1220

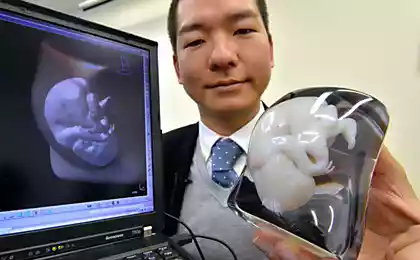

Cosmetic prosthesis gastrocnemius printed on the 3D-printer

Perhaps you are already familiar with our history of the functional mechanical prosthesis fingers and saw the interim results of this venture, which has grown into a separate project. Recently, my experience of creating prostheses added another case, this time, our skills on 3D-scanning, 3D-modeling and 3D-printing found its application in the creation of a cosmetic prosthesis gastrocnemius muscle.

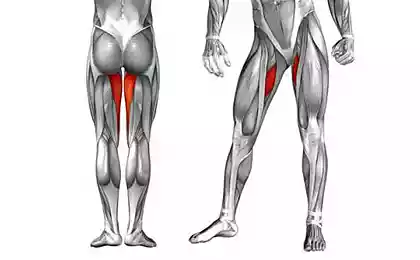

The need for a unique cosmetic prosthesis h4> The story began with a letter from the girl Olga. Olga is a very extreme hobbies - skydiving. As a result of one of the jumps on landing Olga was injured gastrocnemius muscle of the right leg. Now leg muscle tissue is almost completely absent. Visually, it is noticeable that causes discomfort girl. For this reason, there was a need to provide a cosmetic prosthesis. The prosthesis should be as an individual, taking full account of all the anatomical features of the injured leg. On the advice of her friend Olga turned to me.

begins to create a cosmetic prosthesis h4> We met up with Olga and discussed all the details of the work. The action plan was as follows:

The need for a unique cosmetic prosthesis h4> The story began with a letter from the girl Olga. Olga is a very extreme hobbies - skydiving. As a result of one of the jumps on landing Olga was injured gastrocnemius muscle of the right leg. Now leg muscle tissue is almost completely absent. Visually, it is noticeable that causes discomfort girl. For this reason, there was a need to provide a cosmetic prosthesis. The prosthesis should be as an individual, taking full account of all the anatomical features of the injured leg. On the advice of her friend Olga turned to me.

begins to create a cosmetic prosthesis h4> We met up with Olga and discussed all the details of the work. The action plan was as follows:

- 3D-scanning of the feet

- 3D-modeling

- 3D-print cosmetic prosthesis

- Trying

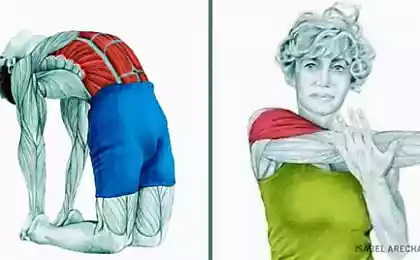

Scanning feet h4> The first thing you had to scan both legs, as the damaged and healthy. For this, we used the scanner Artec Eva. Scanning is a design engineer Alexander Gorodetsky, who developed a body of the scanner. Conveniently, the scanner does not require calibration and use of markers. He makes about 16 frames per second, which are automatically aligned. We needed a scan of a sufficiently high accuracy, so the work was done carefully, not without repeated passes of the scanner.

Even the most thorough scan does not mean that after the completion of this process you will get a perfect and completely 3D-ready model. Scan - this is only a good preparation, a cloud of points over which have yet to work hard and "collect" solid. Scan with a coffee break took approximately two hours.

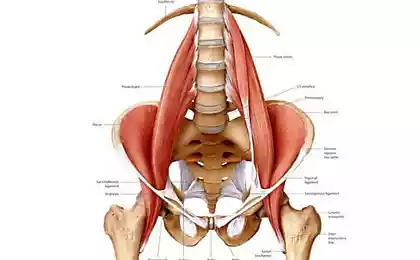

Creation of 3D-model of a cosmetic prosthesis h4> This stage of work was the most labor intensive and time consuming. This task took over my good friend and experienced 3D-modeler Valery Karaoglanyan. Before him was a new challenge for him - to create from the available two point clouds (scans of healthy and injured legs) 3D-model of a cosmetic prosthesis, taking into account all the wishes of Olga. Ready-made solutions to this problem was not.

The first step - a solid-state 3D-modeling in SolidWorks.

When ready solid state 3D-models of both legs, model healthy leg was amended to mirror your height, then out of it, "subtract" volume model of the damaged legs and a predetermined tolerance of the skin to "breathe».

First, the idea was that the inner and outer surfaces are mesh (and at some point the two surfaces, and these were). At the request of Olga mesh made only the inner surface of the prosthesis, and a solid outer left, which led to additional changes in the outer parts of the prosthesis.

To create a surface in a grid had little pozhonglirovat 3D-model of the one program to another. First it was imported into ZBrush, to make UV-scan and create a grid module after that in Photoshop grid was superimposed on the scan, then the 3D-model is back in ZBrush. At this stage there is a problem with giving the thickness, ZBrush gives this possibility, therefore, the process was involved also 3DS Max.

Parallel Alexander Gorodetsky was being developed and 3D-modeling program of fixtures in SolidWorks. When they were ready, they are "merged" with the main 3D-model of the cosmetic prosthesis:

On the creation of 3D-models, of course, it took time. What I have described in the previous two paragraphs - a brief and superficial description of the process. Designers also had to exert all his experience and build an algorithm for creating such a 3D-model from scratch, and it's not easy. As a result, we have been at the hands of a complete, ready-to-3D-printing model sural cosmetic prosthesis.

Time 3D-printing h4> 3D-printing - is the creation of the final stretch of the prosthesis. As a material for the 3D-printing, we chose white durable plastic PA 2200 (polyamide). Very durable and lightweight material perfectly fit for our purpose - creating a cosmetic prosthesis that will be used frequently. For the production of objects of this material applied technology of selective laser sintering (Selective Laser Sintering), when the mass of the powder laser sinters the material at the specified location "growing" volume model.

The stage was volnitelen: we as a team were looking forward to when you can take ready prosthesis in hand and go to the next step - fitting.

Trying sural cosmetic prosthesis h4> Fitting a prosthesis, as expected, has identified as its advantages and disadvantages, which are avoided in the first iteration, it was difficult. During assembly of the prosthesis on the leg attachment worked as it should, and the body sat up on the leg.

It became clear that it was necessary to use some kind of soft material as a layer between the skin and foot prosthesis itself, since the foot sweats, and texture of the material itself is slightly rough to the touch. Perhaps if the outer surface of the prosthesis also netted left, it would have solved the problem with ventilation, the leg would be better to "breathe».

Trying held until Olga were not actively use the prosthesis, as the summer was hot. So the basic testing of cosmetic prosthesis is still ahead.

Summary h4> It was our first experience of a cosmetic prosthesis. In the process, we have made a lot of mistakes, repeatedly passed around the circle, made superfluous actions. But he showed us not only our weaknesses, but also our ability, learned a lot, now we know the short cuts and effective solutions.

The most important opinion in this story - Olga opinion. She was satisfied with the result, according to her, he justified her expectations. She thanked us for the work and promised to share the results of further testing of the prosthesis.

Available enabling technologies h4> Noteworthy moments in this story that make use of industrial technology 3D-printing, is much easier than it might seem. Using professional equipment and knowledge, you can get the desired quality object - prototype prosthesis, figurine, decoration, functional parts, rocket engine, but almost everything that may come to your mind.

Not surprisingly, the Internet is full of articles that someone somewhere and created something using the 3D-printing. Also, it is not surprising the fact that opinions about the possibilities of this technology are different - someone skeptical, someone is an ardent supporter of the home 3D-printers, and someone does not miss the opportunity poholivarit on the advantages and disadvantages of additive technologies. But in my opinion it is not necessary to extol the merits or belittle 3D-printing, you just have to use it to effectively solve problems like any other technology. If you have any interesting suggestions or ideas that you would like to translate, welcome to the comments, maybe together we can create something interesting.

Source: habrahabr.ru/post/237141/

Residents of Donetsk pay tribute to the terrorists, so they do not fall in house

Prosthetic leg, inspired by the mountain goats