569

Biochemical wastewater treatment: all about the aerotank

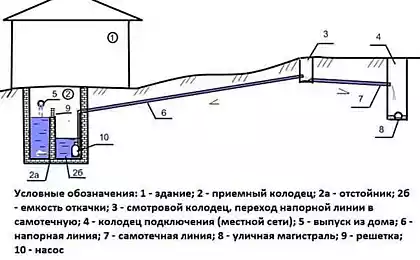

Homeowners are often faced with a serious problem of disposal of domestic waste waters. If it is close to Central sewer, elementary decision – to connect to the mainline. Unfortunately, it is not always possible, so you have to build your own sewage treatment system. One of the ways of disposal of effluent – biochemical treatment. Today it is the most effective, safe and environmentally friendly method of wastewater treatment.

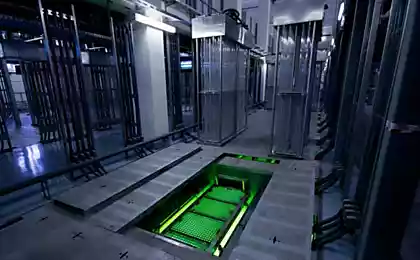

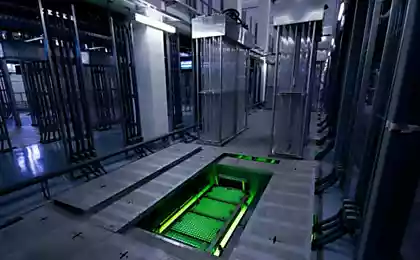

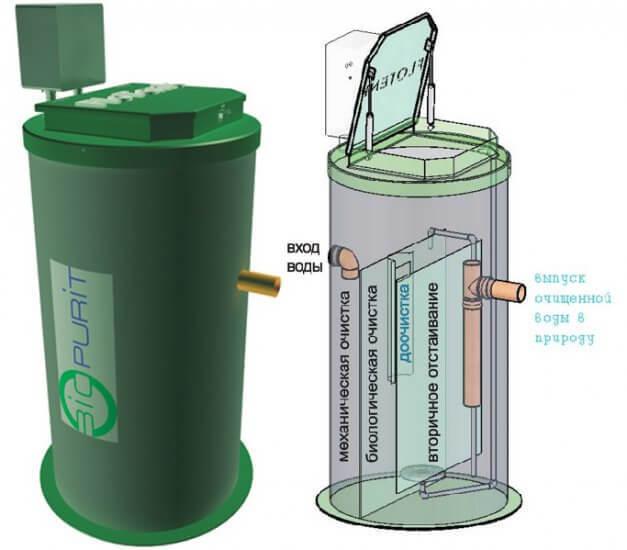

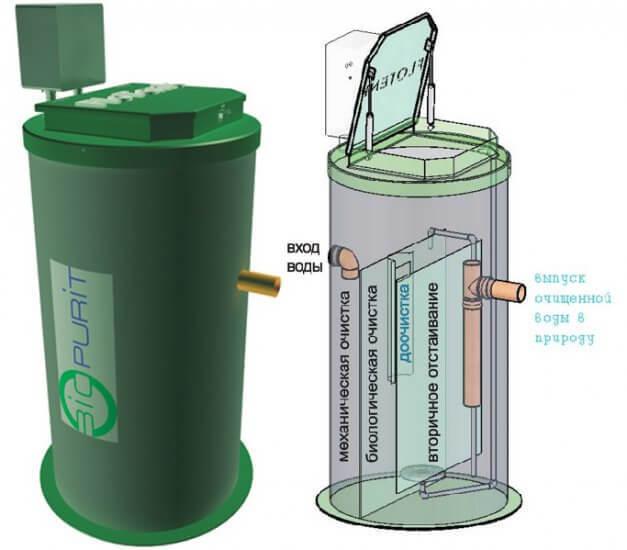

To implement such cleaning requires special equipment, which is called an aeration tank. It is a reservoir divided by partitions into compartments. In the process of purification sewage and the active sludge slowly flows through the tank. The sludge flakes should always be oxygenated and maintained in suspension. For this purpose, the aeration tank is constantly supplied air.

The flow of air can be carried out pneumatically through special diffusers, or mechanical. In the latter case, the device is equipped with a rotating agitator with blades or brushes. They are half-sunk in the liquid state and to rotate continuously, saturating the mixture with air. Mechanical aeration is used only for small installations. In some models, is a mixed aeration: pneumatic and mechanical.

Wastewater treatment occurs in the process of their interaction with active sludge, which accumulated a large number of aerobic microorganisms. Dietary fats, human waste, surfactants, which are very much in the effluent, a perfect breeding ground for bacteria. They decompose them into molecules and almost completely absorb.

For systems of biochemical cleaning technology as used in aeration or forced air. Without it, the aerobic bacteria die. A sufficient amount of oxygen stimulates the microorganisms to multiply and active feeding. They oxidize present in the effluent organic matter, turning it into the sludge flakes. The liquid cleaned of contaminants and becomes transparent. The process takes place in several stages.

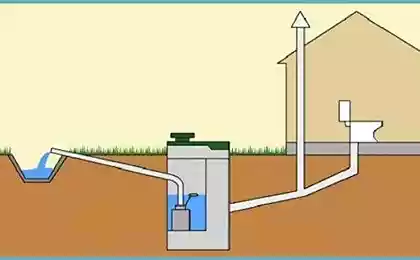

Primary wastewater treatment

Contaminated fluid is fed through the pipe in the receiving chamber. Here is the primary mechanical and biological purification: waste water pass through the filter on which are deposited all the major factions.

Purification with active sludge

Liquid is pumped with the airlift in the aeration tank, where the process of complete destruction of the organics. Depending on the type of the cleaning device, it can have one or more cameras that are drains. In any case, the water contained in the organic matter is completely destroyed.

The sludge separation

At the outlet of the aeration tank the fluid is water with dissolved sludge flakes. It enters the sedimentation tank where the biomass settles to the bottom. Clean water is discharged from the device. The settled stabilized sludge is fed into the aeration tank for the next cycle, and the excess removed into the tank for sediment.

The result of biochemical treatment plant becomes stabilized sludge and technical water. Every 3-6 months the excess sludge by the drainage pump is removed from the system. This mass is to put in a compost pit for digestion, after which it becomes an excellent biological fertilizer. Correctly organized system for deep cleaning results in a transparent odorless technical water. It can be used for irrigation or discharged into storm ditch or drain well. Subject to additional decontamination of this water can be drained in ponds.

System biochemical purification or aeration tanks are produced in various modifications. They can consist of one chamber divided into several compartments, or include multiple interconnected blocks.

In any case, such facilities need electricity and the presence of aerobic bacteria. The indisputable advantages of the aeration tanks are:

— Very high level of wastewater treatment.

— Compact size construction.

— Absence of unpleasant odors during operation of the device.

The efficiency (e required supplies and services vacuum trucks for removal of accumulated wastes).

— No need of arranging additional insulation.

— High performance (system efficiency is 98%).

— Environmental (the aeration tanks are made from safe materials and is completely sealed, so runoff can't seep into the soil).

The disadvantages of the devices include their significant cost and volatility. In addition, such equipment needs regular control, because stagnation is detrimental to microorganisms. Dissolved oxygen should always be evenly distributed on all parts of the aerotank, which is achieved by intensive stirring of the mass. And this requires a constant supply of electricity. In its absence, in terms of lack of oxygen, the microorganisms begin to die EN masse. After three months of "idle" active sludge is completely unsustainable. Therefore, aeration is not recommended in homes where constantly does not live, and appear only periodically. In addition, the efficiency of the biochemical treatment system affected by temperature, pH level, amount of organics in the wastewater and the level of toxins.

Aeration is a practical solution to the problem of disposing of sewage. Various devices can serve at home with a number of permanent residents in them from 3 to 130. High system efficiency ensures almost complete wastewater treatment. From the aeration tank enters water and stable sludge that allows the holder to establish a system of cleaning, not to think about their further disposal. published

Source: www.stroitelstvo365.ru/kanalizatsionnie-sistemi/vsyo-ob-aerotenke

To implement such cleaning requires special equipment, which is called an aeration tank. It is a reservoir divided by partitions into compartments. In the process of purification sewage and the active sludge slowly flows through the tank. The sludge flakes should always be oxygenated and maintained in suspension. For this purpose, the aeration tank is constantly supplied air.

The flow of air can be carried out pneumatically through special diffusers, or mechanical. In the latter case, the device is equipped with a rotating agitator with blades or brushes. They are half-sunk in the liquid state and to rotate continuously, saturating the mixture with air. Mechanical aeration is used only for small installations. In some models, is a mixed aeration: pneumatic and mechanical.

Wastewater treatment occurs in the process of their interaction with active sludge, which accumulated a large number of aerobic microorganisms. Dietary fats, human waste, surfactants, which are very much in the effluent, a perfect breeding ground for bacteria. They decompose them into molecules and almost completely absorb.

For systems of biochemical cleaning technology as used in aeration or forced air. Without it, the aerobic bacteria die. A sufficient amount of oxygen stimulates the microorganisms to multiply and active feeding. They oxidize present in the effluent organic matter, turning it into the sludge flakes. The liquid cleaned of contaminants and becomes transparent. The process takes place in several stages.

Primary wastewater treatment

Contaminated fluid is fed through the pipe in the receiving chamber. Here is the primary mechanical and biological purification: waste water pass through the filter on which are deposited all the major factions.

Purification with active sludge

Liquid is pumped with the airlift in the aeration tank, where the process of complete destruction of the organics. Depending on the type of the cleaning device, it can have one or more cameras that are drains. In any case, the water contained in the organic matter is completely destroyed.

The sludge separation

At the outlet of the aeration tank the fluid is water with dissolved sludge flakes. It enters the sedimentation tank where the biomass settles to the bottom. Clean water is discharged from the device. The settled stabilized sludge is fed into the aeration tank for the next cycle, and the excess removed into the tank for sediment.

The result of biochemical treatment plant becomes stabilized sludge and technical water. Every 3-6 months the excess sludge by the drainage pump is removed from the system. This mass is to put in a compost pit for digestion, after which it becomes an excellent biological fertilizer. Correctly organized system for deep cleaning results in a transparent odorless technical water. It can be used for irrigation or discharged into storm ditch or drain well. Subject to additional decontamination of this water can be drained in ponds.

System biochemical purification or aeration tanks are produced in various modifications. They can consist of one chamber divided into several compartments, or include multiple interconnected blocks.

In any case, such facilities need electricity and the presence of aerobic bacteria. The indisputable advantages of the aeration tanks are:

— Very high level of wastewater treatment.

— Compact size construction.

— Absence of unpleasant odors during operation of the device.

The efficiency (e required supplies and services vacuum trucks for removal of accumulated wastes).

— No need of arranging additional insulation.

— High performance (system efficiency is 98%).

— Environmental (the aeration tanks are made from safe materials and is completely sealed, so runoff can't seep into the soil).

The disadvantages of the devices include their significant cost and volatility. In addition, such equipment needs regular control, because stagnation is detrimental to microorganisms. Dissolved oxygen should always be evenly distributed on all parts of the aerotank, which is achieved by intensive stirring of the mass. And this requires a constant supply of electricity. In its absence, in terms of lack of oxygen, the microorganisms begin to die EN masse. After three months of "idle" active sludge is completely unsustainable. Therefore, aeration is not recommended in homes where constantly does not live, and appear only periodically. In addition, the efficiency of the biochemical treatment system affected by temperature, pH level, amount of organics in the wastewater and the level of toxins.

Aeration is a practical solution to the problem of disposing of sewage. Various devices can serve at home with a number of permanent residents in them from 3 to 130. High system efficiency ensures almost complete wastewater treatment. From the aeration tank enters water and stable sludge that allows the holder to establish a system of cleaning, not to think about their further disposal. published

Source: www.stroitelstvo365.ru/kanalizatsionnie-sistemi/vsyo-ob-aerotenke