497

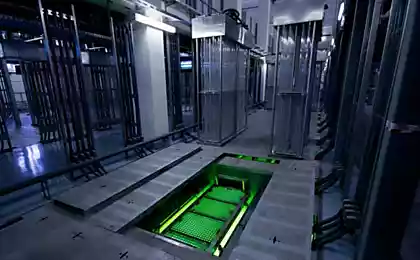

Invented a method of purifying industrial waste water for 3 minutes

The purification of sewage from industrial wastes is one of the most complex and serious environmental problems. The engineers canadian Ryerson University has developed a process of oxidation for processing of biodegradable impurities, which saves time and money.

"We can't turn back time, before the industrial revolution, but can reduce its environmental impact, says El Jeburi, the inventor of the process. — So we need to act fast and find an effective way to remove these impurities. This was the aim of our study".

He engaged, in particular, toxic and not biodegradable naphthenic acids, important for the oil industry of Canada. The natural process of polarisierte of these acids is of about 13 years, that is required so much time that the concentration has reached half of its initial level. But not enough to return wastewater to total water resources.

The process, invented by El Jeburi, not only removes all the impurities is not biodegradable, but does it in less than 3 minutes. After treatment in the waste water remain only quickly biodegradable impurities, which can be subjected to the same treatment, and municipal wastewater. At the same time, the consumption of ozone for water purification is reduced to a minimum, which reduces the overall cost of the entire process 35%-80% in comparison with the traditional approach of oxidation of wastewater.

Technology El Jiburi was registered for a patent and pending canadian Innovation Alliance Oil Sands.

According to statistics, the factories use annually 30.2 billion cubic meters of water and poured 700 million cubic meters of wastewater. This wastewater often dozens of years are in large settling ponds, waiting for the material decays and are at risk of leaks. New technology may help to get rid of the settlers and to completely remove the risk of groundwater contamination with industrial waste.published

Source: hightech.fm/2016/09/06/waste-water

"We can't turn back time, before the industrial revolution, but can reduce its environmental impact, says El Jeburi, the inventor of the process. — So we need to act fast and find an effective way to remove these impurities. This was the aim of our study".

He engaged, in particular, toxic and not biodegradable naphthenic acids, important for the oil industry of Canada. The natural process of polarisierte of these acids is of about 13 years, that is required so much time that the concentration has reached half of its initial level. But not enough to return wastewater to total water resources.

The process, invented by El Jeburi, not only removes all the impurities is not biodegradable, but does it in less than 3 minutes. After treatment in the waste water remain only quickly biodegradable impurities, which can be subjected to the same treatment, and municipal wastewater. At the same time, the consumption of ozone for water purification is reduced to a minimum, which reduces the overall cost of the entire process 35%-80% in comparison with the traditional approach of oxidation of wastewater.

Technology El Jiburi was registered for a patent and pending canadian Innovation Alliance Oil Sands.

According to statistics, the factories use annually 30.2 billion cubic meters of water and poured 700 million cubic meters of wastewater. This wastewater often dozens of years are in large settling ponds, waiting for the material decays and are at risk of leaks. New technology may help to get rid of the settlers and to completely remove the risk of groundwater contamination with industrial waste.published

Source: hightech.fm/2016/09/06/waste-water

Discovered a hidden connection between the immune system and the brain

The exploration station on a drifting ice floe in the Arctic will eat RES