42847

Euromold 2014 - Everything you need to know about the prospects of 3D-printing

2014 was a very eventful. Fortunately, not only in the political sense, but also around our theme - additive technology and 3D-printing. Traditionally, for the year takes place a few dozen conferences and exhibitions, where all the participants of the world market, in one form or another, to talk about their achievements.

International exhibitions I've been in guest roles on Russian as a participant - the company 3DPrintus . The first two exhibitions - Inside3DPrinting in New York and 3D Printshow London focused primarily on companies that provide services for 3D-printing, scanning, creating useful software and so on.

Current Exhibition Euromold in Frankfurt, which will be discussed, is the largest in the world and brings together not only market participants additive technology, but also the traditional production. At Euromold always announce and demonstrate new equipment and professional software solutions.

In this publication, I did not set myself the aim to elaborate on what models of 3D-printers or materials submitted producers (this information is easy to find on the niche sites). First of all, I will share insights of industry and the conclusions that I made dealing with its representatives. And I will try to answer the question: Where is the development of technology and its application in the real world

Popularization h4>

Formally, about the 3D-press heard many, but the application of the technology is still far from the mass market. This is due to barriers such as knowledge of the materials, the presence of 3D-model, non-obvious use of technology to customer problems. Well, of course inert to all new people in general.

Part of the companies in the market is trying to solve this problem. Everyone does it differently.

The company Artec Group, launched its service Shapify , allows anyone to make their instantaneous 3D-scan and after a while to get his miniature a color copy. Artec collected a large booth with lights and scanners in a circle, with the help of which make 3D-scan of a person.

As can be seen, Shapify not the only solution with its 3D-booth ( Botscan were on the other side of the same pavilion), but as far as I I know it is the most successful in terms of the cloud infrastructure, rendering support and fixing models, which makes life easier for those who want to do business on this.

The decision itself is sold under the key, and you can take a risk and start a business, find a successful combination of space, traffic of people and trusted partners 3D-printing. Prices for the franchise from Shapify здесь.

Widely known in narrow circles startup Normal offers a look and feel of their product - customizable pad headphone manufactured specifically for client's ears. And they are known to be very individual.

This is one of the latest examples of combining traditional techniques of mass production and personalization 3D-printing.

In my opinion, quite a good solution and in cooperation with Stratasys it will actively to the masses.

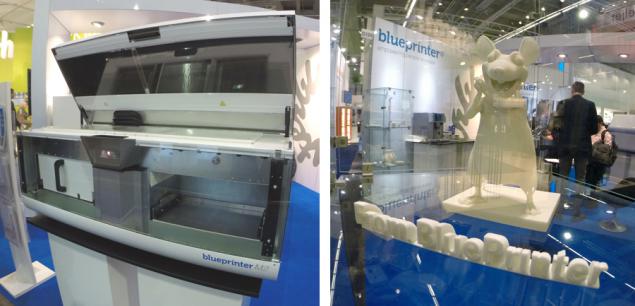

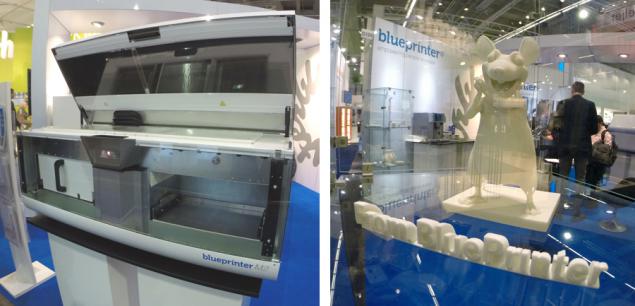

Budget (almost) printers Blueprinter , the print model for technology Selective thermal sintering (SHS) is not the first year on the market, and lately the price is increased from 10 thousand to $ 25 thousand dollars. However, it is the most affordable printer that can produce parts in a small camera (200 x 157 x 140 mm) of the most popular material - polyamide.

The company provides rapid prototyping also Ots in question to popularize the technology. Instead of placing complex engineering solutions or prototypes demonstrate excellent final items, pleasant to the sight and touch. So they do not show the process and their services, and the result for the client and joy.

This is a very useful approach, which conveys to visitors the idea that technology is similar to ordinary people and are used for their benefit.

From the standpoint of the most popular material for 3D-printing (after "home» ABS / PLA) is the absolute leader - a polyamide (nylon) . Production, rendering services on 3D-printing machinery companies EOS buy in large quantities and build your business is on the technology of the manufacturer. Moreover, the recently announced material porcelain , is also produced using the same material.

3D-printing which is not say on TV h4>

It so happened that all the major innovations and so-called third industrial revolution in 3D-printing occurs out of the media spotlight. Of all the new materials, printers and opportunities known only to very close to the subject specialists. Other people (including interested customers) remain in complete ignorance and therefore the introduction of technology and the widespread commercial application among small and medium-sized businesses, as well as B2C is slow.

Personally, I am very interested in the dissemination of this information to the masses, but without excessive cleverness and excessive immersion in the subject. Because most interested will be able to find the information themselves, and those who are 3D-press will help to solve their own problems or business problems, you need to know only about the realistic possibilities.

Everything else should be doing services , creating a "bridge" between the needs of customers and production capabilities.

Big Cars - great opportunities h5>

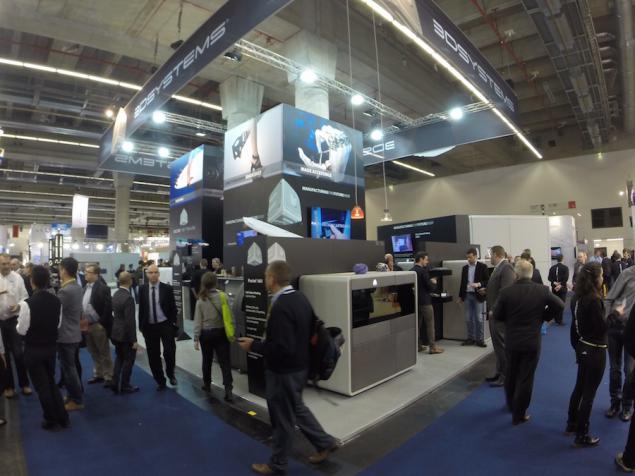

Euromold is the place where the concentration prfoessionalnyh and industrial rolls of 3D-printers. All manufacturers try to bring here the most, the best, great and incredible. It is here that are a big deal about the procurement of such printers.

For example, this year, I saw a very large number of Chinese people (and even some Indians) who are actively discussed purchases of printers, which, of course, suggests that China does not sleep not only in mass production, but soon a 3D-printing .

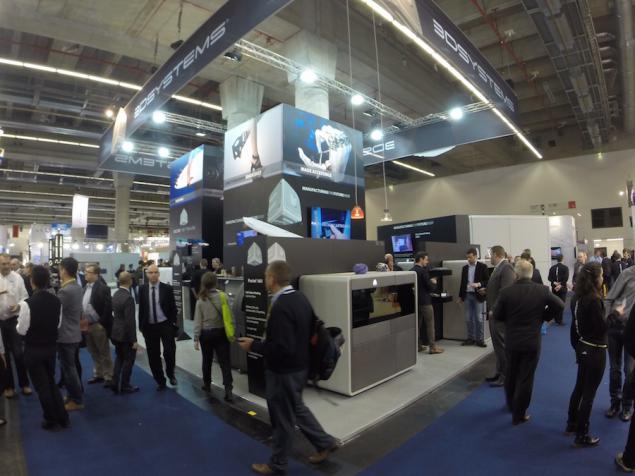

One of the most striking stands, around which all the days were the most people - a stand of 3D Systems , one of the leading manufacturers of 3D-printers.

Alone 3D Systems employees in the original outfit was 98 people. And almost every one of them was always busy socializing with many interested visitors.

The company brought placed on the stand all its latest printer prints from gipsopolimera (full color plaster), photopolymers (precision plastics), metals (titanium, cobalt-chrome, steel) and polyamide (durable and flexible plastic).

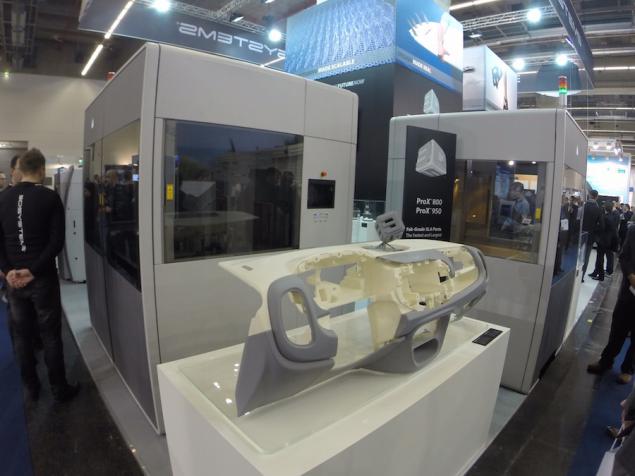

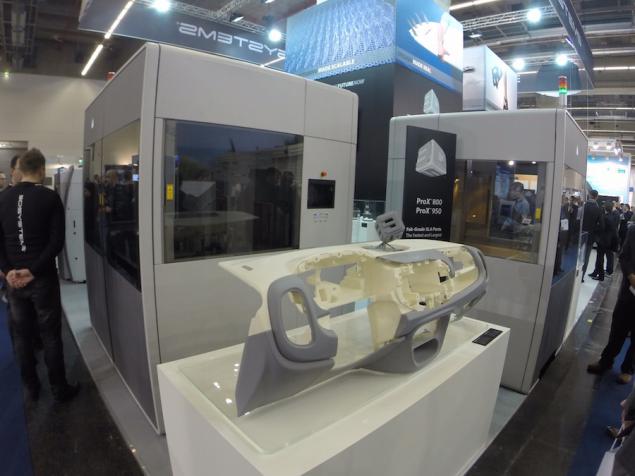

One of the flagships - SLA printer ProX 800, manufactures very large parts of high quality and accurate photopolymer which is suitable for the production of prototypes of car parts.

Also, the new printer is working on technology SLS (selective laser sintering) ProX 500Plus, allowing the company to compete aggressively with the leader in the field of printing plastic powder, the company EOS, printers which are now being used in the vast majority of companies involved in prototyping of these materials.

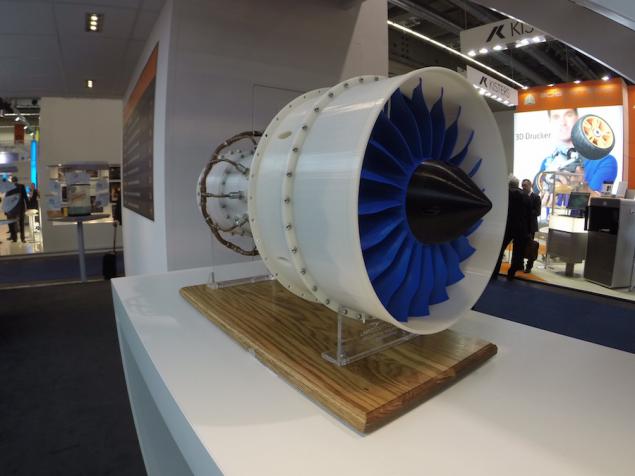

And, of course, the most impressive - a metal 3D-printer ProX 400, weighing several tons, which allows to make very large parts, up to 500x500x500 mm. Model rocket metal speaks for itself.

It is worth mentioning that part of the machine, brought in by the exhibition - it's just a body, without filling inside. To impress guests, but not to show (and drag) superfluous.

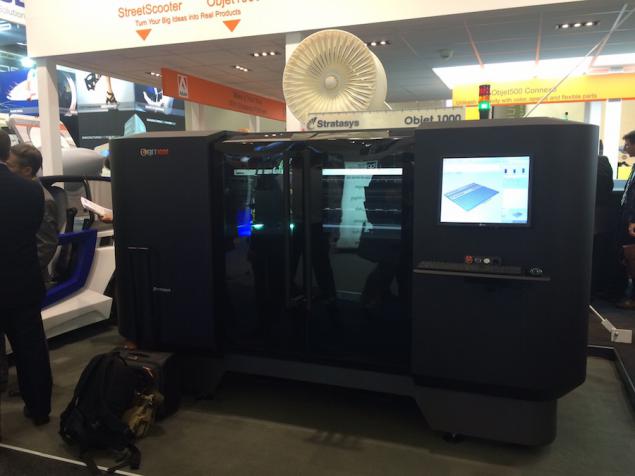

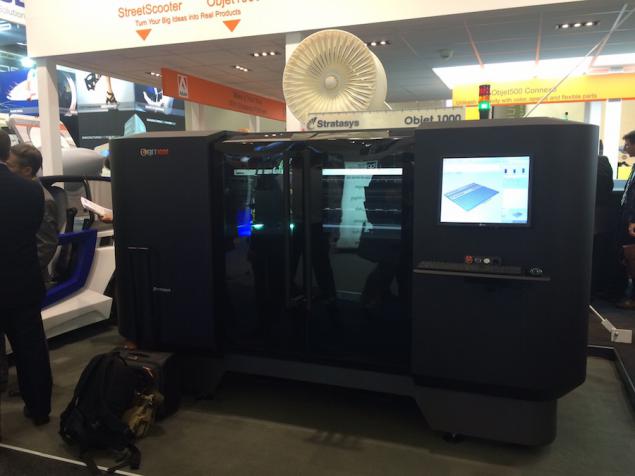

Following a huge stand and leading company - Stratays

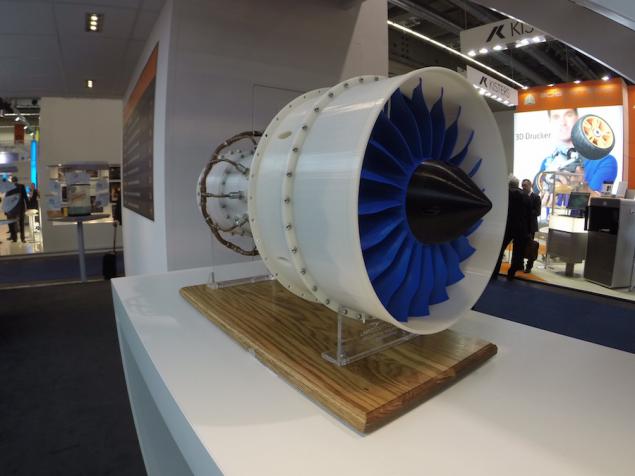

The company decided to beat all his stand in aviation subjects: here and fuselage with seats and business class on the second floor and many other elements.

Stratasys printers are considered as one of the leaders in the field of printing plastic that the company proves, demonstrating the ability to print as a very large parts (pictured above) and medium (on its own technology multi-material multi-color printing).

Here is used when printing multiple colors of plastic at the same time, both durable and flexible (rubber-like) that allows in fact receive very impressive results.

There is a technology and certain disadvantages such as high cost of materials (in comparison with full-color plaster), the limit on the color palette and the need to change the color palette, if you plan to diversify the color of your object.

In general, Stratasys updated almost all of its equipment fleet and actively competes with full-color plaster Projet 660 printers from 3D Systems and large scale printing of plastic with SLA printers from the same 3DS.

However, in my opinion, the most important strategic assets for Stratasys are bought his company Grabcad and Makerbot (+ Thingiverse) - this is what will allow the company to give its clients a full range of features and services around the 3D-printing.

Using the power of the online platform kollaboratsionnoy Gradcad and a huge community of engineers, as well as the largest archive of 3D-models Thingiverse, Stratasys makes the purchase of the equipment even more attractive. In fact they are building a very regular eco-system. This is a great contribution to the future development!

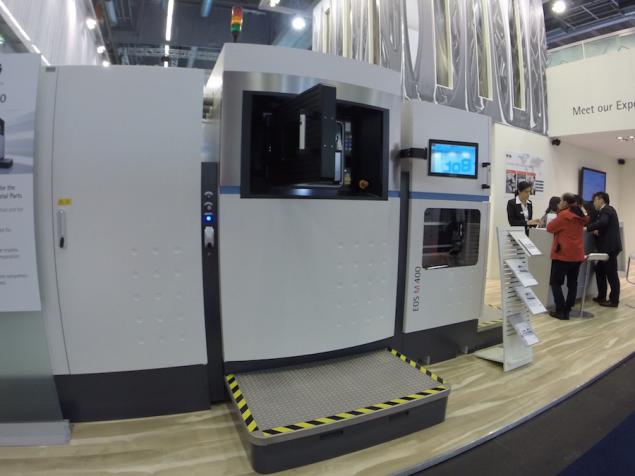

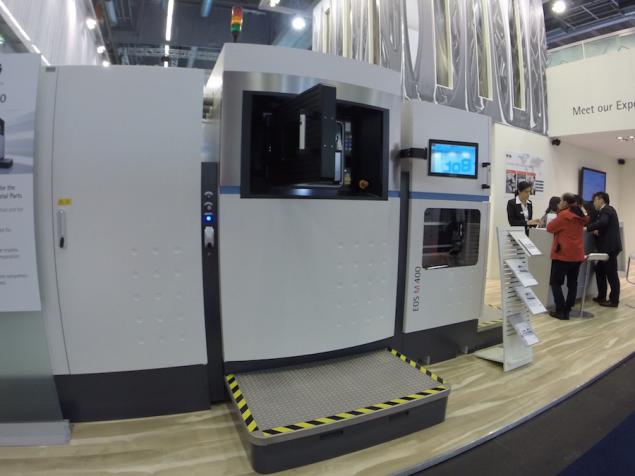

Third industry leader - a German company EOS

At the exhibition the company showed their metal printer EOS M400 camera 400 x 400 x 400 mm and the ability to print from a cobalt-chromium steel, titanium and other metal powders.

EOS uses for its printers very wide range of materials, which are very well located at the booth. Two small video demonstrating this:

And for those who are interested in how the material looks in its original form, the company has prepared tubes with powders:

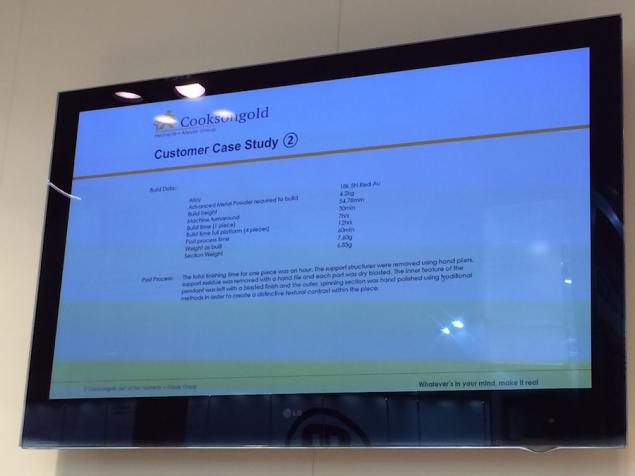

However, one of the most interesting releases of this year, is a partnership with Cooksongold - one of the oldest manufacturers and suppliers of equipment and materials for jewelers in the UK.

Company Cooksongold created jointly with EOS 3D-printer for printing of precious metals. Cooksongold developed powders of 18k gold (pink, yellow, white) and using the printer M080 produces precious products of complex shapes that can not afford the traditional casting.

A company spokesman David Fletcher spoke about the capabilities of a printer to print jewelry. Here are the main points that I would like to mention:

no restrictions on design complex forms that are not available in the traditional casting thin wall products lightweight, hollow products manufacturing permanent link short production time from 4 hours + 1, 5-2 hours to process At the same time, 99% of the unused powder ispolzuetsyav secondary production.

David showed some samples of products.

This suspension, in which the spinning element. All printed at a time.

All parameters of the suspension of manufacturing can be seen below:

This bracelet with segments. Also printed at a time, bezrazёmno.

All products are made by technology SLM - Selective Laser Melting. Final products require the jewelry processing, but as in casting. However, the advantage of the proposed technology Cooksongold and EOS obvious.

Such a method is suitable for the production of exclusive jewelry, as well as individual products manufactured in batches. 3D-press on this technology in the next few months and will be available on our website .

Next, let's talk about the company ExOne , its technology allows

create two types of products: sand molds for casting and subsequent direct printing from steel of different grades.

Most of all, the company is known for its capacity to print from steel and bronze with different ways of postprocessing, resulting in a very unusual products.

Also, it should be noted the huge contribution of ExOne in production of sand molds for casting metals. This technology is actively used in the automotive, aviation and defense industries. One example of what it looks like the result of production parts after use burnt the form below:

Differences and the company SLM (manufacturer of metal printers). At Euromold company demonstrated printed rover Rover Asimov R3C, which next year will go to the moon!

Overview of all those who make contributions to the development of 3D-printing would not be complete without a brief talk about the company Arcam b > - industrial manufacturer of 3D-printers technology EBM (electron-beam melting), which allows to produce precision parts made of titanium.

The company mainly works for the aerospace and medical (orthopedics) spheres. It was her decision to address issues of reducing the weight of structural elements missiles (as an example) and the creation of orthopedic prostheses and inserts adapted to the specific person.

Another very important, but a little less prominent player in additive technology is the company Reninshaw , will present at the Euromold your new metal printer EVO Project.

Printer manufacturers place a strong emphasis on the full automation of manufacturing processes and minimal operator intervention. Printing powder processing, cleaning, recycling - are all controlled by the printer. At the moment, the printer is sharpened by one material. This is a very interesting example of the desire to increase the scope of process automation, as now it is a problem.

Those who expect to see the recently announced printer from HP was disappointed. Since the printer is still far from perfect, to represent him at the fair Euromold would be wrong.

Rumor has it that the printer uses old technology color printing, which had once used and the company 3D Systems (pioneer of color printing). And the products that are now made on 3D-printer from HP, is still very fragile. In general, the printer does not wait for this before 2016.

To summarize for printers and materials, I would like to once again note that the scope of the 3D-printing is much broader than it seems at first glance. And the main task now is to reduce barriers to the use of these technologies for business and customers.

I am convinced that only transparency and IT systems will help to bring these solutions to a wide market. And to invest effort and money should be exactly in the establishment of such infrastructures.

Trends h4>

In conclusion, the article, I would like to share your opinion about where moving technology that will change in the near future and how it will affect the mass adoption of 3D-printing business and a variety of industries.

Automation and conveyor h5> One of the major trends in the next 2-3 years, will be a gradual transformation of industrial 3D-printers in automated production systems. Then efforts technologist / operator of the printer will no longer be sent to the new permanent load, clean models, sieving powder and so on.

Instead, a fully automated system of 3D-printers will do most of the operations on their own, without human intervention. This will allow highly automated processes, which are now made with hands.

This trend is a consequence of "requests" of such large customers as the company General Electrics , which requires manufacturers of printers to create systems for the production of single units not using 3D-printing, and adjustment of their serial production.

Given the advantages of 3D-printing over traditional industries, the emergence of the possibility of serial production of products translate the technology to a whole new level.

Companies such as 3D Systems, EOS and Stratasys actively interact with major clients to create such systems.

Optimize h5>

Another important trend is the creation and development of automated software that allows to optimize the weight, cost, design of any manufactured using 3D-printing objects.

Source: geektimes.ru/company/3dprintus/blog/242224/

Attack of the drones: six months in the US drones 25 times almost collided with the aircraft

In California, earned the biggest solar power plant in the world