577

Crystallization — a new method of wastewater treatment

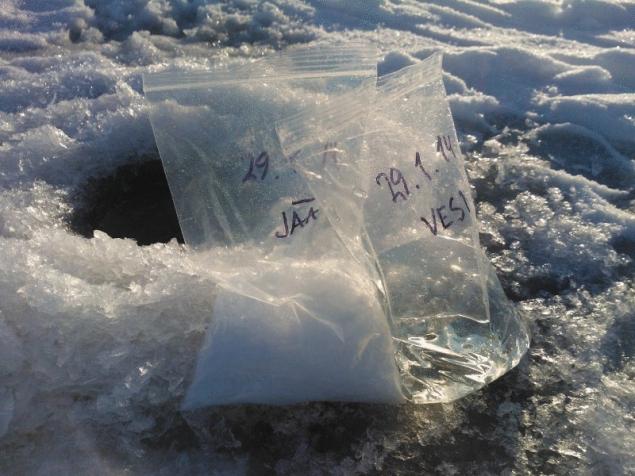

The technology of freezing, or science of crystallization, can be used in wastewater treatment. This is recently demonstrated by researchers from technological University of Lappeenranta (LUT), Finland, using specially designed equipment that allows you to control the speed of ice formation, and the degree of purity, depending on the concentration of wastewater.

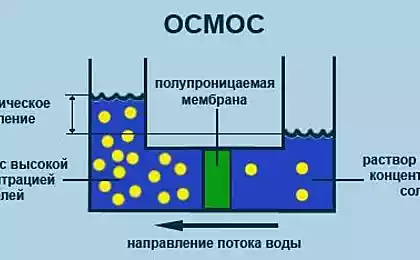

According to the researchers, the freezing of waste water forms a surface layer of cleaner ice, which can then be removed, and after further treatment using membrane filtration, reused, while the remainder of wastewater is more concentrated and toxic – is sent for disposal in special reservoirs.

According to scientists, the developed method is more energy efficient and less resource intensive. First, the freezing point of water requires seven times less energy than evaporation. Secondly, energy is required only for the break-up formed of pure ice, and its transportation from the pool of sewage. In addition, this water is quite suitable for most production processes, which will significantly reduce the use of fresh water.

This technology was developed for use primarily in the mining industry, which produces large amounts of wastewater. In practice, you can freeze the waste water in special pools under the open sky.

To test the viability of the new technology scientists from the faculty of chemical technology LUT has developed equipment that includes a winter simulator that allows to study how the temperature of the cooling air affects the freezing process. According to the test results, the slower the buildup of the ice layer on the surface of the sewage, the less ice remains of impurities.

Further the work of scientists from the LUT will be directed to an extensive study of various types of pools of waste water and determination of the purity of the ice layers, formed by the new technology, as well as on the practical implementation of the freezing technology of waste water samples in mining areas.

Source: www.ozemle.net

Wheatgrass: the Incredible healing properties that few people know

How to make cosy rented apartment