169

Ultrafiltration of water: how does it work and how does it differ from other cleaning methods?

What is ultrafiltration of water?

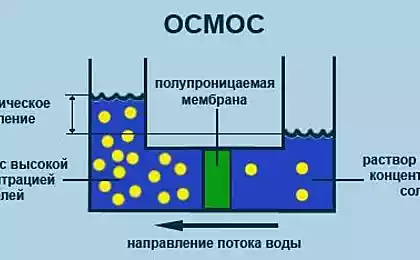

Ultrafiltration is a membrane filtration method that uses a semi-permeable membrane to remove particles up to 0.01 μm from water. Ultrafiltration allows you to effectively remove mechanical impurities, colloidal particles, bacteria, viruses and organic compounds. Water passed through the ultrafiltration membrane becomes crystal clear, without suspended particles and harmful microorganisms.

Unlike microfiltration, ultrafiltration removes smaller particles and microorganisms. Compared to reverse osmosis, ultrafiltration preserves useful minerals in water, ensuring the balance of water composition and its safety for use in industrial processes. More information about the principles of operation and features of ultrafiltration installation can be found on the Iver website.

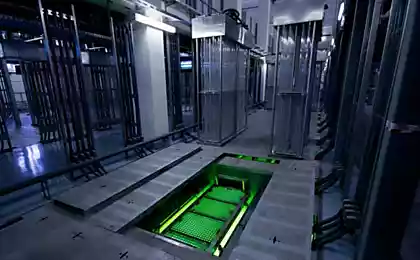

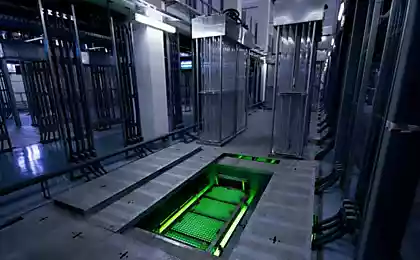

How does an ultrafiltration unit work?

The main elements of ultrafiltration installation

- Membrane module consists of tubes or flat plates with pores with a diameter of about 0.01 μm. The membrane traps particles and microorganisms by passing only purified water. The design of the membrane is resistant to pressure drops and high temperature, which makes it reliable in operation.

- The pump creates working pressure - provides water supply under pressure through the membrane, which increases the efficiency of cleaning. Pumps are selected depending on the required volume of water and the characteristics of the initial liquid.

- Automatic washing system Removes contaminants from the membrane surface, preventing clogging and reducing the need for manual maintenance. Washing is started automatically when a certain level of contamination is reached.

- Water enters the ultrafiltration unit through a pump that creates working pressure.

- Passing through the membrane, the water is purified from mechanical impurities, bacteria and viruses.

- Purified water enters the storage container or is immediately supplied to the system.

- Contaminants are retained on the surface of the membrane and removed during automatic washing.

1. High degree of cleaning

Ultrafiltration effectively removes particles up to 0.01 microns in size, including bacteria, viruses and colloidal particles. This level of filtration provides a high degree of water purification for various industrial processes. Even the smallest contaminants that can pass through microfilters are delayed by the ultrafiltration membrane.

2. Preservation of mineral composition of water

Unlike reverse osmosis, ultrafiltration does not remove beneficial minerals from water, preserving its natural composition. This makes the water safe and suitable for use in the food and pharmaceutical industries. Water retains all the necessary macro- and microelements, providing a stable chemical composition.

3. Cost-effectiveness and efficiency

Ultrafiltration systems consume less energy compared to reverse osmosis plants, which reduces operating costs. In addition, the automatic washing system increases the service life of the membranes and reduces maintenance costs. Membranes are made of durable polymeric materials, which provides resistance to aggressive substances and pressure drops.

4. Ease of operation

The automatic washing system reduces the need for manual maintenance. The membranes are easily replaced and the system is monitored using automatic sensors. It is enough for the operator to control the main parameters of the system through the control panel.

Application areas of ultrafiltration installations

- Preparation of drinking water in industrial enterprises.

- Water treatment for the food industry and pharmaceuticals.

- Use in the chemical and petrochemical industries.

- Wastewater treatment for reuse in the process cycle.

- Production of beverages, beer and non-alcoholic products.

- Water treatment for boilers and heat supply systems.

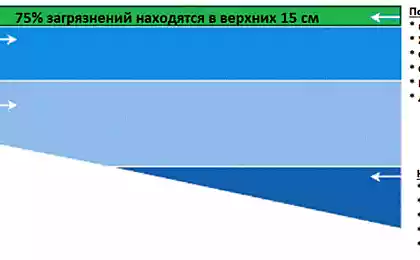

Source water assessment

To select a suitable ultrafiltration system, it is necessary to analyze the source water, determine the level of mechanical impurities, organic compounds and salts. It is important to take into account the level of hardness of water, the content of iron and organic compounds.

Definition of cleaning level requirements

The filtration level of the ultrafiltration membrane is about 0.01 μm. For efficient operation, it is important to consider the amount of water passing through the system per hour. For large industries, systems with increased productivity and an automatic washing system are selected.

Operating conditions accounting

It is necessary to take into account the working pressure, water temperature and chemical aggressiveness of the environment. Membranes must withstand the working pressure without deformation and destruction.

Calculation of operating costs

Membrane replacement and maintenance costs should be included in the system operation budget. For example, information about a suitable water ultrafiltration plant will help plan operating costs.

Conclusion

Ultrafiltration is a reliable and effective method of water purification for industrial processes. The preservation of the mineral composition of water, a high degree of purification and efficiency make ultrafiltration plants in demand in various industries. Detailed information about the ultrafiltration unit can be found on the Iver website.

MrFiller - your reliable supplier of fillers and cosmetics in Ukraine

Why are gifts so important? Ecology of Life and Psychology of Giving