three towers over the building - air intakes. Process air supply requires huge amounts of electricity, and the cessation of the air leads to disastrous consequences, as activated sludge quickly dies, and his recovery may take months (!).

Aerotenki, oddly enough not particularly exude strong odors, so they cover is not planned.

In this photo you can see how dirty water enters the aerotenk (dark) and mixed with activated sludge (brown).

Part of the facilities is currently disabled and abandoned, for reasons which I wrote at the beginning of the post - reduction of water flow in recent years.

After aerotenkov water enters the secondary settling tank. Structurally, they are the same primary. Their purpose - to separate the activated sludge from the already purified water.

Conserved secondary sedimentation tanks.

Secondary sedimentation tanks do not smell - in fact there is already clean water.

Water collects in the annular tray sump leaking into the pipe. Part of the water passes additional UV disinfection and merges into the river Pekhorka, part of the same underground water channel goes to Moscow River.

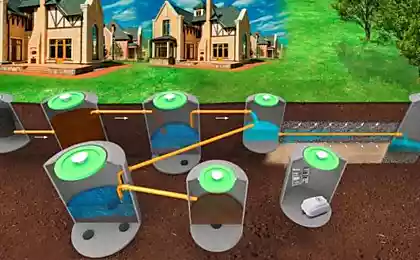

Settled activated sludge is used to produce methane, which is then stored in a semi-subterranean tanks - metantenkah and used to own CHP.

Exhaust sludge is sent to the sludge beds in the suburbs, where it is further dewatered and or are disposed or incinerated.

All

In Moscow, the two largest wastewater treatment plant, about the same size. Each of them cleans half of what "makes" Moscow. About Kuryanovskoy station I already spoke in detail. Today I will talk about Lyuberetskaya station - we again go over the main stages of water treatment, but also touch on a very important subject - both treatment plants are struggling with unpleasant odors by using low-temperature plasma and waste the perfume industry and why this problem has become even more relevant than ever .

50 photos + letters via alex-avr2

First, a little history. For the first time sewerage "came" to the area of modern Lyuberets in the early twentieth century. Then were created Luberetskiy field irrigation, in which the wastewater is still on the old technology seeps through the ground and thus cleaned. Over time, this technology has become unacceptable to an increasing number of waste water and in 1963 built a new treatment plant - Lyuberetskaya. A little later built another station - Novolyuberetskaya actually bordering on the first and uses a part of its infrastructure. In fact now it is one large treatment plant, but made up of two parts - the old and the new.

Take a look at the map - the left, to the west - the old part of the station, on the right, in the east - new:

The area of the station - a huge, straight from corner to corner about two kilometers.

Not difficult to guess - the station is the smell. Previously, he was a little worried about someone, and now this problem has become urgent for two main reasons:

1) When the station was built in the '60s, around almost no one lived. Nearby was a small village, where they lived the workers themselves station. Then the area was far away from Moscow. Now there is a very active development. Station actually surrounded on all sides and new buildings will be more of them. New houses are built on the former even sludge plant site (field, which dumped the remaining sludge from waste water treatment). As a result, residents of nearby houses have to periodically sniff "sewer" smell, and of course they are always complaining.

2) Discharge of water become more concentrated than in the past, in Soviet times. This happened due to the fact that the volume of water used for the last time greatly reduced, while go to the toilet not diminished, but on the contrary - the population grew. The reasons that the "dilution" of water has become much less a lot:

a) the use of counters - the water became more economical to use;

b) the use of more modern plumbing - all rarely possible to meet the current tap or toilet;

c) the use of more economical household appliances - washing machines, dishwashers etc .;

g) the closure of a huge number of industrial enterprises, which consumed a lot of water - AZLK, ZIL, Hammer and Sickle (partly), etc.

As a result - if the station is under construction on the calculated volume of 800 liters of water per person per day, now this figure is not really more 200. Increase in concentration and reduction of flow led to a number of side effects - in sewer pipes are designed for high flow became deposited sediment, resulting in unpleasant odors. At the station became more smell.

To combat the smell of Waterworks, which administers the treatment plant reconstruction works carried out in stages, using a number of different ways of getting rid of odors, which are about the story and go below.

Let's go in order, but rather a current of water. Wastewater from Moscow arrives at the station at Lyubertsy sewer, which is a huge underground reservoir filled with wastewater. Channel gravity and almost all over is a very shallow depth, and sometimes actually do on the ground. Its scale can be estimated from the roof of the administrative building of sewage treatment plants:

Channel width - about 15 meters (divided into three parts), height - 3 meters.

Channel arrives at the station in a so-called receiving chamber from which is split into two streams - the old part is part of the station, the new part. Receiving chamber looks like this:

Channel itself comes from right behind, and divided into two parts, the flow goes through the green channel in the background, each of which may overlap so-called slide gate - special gate (pictured - dark design). Here you can see the first innovation to combat odors. Receiving chamber is completely covered with metal sheets. Previously, she looked like a "pool" filled with fecal waters, and now can not see them, of course continuous metallic coating is almost completely covers the smell.

For technological purposes was left only a very small hatch, lifting that you can enjoy all the bouquet of smells. Greetings from walsk :)

These huge dampers allow overlapping channels coming from the receiving chamber if necessary.

From the receiving chamber is two channels. They, too, has recently been opened, and now they completely cover the metal ceiling.

By overlapping accumulate gases released from the wastewater. This is mainly methane and hydrogen sulfide - both gases are explosive at high concentrations, so the space under the ceiling it is necessary to ventilate, but then the following problem arises - if you just put the fan, the whole point of overlap will just disappear - the smell gets out. Therefore, to solve the problem of ICD "Horizon" has developed and produced a special installation for air purification. Installation is in a separate booth and it is the vent pipe from the channel.

The setting - experimental, for development of the technology. In the near future such facilities will be put on mass treatment plants and sewage pumping stations, which in Moscow more than 150 pieces, of which the unpleasant smell too. Right in the photo - one of the developers and testers to install - Alexander Pozinovky.

...

The principle of the installation the following:

Four vertical stainless steel tube polluted air is fed from below. In these pipes are electrodes to which several hundred times per second, a high voltage (tens of thousands of volts), causing discharges occur and the low temperature plasma. When interacting with it most odorous gases to liquid and deposited on the tube walls. On the walls of pipes constantly dripping a thin layer of water with which these substances are mixed. The water is recirculated, water tank - blue container on the right in the photo below. The cleaned air exits the top of the stainless steel tubes and simply released into the atmosphere.

For those who are interested in the details - photo booth, where everything is explained.

For the Patriots - the installation is completely designed and built in Russia, except for the voltage regulator (in the cabinet below the photo). High part of the installation:

Since the installation of an experimental - it has an additional measuring equipment - gas analyzer and oscilloscope.

The oscilloscope shows the voltage on the capacitors. During each discharge the capacitors are discharged and the waveform is clearly visible process of their charge.

To the gas analyzer is two tubes - one takes air to the installation, the other after. In addition there is a tap that allows you to choose the tube, which is connected to the sensor analyzer. Alexander shows us the first "dirty" air. Hydrogen sulfide content - 10.3 mg / m3. After switching crane - content drops almost to zero: 0.0-0.1.

Further, the supply channel abuts the special distribution chamber (also covered with a metal), where the flow is divided into 12 parts, and goes further in the building of so-called lattice, that is seen in the background. There wastewater passes the very first stage of treatment - removal of large debris. Is not difficult to guess from the title - for this it is passed through a special grille with a mesh size of about 5-6 mm. More details about them can read and see in the post with Kuryanovskoy station.

Each channel also overlaps a separate slide valve. Generally speaking, at the station of a huge number - sticking out here and there :)

After purification of large debris in the water enters the sand trap, which is again not hard to guess from the title are designed to remove fine particulate matter. The principle of operation is quite simple sand traps - essentially long rectangular tank in which water flows at a certain rate, as a result of sand just manages to settle. Also, there is fed air that promotes the process. Sand is removed from the bottom by means of special mechanisms.

As often happens in technology - the idea is simple, but the execution - the complex. So here - this is the most visually "fancy" design in the way of water purification.

Sand traps chosen by seagulls. Generally seagulls on Lyuberetskaya station turned out very much, but it was on the sand trap them most.

Enlarge photo at home and laughed with their kind - funny birds. Called gull lake. No, dark head they do not because they are constantly dipped it where it is not necessary, just such a design feature :)

But soon they will have is not easy - many open water at the station will be covered.

Let us return to the technology. In the photo - the bottom of the sand trap (not working at the moment). That's where the sand settles and from there and removed.

After sand traps water again flows into the common channel.

...

Here you can see how all the channels look at the station, before they began to cover. This channel is now covered.

Frame made of stainless steel cook, like most metal structures in the sewers. The fact that very aggressive environment sanitation - any substance water total 100% humidity, gases contribute to corrosion. Average iron quickly turns to dust in such conditions.

Work is carried out directly over the existing channel - as it is one of the two main channels, it can not be disabled (Muscovites will not wait :)).

In the photo a small level difference, about 50 centimeters. The bottom at this point to make a special form, to quench the horizontal velocity of the water. As a result - a very active wildness.

After sand traps water enters the primary settling tank. The photo - foreground chamber that receives the water from it, it falls into the central portion of the settler in the background.

Classic settler looks like:

...

And without water - so:

Dirty water enters the hole in the center of the sump and enters the total volume. In the sump slurry contained in dirty water gradually settles to the bottom, through which constantly moves ilosgrebatel mounted on a farm, rotating in a circle. Scraper rakes deposit in a special circular tray, and from it, in turn, he falls into a round pit, from which is pumped through a pipe with special pumps. Excess water funneling channel laid in a circle, and thence into the sump tube.

Primary clarifiers - another source of odors at the station, because they are actually dirty (cleaned only on solids) sewage water. In order to get rid of the smell Moskvodokanal decided to cover the lagoons, but then got a big problem. The diameter of the sump is 54 meters (!). Photo with a man for scale:

Moreover, if the roof doing, it must withstand the first winter snow load, and secondly to have only one support in the center - of a sump support itself can not be done because there constantly rotates farm. As a result, it was decided an elegant solution - do overlap floating.

Overlapping blocks assembled from floating stainless steel. Moreover, the outer ring of the blocks are fixed, and the inner part rotates afloat, together with the farm.

This decision proved to be very successful, because Firstly there is no problem with snow load, and secondly, the amount of air is formed, which would have to be ventilated and further purified.

According to the Mosvodokanal this design smelling gas emissions reduced by 97%.

This was the first settler and experimental, which was perfected this technology. The experiment was considered a success and now Kuryanovskoy station already served in a similar way the other settlers. Over time, all of the primary settling tanks will be covered in this way.

However, the process of reconstruction of the long - turn off the whole station at once is impossible to reconstruct the settlers can only be one after another, cutting off one by one. Yes, and a lot of money is needed. Therefore, not all covered lagoons used the third way of dealing with odors - spray neutralizing agents.

Around the primary sedimentation tanks were equipped with special sprays that create a cloud of substances neutralizing odors. Substances themselves not to say that the smell is very pleasant or unpleasant, but quite specific, but their task is not to mask the smell and neutralize it. Unfortunately I do not remember the specific substances that are used, but said at the station - this waste of perfume industry in France.

For special uses spray nozzles which create a particle diameter of 5-10 microns. Pressure in the pipes if I am not mistaken 6-8 atmospheres.

After primary clarifiers water enters the aerotenki - long concrete tanks. They served a huge amount of air through the pipes, and also contains activated sludge - the basis of all biological method of water purification. Activated sludge processes "waste", while multiplies rapidly. The process is similar to what occurs naturally in ponds, but runs much faster because of the warm water, large amounts of air and sludge.

Air is supplied from the main turbine hall, which establishes the blowers. Three towers over the building - air intakes. Process air supply requires huge amounts of electricity, and the cessation of the air leads to disastrous consequences, as activated sludge quickly dies, and his recovery may take months (!).

Aerotenki, oddly enough not particularly exude strong odors, so they cover is not planned.

In this photo you can see how dirty water enters the aerotenk (dark) and mixed with activated sludge (brown).

Part of the facilities is currently disabled and abandoned, for reasons which I wrote at the beginning of the post - reduction of water flow in recent years.

After aerotenkov water enters the secondary settling tank. Structurally, they are the same primary. Their purpose - to separate the activated sludge from the already purified water.

Conserved secondary sedimentation tanks.

Secondary sedimentation tanks do not smell - in fact there is already clean water.

Water collects in the annular tray sump leaking into the pipe. Part of the water passes additional UV disinfection and merges into the river Pekhorka, part of the same underground water channel goes to Moscow River.

Settled activated sludge is used to produce methane, which is then stored in a semi-subterranean tanks - metantenkah and used to own CHP.

Exhaust sludge is sent to the sludge beds in the suburbs, where it is further dewatered and or are disposed or incinerated.

All